Nothing kills sales momentum like a stockout.

Maybe there was an unexpected surge in demand for your brand’s products, or maybe you accidentally forgot to reorder stock in time. Whatever the cause, stockouts lead to backorders, delays, and disappointed customers – none of which are good for your bottom line.

To make sure they always have enough stock on hand many ecommerce brands rely on a periodic automatic replenishment (or PAR) strategy. Using this replenishment method, merchants can take a lot of the guesswork out of reordering and position themselves to meet customer demand more consistently.

In this article, we’ll dive deeper into what the replenishment (PAR) method involves, its benefits, and how real ecommerce brands have implemented it.

What is periodic automatic replenishment (PAR)?

Periodic automatic replenishment, also known as PAR, is an inventory management technique that involves setting a maximum and minimum quantity for each inventory item. These maximums and minimums are referred to as PAR levels.

In the PAR model, a business will carry out periodic inventory counts. If the quantity of a particular item is at or below the minimum PAR level, this indicates to the business that it is time to reorder more of that item. If the quantity of a particular item is at or above the maximum PAR level, the business knows that they have excess inventory and should not reorder any more (or even reduce their inventory).

The importance of consistent stock levels

Maintaining consistent stock levels helps brands avoid supply chain disruptions while minimising inventory costs. It’s particularly important for businesses and organizations that rely heavily on the timely availability of inventory.

In the healthcare industry, for example, the quality of care provided often depends upon the availability of essential tools and medical supplies. Running out of vital supplies could lead to delays in care provided to patients, which is especially dangerous when time could mean the different between life and death.

On the other hand, it’s also highly risky to order excessive amounts of safety stock as a way to prevent unexpected stockouts. This could result in inventory piling up and going unused, eventually expiring and leading to waste. In this case, you’re wasting thousands of dollars on unused inventory, which affects your bottom line. In fact, according to one study, overstocking and stockouts will cost retailers nearly $1.8 trillion in 2023 alone.

That’s where inventory control techniques such as periodic automatic replenishment can benefit a business. By setting minimum and maximum levels for PAR, you can stay on top of your inventory needs and ensure that you’re reordering enough stock on time without overstocking your warehouses.

For example, say you run a hospital and need syringes. If you set your minimum PAR levels for a particular syringe at 1,000 units and your latest inventory count reveals that there are only 1,080 units left, you know to place your procurement order now so that you can get more inventory from your supplier before you run out of stock.

Similarly, if you set your maximum PAR levels for the same syringe at 5,000 units, and your inventory count reveals that you still have 4,500 units left, you know not to restock yet to avoid amassing excess inventory.

Periodic vs. perpetual inventory management

Periodic inventory management involves updating your accounting records only at intervals of time, such as the end of a designated accounting period. This means that when you purchase and sell inventory, you don’t update your inventory count right away – instead, you record the transaction when it happens. When the time comes for a check-in, you can update your inventory levels according to those records.

In contrast, perpetual inventory management involves logging every inventory purchase and sale immediately as it happens, and updating inventory records in real time to reflect those transactions. This approach usually requires the use of dedicated software to automate the process.

Benefits of the periodic automatic replenishment inventory systems

Beyond simply avoiding stockouts, there are many reasons to use the PAR system. Here are some of the top benefits of implementing the PAR method in your brand’s inventory management.

Minimising inventory waste

Excess inventory is one of the leadings causes of inventory waste. If inventory doesn’t get sold, it typically sits on warehouse shelves and eventually expires or becomes obsolete. This deadstock can be notoriously difficult to offload, and often ends up being thrown away – which isn’t good for the environment, and even worse for your ROI.

A PAR inventory system helps you mitigate inventory waste by giving you full visibility into your stock levels. That way, you know exactly which stock levels are running low and need reordering, and don’t accidentally order more inventory than you can store.

This is particularly helpful for businesses or organizations with little space to spare. Pharmacies, for example, need to store certain medications in cold conditions, but have very limited temperature-controlled storage space. A PAR system enables them to keep track of their available space and only replenish stock when necessary, which helps minimise the risk of expiration.

Enhancing customer satisfaction

Periodic automatic replenishment systems allow you to ensure that you always have sufficient stock on hand. This significantly reduces the risk of customer disappointment, since you can ensure timely fulfilment and timely shipments. When you can consistently meet customer expectations in a timely manner, you can improve customer satisfaction and encourage customers to shop with you again.

Managing seasonal demand

If your brand consistently sees demand spike at certain times of the year, the PAR system can help you stock up in advance to make sure you have enough product to satisfy customers. For instance, an ecommerce business that sells snow shovels can adjust their PAR levels when the winter months are coming up to make sure that they reorder on time to meet demand.

“Spikes in order volume can happen at any time, so knowing that our 3PL partner is able to manage huge peaks in business and fulfil thousands of orders in a short time if needed is priceless. With ShipBob, we’re not afraid of going viral! We’re not afraid of blowing up, because we know that ShipBob will be able to handle surges in demand.”

Juliana Brasil, Director of Operations at Food Huggers

Increasing profitability

With a PAR system helping you keep just the right amount of stock on hand, you can significantly reduce costs related to inventory waste and inventory holding. This keeps your overhead costs low, which can boost to your bottom line. You’ll also be able to experience higher profitability since you’re spending less money to store inventory or procure unused stock.

Setting minimum and maximum quantity limits

A periodic automatic replenishment inventory system allows organizations to set minimum and maximum quantity limits for specific items. This makes it easier to maintain optimal stock levels for each item in their inventory. They can easily balance their specific inventory needs against existing stock amounts and preset PAR levels, which allows for enhanced inventory control. This may involve understanding when to replenish stock, how many units to reorder, when to pause retail replenishment purchase orders, and more.

ShipBob customers ace inventory management

Even with a PAR system in place, managing your inventory can be a headache. That’s why a lot of brands turn to expert ecommerce logistics platforms like ShipBob for help storing, balancing, and monitoring their inventory.

With a combination of ShipBob’s inventory management software and fulfilment services, several businesses have experienced massive improvements in their inventory management. Here are some real-life examples of brands that successfully integrated ShipBob’s offerings with the principles of PAR for enhanced inventory management and delivery processes.

MDacne

MDacne is an app that analyses users’ skin and provides fully-customised acne treatment kits. With such a dynamic offering, the brand’s inventory management and fulfilment processes are highly complex and labour-intensive, meaning an out-of-the-box solution wasn’t right for them.

Instead, MDacne partnered with ShipBob. Not only was ShipBob’s dashboard able to give them visibility into all of their SKUs and set PAR levels for each one, but ShipBob’s open API enabled them build custom logic to make fulfilling different product combinations easy.

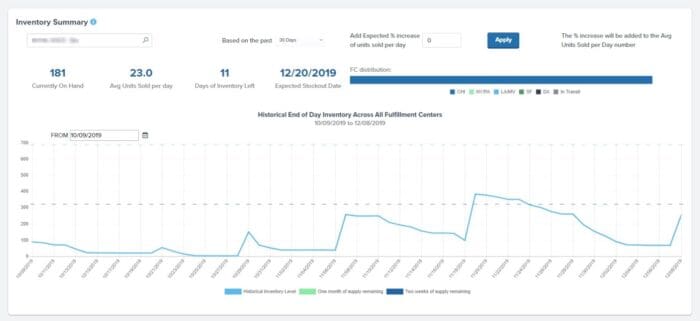

“ShipBob’s analytics tool is really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

IZIMINI’s success story

As a brand that experienced exponential growth at the very beginning, IZIMINI was struggling with inventory management and fulfilment. During the first six months, their products were often out-of-stock while pre-orders piled up. With dreams to expand globally, they knew they needed a better solution.

After switching to ShipBob, IZIMINI leveraged ShipBob’s analytics dashboard to see key inventory metrics at a glance and time replenishment to minimise backorders. They also use ShipBob’s global network of fulfilment centres to store inventory abroad (while maintaining visibility) and scale at a pace that keeps up with global demand.

“We love ShipBob’s technology. The dashboard is very intuitive. I like that we can create our own rules, such as adding marketing insertions to orders, which makes it super easy. For each product, I can choose the packaging preferences and requirements, which is the same with retail preferences.

That’s what I like with ShipBob — there are lots of things I can do myself in the dashboard which wasn’t the case with my previous 3PL. I like to look at the analytics in the ShipBob dashboard, knowing exactly what I have for storage. I can also set up alerts to know when I’m low on inventory for certain products to make replenishment easier. The bundling process is really good. Before ShipBob we would do it with an Excel table, which was a lot to manage.”

The IZIMINI team

Take the next step in inventory management with ShipBob

As a leading ecommerce enablement platform, ShipBob offers specialized features that work alongside PAR principles to help your brand maintain optimal stock levels, reduce shipping costs, and provide efficient delivery experiences.

Here are just some of the ShipBob capabilities your brand can leverage to improve inventory management.

Cloud-based analytics dashboard

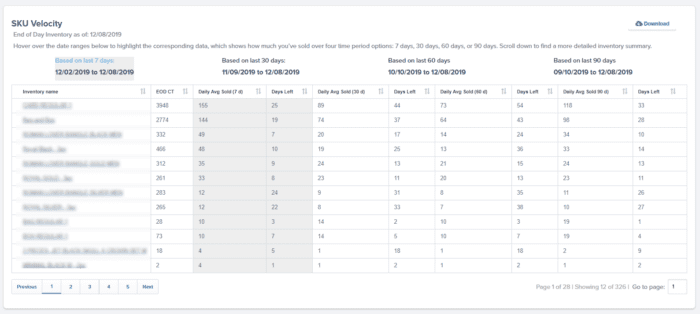

ShipBob’s web-based fulfilment platform delivers deep inventory visibility, as well as an analytics dashboard that lets you monitor inventory KPIs across an order’s whole journey.

Our technology helps you optimise inventory planning with accurate data on inventory history and SKU performance, so you can see how each SKU is selling, how many units are left, and how different SKUs have performed over time. This enables you to strategically plan your inventory replenishment based on demand trends and seasonal fluctuations.

ShipBob even helps you calculate the optimal reorder point, and allows you to set reorder point notifications so that you are instantly notified when a SKU reaches the minimum level. This allows you to reorder inventory seamlessly and avoid expensive stockouts.

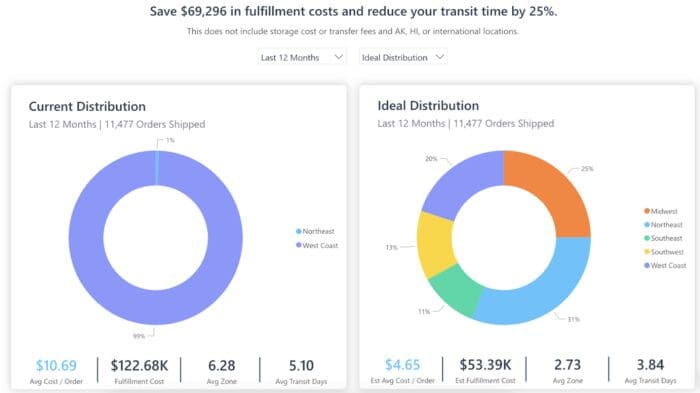

Geographic footprint

With ShipBob’s network of fulfilment centres, you can strategically distribute your inventory to store it closer to your customers to facilitate faster delivery and lower shipping costs.

The proprietary software also gives you visibility into inventory levels across these fulfilment centres and helps you calculate your ideal distribution strategy, so you can continually adjust your inventory allocation to ensure stock availability across the network.

ShipBob WMS for in-house operations

If your brand runs and operates its own warehouse, ShipBob’s proprietary WMS lets you manage your inventory like a pro. The warehouse management system provides you all the inventory capabilities that outsourcing ShipBob customers receive, including:

- Real-time visibility into your inventory at the SKU level

- SKU tracking and performance metrics throughout the fulfilment process

- Automated notifications when a SKU hits its reorder threshold

Omnichannel fulfilment

Balancing inventory across multiple channels can be difficult – but with ShipBob’s omnichannel fulfilment capabilities, it’s easier. ShipBob’s dashboard lets you track inventory flow across your sales channels, so your inventory records are accurate. As a result, you can prevent accidental stockouts that may occur due to inconsistent inventory data.

Global reach

To expand internationally, you’ll need a flexible inventory and fulfilment strategy. ShipBob helps brands grow globally by leveraging an international network of fulfilment centres across the US, Canada, Europe, and Australia. This network allows you to place inventory locally int eh countries you ship to, which helps you ensure stock availability as well as reduce transit times and shipping costs.

To learn more about ShipBob’s inventory management solutions, click the button below to chat with an expert.

Periodic automatic replenishment FAQs

Below are answers to common questions about periodic automatic replenishment.

How does PAR benefit organizations?

PAR helps organizations maintain optimal stock levels, avoid stockouts, minimise inventory waste, and reduce inventory holding costs.

How does ShipBob support global scalability?

ShipBob offers a global logistics solution with an international fulfilment network so you can store your inventory closer to your international customers. This helps reduce delivery times and shipping costs while ensuring that stock is available at strategic fulfilment centres.

What are some real-world examples of brands that have successfully implemented PAR through ShipBob?

Brands such as MDacne and IZIMINI have successfully implemented PAR using ShipBob to get real-time visibility into their inventory, which allows them to replenish their stock on time and maintain optimal inventory levels.

%3A%20Inventory%20Management%20with%20ShipBob%C2%A0%20-%20ShipBob%20Australia&_biz_n=0&rnd=535857&cdn_o=a&_biz_z=1745748910681)

%3A%20Inventory%20Management%20with%20ShipBob%C2%A0%20-%20ShipBob%20Australia&_biz_n=1&rnd=326189&cdn_o=a&_biz_z=1745748910684)

%3A%20Inventory%20Management%20with%20ShipBob%C2%A0%20-%20ShipBob%20Australia&rnd=548151&cdn_o=a&_biz_z=1745748910685)