Warehouse Optimisation Guide

Your ability to receive, store, and ship products efficiently can not only save you money but also improve a customer’s experience with your brand. The thing is, warehousing and order fulfilment can get complicated. An increasing number of SKUs, manual processes, and outdated warehouse systems all contribute to creating bottlenecks.

As a global ecommerce enablement platform with dozens of fulfilment centres that supports thousands of businesses, ShipBob has seen firsthand how warehouse optimisation not only improves operational efficiency, but also directly impacts customer satisfaction.

In this article, we’ll discuss the benefits of warehouse optimisation, a few tips on how you can take your warehouse to the next level, and the advantages of partnering with an end-to-end fulfilment expert.

So, what do you want to learn?

What is warehouse optimisation?

Here’s why should optimise your warehouse

Optimise your warehouse with tips from the experts

Request Fulfilment Pricing

Let’s talk. Our experts can help you boost your order volume by 30% year over year.

A fulfilment expert will get back to you shortly. Privacy Policy

What is warehouse optimisation?

Warehouse optimisation is the strategic process of improving the efficiency, productivity, and accuracy of warehouse operations. The objective is to minimise costs, maximise throughput, and enhance the customer experience through a combination of improved warehouse layout design, technology integration, process reengineering, and employee training.

For ecommerce brands, this optimisation aims to streamline receiving, picking, packing, shipping, and return processes. By doing so, ecommerce businesses help ensure orders are processed in the quickest and most cost-effective way possible.

Here’s why you need to optimise your warehouse

A warehouse is more than just a storage facility; it’s the place where you get to prove why your customers should trust you. It’s what enables you to create a memorable unboxing experience or provide affordable 2-day shipping.

Yet, despite its central role, warehouse efficiency isn’t always at the top of mind for ecommerce businesses. It’s certainly not the most glamorous aspect of running an ecommerce business – in fact, it can be expensive, complicated, and time-consuming.

However, those willing to spend the time, money, and resources to invest in improving their warehouse benefit from these three key advantages:

- Improved productivity: An optimised warehouse streamlines every process. This means less time wasted, quicker turnaround, and the ability to handle a larger volume of orders.

- Greater customer satisfaction: When customers receive their orders on time and in perfect condition, they’re more likely to come back for more. In contrast, delayed or incorrect orders can have an outsized negative impact. An optimised warehouse helps you consistently meet or exceed customer expectations, turning one-time buyers into repeat customers or even vocal members of your brand community.

- Increased profitability: The quicker you can move products in and out of your warehouse, the better your cash flow will be. Additionally, efficient space utilisation can reduce storage and labour costs, which helps protect your bottom line.

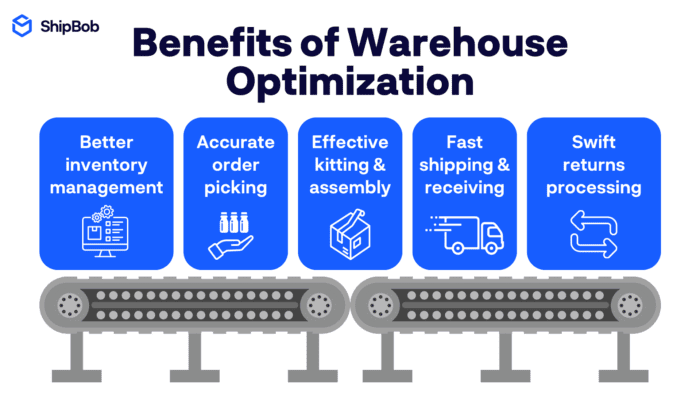

The benefits of warehouse optimisation

Warehouse optimisation offers benefits that go far beyond operational improvements. It has the power to reshape a business’s logistical capabilities, enabling a brand to scale further.

Let’s dig deeper into a few of the most important benefits of warehouse optimisation.

Better inventory management

Inventory management is no small task—especially when your business offers hundreds, thousands, or even tens of thousands of SKUs. Manually keeping track of which ones are running low and which are overstocked is a cumbersome process that’s prone to human error.

But with real-time inventory management systems directing inventory flow and recording inventory movement across a warehouse, businesses have access to instantaneous data regarding stock levels, order status, product locations, and more.

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order.”

Ines Guien, Vice President of Operations at Dossier

By leveraging these real-time insights to, companies can:

- Reduce stockouts: Nothing turns off a potential customer more than finding out their desired product is out of stock. Real-time inventory updates help businesses react swiftly, ensuring stock levels match the demand.

- Optimise storage space: When you understand which products are fast-moving and which are not, it’s much easier to use your storage space efficiently.

- Improve forecasting: Accurate inventory data means better demand forecasting, helping businesses plan for the future more effectively.

Accurate order picking

In ecommerce, warehouse picking and packing errors are costly—not just in terms of monetary loss, but also in terms of customer trust. By introducing smart order picking software and easily readable labels and barcodes into your warehousing operations, pickers are much less likely to make mistakes.

Increasing order picking accuracy through warehouse optimisation naturally:

- Reduces return rates: The cost and hassle of handling returns due to picking errors can be significant. Accurate picking minimises this risk.

- Enhances customer trust: Delivering the correct product on time, every time, enhances customer trust and loyalty.

- Improves operational efficiency: Fewer errors mean fewer re-picks, saving both time and money.

“One of the biggest reasons we went with ShipBob is the multiple checks from start to finish. The WMS makes it really hard to send out the wrong product. It still happens on rare occasions – but it happens a lot less than before. Before we implemented ShipBob’s WMS, our order accuracy rate was around 92%. Now we’re at 99.7% for order accuracy, which equates to 2,100 less mispicks a year on average.”

Jourdan Davis, Operations Manager at Pit Viper

Effective kitting & assembly

Kitting is essentially the process of preparing inventory to be sent out. This can be anything from removing an item from the warehouse’s packaging to combining multiple SKUs into a single package so that they can be sold as a “kit”. Assembly, on the other hand, refers to partly assembling a product before shipping it to the end customer.

Both of these processes take time, attention to detail, and are prone to errors when the correct workflows aren’t in place. By optimising your warehouse for effective kitting and assembly, you can achieve:

- Cost savings: An efficient kitting and assembly process reduces the amount of time it takes to prepare each order, saving on labour costs.

- Enhanced product offerings: An unoptimized warehouse may not be able to offer “kits” or pre-assembled products. Offering these can differentiate a business in a crowded market and lead to higher average order values.

- Inventory efficiency: Tracking inventory becomes more streamlined when items are kitted, reducing potential errors and stockouts.

Fast shipping & receiving

The speed of shipping can make or break a customer’s experience. If your warehouse is unable to quickly unload, inspect, and store products, this can lead to significant bottlenecks, inaccurate inventory numbers, and missed sales opportunities.

An optimised warehouse facilitates faster and more efficient shipping and receiving processes, resulting in:

- Enhanced customer satisfaction: Meeting or exceeding delivery expectations leads to satisfied customers and more positive reviews.

- Competitive edge: Offering expedited shipping options can provide a competitive advantage in a market where customers expect fast delivery.

- Operational savings: Faster warehouse receiving processes mean products are available for sale sooner, reducing potential lost sales due to stockouts.

Swift returns processing

Returns are an inevitable part of ecommerce, but an optimised warehouse can turn this challenge into a strategic advantage. Having an optimised warehouse that can streamline the returns process helps with:

- Customer retention: The average ecommerce return rates range between 20-30%. A hassle-free and efficient return process can lead to higher levels of customer satisfaction and retention.

- Inventory turnover: Efficiently processed returns can be restocked and resold more quickly, reducing holding costs.

- Data insights: Tracking and analising returns can provide valuable insights into product quality, customer preferences, and potential areas of improvement.

7 warehouse optimisation tips (from the experts)

A truly optimised warehouse balances technology and integrations with streamlined warehouse processes and proper training. Only when these three things align will a business experience the full benefits of an efficient warehouse.

To achieve that balance, consider following these best practices as you begin your warehouse optimisation journey.

1. Assess & understand your current warehouse setup

First things first: you can’t fix what you don’t know is broken.

Start by conducting a detailed assessment of your current warehouse setup, staffing levels, and technology. Are employees tripping over each other due to a cluttered layout? Is half your warehouse space gathering dust? Does your order accuracy decline when order volume increases?

Think of this stage as a diagnostic test; the results will indicate what needs to be improved.

You might discover an opportunity to better organise your warehouse, invest in new equipment, or upgrade your warehousing racks and shelving systems. Whatever it may be, this initial evaluation is your roadmap for actionable changes.

2. Define your objectives & pain points

Now that you’ve audited your current setup, you need to define what it is you’re trying to achieve.

Ask yourself: what is the brand aiming for? Is it:

- Reducing shipping times to improve customer satisfaction?

- Cutting down operational costs to improve profitability?

- Increasing accuracy in picking and packing to reduce returns and associated costs?

- Improving space optimisation to satisfy growing customer demand?

Specific goals will offer you direction and purpose, allowing you to better plan out your strategy.

During this stage, remember to keep the customer a priority. For example, if one of your objectives is to reduce costs, but that in turn compromises the speed or accuracy of shipping, you might inadvertently affect customer satisfaction negatively.

Therefore, try to find a balance between operational efficiency and customer-centric goals.

3. Get your inventory management right, first

Once you’ve assessed your current setup and defined your objectives, the first warehouse function to optimise is your inventory management. From reducing holding costs to improving cash flow, the right inventory control techniques and systems can drastically improve the efficiency of your warehouse.

Imagine this: you roll out a fantastic sale on a particular SKU, only to realize after the fact that you’ve got very few units left to sell. Alternatively, say you have mountains of products collecting dust, and they go obsolete before you’re able to sell them.

Real-time tracking is the solution to these sorts of issues. Deep visibility into inventory movement in your supply chain provides you with the best data on which products are running low, and which need to be cleared out.

Inventory management tools and techniques can also be a lifesaver when it comes to seasonal fluctuations in demand. Some software solutions like ShipBob’s even offer demand forecasting based on your order history, so you can study past sales patterns to stock up on seasonal favorites ahead of time.

4. Adopt a warehouse management solution (WMS)

A well-chosen warehouse management system (WMS) centralises data and automates many of the tasks that would otherwise be labour-intensive and prone to error (such as receiving, shipping, storage, picking, kitting, packing, etc.).

A WMS streamlines these processes and provides a single source of truth, so you aren’t left guessing or cross-referencing multiple systems to figure out what’s happening in your warehouse.

Adopting a warehouse management system will require an initial investment up front. However, in the long run, the benefits far outweigh the costs. With a WMS you’ll be able to achieve:

- More accurate inventory counts

- Better order efficiency

- More productive warehouses

- A reduction in operational costs

- Faster shipping

5. Consider Lean warehousing techniques

Incorporating principles of Lean management helps reduce time spent on non-value-added activities. Originating from the manufacturing sector, Lean is all about doing more with less.

For example, your employees may be walking an extra 200 steps just to pick an item that’s not strategically placed. Lean techniques would pinpoint this inefficiency, which you can then work towards improving. It’s like feng shui for your warehouse; every element has a purpose and a place, thereby streamlining operations.

6. Invest in staff training

A warehouse is only as efficient as its least-trained employee. If employees aren’t properly trained, they won’t perform tasks to the best of their abilities.

Holding periodic training sessions and implementing a labour management system to measure the efficacy of employees will help you identify areas where further training is needed. Investing in staff training ensures that everyone understands not just the what, but the why and the how of their tasks. This leads to fewer errors and less rework.

7. Outsource warehouse management to a 3PL

Optimising a warehouse to compete with today’s retail giants is no easy task. It takes time, significant investment, and expertise that many businesses simply don’t have in-house. This is where outsourcing to a 3PL or logistics partner can simplify things.

A 3PL specializes in all things logistics, from warehouse inventory management to warehouse putaway, picking, packing, shipping, and so much more. This means they have the experience and smart warehousing technology to optimise each step of the supply chain. By handing off your warehouse management to an expert partner, you’re essentially plugging into their existing infrastructure, benefitting from their economies of scale, and freeing yourself to focus on other core aspects of your business.

Moreover, these experts often have networks of multiple distribution centres, enabling you to strategically place your inventory closer to your customer base. Leveraging such a network not only reduces shipping times and costs, but also builds in a safety net for your inventory. For example, if you run out of stock in warehouse A, you can continue to ship orders from warehouse B (an option only possible with a distributed inventory system).

Emerging trends and the future of warehouse management & optimisation

As technology progresses, businesses must find ways to leverage tech advancements to further optimise operations–especially within their warehouses.

Advancements like artificial intelligence (AI), robotics, and machine learning are revolutionizing everything you can do in an ecommerce warehouse, from inventory management to order fulfilment. AI algorithms can predict inventory needs with uncanny accuracy, and robotics

can improve warehouse efficiency by automating the picking process.

Big data and analytics also play a large role in the future of warehouse optimisation. As the volume of data generated by ecommerce businesses continues to grow, there is more need for sophisticated data collection and analysis tools. These metrics can provide insights into customer behaviour, operational bottlenecks, and forecast future demand based on historical data.

So, where does ShipBob fit? At ShipBob, we’re a tech-enabled fulfilment platform that’s committed to staying at the forefront of cutting-edge warehouse technology.

We understand that today’s warehousing solutions need to be flexible, scalable, and intelligent. By adopting these emerging technologies, we’re not just enhancing our capabilities; we’re setting the industry standard for modern and customer-focused warehousing solutions.

While nobody can predict the future with absolute certainty, the trends are clear: warehouse management is becoming smarter, faster, and more data-centric. Businesses that fail to adapt risk falling behind, not just in warehouse operations but in market competitiveness and customer satisfaction.

ShipBob: Your partner in warehouse optimisation & inventory management

By now, you know that effective warehousing isn’t just about storing products. It’s a critical component of your supply chain that influences your operational efficiency, customer satisfaction, and competitive edge in the marketplace.

Partnering with an end-to-end fulfilment partner like ShipBob can help you overcome the complexities and streamline every aspect of your operations.

Smoother inventory management

Mismanaging your inventory can lead to overstocking, understocking, and a lot of headaches. ShipBob offers a real-time inventory management system that allows you to keep an eye on your stock levels, no matter where you are.

Using ShipBob’s outsourced fulfilment solution, you can easily distribute your inventory across multiple warehouses, sync your orders in real-time, and set inventory reorder points to ensure you always have enough stock to meet customer demand.

A WMS that never stops optimising

ShipBob’s WMS is a one-stop shop for everything you need to manage fulfilment. From order and transportation management to reporting and analytics, ShipBob’s WMS provides a holistic view of your entire supply chain operations.

No more stitching together various tools and hoping that the information is accurate; instead, ShipBob’s proprietary software provides a single platform from which you can see and control all your warehousing activities.

“Using ShipBob’s warehouse management system and merchant application was a no-brainer. The thought of having to Frankenstein many tools and APIs together, plus the costs and uncertainty in performance, was a non-starter for other options.”

Courtney Lee, founder of Prymal

Hand off all logistics to the leading outsourced fulfilment partner

If you’re feeling overwhelmed by the intricacies of warehousing and logistics, you’re not alone. Many ecommerce businesses find that their expertise lies in product development, marketing, and customer service, not in running a warehouse.

If this sounds like you, why not hand off all logistics operations to experts who live and breathe it? ShipBob’s end-to-end logistics solution offers a combination of experience and technology to seamlessly manage your entire fulfilment process. From receiving inventory and storing products to picking, packing, and shipping orders, ShipBob takes care of everything behind the scenes.

To learn more about how ShipBob can help optimise your warehousing operations in particular, click the button below.

Warehouse optimisation FAQs

Below are answers to common questions about warehouse optimisation.

What role does technology play in warehouse optimisation?

Technology plays a major role in regards to optimising a warehouse. With so many moving parts, data can quickly get out of sync if you’re tracking things manually or attempting to integrate multiple technologies at once. Implementing a single warehouse management system can greatly reduce errors and make for a much smoother process.

How can efficient picking and packing processes improve my warehouse operations?

Efficient picking and packing processes reduce the time it takes to locate and dispatch items, leading to faster order fulfilment. Optimisation in these areas also minimises errors, reducing the likelihood of costly returns.

How does shipping and returns management affect warehouse optimisation?

Efficient shipping and returns management creates more space for new inventory and streamlines reverse logistics. Poorly managed shipping and returns can lead to inaccurate inventory levels and increased storage costs.

How can I integrate the strategies discussed in this article into my existing warehouse operations?

To integrate new optimisation strategies, start by assessing your current operational weak points. Implement solutions gradually, measuring their impact before moving on to the next. Partnering with an expert like ShipBob can significantly accelerate the optimisation process.