Table of Contents

** Minutes

What is supply chain convergence?

The evolution of supply chain convergence: where did it come from?

Economic implications of converged supply chains

The role of data analytics platforms in ecommerce supply chains

Charting the way forward with ShipBob: steps to embrace supply chain convergence

When it comes to supply chain management, most ecommerce businesses are prepared for the worst while hoping for the best. Many business owners experienced what a disruptive environment truly feels like when supply chains around the world were challenged during the COVID-19 pandemic.

The thing is, it doesn’t necessarily take a global pandemic for supply chain operations to falter.

It can happen simply due to ineffective planning, risk management, warehouse use, or sourcing strategies.

So, what can you do to strengthen supply chains? Well, some businesses are turning to a concept called supply chain convergence. In this guide, we’ll uncover what this concept means, how it benefits modern ecommerce businesses, and how you can take steps to implement it.

What is supply chain convergence?

Supply chain convergence refers to the process of integrating all aspects of a supply chain into a unified system. It’s a form of supply chain digitization that ensures every element, from sourcing raw material inventory to product delivery, is coordinated and managed through a centralised platform. By doing this, it provides a holistic overview of a business’s local or global supply chain — allowing for better decision-making and improved efficiency.

This approach contrasts with how many business owners currently manage their supply chains. Usually, they use various disconnected systems which can create isolated pools of data or “data silos.”

For instance, a business that doesn’t use supply chain convergence might manually keep track of its inventory, use a third-party platform to source its product, use another platform for shipping, etc. This scattered method can cause inefficiencies and errors across the supply chain.

The evolution of supply chain convergence: where did it come from?

As ecommerce companies grow in size, their supply chains become more complex. The need for more SKUs increases complexities in sourcing, procurement, inventory management, package tracking — the list goes on. Managing all of this the traditional way with siloed data and separate systems is inefficient, unsustainable, and leaves supply chain processes vulnerable to disruption.

The evolution of supply chain convergence began as a response to these challenges and was primarily driven by technological advancements capable of better handling these complexities.

(De)centralised technology platforms

In the past many companies managed their supply chains using decentralized technology platforms . This means each part of the supply chain, like buying supplies, storing products, shipping, and customer service, works on its own using different systems.

This kind of setup often leads to problems. Important information gets stuck in one place and isn’t shared, making it hard for different parts of the company to work together, ultimately resulting in misalignment.

However, centralised technology platforms are revolutionizing the way information is shared. They integrate every aspect of the supply chain into a unified system—whether you’re using a decentralized supply chain or not. This integration simplifies the process of accessing crucial information, ensuring that all departments within the company are aligned. It also enhances the company’s ability to adapt quickly to emerging challenges, fostering a more resilient supply chain.

(In)efficient returns management

The returns management process has traditionally been a challenge in the supply chain, often viewed as a necessary evil rather than a strategic component. An inefficient returns process leads to increased costs, inventory management problems, and customer dissatisfaction.

However, the modern approach to returns management integrates returns into the overall supply chain strategy. By leveraging technology to process returns more efficiently and gathering insights from return data, businesses can reduce returns, which then reduces costs and improves profitability.

The rise of third-party logistics

The rise of third-party logistics (3PL) providers has been a significant driving force in the evolution and convergence of supply chains. Businesses managing logistics in-house often deal with inefficiencies due to a lack of expertise and resources. The emergence of 3PLs has offered businesses access to specialized logistics services, advanced technology, and a vast network of distribution centres.

From warehousing and transportation management to order fulfilment and inventory management, 3PLs have revolutionized how companies approach their logistics needs. This integration enables businesses to optimise their supply chains, reduce costs, and focus more on selling their product.

Sustainability and ethics in fulfilment

Sustainability and ethics have become increasingly important in business overall. Traditional supply chains often overlooked these aspects, leading to practices that weren’t eco-friendly or socially responsible.

However, supply chain convergence has made these practices more accessible than ever before. Businesses are now integrating sustainable practices into their supply chains, such as using eco-friendly materials, eco-friendly shipping to reduce carbon emissions, and ensuring fair labour practices. This shift not only helps in building a positive brand image but also contributes to the long-term viability of the business and the environment.

Scalable personalisation and customisation

The evolution of supply chains has highlighted a key challenge: the need for personalisation and customisation at scale. Traditional logistics, with their rigid, one-size-fits-all approach, often led to inefficiencies and a disconnect between consumer desires and product offerings.

However, with the help of technology and supply chain convergence, businesses are able to adapt more dynamically to consumer demands.

“ShipBob’s API lets us build custom logic since we ship personalised products with lots of variations in the kits we send. We can write a few lines of code instead of creating a manual kit for each possible order combination as we’d have to do in a tool like Shopify.”

Oded Harth, CEO & Co-Founder of MDacne

This shift enables businesses to offer a broader variety of products, tailored to individual preferences, without incurring the high costs traditionally associated with customisation.

Economic implications of converged supply chains

According to a white paper by GEP, one of the most common concerns raised by supply chain leaders was related to supply chain gaps resulting in higher costs.

Image credit: GEP

Just imagine, if your data isn’t giving you the whole picture of what your inventory status is, then you might be ordering excess stock. Or, if your transportation isn’t optimised then you might be paying more in shipping fees.

All of these supply chain gaps become increasingly more critical as your business scales. For instance, without real-time inventory data, you might need to spend more time pulling reports and analising stock counts to determine how much inventory you have on hand versus how much you need. This eats up a crucial resource for any business owner — time.

“We utilise ShipBob’s Inventory API, which allows us to programmatically retrieve real-time data on how many units of each product are currently stored at ShipBob’s warehouses. We currently use this API to generate custom reports to tie this inventory data into our accounting platforms.”

Waveform Lighting Team

The following is a high-level example of the differences between a business using supply chain convergence versus one that isn’t.

| Aspect | Without convergence | With convergence |

| Operational efficiency | Lower efficiency due to disjointed processes | Higher efficiency due to integrated processes |

| Cost management | Increased costs due to inefficiencies and redundancies | Reduced costs through streamlined operations |

| Adaptability to market changes | Slower response to market changes and consumer demands | Quick adaptation to market changes and demand |

| Inventory management | Potential for overstocking or shortages due to poor inventory tracking | Optimised inventory levels, reducing waste |

| Customer satisfaction | Potentially lower due to slower operations and response times | Improved due to efficient operations and faster response times |

Although it’s difficult to measure precisely how much a business can save by implementing supply chain convergence, it’s important to consider that these savings can be significant and multifaceted.

Moreover, the integrated nature of a converged supply chain allows for better data analytics and decision-making, further enhancing strategic planning and long-term profitability.

The role of data analytics platforms in ecommerce supply chains

Data analytics platforms play a crucial role in improving ecommerce supply chain visibility. By integrating technology and automation, they provide essential insights for efficient operation:

- Inventory management solutions enable real-time tracking to maintain optimal stock levels. This reduces holding costs, prevents stockouts, and provides insights for better demand forecasting.

- Warehouse automation improves the accuracy and speed of order processing. This combination of technology and equipment helps in reducing picking and packing time and, combined with data analytics, ensures a seamless flow of information.Warehouse automation can come in many forms such as robotics, artificial intelligence (AI), warehouse management system, inventory management system, and more.

- Order fulfilment should be every company’s number one priority. Choosing a comprehensive order fulfilment solution that leverages data analytics is key to success. These solutions analyse customer orders, provide real-time tracking of order processing, and optimise shipping routes and methods.

- Distributed inventory involves strategically placing inventory based on sales trends and geographical data. This strategy reduces shipping costs and delivery times, with data analytics playing a crucial role in determining inventory distribution.

- The right replenishment strategies can significantly impact a business’s bottom line. An example of this is through using the reorder point formula which demonstrates how data-driven approaches ensure timely replenishment.

Real-time insights are a key component to managing all of the areas mentioned above. Without it, you won’t have updated information and may be basing your decisions on outdated data.

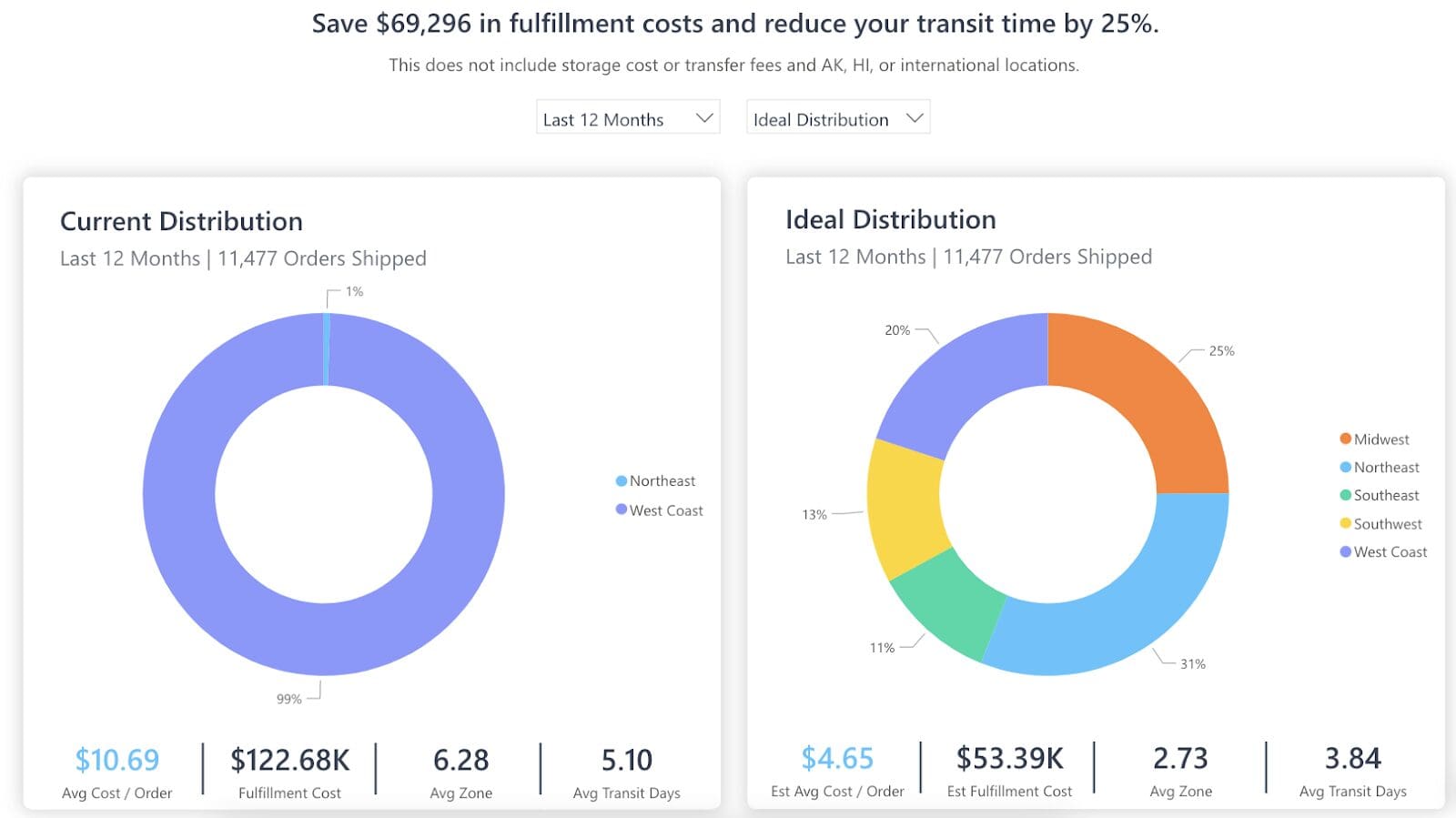

Just take the example below, for instance. ShipBob’s dashboard and analytics tools dynamically update as orders are dispatched to show you exactly how much each order is costing you as well as how to save money with an ideal distribution strategy.

This level of insight is crucial for optimising profitability, improving customer satisfaction, and making strategic adjustments.

Charting the way forward with ShipBob: steps to embrace supply chain convergence

ShipBob stands at the forefront of supply chain convergence. Offering an end-to-end fulfilment solution that seamlessly integrates various supply chain components into a unified system—ShipBob is redefining the standards of modern fulfilment.

A WMS that centralises information

ShipBob’s warehouse management system (WMS) is a testament to its commitment to technological advancement. It streamlines warehouse operations, ensuring that every item is stored, picked, packed, and shipped with efficiency and accuracy. This system is crucial for businesses looking to scale quickly without sacrificing operational quality.

Inventory management that doesn’t leave you in the dark

When it comes to inventory management, ShipBob offers a dynamic approach. By providing real-time data and insights, businesses can maintain optimal stock levels, reducing the risk of stockouts or excess inventory. This level of management is vital for adapting to fluctuating market demands.

Outsourced fulfilment made easy

By entrusting the logistics to ShipBob, businesses can focus on their core competencies knowing that their fulfilment needs are in expert hands. Fulfilment is a costly and complex component of ecommerce that requires specialized expertise, technology, and resources. With ShipBob you can easily expand your business’s reach without the burden of managing fulfilment centres. ShipBob has a global network of fulfilment centres across North America, the UK, EU, and Australia so you can reach customers no matter where they’re located.

The convergence of these services creates the ultimate supply chain convergence machine. ShipBob doesn’t just offer individual solutions; it integrates them seamlessly, providing a comprehensive system that covers every aspect of supply chain management.

Get started with ShipBob

Interested in leveraging one of ShipBob’s fulfilment solutions to help streamline your supply chain? Connect with our team to get started with the right solution for you.

Supply chain convergence FAQs

Below are answers to common questions about supply chain convergence.

What are the economic implications of adopting a converged supply chain approach?

The adoption of a converged supply chain approach leads to improved economic outcomes through enhanced supply chain efficiency, cost savings, and customer satisfaction.

What steps can businesses take to align with the principles of supply chain convergence?

Businesses can align with the principles of supply chain convergence by adopting integrated supply chain technology solutions, streamlining their logistics processes, and collaborating with a fulfilment provider like ShipBob.

How does technology play a role in supply chain convergence?

Technology is crucial in supply chain convergence. It creates a connected ecosystem and enables the integration and optimisation of various supply chain components, leading to increased efficiency, accuracy, and real-time decision-making capabilities.