Table of Contents

** Minutes

The advantages of virtual warehousing

Unlocking a virtual approach to warehousing

Imagine this: your ecommerce business is thriving, and you decide to expand into a new warehouse. But once you do, you realize that you don’t know what’s going on with half of your stock. How are you supposed to monitor your inventory levels if you can’t be in two places at once?

In this situation, a virtual warehouse can help. By creating and using a virtual warehouse, growing brands can achieve a holistic inventory view, and track and manage inventory across all their warehouses and channels in just a few clicks.

In this article, we’ll discuss what a virtual warehouse looks like, its advantages, and how to implement one in your own inventory management.

What is virtual warehousing?

A virtual warehouse refers to a digital representation of inventory that’s physically located within warehouses or storage facilities.

Virtual warehouses enable growing ecommerce businesses to maintain a single, holistic view of their inventory, even as they store stock and fulfil orders from multiple physical spaces or across multiple channels.

While physical warehousing processes only deal with the inventory that’s present in the warehouse, virtual warehouses allow brands to manage their entire inventory. Physical warehousing involves physical activities (such as unloading pallets and storing products), virtual warehousing leverages technology to record data, provide real-time analytics, and deliver actionable insights that brands can use to optimise their overall inventory operations.

The advantages of virtual warehousing

Having a virtual warehouse offers brands a lot of benefits, many of which positively impact your entire supply chain. Here are some of the most prominent advantages of digital inventory warehousing for ecommerce brands.

Better inventory control

When you can see all your inventory at once through a virtual warehouse, it is much easier to balance inventory levels across locations. This helps you allocate inventory more strategically to meet customer demand and avoid costly stockouts and deadstock.

Lowered shipping costs and transit times

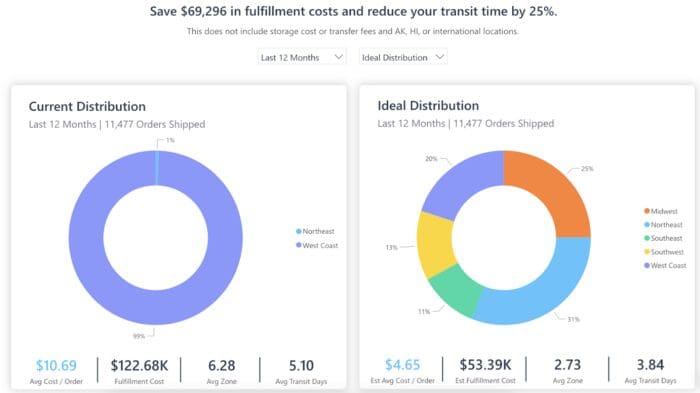

Distributing inventory is a crucial part of keeping shipping costs and times low – and with a virtual warehouse, your brand can manage these locations more easily.

If your customers are geo-dispersed, storing inventory and fulfilling orders from one warehouse forces some customers to endure high shipping costs and long wait times. By splitting your inventory across multiple strategically located warehouses, your brand can place inventory closer to customers and minimise shipping costs and lead times.

A virtual warehouse not only allows you to manage inventory across all your locations, but can also provide you with insights on what to store where. For example, ShipBob’s dashboard offers brands a tool that uses order data to calculate the most strategic distribution across our fulfilment centre network to keep costs low.

Real-time analytics and insights

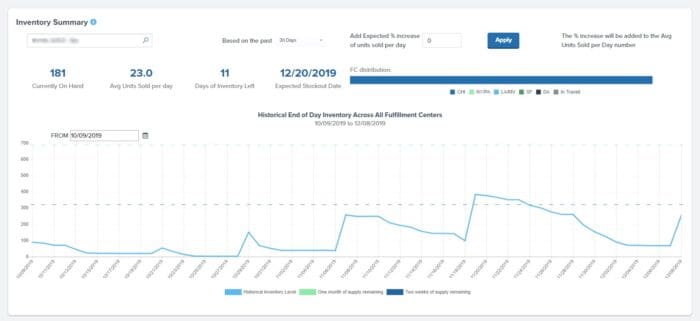

Tracking inventory data and pulling insights manually for one warehouse is hard enough, let alone multiple. Virtual warehouses will automatically track key metrics (such as SKU levels, storage costs, and days on hand), saving you the time and effort of calculating them yourself.

The best virtual warehouse software solutions will update these metrics in real-time. ShipBob’s dashboard, for example, offers on-demand inventory level tracking, as well as up-to-date information on fulfilment and shipping KPIs.

This provides you with the most recent data, which in turn helps you make even better decisions regarding your inventory.

Optimised storage

A virtual warehouse provides a comprehensive understanding of your entire inventory’s movement, which you can use to optimise your storage for operational efficiency and cost.

For example, if you discover that one of your SKUs is turning over very quickly at a particular warehouse, you can allot more storage room for that SKU and keep more units on hand. You can also move the SKU to a more accessible storage location to make it easier for workers to pick units during fulfilment.

Virtual warehousing solutions like ShipBob’s dashboard also give you the data and insights you need to track storage costs, improve demand forecasting, calculate reorder points to further optimise storage.

Check out ShipBob's Warehouse Management System (WMS)

ShipBob's WMS helps your warehouse reduce picking errors, manage inventory in real time, and fulfill orders faster.

Unlocking a virtual approach to warehousing

If you’ve never used a virtual warehouse before, you might feel lost on how to implement one. Here are some actionable steps for introducing a virtual warehouse into your operations.

1. Assess your current warehousing infrastructure

Start by taking a look at your current physical warehousing operations, and determine what inefficiencies or problems you want a virtual warehouse to solve. Some common areas for optimisation include:

- Balancing inventory levels

- Inventory distribution

- Visibility into inventory flow

- Standardization across warehouse processes

- Cost reduction

- Order fulfilment speed

- Inventory storage

By creating a list of improvement areas, you’ll be better equipped to find the right solution that meets your needs.

2. Determine your must-have features

There are many smart warehousing solutions on the market, so it’s important to establish what capabilities you’re looking for.

At minimum, you will probably need a solution that offers:

- Capacity for all your data storage

- Intuitive navigation

- Omnichannel visibility from a single platform

- Real-time data and inventory tracking

- Deep analytics on inventory movement and performance

- Automation for inventory management activities

It is also important to consider how your virtual warehouse solution can keep pace with your brand as it scales. For example, if you plan to begin selling through a retail partner or retail stores, make sure that your software of choice can track and manage inventory through that channel.

3. Integrate it with ecommerce platforms & tools

A good virtual warehouse will integrate with your existing tech stack. It’s particularly important that your virtual warehouse solution connects directly to your ecommerce platform, so that it can automatically update your inventory levels every time a customer places an order on one of your channels.

4. Train your team on software

It’s absolutely crucial to train all of your warehouse teams to use your virtual warehouse. That way, you can make sure that every location in your warehousing and fulfilment network is synched and daily processes flow smoothly. In addition to onboarding your teams, it’s also a good idea to offer regular, ongoing training to both new and experienced staff.

5. Monitor performance and optimise continuously

The best way to know if your virtual warehouse solution is working is to track your brand’s warehousing performance over time. Specifically, note whether any of the following inventory and order metrics have improved since implementing your virtual warehouse:

- Holding costs

- Stockout rate

- Lead times

- Inventory accuracy

- Inventory shrinkage

- Stock to sales ratio

- Inventory turnover

- Order cycle time

6. Choose the right logistics partner

Implementing and managing a virtual warehouse on your own can be more trouble than it’s worth. Instead, many ecommerce brands choose to partner with a professional logistics solution that provides virtual warehousing capabilities.

These partners usually provide inventory and warehouse management software in addition to other services, such as inventory storage in co-warehousing or flexible warehousing space, order fulfilment, and shipping.

ShipBob, for example, is an expert logistics provider that offers brand both outsourced and in-house solutions. For brands looking to take warehousing operations off their plates, ShipBob will store and fulfil orders on a merchant’s behalf. If your brand needs a way to optimise processes in your own warehouse, ShipBob’s proprietary warehouse management system (or WMS) empowers your team to achieve higher operational efficiency and accuracy.

With both solutions, merchants have access to ShipBob’s dashboard, where they can “virtually see” their inventory across all fulfilment centres and sales channels, and access top-notch supply chain analytics.

ShipBob: pioneering virtual warehousing solutions

Ecommerce is a global phenomenon that is constantly evolving. To thrive in this landscape, brands must take their products to new locations and expand their sales channels – but to do so successfully, brands need a scalable way to manage their inventory wherever and however they sell.

A virtual warehouse solution like ShipBob’s dashboard gives brands a way to maintain visibility and control of their inventory, even as they grow. Through a single platform, ShipBob customers can manage stock levels at dozens of fulfilment centres, optimise allocation across locations and channels, and access key metrics a glance to help them make more strategic decisions.

One of these customers is Baby Doppler, one of the leading online fetal doppler retailers worldwide. Before partnering with ShipBob, they had a lot of trouble achieving inventory visibility. None of the providers they worked with gave them unified data that let them view their inventory holistically, and pulling insights from their reporting was a struggle.

Outsourcing fulfilment and inventory distribution to ShipBob changed the game. Not only did ShipBob’s dashboard finally deliver the comprehensive inventory visibility they were looking for, but ShipBob’s team took care of physically distributing their inventory for them.

“Partnering with ShipBob, we joined their Inventory Placement Program, which helps us distribute our inventory to strategic hubs across the US so we don’t have to manage multi-location inbound shipments or identify the most optimal fulfilment centre locations ourselves.

This finally gave us the visibility and analytics we were looking for. Through the program, we get real-time insight into how much inventory to allocate to a specific warehouse, our current on-hand inventory levels, and how long each SKU is going to last by location. ShipBob provides a lot of distribution metrics, and everything presented is useful.

ShipBob’s Inventory Placement Program provides visibility into inventory movement that’s absolutely key for anyone running a business. The data is easily accessible, and it shows exactly how inventory is being split across ShipBob’s network of warehouses.”

Mithu Kuna, Founder and CEO of Baby Doppler

By leveraging insights from ShipBob’s dashboard alongside ShipBob’s global fulfilment centre network, Baby Doppler now ships 87% of orders from Zones 1-4, and can follow through on their 2-day delivery promise.

“Overall, our customers seem much happier since we switched to ShipBob, and we’re not getting negative reviews on our 2-day shipping anymore. Since switching to ShipBob from other 3PLs, our overall customer rating has been climbing steadily to get closer to our previous nearly perfect 5/5 rating, I believe largely due to improved shipping performance and service levels provided by ShipBob.”

Mithu Kuna, Founder and CEO of Baby Doppler

To discover how ShipBob’s solutions can help you optimise your warehousing, click the button below.

Virtual warehouse FAQs

Below are answers to common questions about virtual warehouses.

How can I train my team to adapt to a virtual warehouse system?

When onboarding users to a virtual warehouse system, make sure to instruct your team on how to:

- Navigate the platform

- Carry out daily tasks using the platform (such as inventory receiving, storage, and order picking)

- Monitor key inventory and warehousing KPIs through the software

- Reach out to customer support if necessary

What are the cost implications of transitioning to a virtual warehouse?

When transitioning to a virtual warehouse, you must consider the cost of the software itself (as well as any on-premise implementation costs), any user training, integrations, and more. However, this cost may be offset by the value that the virtual warehouse delivers in terms of inventory visibility and control across your supply chain and sales channels.

Is virtual warehousing suitable for businesses of all sizes?

While businesses of all sizes may benefit from a virtual warehouse solution, some brands may benefit more than others. A virtual warehouse can be particularly useful for brands that are:

- Growing quickly

- Utilising multiple physical warehouses or fulfilment centres

- Selling on multiple channels (both DTC and B2B)

- Struggling to manage inventory or maintain inventory visibility across their operations

How does ShipBob integrate with virtual warehouse systems?

ShipBob’s outsourced and in-house fulfilment solutions come with a built-in inventory management system. This IMS software takes the form of ShipBob’s dashboard, and enables brands to view, track, and monitor inventory movement and metrics in real-time across all active warehouses and sales channels.