Learn how apparel brand Elwood Clothing optimises fulfilment for thousands of SKUs with ShipBob’s WMS while saving money and sailing through peak seasons.

“Choosing ShipBob WMS to power our warehouse was the best decision I’ve ever made as a business owner. We have so many SKUs already, and we’re adding hundreds, maybe even thousands of SKUs every month, on top of growing order volumes.”

Tim Poyer, VP of Operations and Logistics at Elwood Clothing

Customer Profile

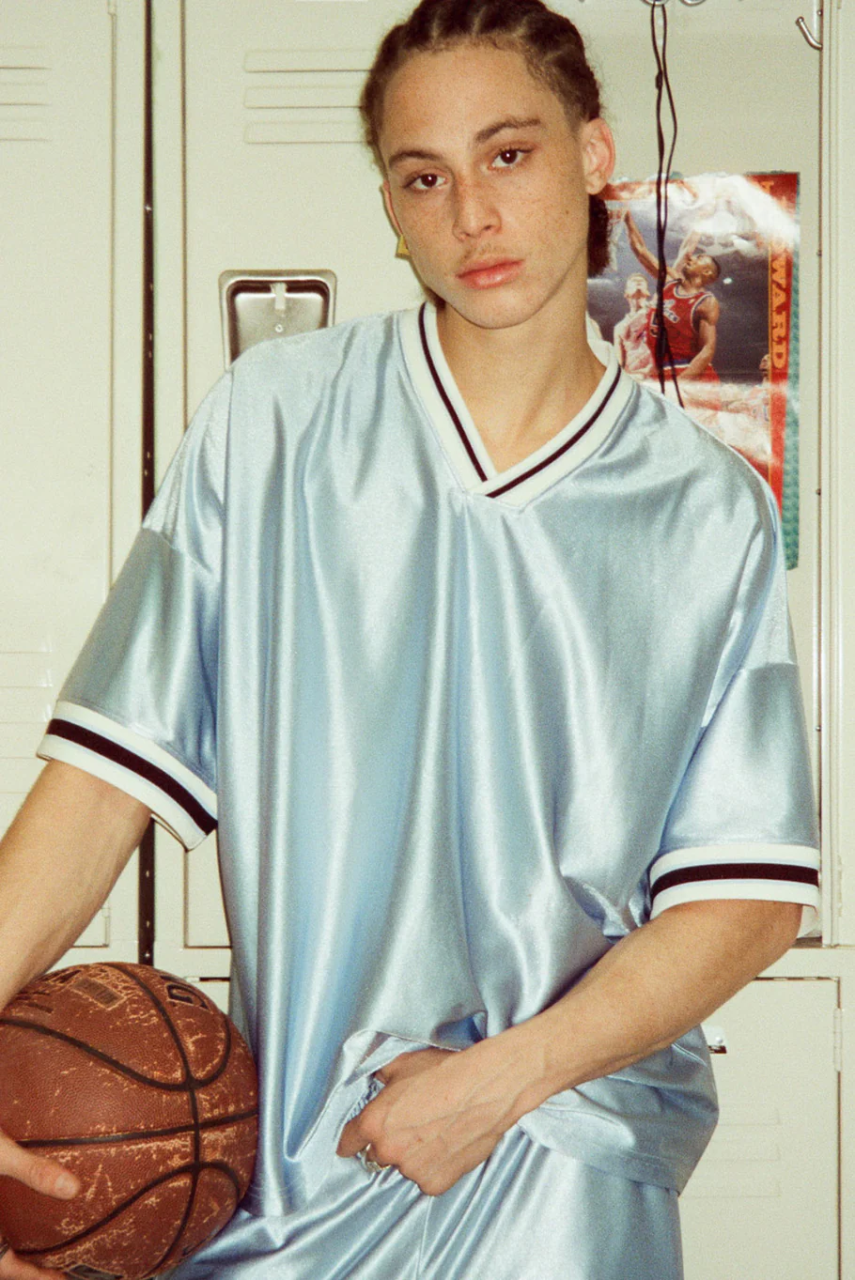

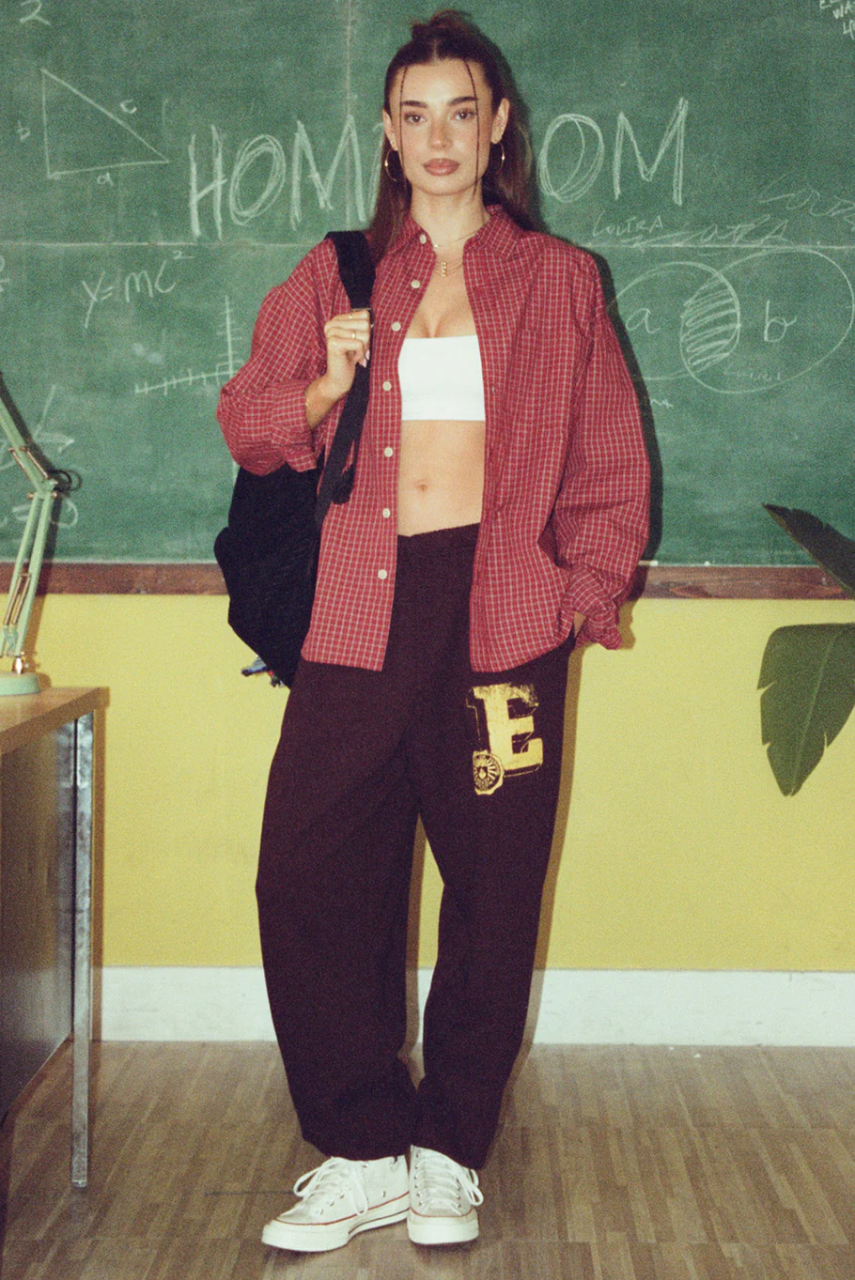

Based in Los Angeles, California, Elwood Clothing combines iconic fabrics, washes, and silhouettes to create classic, everyday wear that stands the test of time. Their unisex lines include hoodies, crew necks, T-shirts, sweatpants, and other wardrobe essentials – all inspired by authentic vintage design and detailing.

Key metrics

- 100% growth YoY every year since 2020

- $200,000 saved on shipping per year with ShipBob

- 3,500+ SKUs

- 70K orders/month fulfilled during peak with ShipBob WMS

About Elwood Clothing

Elwood Clothing thinks everyone can look cool.

When three business partners purchased Elwood from its previous owner in 2020, that was their mission: to create contemporary clothing that was wearable and stylish for everyone.

The trio kept the name but pivoted the brand from fast-fashion to re-imaged streetwear that focused on vintage-inspired quality fabrics, with a core collection of affordable and timeless wardrobe staples.

Before long, Elwood’s sales started skyrocketing, and the brand has been growing 100% year-over-year ever since.

We sat down with Tim Poyer, VP of Operations and Logistics at Elwood Clothing to discuss how ShipBob WMS has transformed their brand’s warehouse efficiency, cost-savings, and scalability.

Managing thousands of SKUs while scaling using ShipBob WMS

As told to ShipBob by Tim Poyer, VP of Operations and Logistics at Elwood Clothing.

When we first took over the business in 2020, we just had the few products we’d bought from Elwood’s previous owner, so it made sense to use Shopify to manage such a small catalogue . We also were only shipping 15-30 orders a day, so we used a label generation solution to print out each order and picked and packed every item ourselves.

But then our business started growing like wildfire. We were doubling in size every year, adding thousands of SKUs as we developed our own clothing line – and at the rate we were scaling, our patchworked fulfilment solution just wasn’t cutting it. We were so busy, and trying to manage 3,500+ SKUs through Shopify alone was simply unsustainable. I knew we needed a more robust, comprehensive solution to support our operations at scale.

I thought my only option was outsourcing fulfilment and shipping completely, so I reached out to both ShipBob and one of their competitors. During my conversation with ShipBob, their team mentioned that that ShipBob actually offers its proprietary warehouse management software (WMS) as a standalone solution, so ecommerce brands can use it to power their own warehouses.

I was thrilled! This meant that I could keep my existing warehouse facility, keep all my inventory where it was, and still optimise our warehouse operations. It was exactly what I was looking for.

Getting hands-on onboarding in our warehouse for a flawless WMS transition

Implementing ShipBob’s WMS in our warehouse was so much easier than I expected, because ShipBob sent a representative out to our warehouse for a couple of weeks to essentially revamp our entire operation. We got new racking and equipment, and they showed us how to set up all our inventory storage locations, hardware, and software, including both their desktop and WMS application (ToolBob) for managers and the mobile app for pickers (MiniBob).

“I couldn’t believe that ShipBob would actually send one of their team members out to our warehouse to be boots-on-the-ground and help us set up ShipBob WMS in our facility. I don’t know of any other provider that would do that. Usually, they show you the software, leave you to figure it out on your own, and tell you to reach out to support for questions. ShipBob was nothing like that – the onboarding was so hands-on, from beginning to end.”

Tim Poyer, VP of Operations and Logistics at Elwood Clothing

Most importantly, they didn’t leave until everything was right. It wasn’t like they had a deadline for finishing the setup, and if we didn’t meet it, we’d have to finish on our own – not at all. Instead, they took their time and made sure we were in a good place and were comfortable operating independently before they left. They never left us high and dry.

Having someone right there with us to walk us through the whole implementation process in-person was amazing. We also had an Implementation Manager, Lacey, who helped coordinate all the onboarding and training for me and my team, which was awesome as well. Overall, we had so much support, and it really made the transition seamless.

Optimising picking through ShipBob WMS for peak efficiency

ShipBob’s WMS has completely transformed our operations. It makes the receiving process very easy and straightforward, and the stowing tag system that’s built into the WMS has been so helpful. We also have a dedicated location for every SKU and corresponding barcodes that pickers scan to update inventory counts in the ShipBob dashboard in real time, which we never had when we were managing inventory through Shopify. Everything is so seamless now, even with thousands of SKUs in our portfolio.

“Choosing ShipBob WMS to power our warehouse was the best decision I’ve ever made as a business owner. We have so many SKUs already, and we’re adding hundreds, maybe even thousands of SKUs every month, on top of growing order volumes. If we had kept using our old, patchworked approach to warehouse management and fulfilment, we would have been in a lot of trouble – we wouldn’t have been able to manage inventory or keep up with demand, let alone scale. ShipBob’s WMS allows us to do all of that. It’s been such a great solution for us.”

Tim Poyer, VP of Operations and Logistics at Elwood Clothing

I also love what ShipBob WMS has done for our fulfilment operations.

With our old solution, there was no real method or any sort of organised way to pick orders; ShipBob’s WMS, on the other hand, offers many different flexible picking options that direct and optimise picking flows for us.

We use cluster picking, where ShipBob’s WMS automatically groups orders with common items together, assigns them all to one cart, and calculates the best route to take us through our warehouse and pick all those orders at the same time.

Our fulfilment is so much more efficient now – we can easily ship 1-2K orders a day, no problem.

Before, averaging 15K orders a month would have been a struggle – but with ShipBob WMS, it’s a breeze.

That capacity has been crucial to getting each customer their tracking number and their order out on time, which helps us win business and get even more orders.

Saving $200K with ShipBob’s courier selection algorithm and logistics network

We’re saving a lot of money on shipping thanks to ShipBob WMS. The software has the ability to leverage different couriers’ shipping rates against each other to give you the best rate for each order, both in terms of cost and transit time. This means we can automatically ship every order through the cheapest and fastest courier option.

We also get access to ShipBob Logistics, which includes ShipBob’s outbound sortation solution and has saved us time and money thanks to their economies of scale. We don’t have to sort DTC parcels manually by courier anymore; all we have to do is label orders, and every day, ShipBob picks up gaylords of unsorted packages directly from our warehouse. That same day, ShipBob brings them back to one of their sortation facilities, where their automated sorters get each package in a gaylord for the right courier, and then the couriers come pick them up for final-mile delivery.

Because ShipBob has built out a large volume and density of outbound orders in the regions they operate in, couriers will come to their sites for pickups more frequently than what they’d do for a single brand. This means that our orders are getting picked up by couriers faster, which minimises lead times. It also enables zone skipping, so we’re shipping orders from lower zones to save money while still getting orders to customers in a few days.

“ShipBob Logistics has been great for us. Rather than having to sort every DTC package by courier and service ourselves, everything goes into one bin and ShipBob picks it up, brings it to their facility, and sorts it there. It’s saved us enormous amounts of time and effort, and I don’t have to go back and forth with couriers all the time, or worry about whether they’ll have enough trucks, or if their trucks are too full, or if they’ll have to come back again to get another shipment. It’s been really great to hand off that aspect of logistics to ShipBob.”

Tim Poyer, VP of Operations and Logistics at Elwood Clothing

All in all, ShipBob’s saved us over a dollar per package, easily – and with us shipping out 200K orders in a year, that’s at least $200,000 that we get back on our bottom line.

Sailing through BFCM and fulfilling massive order volumes with ease

One of the most valuable aspects of ShipBob WMS for our brand has been its ability to flex and scale with our order volumes – especially during peak season.

This past peak, we were expecting a huge swell of orders, and brought on extra staff for fulfilment during BFCM. We were able to train them on ShipBob WMS really easily (it’s a very intuitive system), and in just a day or two, they were up to speed.

We ended up doing 70K orders in just one month during peak season, and because we had ShipBob WMS in place, we were shipping orders out within days instead of what would have taken much longer previously. That’s kind of crazy to me, because we’re a small business; we have maybe 10 people on fulfilment, so the fact that ShipBob WMS enabled us to pick, pack, and ship that many orders so quickly is a testament to how well the system works.

Looking forward to calls with ShipBob’s support team

Our support team at ShipBob has been just fantastic. I look forward to my calls with our account manager Martin every week. We’ve developed a great working relationship, and if any issues pop up, I immediately go to him and he helps me solve them.

I also appreciate that ShipBob offers internal chat channels for merchants to use for smaller things. If I have a question, or a simpler ask, I can post it in that channel and get help really quickly.

What’s next for Elwood Clothing

We’ve seen tremendous growth over the past few years, in part because our logistics have been so smooth. Our product is amazing, and so is our marketing, so logistics were the last piece of the puzzle – and I always tell my business partners, “You do what you want to do. Don’t hold back, because of logistics or operations. I will find a way to kind of take care of it.” With ShipBob, I feel like I’ve been able to follow through on that promise, and we’ve been able to keep up with this rapid growth.

Because we’ve scaled so quickly, I think Elwood is in a sweet spot where we have more breathing room to focus on other initiatives. We’re considering adopting ShipBob’s hybrid fulfilment solution, where we keep our in-house operations on the West Coast on ShipBob WMS but also outsource some of our fulfilment to ShipBob’s team at their fulfilment centres. Distributing inventory and fulfilling from other locations like the East Coast or Canada would reduce transit times and costs even more as we grow, so we’ll definitely be looking into that.

But mainly, our goal is to maintain our current level of stellar service. We want to keep doing what we feel is right for our customers, keep price points fair, and keep creating and delivering quality style that everyone can enjoy.

Elwood Clothing’s team at ShipBob

Sean Morris

Sean is the Account Executive who helped Elwood Clothing get started with ShipBob.

Lacey Elliot

Lacey is the Implementation Manager who onboarded Elwood Clothing.

Martin Niemczewski

Martin is the Merchant Success Manager at ShipBob who supports Elwood Clothing.

Get started with ShipBob

Interested in using ShipBob’s WMS in your own facility? Want to learn more about ShipBob’s hybrid fulfilment solution? Connect with a member of our team to get started.