Table of Contents

** Minutes

Step 1: Assess your current warehouse organisation

Step 2: Define your warehouse organisation goals

Step 3: Implement changes to optimise your organisation

Why is it important to organise your warehouse?

When a space is organised, it usually boosts productivity. An organised kitchen is easier to cook in; an organised office minimises distractions; an organised grocery store helps you find and purchase what you need quickly.

An ecommerce warehouse is no exception.

Warehouse organisation goes hand-in-hand with good warehouse management. If your warehouse space is well-organised and your warehouse setup is optimised, it allows for more ease of movement and helps create a more efficient warehouse.

This, in turn, means that your staff can quickly complete their tasks and inventory can move seamlessly within the warehouse, which will increase your brand’s productivity and help you stay on track to hit your performance goals.

So how should an ecommerce brand go about organising its warehouse space? In this post, we provide you with a detailed guide on the 3 steps that you can take to successfully optimise your warehouse organisation.

Step 1: Assess your current warehouse organisation

Warehouse organisation refers to how items, workstations, and activities are laid out and physically positioned within a warehousing space.

Usually, a brand’s warehouse organisation is extremely strategic, and designed to make the most of the available space while ensuring that workers can easily find items and perform functions quickly and safely.

However, many businesses struggle with their warehouse organisation because they don’t know that their existing operations could be improved – or, if they do, they don’t know how to begin the optimisation process.

Ideally, it’s best to start by assessing your current warehouse organisation to look for any inefficiencies or problem areas.

For this first step, there are several aspects of your warehouse organisation that you’ll need to review. Take the time to thoroughly assess each aspect and make a note of issues or potential improvements.

Cleanliness

In a cluttered workspace, it’s difficult to find what you need or move around easily, which can lead to inefficiencies. Not only that, but warehouse clutter sometimes poses a safety hazard, which may lead to accidents and injuries.

So, when evaluating your current warehouse organisation, one of the first things you need to assess is how tidy your warehouse is and whether maintenance is done properly.

Take note of details to properly evaluate the tidiness and maintenance of your warehouse, such as:

- Old packages on the floor or taking up valuable space

- Unused equipment or pallets blocking aisles

- Spills that are left uncleaned (which pose a safety hazard)

- Cluttered workstations or messy floors that are difficult to navigate

- Trash or discarded materials that aren’t properly disposed of

Safety

There may be some safety risks associated with how your warehouse is currently set up. Shelves are overloaded with inventory, for example, are at risk of breaking and causing inventory damage and accidents. Similarly, when you store heavy items higher up on the shelves, there’s a high risk that they could topple off and put your staff in danger.

If you’re going to optimise your warehouse organisation, it’s crucial to carefully check for and identify any safety issues.

In addition to assessing your warehouse layout and storage systems for potential hazards, you should also review your warehouse safety protocols. Make sure you clearly specify where and how certain items should be stored or handled within the warehouse to avoid safety risks and liabilities.

For example, you should store hazardous chemicals away from other inventory and equipment and in cool, well-ventilated areas. They should be placed on sturdy shelves and be clearly marked with caution signs. Moreover, the warehouse staff handling those items should have access to appropriate PPE and any necessary safety equipment.

WMS

Important functions such as receiving, storage, picking, packing, labelling, and shipping typically take place at different physical locations within a warehouse. For your warehouse to be properly organised and optimised, these functions need to work together seamlessly.

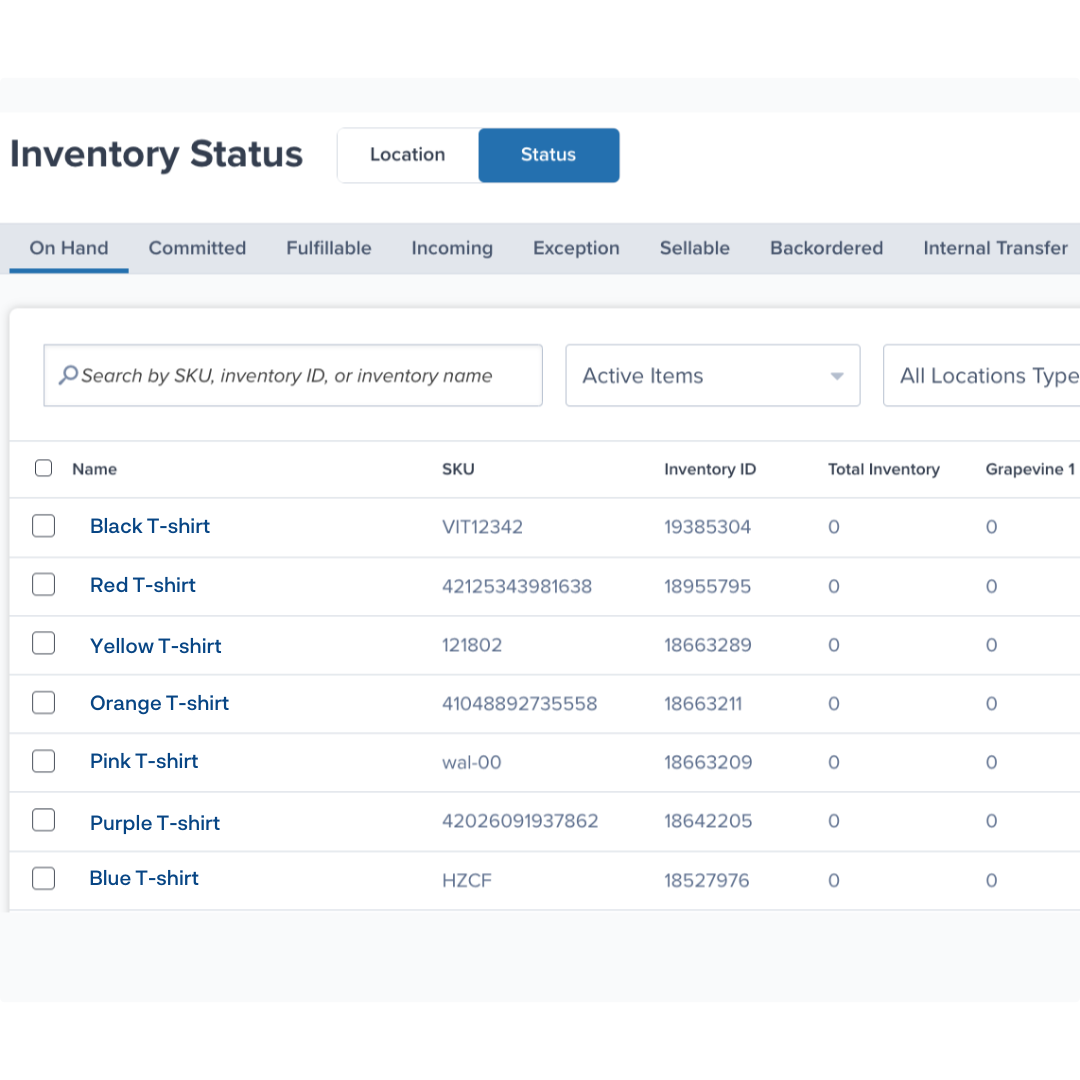

To achieve this, most brands use a warehouse management system (or WMS) that provides full visibility into all these different functions and allows for effortless information exchange.

Take a close look at the warehouse management system you’re currently using to see if it’s lacking key features, such as location-specific inventory visibility, intelligent cycle counts, step-by-step packing flows, and real-time analytics.

Without these functions, different warehousing functions fall out of sync, which could seriously affect your warehouse productivity. But with the right WMS, your brands can track warehouse inventory, manage orders, save time, and reduce order errors.

Cross-training

When your warehousing staff is equipped with the necessary skills to fulfil different responsibilities, you can improve flexibility in your warehouse.

This makes cross-training crucial, as it ensures that each team member has the skills needed to perform different tasks inside the warehouse, and subsequently streamlines workforce allocation.

For example, say there’s an increased need for staff in the receiving dock. You could allocate workers from other teams to help out and quickly complete the receiving process, which prevents disruptions or backlogs and keeps operations moving seamlessly.

When assessing your warehouse organisation, be sure to analyse your staff’s training levels and your cross-training efforts (if any). If your staff doesn’t have the necessary training to switch between different roles, you may need to set aside time to cross-train them more thoroughly.

Inventory management

Another crucial aspect of your warehouse organisation that needs reviewing is your inventory management.

Consider how your inventory is currently managed, and pinpoint any common issues that your team runs into. Ask yourself the following questions:

- Are you running out of stock frequently?

- Are you overstocking and running out of storage containers or space?

- Do you have full visibility into your inventory movement across the warehouse?

- Do you often experience issues with missing information or inaccurate inventory records?

When there’s proper visibility into your inventory levels, you can get a more accurate inventory count. That way, you can effectively plan your replenishment strategy so that you don’t experience issues with stockouts or overstocking.

Additionally, make sure to review how quickly your inventory is selling. Categorize SKUs by how quickly they sell so you can get a better idea of which inventory items to prioritize and which items tend to sit stagnant in the warehouse.

You should also assess your existing inventory management system. If it doesn’t give you the kind of inventory information you need when you need it or automatically sync your inventory data in real-time so you get the most accurate information, it’s probably time to upgrade.

Space utilisation

One of the most important parts of your warehouse organisation is your use of space. Warehouse floor space is expensive, so you’ll want to make sure you’re maximising your available storage space, and using the right types of storage and shelving solutions.

Start your assessment by calculating your warehouse capacity and then comparing it to your existing inventory levels, as well as floor usage. Then review how items are stored to determine if there are optimisation opportunities.

“Prior to ShipBob, we had our most popular products at the front. Through the implementation process we learned that if you’re commonly picking certain items, they should be stored in the back so you aren’t carrying them around while you’re picking other items. Our best sellers are at the end of the pick path now, so once we’ve picked those, we’re already back at the pack stations.

We even changed the way we stowed products. For example, we would have similar items in the same area — take shirts, for instance. Because they were so close together, there was a high likelihood that we picked the wrong size or the wrong colour because all of our shirts looked similar and were physically right beside each other.

Once we set up ShipBob’s system, we were putting those similar items (that weren’t ordered together) in all different places in the warehouse. After that, our pick accuracy went way up. Getting out of our own way of thinking was eye-opening.”

Adam LaGesse, Global Warehousing Director at Spikeball

Step 2: Define your warehouse organisation goals

You’ve evaluated your warehouse on several criteria, and identified areas for improvement. But before you start making changes, it’s important to set specific goals to work toward, so you can measure how impactful your efforts have been.

Warehouse organisation goals may vary for different businesses, but usually involve some standard warehouse KPIs. Here are some common goals that brands aim to achieve through warehouse reorganization.

Faster order fulfilment

When your warehouse is properly organised, the inventory and equipment involved in the fulfilment process is where it’s supposed to be and your warehouse layout is optimised to allow for easy movement.

This means that picking teams can easily move between aisles, find and pick the correct SKUs, and send them to packing. As a result, packages can be shipped out more quickly and efficiently. Shorter lead times in fulfilment often translates to faster delivery times overall, which delight customers and help a brand stay in business.

“A large chunk of our orders are subscription orders. With ShipBob, those orders are processed at midnight on the day they are due to reoccur. So by the time we’re logging on in the morning, those subscription orders have already been packed and fulfilled. The process is totally automated, we don’t have to do anything. That just speaks to ShipBob’s efficiency and the scale of their fulfilment centres.”

Callie Tivnan, E-commerce Manager, and Christina Williams, Customer Success Manager at Barefaced

Improved accuracy

In an organised warehouse, inventory is properly categorized and stored in assigned sections. There are labels and signage to help workers easily identify where certain items should be stored, which allows them to put away inventory in the right locations.

This also means that pickers can easily identify where they need to go to pick the items, making it easier to find the right items in as little time as possible.

All of this contributes to improved accuracy in various aspects of your warehousing operations. You can monitor how accuracy improves by tracking metrics like number of mispicks, OTIF rate, and rate of returns.

Increased productivity

An organised workspace allows your warehouse staff to move quickly within the warehouse and complete their tasks in a timely manner. This means different warehousing processes can work together seamlessly, allowing for proper inventory flow.

There are also no disruptions or delays resulting from disorganization and clutter, which can significantly improve your warehouse productivity.

You can measure how reorganization affects productivity by tracking KPIs like receiving cycle time, picking efficiency, and order lead time.

“ShipBob’s WMS has more than doubled, if not tripled, our productivity in terms of labour hours. Our average days to ship is now only 0.8 days, so most packages are shipping same-day or next-day, with rare exceptions. We’ve cut 4 days of lead time because orders are getting processed, fulfilled, and shipped more efficiently. When we first started with ShipBob, we were doing about 15K orders per month, and now we’re processing 30K — double what we were doing just six months ago.”

Ben Tietje, Co-Founder and CEO of Earthley

Reduced waste

Disorganization in the warehouse creates waste, including trash, obsolete inventory, and unusable storage space. However, when you properly optimise your warehouse layout and storage systems, you can minimise clutter and maximise your floor space. This automatically translates to reduced waste, and a safer, tidier environment.

Step 3: Implement changes to optimise your organisation

With goals set, it’s time to actually implement changes in your warehouse organisation to optimise it. What changes you make and how drastic those changes are may vary, depending on your initial assessment and what goals your brand prioritizes.

Here are some of the most common adjustments ecommerce brands make to their warehouse organisation, and the impact those adjustments have on operations.

Improve your warehouse layout

Your warehouse layout should help processes flow smoothly with minimal disruptions. In most cases, this involves setting up different zones corresponding to the order of operations so that inventory moves seamlessly between different departments.

In a typical warehouse, there is a receiving dock where inventory comes in, and sometimes a staging area used to unwrap and unpack pallets.

Next, inventory moves to the storage area, which may also be subdivided into multiple zones depending on your storage method. Aisles and racking systems should be set up in such a way that pickers can easily move around without anything blocking their path.

Your warehouse slotting system should also categorize your inventory based on shared characteristics, and position them in dedicated areas of the warehouse so workers can know the exact location of certain items and can easily navigate to the designated area to complete the picking process.

Once inventory has been picked, it is sent to the packing area, where assigned workers prepare them for shipping.

Your assessment process should have given you a few ideas on how to optimise your warehouse setup for better organisation. Some optimizations may include:

- Assessing your warehouse’s floor plan for unused or repurposable spaces

- Creating more space between different aisles to avoid wait times and safety hazards

- Labeling storage areas clearly, and using barcodes to ensure picking accuracy

- Choosing a different racking system to increase storage capacity and provide easy access to inventory

- Dedicating workstations to a single activity to minimise confusion

Maintain a regular cleaning schedule

The best way to keep your warehouse free of clutter is by following a regular cleaning schedule. Ideally, you should have dedicated staff assigned to take care of recurring cleanups. Some warehouses might also provide a checklist for employees to complete at the end of their shift. Some warehouses might also have task management software to help organise cleanup schedules.

For example, packing staff may be required to throw away any packaging waste created by the end of their shift as well as put away any unused materials.

Don’t forget to have a procedure in place for taking care of sudden and unexpected hazards. This may include spills that could cause workers to slip and fall, or large hazards that workers have to maneuver around.

Conduct regular safety training sessions

It’s important that your entire warehouse staff is properly equipped to maintain a safe working environment. Besides implementing standard safety measures in your warehouse, your staff should also be kept up to date on those safety protocols and procedures, so they know what and what not to do.

In safety sessions, be sure to:

- Share regular reminders about how to store inventory, especially on the upper racks, to avoid accidents

- Let team members know how they should alert the cleaning staff about spills and hazards that need to be cleaned up

- Reiterate how to handle hazardous chemicals (if any) and the importance of using appropriate PPE

Perform regular maintenance

When equipment suddenly stops working in your warehouse, it can cause serious delays and disruptions. This can throw your whole warehouse organisation for a loop, which will subsequently impact the rest of your operations.

It’s important to prevent this by performing regular maintenance so you can get ahead of any necessary repairs before it’s too late.

Conduct periodic warehouse inspections to identify any maintenance opportunities. Keep in mind that maintenance may not only be needed for your equipment, but for other physical aspects of your warehouse as well.

For example, shelves may need repairing and lights may need replacing so your staff has a safe and functional working environment that allows them to perform their job functions with minimal issues.

Invest in new equipment

Sometimes, regular maintenance alone won’t cut it. Some equipment may be beyond repair and will need to be replaced entirely. If you’re still relying on outdated forklifts, pallet racks, and other tools, it may take a longer time to complete certain tasks, or you may risk getting suboptimal results.

Consider investing in new equipment that can help to improve efficiency in your warehouse, reduce waste, and optimise warehouse organisation.

For instance, implementing box selection software in the packing process can significantly speed up fulfilment, as packing staff won’t have to struggle to find the right box for each shipment. Moreover, this will help to minimise waste since you’ll be using the best-fitting box every time.

Similarly, you may consider using software to simplify your fulfilment process. Some programs will calculate the most optimal picking routes depending on SKU locations and warehouse layout, and automatically generate picking lists according to those calculations.

You can use this to ensure that pickers have to travel for the least amount of time and complete their tasks as efficiently as possible.

Upgrade your storage and shelving systems

Traditional racks and shelves may be perfectly capable of storing inventory, but they don’t always make operations more efficient. Consider the needs of your business, and look for storage and shelving systems that will help you make the most use of your available floor and vertical space.

For example, automated warehouse storage systems like vertical carousels function like a Ferris wheel, and help you make the most of your overhead storage space. Workers can control these carousels with the simple push of a button to quickly retrieve the items they need, and these carousels store many units without taking up too much floor space.

However, vertical carousels may not necessarily work for all types of businesses, as some brands may need to opt for horizontal shelving systems because of their products and space limitations. Whatever solutions you choose, make sure your storage is compatible with your SKUs, your staff, and your safety.

Make use of labels and signage

Even if your inventory is properly organised on appropriate shelves and your warehouse layout is neatly set up for ease of movement, organisation isn’t complete without proper labels and signage.

Using a warehouse labelling system, your staff should be able to easily identify what specific zones are for and where certain items are stored. Make sure to use big, bold fonts with appropriate graphics that people can understand.

Proper signage will significantly improve your warehouse putaway process, as workers can more easily identify where to place certain SKUs. This speeds up the process, improves accuracy, and helps prevent unnecessary delays and bottlenecks in the fulfilment process.

Invest in employee cross-training

Cross-training your employees in multiple areas of the warehouse can help increase flexibility and adaptability, so don’t be afraid to invest time and energy into equipping your team with essential, versatile skills. That way, staff shortages in one process won’t be too detrimental to the rest of your operations, as you can easily adjust worker allocation to make up for the shortage.

Implement a warehouse management system

Finally, don’t forget to implement a warehouse management system to support your organisation efforts and streamline key activities. Data from your WMS can help you:

- Classify and slot inventory appropriately

- Monitor inventory movement through the supply chain,

- Forecast how many how many units you have left

- Strategize where to store certain SKUs based on the frequency at which they’re picked

- Plan picking routes for speed and efficiency

The right WMS will also coordinate different activities (such as receiving, fulfilment, and shipping), increase picking accuracy, and integrate seamlessly with your ecommerce platform and existing tech stack to create a truly seamless warehousing experience.

Why is it important to organise your warehouse?

Warehouse organisation isn’t just a nice-to-have; it’s a strategic asset. While it does make your space look nicer, keeping your warehouse clean, tidy, and orderly benefits your business in all kinds of other ways. Most notably, it can:

- Save you money: Organising your warehouse saves money by reducing errors, cutting down on wasted time and materials, and improving inventory accuracy. Streamlined operations mean fewer costly delays, lower labour expenses, and minimised losses due to misplaced or damaged stock.

- Increase productivity: Efficient organisation directly impacts productivity. Workers spend less time searching for inventory, navigating cluttered spaces, or correcting picking errors, allowing them to fulfil orders faster and with greater accuracy. This not only speeds up operations but also improves customer satisfaction by ensuring orders are correct and delivered on time.

- Minimise waste: When your warehouse is organised, it’s easier to pinpoint areas, functions, processes, and tools that are unnecessary. As a result, your business can eliminate redundancies and instead invest materials, time, and effort into things that matter most.

- Improve inventory management: When items are stored in logical, easily accessible locations and regularly audited, it’s much easier to track stock levels in real-time. This prevents overstocking, understocking, and the dreaded stockouts that can stall business and disappoint customers.

- Protect your workers: Maintaining a clean, orderly warehouse enhances workplace health and safety. Clearly marked aisles, proper shelving, and tidy storage areas ensure compliance with safety regulations and help reduce workplace accidents.

Outsource your warehouse management to ShipBob

Organising your ecommerce warehouse is crucial, but it can be a huge lift. For many brands, the easiest and most cost-effective way to achieve stellar warehouse organisation is to partner with a professional fulfilment partner like ShipBob.

ShipBob will store and manage your inventory for you, so you never have to worry about your warehouse organisation again. Your inventory can be distributed strategically across dozens of global fulfilment centres, where an experienced fulfilment staff will take care of picking, packing, and shipping out your DTC and B2B orders, as well as your retail dropshipping and distribution.

As an expert supply chain enablement platform, ShipBob utilises supply chain automations such as barcoding and inventory scanners to improve putaway and picking accuracy, automatic pick list generation to streamline the picking process, and Cubiscan machines to select the ideal box size for every shipment.

You can also monitor warehouse operations through ShipBob’s dashboard, and access real-time data and analytics on warehouse KPIs, inventory levels, and fulfilment and shipping performance which you can leverage to scale your brand.

Every ShipBob fulfilment centre is run using our proprietary WMS, which is designed to streamline your warehousing operations while provisioning deep visibility. Brands looking to keep fulfilment in-house can implement ShipBob’s WMS in their own warehouse(s) to achieve:

- Checks and balances at every stage

- Location-specific inventory visibility

- Intelligent cycle counts

- Prescriptive, visual step-by-step packing workflows (including gifs to show an exact pack-out process)

- Flexible options for batch, auto-cluster, custom cluster, and single-order picking

To learn more about how ShipBob’s outsourced fulfilment solutions and WMS can help you master warehouse organisation, click below to connect with a logistics expert.

Warehouse organisation FAQs

Below are answers to the most common questions about warehouse organisation.

Why is warehouse organisation important?

Proper warehouse organisation is essential for businesses as it improves efficiency in the warehouse, reduces errors, minimises waste, speeds up fulfilment, and helps ensure workplace safety.

How can I measure the effectiveness of fulfilment operations in the warehouse?

You can measure the effectiveness of your fulfilment operations by keeping track of warehouse KPIs that are relevant to your fulfilment process. This may include metrics such as picking efficiency, picking accuracy, picking cycle time, order lead time, on-time shipping rate, and more.

What are some common mistakes to avoid when organising a warehouse for ecommerce fulfilment?

Some of the most common mistakes to avoid when organising a warehouse for ecommerce fulfilment include not having real-time inventory visibility, not investing in cross-training, using a poor quality or outdated WMS solution, and lack of safety policies or protocols.

How can I organise my warehouse for efficient picking and packing of orders?

Optimising your warehouse design and layout is the best way to organise your warehouse for efficient order picking and packing.

Slot popular SKUs in easy-to-reach places, and group similar types of products together in the same area. Label everything, maximise your available storage space with racking systems, and leave plenty of aisle room for pickers to travel safely and quickly.