Table of Contents

** Minutes

What is collaborative planning, forecasting, and replenishment (CPFR)?

The benefits of CPFR in supply chain management

ShipBob’s industry-leading fulfilment services align with CPFR principles

Supply chain optimisation is vital for any ecommerce business that wants to increase its bottom line and improve its efficiency.

However, you can’t optimise only some parts of the supply chain and expect great results as problems in one area can easily lead to inefficiency and issues in other stages. So the supply chain must be optimised in its entirety, involving all your processes and supply chain partners.

This is where collaborative planning, forecasting, and replenishment (CPFR) comes in. This process allows you to fully optimise your supply chain for greater efficiency at a lower cost.

This post serves as a comprehensive guide into CPFR, and the processes involved in it. It outlines how your supply chain can benefit from it and how to implement this principle into your processes. Let’s get started.

What is collaborative planning, forecasting, and replenishment (CPFR)?

Collaborative planning, forecasting, and replenishment (CPFR) is the method of coordinating various supply chain tasks between multiple parties (i.e., manufactuerer, retailer, etc.) to meet customer demand while minimising costs. It requires strategic supply chain planning and seamless communication to facilitate accurate forecasting and replenishment as well as efficient supply chain execution.

The four phases of the CPFR model

The CPFR model consists of four main phases.

1. Strategy and planning

The strategy and planning phase of CPFR is where you lay out the plan for cooperative interactions between different players in the supply chain. Every organisation that’s involved in the supply chain (i.e., suppliers and manufaturers, retailers, etc.) needs to establish parameters for cooperation and chart out communication strategies. This is also the phase where you define roles and responsibilities as well as procedures involved in carrying out your partnerships.

2. Demand and supply management

During the demand and supply management phase, you focus on planning your orders to ensure accurate and timely replenishments. This requires forecasting orders based on anticipated demand (i.e., seaonal demand, holidays and peak season, etc.) and then planning your inventory orders accordingly.

3. Execution

The third phase is the execution phase where the plans and procedures you’ve previously laid out are physically executed. It involves all aspects of production, storage, dispatch, and delivery of products to the end customers.

4. Analysis

The analysis phase is where you look back at your supply chain process and evaluate its effectiveness. It involves assessing how the overall supply chain performed, analising metrics, and how well you managed exceptions.

The CPFR process

Based on the above phases, the CPFR process can be broken down into nine steps:

1. Developing an agreement – For CPFR to work, manufacturers, retailers, and suppliers should agree on how communication will be carried out. You start out by defining the conditions of your CPFR cooperation and coming to an agreement with all your supply chain partners. Make sure to formalize this agreement by having it in writing and sharing procedures and business processes with all involved parties.

2. Creating a joint business plan – Similarly, there should be an agreement between all your trading partners about the business plan. This plan should be very specific, clearly laying out details related to order data and organizational management. The goal is to ensure that everyone is working toward a common goal and enabling business success in the process.

3. Making a sales forecast – The next step is forecasting sales using the business plan created earlier. How many units do you expect to sell? Are you anticipating increased order volume around a certain sales holiday? Production and inventory planning should be accounted for when making this forecast.

4. Identifying exceptions and deviations in the sales forecast – Initial sales forecasts are rarely accurate. So the next step of the CPFR process involves identifying variations that could impact the supply chain. Look into the projections that were made at various stages of the supply chain. Compare them to identify any exceptions or deviations in the forecast.

5. Resolving exception items – As soon as the exception has been identified, it’s important to inform all the parties impacted by it. Then make adjustments to the sales forecast after you get clarification about the exceptions and deviations.

6. Creating an order forecast – You then use the sales data to forecast your orders. The structural requirements of your business plan will influence this prediction.

7. Identifying exceptions and deviations in the order forecast – Similar to step four, your order forecast may not be accurate the first time. You need to look at previous projections to identify any exceptions and deviations that could impact your production and replenishments.

8. Resolving exception items – Similar to step five, make sure to quickly communicate exceptions and deviations with all the impacted parties. Then adjust your order forecast once you get clarification.

9. Generating orders – The above step will help you finalize your order prediction, following which you’ll need to go through the process of ordering goods.

The benefits of CPFR in supply chain management

CPFR ensures improved efficiency and better inventory management, which subsequently benefits other aspects of your supply chain. Let’s take a look at some of the key ways in which CPFR can benefit your supply chain management.

Reducing costs and enhancing efficiency

When every involved party in the supply chain communicates proactively, issues are mitigated on time and challenges are addressed before they escalate. The ability to quickly communicate and resolve issues enhances the efficiency of your supply chain operations, allowing everything to flow seamlessly with minimal disruptions. Moreover, there’s a lower risk of delays that could impact your overall supply chain efficiency.

When your supply chain is optimised, you directly benefit by reducing the costs associated with delays and disruptions. You’re spending less on overhead costs related to running your supply chain operations whether its the cost of additional labour or the cost to carry excess inventory. The enhanced material flow also means you’re freeing up working capital that could be utilised to run other aspects of the business.

More importantly, CPFR allows you to enhance precision in your demand and order forecasting. That means you’re ordering the right amount of inventory at the right time, which minimises stock shortages and prevents overstocking. You’re not paying for excess inventory or spending money on the costs associated with carrying them. Not to mention the wasted expenses on discarding spoiled or obsolete inventory.

Improving forecast accuracy and customer service

On a similar note, enhanced supply chain forecasting is the leading benefit of CPFR. Your forecasting process goes through multiple checks and balances, giving you the opportunity to identify deviations and exceptions and create more accurate predictions. As a result of this improved forecasting precision, you can plan your procurement more accurately.

This allows you to restock the right amount of inventory at the right time. So you can avoid stockouts that might result in customer disappointment. You can ensure that you’re always maintaining optimal stock levels to meet consumer demand.

Even if stockouts do occur due to uncontrollable circumstances, CPFR ensures that every involved party stays informed about the situation. This helps you quickly come up with a resolution, as well as improve your customer service by providing timely updates.

ShipBob offers integrations with platforms like Gorgias to automate the process of notifying customers when orders are in exception so that they’re always in the know. Moreover, your customer support team can take further action directly on the dashboard, which speeds up the process of canceling orders or adding items.

ShipBob’s industry-leading fulfilment services align with CPFR principles

ShipBob offers industry-leading products and services that allow you to successfully incorporate CPFR principles into your supply chain. From a warehouse management system (WMS) that gives you better visibility and control to offering an end-to-end managed freight program – ShipBob’s solutions help you enhance communication and collaboration throughout the supply chain.

Leverage a network of global freight partners

ShipBob’s end-to-end managed freight program, FreightBob, allows you to improve your inventory procurement process. You get to choose from a variety of preferred freight providers from ShipBob’s network, which gives you the assurance of working with reliable partners to support your CPFR efforts.

On top of this, ShipBob can also distribute your inventory across our US fulfilment centres as soon as it arrives at a ShipBob Hub. By leveraging our inventory distribution and placement program, you minimise the need to work with third-party services that could muddle the collaboration process so you can successfully implement the CPFR model into your supply chain. Moreover, you get to enjoy reduced costs by unlocking preferred costs and priority partner rates when tapping into our global freight network.

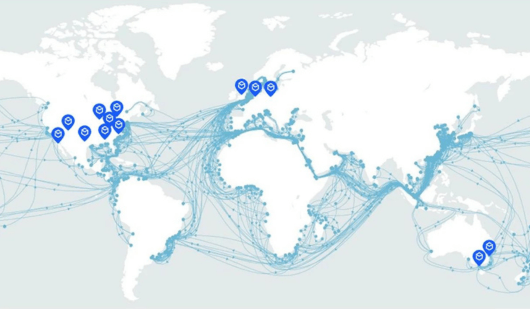

Gear up for a global expansion

With ShipBob’s global network of over 50 fulfilment centres, you can seamlessly incorporate the CPFR principles even as you expand internationally. By storing your inventory across the globe in ShipBob’s international fulfilment centres, you can speed up transit times and cut down on international shipping costs to ship to customers in over 200 countries.

Our delivered duty paid (DDP) solution further enhances transparency by allowing you to pay applicable customs fees on behalf of the customer. That way, you can improve cross-border transparency and avoid surprising customers with fees during delivery.

ShipBob’s powerful technology lets you centralise this global fulfilment network and manage it all in one place. That means that even if you have inventory in several countries, you can manage it from one dashboard. ShipBob’s technology gives you real-time logistics transparency so you can easily collaborate with relevant parties to support your CPFR efforts.

Improve inventory visibility

A vital aspect of successful CPFR implementation is inventory visibility, and ShipBob provides it with powerful inventory management software. It gives you real-time visibility into your inventory levels to simplify information sharing and ensure that everyone’s on the same page throughout the supply chain.

Knowing how much inventory you have and how much is in various stages of the supply chain is essential for sharing information that’s accurate and timely. It also helps you make more accurate predictions about your requirements. This allows you to ensure better accuracy in how you coordinate with supply chain partners.

Powerful analytics and forecasting

To help with your order forecast and demand planning, ShipBob gives you comprehensive analytics into purchasing trends and sales history. You can then use the data to calculate your reorder point and set a notification to ensure that you’re immediately alerted when stock dips below a certain level.

This is crucial to maintain optimal stock levels at all times, so you never run out of stock or order excess inventory. It gives you sufficient time to communicate with your supply chain partners and place your replenishment orders with their lead time in mind before you actually experience a stockout. Moreover, your reorder points calculation helps you fine-tune your demand forecasting in the future.

Enjoy seamless omnichannel fulfilment

ShipBob’s solutions help you manage fulfilment for all your retail channels under one roof to support the implementation of CPFR principles. This includes fulfilment for orders that are coming through your website and online marketplaces, but also retail distribution and retail dropshipping as well as Amazon FBM. ShipBob even helps you prepare your inventory to meet the strict guidelines provided by Amazon for FBA.

By centralising your omnichannel fulfilment with ShipBob, you can eliminate the complexities of coordinating with multiple fulfilment partners. This makes it easier to streamline your supply chain and incorporate the CPFR principles across all your sales channels.

Centralise your warehouse management

Maybe you have your own warehouse and want to keep fulfilment in-house. ShipBob’s powerful WMS lets you centralise the way you manage your warehouse. It comes with comprehensive features for warehouse and inventory management as well as picking and packing, and reporting and analytics. It also lets you manage your orders and transportation all in one place.

ShipBob integrates with leading ecommerce platforms and tools and offers an open API that gives you the freedom to build your tech stack exactly how you want. You can integrate with your existing information systems to maintain a single source of truth to streamline and centralise your supply chain communications. It eliminates information silos and allow for more seamless supply chain collaboration.

Get started with ShipBob

Interested in leveraging ShipBob’s fulfilment platform? Connect with our team to learn more and get a customised pricing quote.

Collaborative planning, forecasting, and replenishment FAQs

Below are answers to common questions about CPFR (or collaborative planning, forecasting, and replenishment).

What does CPFR stand for?

CPFR stands for collaborative planning, forecasting, and replenishment. CPFR is a planning process that involves supply chain partners aligning to efficiently meet customer demand at a low cost.

How does CPFR differ from traditional supply chain management practices?

Traditional supply chain management practices focus on specific areas of the supply chain and tend to be disjointed. Meanwhile, CPFR covers the entire supply chain process and ensures a seamless collaboration between all stages.

What is the difference between CPFR and S&OP?

CPFR is a supply chain management model that focuses on collaboration and coordination between various supply chain partners. Meanwhile, S&OP (or Sales and Operations Planning) is a supply chain process that helps leaders make important business decisions. CPFR is a process of planning that includes vendors and partners, whereas S&OP is an internal planning process.

What are the key components of a successful CPFR strategy?

A successful CPFR strategy requires strategy and planning, demand and supply management, execution, and analysis.

Can CPFR be leveraged within all industries?

CPFR is most commonly used in the consumer goods and food and beverages industries. However, it can be leveraged within all industries to improve efficiency and streamline communications.