Warehousing is expensive.

Setting up and maintaining a warehouse makes up a significant portion of your overall ecommerce operational costs and has a heavy impact on your bottom line. If you’re considering renting or buying a warehouse, you need to keep these expenses in mind. Optimising your ecommerce warehouse costs will help your brand increase profitability but it can be challenging to do.

That’s why we’ve put together this comprehensive guide to give you a better understanding of the various warehouse costs, how warehouse pricing is calculated, and whether buying or renting would be a better option for you. Additionally, we’ll show you how you can optimise your warehouse costs so they aren’t cutting into your revenue. Let’s get started.

Understanding warehouse costs: where do they come from?

Warehouse costs refer to the expenses incurred to run a warehouse. These costs are a combination of expenses that help a warehouse run efficiently, not just the cost of renting warehouse space. Some of these are variable costs, meaning that you can expect the total cost of running a warehouse to change each month.

Having a thorough understanding of the various warehousing costs is essential for effective supply chain management. It gives you a realistic picture of your inventory holding costs so you can identify opportunities for cost reduction. Let’s break down the main components of warehouse costs.

Rent

If you’re renting warehouse space, rent will make up a significant portion of your total warehouse expenses. Rent is typically calculated based on square footage, warehouse rental costs will vary depending on the total storage space you use. Some warehousing companies will also charge you for the number of items you’re storing in the facility.

Upkeep

For businesses that own their own warehouse, the cost to maintain the facility is included in the overall warehouse expenses. This includes the cost of regular maintenance, cleaning, and repairs as well as any improvements they make to the space.

Utilities

Basic utilities such as electricity, heating, water, internet, and waste disposal are an essential part of running a warehouse. These typically fall under storage costs and may be variable depending on usage. For example, you may spend more money on heating during the winter months whereas electricity costs may increase during the holiday rush as your warehouse functions overtime to support increased customer demand.

Labor costs

A significant portion of your warehouse operational expenses goes into labour costs. This includes labour wages for workers across various stages of the warehouse processes including picking and packing staff, managers, forklift operators, and other staff members. Some of these labour expenses fall under material handling costs and may even be variable depending on whether you hire temporary staff during peak seasons.

Equipment costs

Equipment costs include the expenses incurred to purchase, rent, and maintain different types of warehouse equipment. This includes forklifts, conveyor belts, pallet jacks, AS/RS systems, automated guided vehicles, and other equipment used to perform various warehousing operations.

Technology costs

Modern warehouses make use of technology such as warehouse management systems (WMS) and inventory management systems to streamline processes. The cost to purchase or use this technology adds to the total cost of warehousing.

Order fulfilment costs

The expenses involved in fulfilling orders are another major contributor to your total warehouse costs. This typically accounts for packaging materials and order shipping. If you choose to customise aspects of your unboxing experience (e.g., custom packaging, marketing inserts, etc.), this is an added expense under fulfilment costs.

Insurance and taxes

Businesses need to insure their warehouses to protect against damage, injury, or theft. So you’ll also spend money on warehouse insurance costs, which may vary depending on the types of goods stored and their value. Additionally, there may be miscellaneous taxes such as property taxes that may be incurred to maintain your warehouse.

How is warehouse pricing calculated?

How you calculate warehouse pricing depends on factors such as the pricing model you use and whether you buy or rent warehouse space. In most cases, the main considerations are the monthly or annual rate to use the space and the estimated operating expenses to run your warehouse.

Common warehouse pricing calculations/rates

Fixed variable pricing is the most popular pricing model, where the business rents, leases, or buys a fixed warehouse space. In the case of rentals, the business will pay a fixed monthly fee for using the storage space regardless of whether you use the full warehouse capacity. This is typically calculated per square foot where you account for the total square footage of the space and the per square foot cost.

The following formula can be used for calculating this type of warehouse pricing:

(Total rental space x Rental cost per square foot) + Operating costs = Monthly warehouse cost

For example, if you’re renting a 10,000-square-foot space at $7 per square foot and incurring $25,000 in operating expenses per month, your monthly warehouse cost would be as follows:

Monthly warehouse cost = (10,000 x 7) + 25,000

= 70,000 + 25,000

= $95,000

Depending on the warehouse type, you may even incur additional expenses for value-added warehousing services such as kitting, assembly, and fulfilment. You’ll typically see fulfilment providers offering these additional services in addition to storing inventory with distributed warehousing. In this case, you’re outsourcing the entire warehousing operation so there won’t be any overhead costs on top of what you’re paying for the service.

Another pricing model commonly used in on-demand warehousing is the transaction/unit rates model where rates are calculated according to the transactions or units. In this pricing model, you may get charged a fixed fee per unit or pallet or even per transaction or shipment. For example, ShipBob’s pricing for DTC order fulfilment includes per-pick pricing in addition to other standardized fees.

Calculating costs using this pricing model is more straightforward unless there are additional charges involved. You’ll simply have to multiply the per unit/transaction cost with the total number of units or transactions. For example, if you’re getting charged $6 per pallet per month to store 1,000 pallets, then the total monthly warehouse cost will be $6,000.

Buying vs. renting: cost breakdown

Whether to buy or rent is a major consideration when you’re looking to optimise your warehouse costs. While buying may require more initial investment, you may end up saving more on monthly expenses further down the line. Meanwhile, renting may involve a significantly lower investment, making it an ideal option for smaller operations and businesses with a smaller budget.

Costs for buying a warehouse:

- Property cost (ranges between $625,000 and $750,000 for a 5,000 square foot space)

- Maintenance costs (for set up, repairs, and upkeep of the property)

- Applicable taxes

Costs for renting a warehouse:

- Rental cost (approximately $8.84 per square foot in the United States, which may be subject to increase)

- Applicable taxes

Regardless of the choice, you’ll still be managing your own warehouse and fulfilment. This means you have to account for the NNN/CAM charges, which are all the expenses not included in the rent or property cost.

In other words, both renting and buying a warehouse will incur operational expenses and other hidden costs of self-fulfilment. This includes costs related to labour, material handling, packing materials and supplies, transportation, and shipping insurance to name a few.

How to optimise your warehouse costs

How much you spend on your warehouse will impact your total inventory costs, which will eventually influence your bottom line. So optimising your warehouse costs is a vital step to reduce your inventory holding costs and subsequently increase profitability.

Reassess your warehousing needs

Start by looking at your existing space to get a better idea of your warehousing needs. This will help you assess whether your current spending aligns with your actual warehousing needs.

Do you really need all the space that you’re currently renting? Are you spending too much to store items that don’t move quickly? Is it possible to move some of the items offsite? Or can you use a consolidation warehouse to minimise shipping costs?

These are all important questions that you need to ask to get a realistic understanding of how much you should actually be spending on warehousing. Then find out where you need to make adjustments to reduce your overall expenses.

Optimise your space utilisation

Optimising your warehouse space utilisation is one of the first steps to reduce your warehouse costs. It involves making better use of the existing space so that you can get the most out of your spending. Essentially, you can optimise your warehouse costs when you spend less to store more inventory.

You can optimise your space utilisation by improving your warehouse layout and storage systems to fit more inventory. You may be able to replace your existing racks with AS/AR systems that will help you make better use of vertical storage space, for example. Similarly, you can make use of other storage systems that will help you fit more inventory at a time.

Avoid overstocking

Carrying excess inventory is one of the biggest contributors to unnecessary warehouse spending. This is when you overstock on inventory that moves slowly, which means it’s taking up the space that could’ve been used to store more profitable items that move quickly. As a result, your inventory holding costs keep adding up while your capital gets tied up on inventory that you can’t sell.

It’s crucial that you avoid overstocking to reduce your ecommerce warehouse costs. You can do this by accurately forecasting your inventory needs based on changes in consumer demand. Then plan your procurement strategically based on these predictions to make sure you’re not procuring more inventory than you really need.

Improve inventory flow

An important step to reduce your warehouse costs is to make sure goods are not accumulating at various stages of the warehouse process. This means you need to maintain a smooth inventory flow so that goods are quickly moved to the next stage of the supply chain instead of taking up valuable space in the warehouse.

You can do this by setting up your warehouse space based on the logical flow of inventory. For instance, putting fast-moving items closest to the shipping docks will make them easier to access. That way, you can keep these items flowing and quickly move them out of the warehouse.

Improve operational efficiency

While reducing your spending on the actual space is one way to reduce warehouse costs, you can further experience cost savings by reducing your overhead expenses. This would involve improving the efficiency of your warehousing operations so that you’re not overspending on labour or utilities.

If your warehouse staff is spending more time than required to perform specific tasks, your expenses will quickly build up and add to your operational costs, which further impacts your total warehousing costs. It pays to invest in automation technology and other tools that will streamline your operations and help your staff do their jobs more efficiently.

For instance, warehouse management software can generate picking lists with optimised picking routes. This will reduce transit time and ensure that your picking staff can complete their picking lists faster. Additionally, you can make use of robotics and other automation software to automate certain tasks such as transporting picked goods to the packing bay or sorting picked items. This will free up the time of your warehouse staff so they can focus on other important activities that need human involvement.

Consider outsourcing fulfilment

From the cost to buy or rent a warehouse to the cost of running your warehousing operations–your total warehouse costs can quickly add up when you’re doing everything in-house. This is particularly true if you’re running multiple warehouses from multiple locations. So sometimes, outsourcing your entire storage and fulfilment operations may be the most cost-effective solution.

Many 3PL providers will store your inventory for you so you don’t have to rent or buy your own warehouse space, which helps you save a significant amount of money. Moreover, no warehouse space means no expenses on overhead costs, helping you cut down your total warehouse costs. In addition to fulfilling your orders for you, they’ll take care of the complexities involved with inventory and warehouse management. That way, you don’t have to spend additional resources or hire additional warehouse staff to add to your warehouse costs.

How AutoGeek slashed their warehousing costs with ShipBob

AutoGeek had been carrying out fulfilment in-house for decades, but this eventually became unviable as the business grew. They had a 30,000-square-foot warehouse in Florida and a 35,000-square-foot warehouse in Indiana, totaling 65,000 square feet of storage space. However, having an expansive product catalogue and a growing order volume meant that the business was soon going to run out of room.

Moreover, the company was spending too much on fixed overhead costs even though their warehousing needs varied. For instance, they would have a team of 30 people shipping out 1,000 packages one day, and they still had 30 people in the warehouse even when they only needed to ship out 400 packages. As a result, they had much higher fulfilment costs because their overhead was fixed.

Due to these factors, AutoGeek decided to outsource fulfilment for their DTC orders to a 3PL. One of the main reasons they chose to work with ShipBob was the ability to compare courier rates for each order. This considerably reduced their shipping costs as they were able to ship each order through a courier that could send it the cheapest.

Additionally, leveraging ShipBob’s outsourced fulfilment allowed them to minimise their overhead. They were able to enjoy a flexible solution that could adapt to their changing labour needs. Since outsourcing to ShipBob, their numbers have gone down significantly, which has helped them improve margins.

ShipBob’s 3 unique approaches to warehousing

Leveraging the right warehouse technology can help you improve various aspects of your in-house operations to cut down on warehouse costs. From automation tools to improve efficiency to accurate demand forecasting to optimise procurement, you can find plenty of opportunities to reduce costs. Even when renting or buying your own warehouse seems much too expensive, you can even turn to outsourced fulfilment options.

Fortunately, ShipBob supports all of these approaches with world-leading warehouse management software and outsourced fulfilment services. You can even take a hybrid approach to manage some of your fulfilment in-house while ShipBob eases your load and helps you save more on your warehousing expenses.

Outsource everything fulfilment and warehousing to ShipBob

ShipBob’s outsourced fulfilment solution takes the pressure off renting and managing your own warehouse. With this service, you can send your entire inventory to ShipBob and we’ll store it for you. That means you don’t have to rent or buy warehouse space, allowing you to save significantly on warehousing costs.

Our network of 50+ fulfilment centres across the U.S., Canada, Europe, and Australia allows us to strategically distribute your inventory as needed. This allows you to take advantage of our overseas fulfilment centres to store your inventory closer to your international customers without dealing with the complexities and expenses of renting a warehouse in another country.

The benefits don’t just end at leveraging our warehouse space. Outsourced fulfilment means we take care of all the inventory management and fulfilment processes on your behalf. You won’t have to pay for additional labour costs or overhead expenses to operate your own warehouse. This results in significant cost savings, which brings down your overall operational expenses.

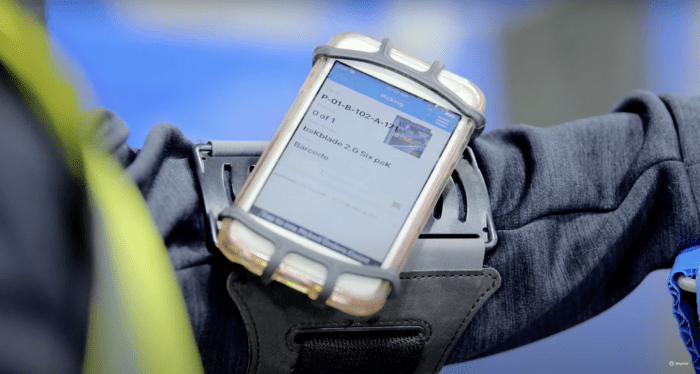

Power in-house operations with ShipBob’s WMS

If you prefer to make use of your existing warehouse space but cut down on your expenses, ShipBob’s proprietary WMS offers the perfect solution. The platform serves as a single source of truth to streamline your warehouse management process.

The easy-to-use platform lets you quickly ramp up new and temporary staff, so you don’t waste too much time on onboarding and training.

By automating and assisting with certain tasks, the WMS helps you improve productivity in the warehouse. For instance, it calculates optimal picking routes and generates optimised picking lists accordingly. This reduces travel time and helps your picking staff to seamlessly complete their pick lists with minimal back and forth.

The ShipBob WMS provides flexible options for batch, auto-cluster, custom cluster, and single order picking. It analyses the optimal pick method for your warehouse so you can improve pick and pack efficiency.

The WMS also helps with order routing and courier selection. This makes it easier to find the most optimal transportation routes and find the most affordable shipping option to cut down on shipping costs.

Adopt hybrid fulfilment for the best of both worlds

To enjoy a little bit of both, you can even opt for hybrid fulfilment where you fulfil some of your orders in-house while ShipBob takes care of the rest. For example, you may choose to outsource your DTC orders and fulfil your Amazon orders in-house if your existing system is working for you. Alternatively, you can have ShipBob fulfil your B2B orders and manage your retail distribution while you focus on fulfilling your DTC orders.

The best part is that you can find the perfect hybrid fulfilment mix that will work best for you in improving efficiency and reducing warehouse costs.

Get started with ShipBob

Interested in leveraging ShipBob’s fulfilment solution? Connect with our team to learn how ShipBob can help you streamline warehouse and fulfilment costs.

Warehouse costs FAQs

Below are the most commonly asked questions about warehouse costs.

What are typical overhead expenses in a warehouse operation?

Utilities, maintenance costs, labour costs, equipment costs, and packing supplies make up a majority of the overhead expenses in a warehouse.

What factors most significantly impact warehouse costs?

The size and scale of the operation, location, labour costs, and storage and handling most significantly impact warehouse costs.

How can technology reduce warehousing expenses?

Technology can reduce warehousing expenses by automating manual tasks and streamlining processes to improve efficiency.

What are the best practices for managing warehouse pricing?

Improving operational efficiency, minimising errors, automating certain activities, and outsourcing fulfilment are some of the best practices for managing warehouse pricing.