Table of Contents

** Minutes

How does product allocation planning benefit ecommerce?

3 product allocation strategies

Product allocation best practices

How ShipBob helps ecommerce store owners meet customer demand

Remember when there was a toilet paper shortage?

Thinking back to the early days of the pandemic, businesses that sold essential items such as toilet paper and hand sanitizer had to put a quantity limit on how much each customer could purchase at once. This strategy helped to ensure that demand was distributed fairly among all customers.

That’s just one example of why product allocation planning is important. Selling a high-demand product, launching in new markets, or expanding into new sales channels can impact the decisions you make on where to distribute your product(s) across different sales channels and warehouse locations to meet demand.

Whether you sell in one country or internationally, run both a physical store and an online store, offer B2B ecommerce services, or your inventory levels are low but demand is high, it’s always a good idea to have a product allocation plan in place to optimize your supply chain and improve customer satisfaction.

In this article, you’ll learn the benefits of having a product allocation strategy, how to implement it, and how ShipBob’s fulfillment expertise can help you meet customer demand.

What is product allocation?

Product allocation involves the process of distributing, tracking, and managing ecommerce inventory across a distribution network as well as sales channels to meet customer demand. Product allocation can also help maximize your logistics operations by strategically distributing product to optimize inventory and reduce shipping costs.

How does product allocation planning benefit ecommerce?

Product allocation planning can help you bulletproof your retail supply chain. Here’s how: without thinking through how you will allocate products and forecast inventory based on past purchasing trends, you risk stockouts, backorders, and other inventory issues that result in profit loss and low customer satisfaction.

Product allocation planning is also beneficial when there is a sudden influx in demand but supply is limited. This could happen due to several factors, such as seasonality, manufacturing and work-in-process delays, as well as other factors that could limit the amount of product available.

Here are just a few of the benefits of having a product allocation plan for your ecommerce business.

1. Managing inventory allocation

With product allocation processes in place, you can decide how to best allocate inventory across your ecommerce supply chain by optimizing inventory levels based on where there is the most demand.

Proper inventory allocation can help you save significantly on inventory storage costs by optimizing inventory levels without overstocking (or not stocking enough to meet demand) in different locations. For instance, if you sell swimsuits and beach towels, you might consider storing more inventory in areas closer to beaches or popular summer vacation areas rather than colder areas that are far from the water.

2. Avoiding inventory wastage

Effective product allocations ensures that you have the right levels of stock in the right place and at the right time. In some cases, inventory is wasted due to low demand but high inventory levels allocated in the wrong place or season. A product allocation plan can help reduce inventory wastage by optimizing inventory levels across your entire network.

If a business distributes too much inventory through a certain distribution channel that lacks demand, while neglecting those that experience high demand, that business will end up with a surplus of unsold dead stock (i.e., unsellable inventory).

3. Better understanding of customer behaviors

By making product allocation a priority, you ultimately learn more about your customers. By keeping tracking of historical order data, you can collect insights on your customers’ buying behaviors. It’s important to note that no two businesses are the same (compare seasonal vs. year-round demand here).

Understanding key info and customer data (e.g., which seasons and months buyers are likely to make purchase, which items are more popular than others, where they are located, and how much customers are likely to purchase at once) can help you not only make better decisions on your inventory but also help understand your customers on a deeper level.

4. Promoting optimal store allocation

Say you run both a brick-and-mortar store and an online store. You can use historical order data to determine how much inventory to display in your physical store and how much to reserve for online orders.

If your business has 500 purses in your available inventory that you plan to sell in both a physical store and through an online shop, and based on past order data you know that 70% of purse sales occur online, you can forecast demand and optimize product allocation by displaying 150 purses in your store and holding 350 purses for online sales.

Of course, you should take other considerations into effect, such as if COVID affected your online vs. in-person sales, whether you will be reopening and relying more on in-person business, increasing your online spend budget, etc., and you may need to adjust accordingly.

The same goes if you solely sell online and store inventory in multiple fulfillment center locations. You can determine where a bulk of your customers live and store more inventory in the warehouse(s) closer to where there is a higher demand. For example, you may find that your current fulfillment location is extremely inefficient at reaching the majority of your customers.

That way, you can better optimize inventory storage and ensure that there is always inventory available at locations closest to your customers — which also results in lower shipping costs, average shipping zones, and transit times.

3 product allocation strategies

There is no “one-size-fits-all” approach to product allocation, and how you allocate your product(s) will be based on how your supply chain operates. If you oversee a multichannel retail strategy, you will need to take a more aggressive approach in how you allocate product across your network.

Here are a few examples of production allocation strategies used in ecommerce.

1. Equal allocation

Equal allocation refers to distributing your entire product line evenly across your distribution network, so each distribution center has the same amount of every SKU in stock.

If your business sells shirts to customers at a brick-and mortar-store, and you also store inventory in several fulfillmen centers for online sales, both your store and every fulfillment center would receive the same amount of every product (e.g., 20 red shirts, 20 blue shirts, and 20 yellow shirts).

2. Trend allocation

Trend allocation focuses on the distribution of your stock based on where certain types of products are trending and where they are being sold.

Let’s say you sell discs for frisbee golf, and the sport is becoming more popular on the East Coast of the United States. Even though the game is played across the US, you might consider splitting inventory across the US but storing the bulk of your stock in a fulfillment center located in New York or Pennsylvania.

If you can learn to master and predict product trends more accurately, then you can use product allocation to divert more product to the locations where there is the most demand.

3. Universal allocation

Similar to equal allocation, universal allocation is another basic strategy that involves distributing all of your inventory across sales channels equally. This is more commonly used by businesses that don’t have a large product line or catalog.

Depending on what you sell, this product allocation strategy could be all you need, but most businesses choose to optimize their inventory based on several factors to ensure demand is met and enough inventory is stored closest to their customers.

Note: With some inventory management systems and logistics companies, you can centralize your inventory across sales channels and fulfill orders using all inventory, regardless of the channel.

Product allocation best practices

Depending on your supply chain, there are a number of ways to efficiently allocate product. Here is an overview of product allocation best practices:

Use product allocation software

As you expand into new sales channels, distribution locations, and markets, implementing technology to help you track inventory will help you save time, eliminate human error, and create a more efficient supply chain.

Though it’s possible to manually track inventory, online brands often use technology and inventory automation tools, such as inventory management software, to track inventory in real time — especially if you store inventory in multiple locations or sell across different channels.

“We roll out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each week. It’s really easy to create new SKUs and restock existing ones using ShipBob’s technology, which is especially important with high inventory turnover.”

Carl Protsch, Co-Founder of FLEO

There are several inventory apps on the market to choose from that integrate with the most common sales channels in ecommerce, from Shopify to Amazon to Facebook, to connect to your tech stack, so you can track inventory all from one dashboard.

Use demand forecasting

There are always going to be shifts in demand, but that doesn’t mean you can’t use data to make informed decisions. Demand forecasting is one of the most powerful ways to better allocate product to meet demand across your distribution centers and channels.

Forecasting demand can also help you make better decisions on other parts of your business, such as when to run a promotion or flash sale, when to hire more staff, how much warehouse space you will need, and more.

“I am a bit of an analytics nerd, so I love the ShipBob dashboard because I didn’t have access to this level of visibility before. I also love the ability to see remaining inventory — that’s so huge. Before, we were counting one by one in my house, but that’s being taken care of by ShipBob now.”

Andrea Hamilton, founder of The Finer Things 1920

Maintain healthy inventory levels

Maintaining an optimal amount of inventory (also known as stock control) is one of the most important aspects of inventory management, from optimizing stock levels in a warehouse(s) to stabilizing inventory storage costs, to maintaining enough stock to meet customer demand.

By keeping track of your inventory levels across a distribution network, you’re also able to optimize your inventory replenishment process. Once you have an understanding of how much product you want stored throughout your supply chain, you can use inventory tracking tools to set up automatic notifications of when an SKU has hit its reorder point and even put the reordering process on autopilot.

“Another ShipBob integration I love is Inventory Planner. It saves me hours every week in Excel spreadsheets, and I can raise a PO in minutes when it used to take me hours.

For every order I placed for years, I was ordering too much or not enough. Between inventory forecasting tools and the ability to auto-create WROs, we don’t have stockouts much anymore. I sleep better at night.”

Wes Brown, Head of Operations at Black Claw LLC

Partner with a 3PL

Product allocation impacts the speed of how quickly you deliver orders to your customers. That’s why location is key here. You might have enough inventory to fulfill orders, but where you distribute your inventory is just as important. To meet customer demand, you have to be ready to meet customer expectations.

For instance, it can be inefficient to store all your inventory in California if most of your sales are coming in from the East Coast of the United States. But if you don’t have access to a fulfillment center closer to the East Coast, then you risk paying more in shipping costs and slowing down transit times for your customers.

To establish a product allocation plan that reduces logistics costs and improves last-mile delivery, you will need access to different fulfillment center locations, inventory management tools, and the ability to track inventory in real time across your network from one dashboard.

Many ecommerce businesses don’t have the time, money, or access to the robust infrastructure needed to strategically allocate inventory. That’s why many fast-growing brands partner with a third-party logistics (3PL) company like ShipBob that takes care of the entire retail fulfillment process, which can help you improve your product allocation strategy.

How ShipBob helps ecommerce store owners meet customer demand

At ShipBob, we understand that product allocation can be tricky to manage. That’s why we focus on supporting ecommerce store owners by helping them allocate products across different locations and sales channels to ensure there is optimal amount of product in right place(s) at the right time.

ShipBob offers expertise in helping businesses experiencing various growth patterns, including the ability to make better decisions on how much inventory to store at all times and where.

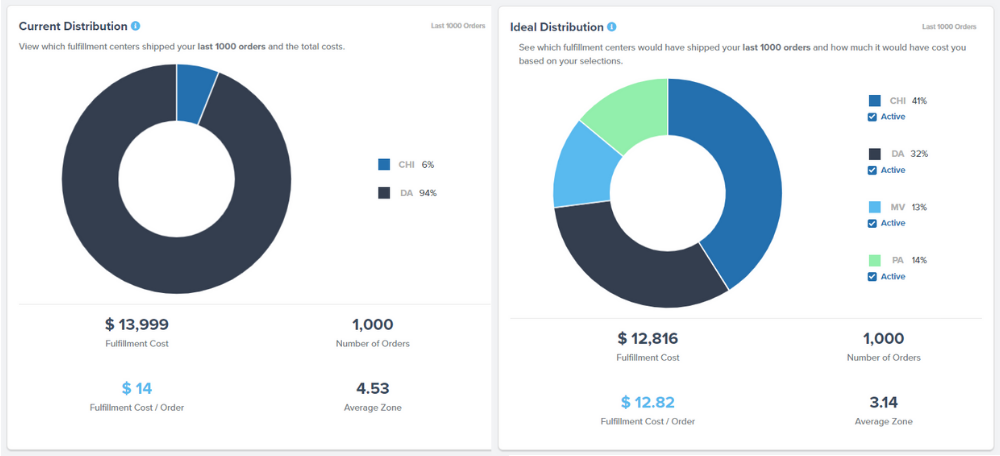

Because ShipBob’s fulfillment network is powered by a centralized tech stack, you’re given access to advanced data and analytics tools that can help you make better decisions on inventory allocation by understanding where your customers are located and what an ideal distribution plan would look like.

With ShipBob, you get answers to questions like:

- How should I distribute my inventory across ShipBob’s fulfillment network?

- What would my shipping costs be if I went from one fulfillment center to two (or two to three, and so on)?

- How many days of inventory do I have left before I run out?

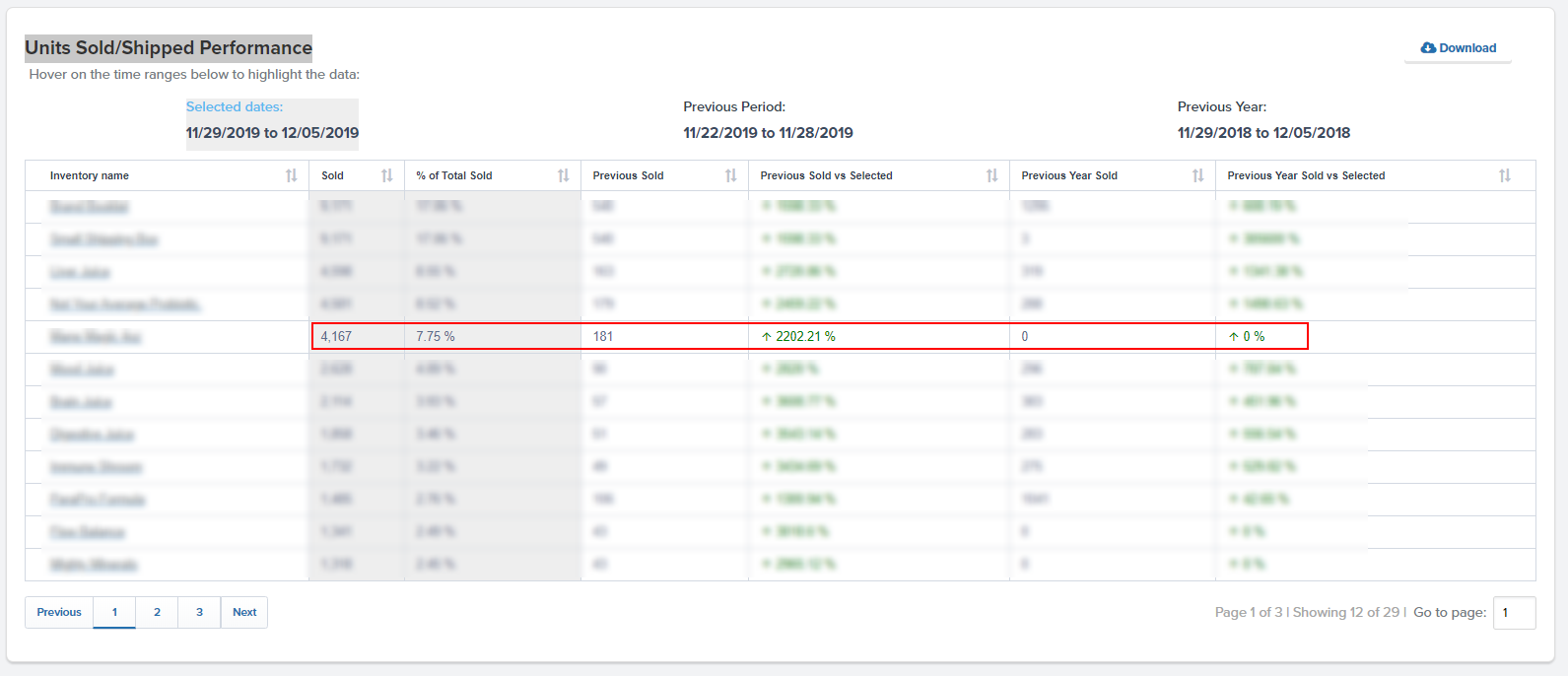

- What is my SKU performance over time?

- Where are my customers shipping to most often?

ShipBob also offers inventory forecasting functionality to determine how much inventory you need to order and when.

Get answers to questions like:

- How much stock do I currently have on hand?

- What were my historical stock levels at any point in time in any location?

- How many days do I have left until a SKU will be out of stock?

- By when do I need to reorder inventory for each product?

- If I run a flash sale on my site, how will this affect my available stock levels?

- How does product demand compare to previous periods?

- How are my sales affected by different seasons and months?

- What are my best-selling items?

- Which items are not generating sales?

Our dashboard also allows you to see exactly how much stock you have in every ShipBob location, which makes inventory tracking quick and easy.

Partner with ShipBob

ShipBob partners with fast-growing ecommerce brands by offering a global fulfillmentnetwork, built-in inventory management tools, and the expertise and support needed to grow their business successfully online.

With ShipBob, you save time and money while optimizing your logistics strategy. For more information on how ShipBob can help you grow your ecommerce business, click the button below.

Product allocation FAQs

Here are answers to some of the top questions people have about managing product allocation.

What does product allocation mean?

Product allocation involves the process of distributing, tracking, and managing inventory across a distribution network to meet customer demand. Product allocation can help to maximize your logistics operations, costs, and storage while meeting customer expectations on shipping costs and shipping times.

What is an example of product allocation?

Say your business has 1,000 hand sanitizers in inventory, which you plan to sell in both a physical store and through an online shop. Based on historical order data, you know that 80% of hand sanitizer sales occurred online. Using this data, you can better forecast demand and optimize product allocation by reserving 200 units of hand sanitizer for your physical store and holding 800 bottles of hand sanitizer for online sales.

Why is product allocation important for ecommerce?

Product allocation is important for ecommerce businesses because it promotes better inventory management to enable distribution expansion across sales channels and locations. Having a product allocation plan can help online brands forecast demand, better understand buying behavior, optimize storage costs, and avoid stockouts so customer demand is met.

How do you use product allocation across warehouses?

There are multiple allocation methods that businesses can use when allocating products across warehouses, but the best approach to distributing products across different warehouse locations is to look at historical order data and split inventory across locations according to past order trends, best-sellers, items frequently purchased together, and more.

If you’re just launching your online business and you want to sell across the US, you might consider choosing a centralized warehouse location, such as somewhere in Midwest, to optimize shipping costs and transit times.