Table of Contents

** Minutes

The importance of warehouse design and setup

4 processes to keep in mind when designing your warehouse layout

6 warehouse layout design best practices

Warehouse layout design checklist

Nothing is better than starting with a blank slate.

Signing a lease for your first warehouse provides an opportunity to build your retail fulfilment engine from scratch.

It’s an exciting step towards business growth, but now comes the hard part.

Just like furnishing a new home, renting a warehouse takes time and planning to make the most of the space to meet your logistics operations needs.

But where do you start? In this guide, we’ll dive into what goes into setting up a warehouse layout, warehouse processes you need to know during the design process, warehouse optimisation best practices, and more.

The importance of warehouse design and setup

Setting up a warehouse is more than just stocking shelves with ecommerce inventory. A warehouse should be designed to optimise storage and streamline fulfilment workflows.

Investing in a warehouse is a tremendous undertaking; it involves supply chain planning, budgeting, financing, and executing in-house fulfilment.

A large part of your warehouse efficiency comes back to how your warehouse is set up, so it’s crucial to design your warehouse appropriately so you’re set up for success. As a leading logistics and fulfilment provider, ShipBob has experience designing and setting up warehouses. Here’s what we’ve learned.

Your warehouse needs to work for you

First of all, your warehouse should allow you and your team to fulfil your orders efficiently and accurately. Keep your products and customer experience at the top of mind as you search for and design your warehouse.

During your search for a new warehouse space, you should look for a space that meets your needs, all the way from loading docks to optimal storage space. This way the flow of goods is seamless and allows greater warehouse efficiency.

When you design your warehouse around your brand’s specific needs, you ensure your square footage is fully used, you can control your products and how they’re picked and packed, and more.

Unnecessary equipment will get in the way

While equipment can help your business be more efficient, it can also take up space and make things more complicated if not utilised properly. Having more equipment than you need means warehouse space is wasted (minimising your available space for inventory storage) and fulfilment processes and employee training is overcomplicated.

Additionally, a surplus of equipment may pose a safety concern for warehouse employees if space is compromised, and equipment isn’t properly maintained.

Warehouse & inventory audits require organisation

In order for you and your team to complete warehouse and inventory audits, you need to make sure your warehouse is organised and orderly. If you have SKUs haphazardly scattered around the warehouse, you’ll struggle to keep track of inventory and warehouse efficiency and accuracy will be impacted.

Stay organised by setting up warehouse storage solutions like warehouse shelving racks and pallet racks, storing inventory in bins, and label products clearly and accurately.

Regulatory compliance is only as complicated as you make it

Try not to overthink regulations for designing and setting up your warehouse. Many of OSHA’s warehouse regulations are straightforward. OSHA’s main goal is to create and ensure the warehouse is a safe work environment for employees. See a complete list of OSHA’s regulations for warehouses here.

You may need other licenses and certifications to operate a warehouse. Check with your state and local government and regulatory bodies to make sure you’re properly set up.

Once you find the right warehouse, planning and designing the layout is a crucial first step as it will impact supply chain efficiency.

4 processes to keep in mind when designing your warehouse layout

As you begin building a proper warehouse layout, you will want to focus on functionality and efficiency.

You will have to think beyond how to fit all your inventory in the space available and consider different ways in which you can optimise the space to minimise costs and improve productivity.

Before you begin designing the layout of your warehouse, here are the four primary fulfilment processes to keep in mind.

1. Warehouse receiving and stowing

A poor warehouse receiving process can can lead to stock control issues and high operational costs. As soon as you receive new inventory, your staff should be prepared to check every truckload and shipment, including the quantity, integrity of seals, and product codes to ensure that what’s in the boxes matches what you ordered and expect.

Depending on the size and volume, unloading inventory might require heavy lifting and equipment such as forklifts and pallet jacks. Based on the size, weight, and type of products you sell, inventory can be stored either on a palette, a shelf, or a bin.

2. Inventory tracking

Once you receive inventory, you will need a system to track what’s available to sell. Manually tracking inventory will only get you so far, and once monthly order volume increases, it will soon become inefficient — not to mention it will cost you.

The ability to track inventory in real time is an important part of the ecommerce supply chain and critical for ecommerce brands that want to scale.

This can be done by implementing an inventory management software that provides a real-time overview of current inventory levels to ensure you have enough stock to meet demand and replenish inventory accordingly.

Investing in the right technology to manage inventory will power up your warehouse and set your team up for success.

3. Warehouse picking

Warehouse picking requires the right warehouse setup and layout design for the process to be as smooth, accurate, and efficient as possible. As you think through possible ways to design a picking workflow, consider the following:

- How will you generate pick and assign out picking lists?

- How far will the picking team need to walk to pick items?

- How will the picker know where items are located?

- Will do batch picking?

How your picking team operates will determine how quickly items are picked without compromising accuracy.

4. Shipping process

Now comes the shipping process. You and your team is responsible for loading trucks and making sure that all orders are picked, packed, and shipped accurately when they leave the warehouse. Be sure to accommodate room in your warehouse for a large volume of orders being loaded simultaneously.

You also have the option to choose between parenting with major domestic and international couriers, regional parcel couriers, or a mix of all. It all depends on where your warehouse and customers are located. Once you choose the right couriers to partner with, you can negotiate shipping rates and schedule pick-up times.

Once orders are in the courier’s hands, you can send order tracking to share updates with your customers, so they can be notified on when to expect their delivery.

6 warehouse layout design best practices

How you design your warehouse’s layout depends on your business. For instance, storing furniture pieces requires a different storage layout plan than stocking small, delicate jewelleryitems with multiple SKUs.

However, across the industry, there are warehouse layout design best practices to keep in mind (even though your layout will need to change over time as you grow).

1. Outline the warehouse workflow

When brainstorming a warehouse layout design, you need to draw out the internal warehouse workflows and how each will connect with one another. And you will need to plan it around dock doors from where the couriers will drop off and pick up.

From receiving inventory to stowing items on warehouse racks, to picking and packing items, to preparing orders for shipment, map out the ideal work spaces that will maximise efficiency, keep the warehouse organised, and enable productivity. Don’t forget to consider ways to minimise any safety issues and the overall wellness of your team.

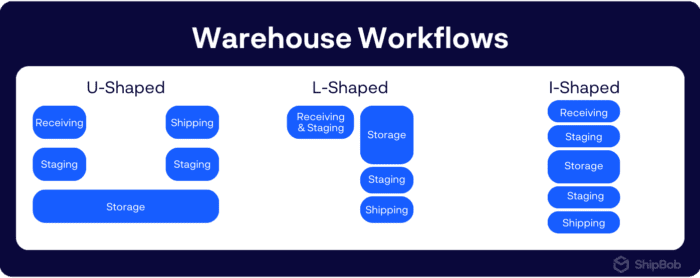

When setting up your warehouse, consider these different types of warehouses:

U-Shaped – this warehouse floor plan is the most common because it is straightforward and makes picking and packing easy. In this warehouse flow, inventory is placed in a semi-circle shape. Receiving and shipping take place at different ends of the U.

L-Shaped – this type of warehouse flow is commonly found in warehouses that are also shaped like an L. With this layout, there is less back and forth movement which deters bottlenecks and congestion. Receiving is at the far end of the L, with storage at the 90 degree section of the L, and shipping area at the top of the L.

I-Shaped – this type of warehouse layout is more common among mid-market and enterprise brands that have larger warehouses, higher order volumes, and a greater budget for equipment and machinery. This layout is similar to an assembly line with receiving at the beginning end, storage in the middle, and shipping at the opposite end. This streamlined warehouse flow helps with reducing congestion and faster throughput.

2. Define the warehouse work stations

When setting up warehouse work stations, ask yourself these questions:

- What are the essential work stations that you need?

- Do you have enough space in your warehouse layout design for all your employees to work comfortably?

Oftentimes, creating one-way workflow is the most efficient way to set up warehouse work stations. A simple one-way flow helps to ensure safety and eliminate congestion in the warehouse.

Once you determine how to set up different work stations, you can create paths with signs or floor tape to provide clear direction for your staff.

3. Optimise for storage

Warehouse best practices include choosing the right inventory storage system that will optimise the picking, packing, and shipping process to ensures order accuracy, efficiency, and speed.

Reorganizing routes or zones, or even an entire warehouse, can seem like a daunting and time-consuming project. You will need to determine how to best store inventory to optimise carrying costs, move large amounts of inventory to different locations, and make sure its done correctly so it doesn’t cause any issues during the picking process.

To optimise storage and warehouse processes, be sure to learn how warehouse slotting works, so you can organise your warehouse around functionality and efficiency.

4. Implement a warehouse management system

Using a warehouse management system (WMS) can lead to lower error rates, improved overall warehouse performance, and more timely inventory replenishment. Though a WMS will not directly impact the warehouse layout design, it will impact the way you layout the equipment and work stations.

Warehouse automation is an integral part of optimising the supply chain, as it reduces the time, effort, and errors caused by manual, variable tasks.

Fulfilling in-house is a huge operational and financial undertaking. Good planning is necessary to develop the infrastructure, secure the warehouse(s), and purchase the equipment you’ll need.

Outsourcing fulfilment to a tech-enabled 3PL like ShipBob can eliminate the stress and energy of managing a warehouse, help you cut overhead costs, and provides you access to best-in-class technology, so you can view inventory and order status in real time, even across multiple fulfilment centre locations.

Here’s an example of a $20 million brand that was managing their own warehouse, but decided to outsource direct-to-consumer fulfilment to ShipBob:

After launching two years ago, managing their own large warehouse, and hitting the $20 million-mark in annual sales, one ecommerce brand finally decided to move order fulfilment from their own warehouse to ShipBob.

They found ShipBob’s value is the ability to scale across the country with fulfilment centres throughout the US, and the ability to send out more packages than they could do in-house.

“ShipBob’s value is the ability to scale across the country, with fulfilment centres throughout the US and the ability to send out more packages than we are able to in-house. ShipBob is an excellent solution for businesses that are looking to grow and scale.”

Read the full story here.

Read more ShipBob case studies here.

5. Adapt the picking and packing area

Planning out a picking workflow ahead of time will help you get your warehouse up and running on the right foot. But it’s important to note that an efficient warehouse will continuously need to improve the picking and packing process to encourage high order accuracy — especially as your business grows.

Optimising warehouse picking processes and/or implementing order picking software are two of the most effective ways to optimise the supply chain. Depending on the warehouse size, number and types of products in it, and total staff count, one picking strategy may suit you better than others.

Here are a few common warehouse picking strategies you can implement:

Batch picking

Batch picking consists of working on the same orders in bulk or batches all at once in a row, instead of one at a time or by different people in between other orders. This picking strategy is ideal for fulfilling many identical orders that use the same SKUs.

Zone picking

Zone picking consists of assigning pickers to a specific area of the warehouse and only pick one order at a time within that area. If an order needs products from more than one zone, it is handed off usually via a conveyor belt.

Wave picking

Wave picking is a combination of batch and zone picking, where a picker will stay within a zone but pick more than one order at a time. This strategy works best for warehouses with large numbers of SKUs.

Discrete picking

Discrete picking is when a picker works on one order at a time as each one is placed. The same picker retrieves all SKUs in the order and can handle orders across the facility. This method is best for small businesses with low SKU counts and/or small warehouses or storage facilities.

Whatever picking strategy you decide to implement, the goal is to enhance team productivity and maintain a high order accuracy rate as your business grows.

6. Collect employee feedback

It’s important to speak to your employees and get their feedback and implement any changes that will help with their day-to-day tasks. Ask your employees to review the warehouse layout design and any suggestions they can think of to improve it.

Your picking team will understand your current warehouse layout better than anyone because they’re constantly moving around the entire space. Be sure to work with them to identify opportunities to create better fulfilment workflows that eliminates headaches, confusion, and human error during the entire process.

Warehouse layout design checklist

Planning and designing a warehouse is a huge undertaking. To help you get started, here is a simple warehouse layout design checklist. Consider the following questions to help you make better decisions as you plan your ideal warehouse layout.

1. Is your design optimised for your warehouse workflows?

- How are you reducing inefficiencies, such as long walks between each order picked?

- What picking strategy will you implement?

Decide how you’ll create an efficient workflow before you establish workflows, productivity zones, inventory storage areas, and equipment storage.

2. Does your design take equipment space into consideration?

- Can a forklift get around in a safe distance via routes marked on the ground?

- What about people?

- What type of equipment will you need to pick and pack items off your shelves?

- Where will store the equipment so it’s easily accessible?

For instance, if you use one piece of equipment after another, but the two are stored on opposite ends, it can cause inefficiencies and slow down processes.

3. Does your design include enough room for growth?

- How are you utilising space both vertically and horizontally?

- Are you at 100% capacity?

- Will you need to re-rack over time?

Make sure to plan for future growth to avoid the need to recreate your entire warehouse design from scratch; use digital twin technology so that as you grow, your layout and processes should provide flexibility to scale.

4. Will your design allow employees to move freely and without obstruction?

- Can your team move freely?

- Is the space designed to minimise safety risks?

Be sure to create safe productivity zones for your employees to move throughout the warehouse efficiently. Plan ahead to avoid unnecessary congestion or overcrowding of staff. This will also help to eliminate error during the fulfilment process.

How ShipBob’s warehouse design setup works for ecommerce

Leasing, designing, and managing a warehouse can not only take a considerable amount of time, but it’s also a big investment for a lot of effort, which could be used on other aspects of your ecommerce business.

Once ShipBob’s receive your inventory, we follow standardized processes to optimise storage to help save you on costs. Even as you expand into more warehouse locations, you can keep track of storage expenses from the ShipBob dashboard:

Along with optimising storage costs, you don’t have to worry about hiring staff to manage demand, design, and optimise picking workflows, or worry about investing in technology and equipment.

Here are some of the other benefits of outsourcing warehouse management and fulfilment to ShipBob.

Warehouse setup around order assembly

Across all ShipBob warehouses, the warehouse layout is centered around efficiency, accuracy, and consistency. Our warehouse setup ensures that items can be located and pick efficiently to improve order accuracy while speeding up the fulfilment process.

Whether it’s assigning pickers optimised routes, opening more fulfilment centre locations (across the US and globally) to cut down on shipping times, or improving our picking and packing processes, ShipBob is constantly looking for ways to improve and achieve higher levels of efficiency.

Along with having control over operations, ShipBob owns the entire order tech stack, which increases the velocity and scale at which we can make any type of change to our technology based on real-time customer feedback.

Inventory control and labelling

With so many products shuffling in and out of each warehouse, ShipBob uses a proprietary WMS to help you control inventory as we make use of unique barcodes across the warehouse.

Every action ShipBob performs — receiving, counting, picking, packing, returns, etc. — is handled much more efficiently when a barcode is adhered to each item. ShipBob highly encourages the use of product barcodes, so we can accurately scan and stow each item. Learn more about our barcode process here.

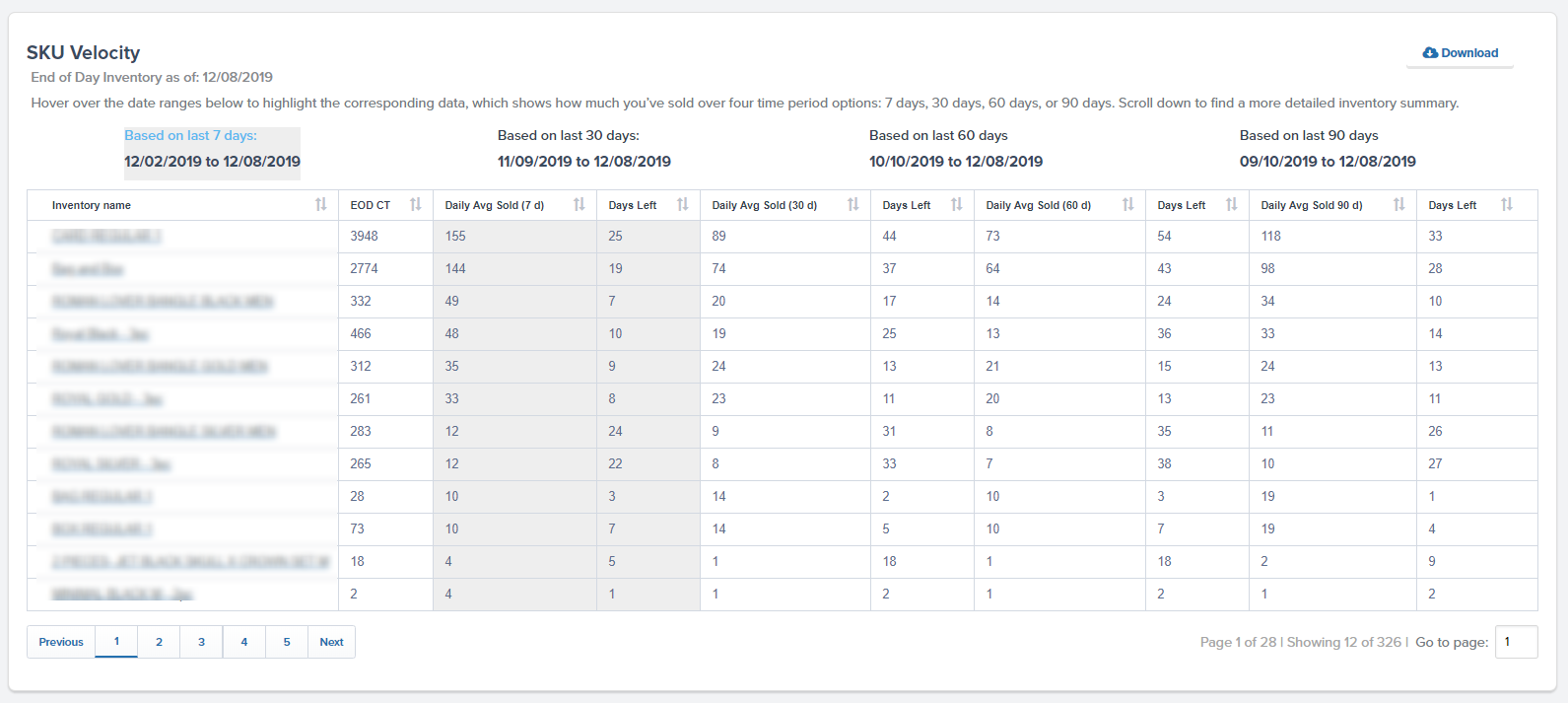

From the ShipBob dashboard, you get a full inventory overview, including days of inventory on hand remaining, so you can better forecast demand and set proper reorder notification points based on historical data:

“So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on. I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

Organising SKUs

With ShipBob, you can easily connect your store(s) and even design a multichannel distribution system that lets you sync SKUs and orders to view all inventory, fulfilment centres, sales channels, and customers in one place.

At ShipBob we constantly organise SKUs to fit the warehouse layout and make it easier for fast moving SKUs to be placed closer to the picking area or reevaluating SKUs that are performing less than average.

For instance, from the ShipBob dashboard, you can:

- Visualise SKU velocity and days of inventory remaining on hand.

- Input changes in projected order volume or scenarios to calculate changes in inventory turnover.

“We roll out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each week. It’s really easy to create new SKUs and restock existing ones using ShipBob’s technology, which is especially important with high inventory turnover.”

Carl Protsch, Co-Founder of FLEO

Consistency across all locations through proprietary software

Warehouse management in one facility to the next is possible by providing a consistent experience to all customers in all locations.

ShipBob’s owns the entire tech stack that powers our distribution centres to provide consistency, reliability, and speed across our entire domestic and international fulfilment network. You can take a look at ShipBob’s locations here.

Our WMS also acts as a control centre to compile all distribution metrics, including fulfilment performance and shipping insights, across all elements of our fulfilment centres.

Our WMS connects with our best-in-class merchant dashboard, so you can view insights related to:

- How many orders per hour a picker can pick

- How long it takes to receive, count, and stow new inventory that arrive

- How well ShipBob is hitting SLAs

- How many and which orders can’t be fulfilled because of inadequate stock levels

- How many days does it take for my orders to be delivered

”As our business grew, fulfilling orders quickly became very time-consuming, and warehouse operations became a challenge. We found ShipBob, who checked all our boxes for a 3PL. They have ended up being the perfect solution for us and we have never looked back!”

Get started with ShipBob WMS

To learn more about how ShipBob can help you optimise warehouse management and fulfilment with our WMS, click the button below.

Warehouse setup FAQs

Warehouse setup is a huge undertaking and it involves more than simply storing sellable inventory on shelves. Here are answers to common questions related to ecommerce warehouse setup.

How do you set up a warehouse?

The first step is to determine how you will store inventory to optimise space to keep storage costs low. The next step is to consider the different stages of the fulfilment process, from receiving inventory to shipping orders. You will need to consider where to set up different work stations for receiving, picking and packing, batch orders, and more that makes it easy for order fillers to pick and pack items and have orders shipped out quickly.

Why is warehouse layout design important?

Warehouse layout design is important because it can either increase or reduce costs and efficiency. A proper warehouse layout design provides functionality and efficiency. By carefully planning a warehouse layout design, you can decrease storage costs and speed up the fulfilment process without comprising order accuracy.

What’s the best warehouse layout?

Warehouse slotting is a common practice in ecommerce, which involves organising a warehouse to maximise space and make picking more efficient. Efficient slotting can also improve inventory management processes and reduce overall warehousing costs. Slotting is often organised by SKU number, product type, or any other type of product characteristic.

What are the benefits of efficient warehouse setup?

There are several benefits of efficient warehouse setup, including:

- Optimised logistics costs

- Improved order accuracy

- Faster throughput

- Greater employee efficiency during stowing, picking, and packing

- Better use of available warehouse space

- More efficient fulfilment process

- Contribute to overall optimised supply chain