Effective inventory replenishment takes a lot more work than many people realize.

The act itself is simple; it’s fairly easy to submit a purchase order, receive the stock, and store it. But if you want the optimal outcome for your business – to reorder just the right amount of stock to meet customer demand, and to have it arrive at precisely the right time – that takes planning.

Replenishment planning can be difficult, but the results are worth the effort. When you take the time to figure out how much inventory you’ll need, when you’ll need it, and how to get it, your brand will be able to maximize sales without fear of stocking out or overstocking.

In this article, we’ll cover what replenishment planning is, its key aspects, and how an expert partner like ShipBob can both equip and help you to master it.

What is replenishment planning?

Replenishment planning is the process of assessing your inventory needs and strategizing how to reorder inventory to best meet those needs.

Specifically, replenishment planning entails:

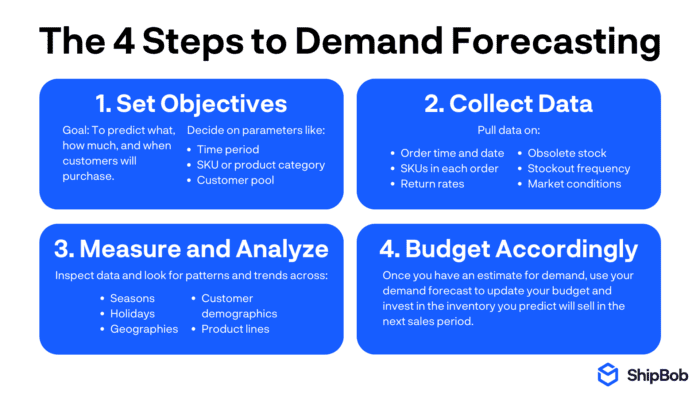

- Forecasting demand to determine how much of which products you will need to in the future.

- Tracking current inventory levels to establish what quantity to reorder for each item.

- Coordinating and collaborating with suppliers, manufacturers, vendors, distributors, and other stakeholders to time replenishment correctly (taking lead times and transit times into account).

The goal of these activities – and of replenishment planning in general – is to make sure that your brand stays stocked with the optimal levels of each product, so that you can capitalize on demand without running out of stock (which leads to lost revenue) or ending up with tons of excess stock (which is expensive to store).

Why is it important to plan replenishment?

Planning replenishment is a lot of work – so why can’t businesses just “wing it?”

You could, but a guesswork approach to reordering inventory almost always causes huge problems down the line. Replenishment planning helps you to avoid these issues and sets your supply chain up for success.

For instance, one of the most common reasons brands plan replenishment carefully is to prevent stockouts. It allows you to anticipate your inventory needs and restock the right quantities at the right time, so you can maintain sufficient stock levels and effectively meet customer demand. This helps you to avoid expensive stockout costs, such as canceled orders, backorders, lost sales, and lower customer satisfaction.

Replenishment planning also minimizes your risk of overstocking. When you’ve calculated precisely what order quantity you need based on demand patterns, existing stock levels, and safety stock, you won’t accidentally order too much inventory that ends up collecting dust on shelves. This lets you keep inventory holding costs in check, avoid amassing deadstock (which is difficult and expensive to move out), and frees up more space to store in-demand items.

What are some examples of replenishment planning?

Replenishment planning involves lots of different activities. Here are some examples to give you an idea of what goes into the process:

- A brand wants to reorder more units of their high-demand SKU for the next quarter. Before placing a purchase order, the brand estimates how much demand they’ll see for that SKU by using inventory analytics to identify sales patterns, trends, and historical sales performance.

- Another brand knows the total number of units they need. To make sure they don’t overstock, they track their current inventory levels in real-time and set up automated alerts to remind them to reorder only when stock dips below a certain threshold.

- A business is ordering more product from their manufacturer. The business is careful to calculate production lead times and factor that time into their stock replenishment timeline. That way, they can place their order with enough time for stock to arrive before they run out of their current inventory.

- A brand uses two fulfillment centers. Fulfillment center A sees a lot of demand for a particular SKU and is selling out of it fast, while fulfillment center B sees almost no demand for it. To restock fulfillment center A quickly, the brand takes some stock from B and transports it to A.

How replenishment planning fits into the inventory management picture

Replenishment planning is a key aspect of overall inventory management. After all, without periodic replenishment, there would be no inventory to manage.

But many of the principles of effective replenishment planning are also used more broadly in inventory management to reduce costs, boost supply chain efficiency, and deliver a better customer experience.

Here are some of the most crucial tools and strategies that ecommerce brands use in both replenishment planning and inventory management.

Product demand forecasting

Demand planning isn’t just important when replenishing inventory; it also gives you deeper insight into your overall product catalog and helps you save money on inventory management.

Brands almost always leverage historical order data, information on past sales trends and seasonal demand patterns, and inventory data to fine-tune their future demand predictions. This data not only guides your calculations for how much inventory to reorder right now, but also gives you insight into SKU performance and your overall product catalog.

With this data, you’ll be able to determine which SKUs are your best-selling and slowest-moving, as well as which see the most demand and when. You can then adjust your product catalog accordingly to capitalize on demand and fill your inventory with products that actually sell.

Accurate demand forecasting also helps you cut back on unnecessary spending. When you know which products will sell and correctly estimate how much you’ll need to meet demand, you are far less likely to amass excess inventory or end up with obsolete or deadstock. This in turn reduces the amount of storage space you’ll need and minimizes your inventory carrying costs.

Inventory restock scheduling

Timing is everything when it comes to both replenishment planning and inventory management in general. If inventory doesn’t arrive where it’s supposed to on time (whether it’s a restock shipment from a manufacturer or any movement of inventory), it can wreak havoc on your supply chain and productivity.

For that reason, good inventory management and replenishment planning are built on scheduling. As you are planning your inventory flow, it’s important to consider factors that can influence your inventory’s arrival timeline, such as:

- Production lead times

- Seasonality and seasonal pressures

- Reliability and responsiveness of stakeholders

- Cross-border complexities

That said, even the most thoroughly-planned schedule can be upended. Unexpected disruptions and delays are inevitable, so brands must make sure they have appropriate safety stock levels on hand at any given moment to maintain operations while waiting out a supply chain bottleneck.

Real-time inventory tracking

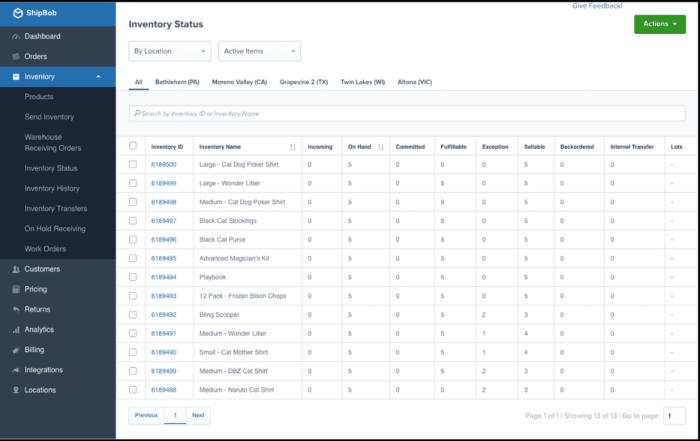

Effective inventory management goes hand in hand with real-time inventory tracking. When you get real-time visibility into your inventory, you can see exactly how much stock you have left across channels and locations. This insight informs your replenishment planning as well as your inventory management strategy in general.

With real-time inventory tracking, you’ll be able to calculate when you’ll likely run out of stock based on your current inventory levels and your sales trends. As such, you can make informed decisions about when to reorder inventory to avoid stockouts.

Additionally, real-time inventory tracking allows you to track inventory across various warehouses. This allows you to see which locations are running low on stock and adjust your inventory allocation accordingly. As a result, you’ll be able to maintain optimal stock levels across various warehouses and ensure seamless supply chain operations.

ShipBob’s vital role in replenishment planning

Replenishment planning can be tricky, but it’s much easier with the right supply chain partner by your side. ShipBob, for instance, equips brands with the technology, data, and best practices they need to facilitate more timely, accurate replenishment and stay stocked all year round.

Here’s a deep dive into how ShipBob can assist your brand with replenishment planning, plus optimize your entire inventory management strategy.

Advanced inventory management systems

ShipBob’s platform features built-in inventory management software that you can leverage to inform and improve your replenishment efforts. The proprietary software comes with real-time inventory tracking capabilities, so you can accurately monitor inventory levels and locations across different warehouses and sales channels.

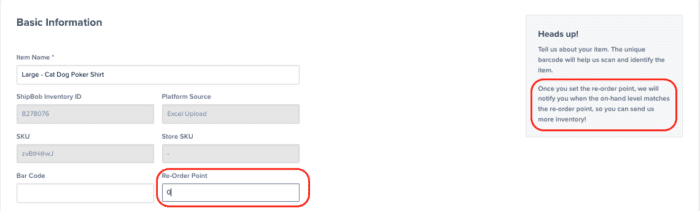

ShipBob’s dashboard also enables you to set up automatic notifications when a SKU’s inventory level dips below a certain predetermined reorder point. This helps you stay on top of inventory replenishment, and reorder inventory at the most opportune time to avoid both overstocking and stocking out.

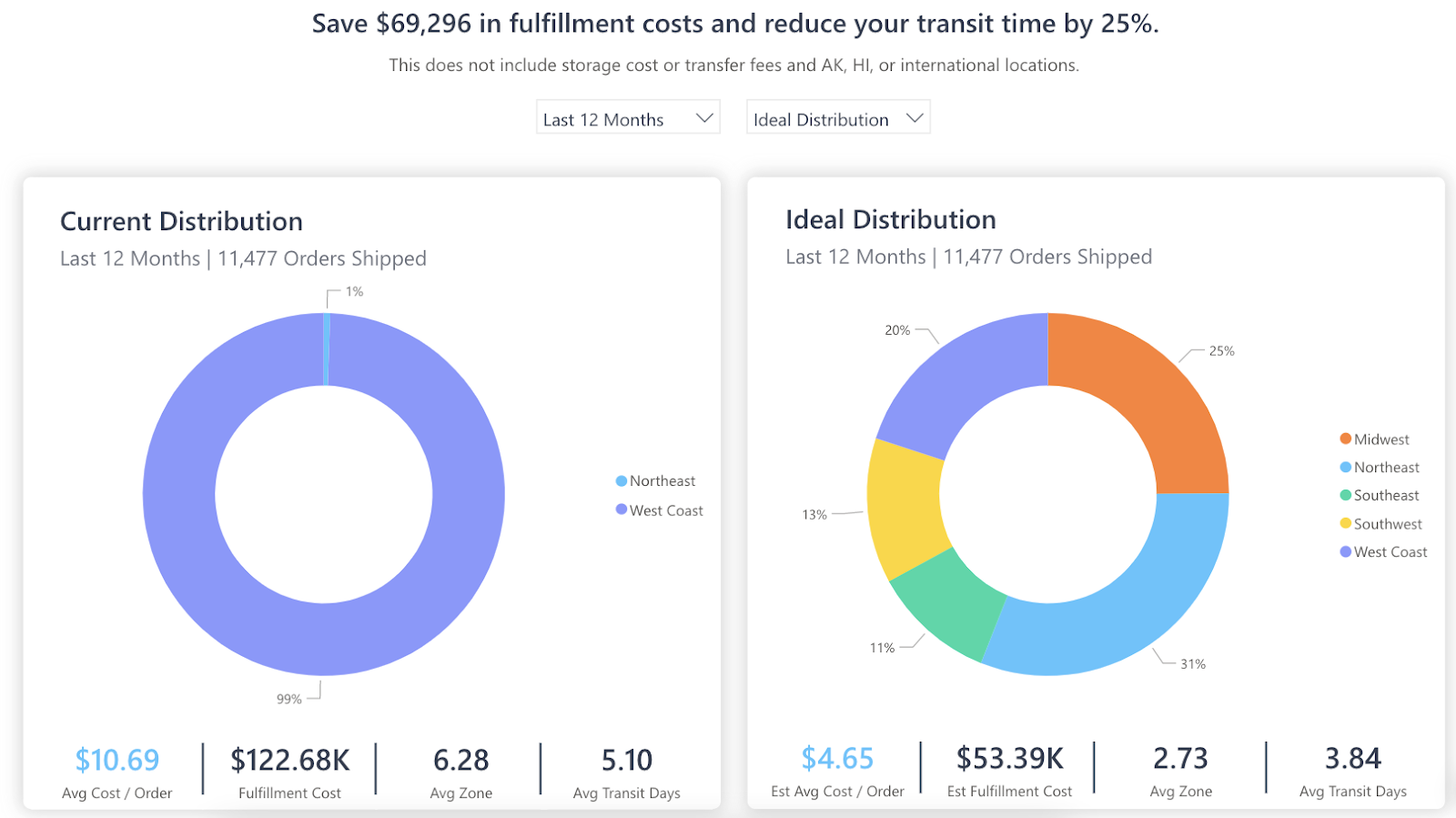

ShipBob’s platform even offers an Ideal Inventory Distribution tool, which leverages your brand’s actual historical data to calculate the most ideal split of inventory across ShipBob’s fulfillment center network that will best enable you to meet customer demand. It also allows you to see if you need to reallocate inventory from one fulfillment center to another to ensure optimal stock levels.

IDEAL INVENTORY IMAGE

Strategic Inventory Placement Program (IPP)

It’s one thing to place an order for more inventory; it’s another to figure out where to place that inventory, receive it, and distribute it. ShipBob takes all this off your plate through the Inventory Placement Program: a solution designed to streamline and automate the process of allocating and distributing inventory.

With this program, you can send all your inbound inventory from manufacturers to a single hub location for the sake of simplicity. ShipBob will then automatically calculate the ideal distribution of inventory across various fulfillment centers (based on your order history) that will ensure optimal stock availability at every location – and minimize your shipping times and costs.

ShipBob will even take care of physically distributing your inventory across different regions for you. On top of saving you time, this approach can help you achieve enormous cost-savings and peace of mind.

“Since launching in the program, we’ve been able to allocate our inventory across 4 of ShipBob’s fulfillment centers in the United States, which cut our shipping times by a third – from 5.2 days down to about 3.6 days. Not only has transit time dropped, but at the same time we reduced fulfillment costs by over $2 per order compared with our old 3PL. This combination has been key to profitable growth this year.

And the cost to split inventory this way? It’s a no-brainer. It costs less for us to deliver all inventory to one location that’s close to our manufacturer partners in NJ, and let ShipBob take care of splitting the inventory between the four different warehouses than it would for us to ship and handle logistics ourselves.”

Matt Crane, Co-Founder and Chief Science Officer at Semaine Health

Data analytics and reporting

ShipBob’s free analytics reporting tool gives you comprehensive insights into your inventory performance, providing easy access to metrics like:

- On-hand inventory

- Historical stock levels

- Days left until stockout

- Average daily velocity per SKU

- The five best and worst performing SKUs

With this information at your fingertips, you are better equipped to make key inventory decisions about replenishment, catalog management, demand forecasting, and more.

Case studies and ShipBob success stories

ShipBob’s replenishment planning solutions have empowered some of the fastest-growing ecommerce businesses optimize their inventory procurement process.

IZIMINI

Brands like IZIMINI were able to centralize their inventory management with ShipBob, even as they expanded internationally. The brand distributes their inventory across various locations in Australia and the U.S. with plans to expand to Europe. Additionally, IZIMINI products are now stocked in 65 retail stores. Across all these locations, they have one dashboard to track and manage all their inventory.

This children’s brand makes use of ShipBob’s intuitive dashboard to customize their inventory management efforts. They use the Shopify integration to easily sync all their new products into the platform, which allows them to instantly start tracking the new items in inventory.

The analytics dashboard lets them know exactly what they have in storage. They can even set up alerts to get notified when they’re low on inventory for certain SKUs. This allows for timely replenishment before they run out of stock, so they can effectively meet customer demand and improve satisfaction rates. Since partnering with ShipBob, IZIMINI has experienced 70% year-over-year growth with over 800 5-star ratings.

“I like to look at the analytics in the ShipBob dashboard, knowing exactly what I have for storage. I can also set up alerts to know when I’m low on inventory for certain products to make replenishment easier. The bundling process is really good. Before ShipBob we would do it with an Excel table, which was a lot to manage.”

The IZIMINI team

ZBiotics

Before taking advantage of ShipBob’s Inventory Placement Program, ZBiotics had a dedicated inventory planner manually calculating which SKUs to send to which fulfillment centers. The brand was then shipping LTLs (less-than-truckloads) to each fulfillment center, which significantly added to their costs.

After transitioning to ShipBob’s IPP, the brand now sends a truckload of inventory to one hub. ShipBob then uses real-time data to analyze the brand’s recent inventory positions and then distributes the inventory accordingly. This has helped ZBiotics to save a significant amount of time, energy, and money, simplifying the inventory replenishment process.

“My favorite thing about the Inventory Placement Program is that it takes the burden off of our team and it’s based on real-time calculations, giving us the right distribution by SKU at each fulfillment center.

It’s comforting to know that we have a good balance between fulfillment centers on a day-to-day, week-to-week, and month-to-month basis, so our customers receive packages via the lowest shipping zone possible among the four ShipBob fulfillment centers we’re in across the US.

That ultimately helps us get products to our customers faster, giving them a great ZBiotics experience from start to finish.”

Michael Mullaney, VP of Supply Chain at ZBiotics

Baby Doppler

Baby Doppler also makes use of the Inventory Placement Program to streamline the replenishment process. The program provides them with real-time insights into key metrics, which help them make informed decisions on how to distribute and replenish inventory at various locations. The Baby Doppler team can easily get a snapshot of their inventory needs without having to ask multiple people from various sources or manually calculating how to replenish inventory. The program even makes recommendations on ideal inventory split based on changing inventory levels, order data, and customer behavior.

As a result, they’ve been able to save time figuring out which products need to be replenished and at what quantities. This has helped them to focus on other strategic priorities to grow their business.

“Partnering with ShipBob, we joined their Inventory Placement Program, which helps us distribute our inventory to strategic hubs across the US so we don’t have to manage multi-location inbound shipments or identify the most optimal fulfillment center locations ourselves. This finally gave us the visibility and analytics we were looking for.

Through the program, we get real-time insight into how much inventory to allocate to a specific warehouse, our current on-hand inventory levels, and how long each SKU is going to last by location. ShipBob provides a lot of distribution metrics, and everything presented is useful.”

Mithu Kuna, Founder and CEO of Baby Doppler

To find out more about how ShipBob can help your ecommerce brand master replenishment and inventory optimization, click the button below.

Replenishment planning FAQs

Below are answers to the most commonly asked questions about replenishment planning.

What is the difference between inventory management and replenishment planning?

Inventory management is the process of tracking, ordering, storing, and selling a company’s goods. However, replenishment planning is mostly focused on the process of tracking a company’s inventory needs and ordering more inventory according to those needs.

How can replenishment planning help prevent stockouts?

Replenishment planning ensures that you’re reordering the right products in the right quantities and at the right time. As such, it helps you restock inventory before your current stock runs out.

What tools are essential for effective replenishment planning?

For effective replenishment planning, you need to have real-time inventory visibility along with analytics data on SKU-specific performance, historical sales trends, demand patterns, and more. As such, you need tools that will help you with inventory analytics and management.

How does ShipBob’s Inventory Placement Program (IPP) work?

With ShipBob’s Inventory Placement Program (IPP), merchants in the U.S. can send their entire inventory to one hub location. ShipBob will then use proprietary algorithms to calculate how to distribute the inventory strategically across various fulfillment centers based on each business’s unique order history. The team then sends the inventory to the recommended locations to ensure optimal stock availability.

Can small businesses benefit from ShipBob’s replenishment planning solutions?

Yes, small businesses can use ShipBob’s replenishment planning solutions to save time and simplify their inventory replenishment process. They can use the analytics dashboards, inventory tracking, and data-backed recommendations to make more informed replenishment decisions.