With so much happening in your ecommerce business every day, it’s easy to forget things – especially when it comes to replenishing your stock. While you’re focusing on other priorities, orders keep coming in, depleting your inventory, and before you know it, you’ve stocked out without even realizing you were low on units.

Failing to reorder on time can cause a lot of problems (unexpected stockouts, last-minute hassles, backorders, delays, etc.), but it’s not practical to monitor your SKU levels every hour of every day. That’s why many ecommerce brands turn to automated replenishment solutions to do it for them, and help them time replenishment perfectly.

In this post, we’ll explore what automated replenishment is, how it benefits ecommerce brands, and how an expert fulfillment partner like ShipBob can help you leverage it to optimize your inventory management.

What is automatic replenishment?

Automatic replenishment refers to using ecommerce automation to help time and optimize inventory restocking. It combines software, technology, and human effort to:

- Track your inventory levels in real-time

- Analyze sales patterns and lead times to help a merchant accurately predict their inventory needs

- Identify when stock reaches a certain level (or threshold)

- Notify stakeholders when a SKU hits its threshold to remind them to place an order for more stock

Some automated replenishment systems take it a step further and actually automatically place replenishment orders for you to save you time and prevent stock outs.

How do auto-replenishment systems work?

Auto-replenishment systems have three core capabilities, which work together to help ensure that brands reorder stock at the ideal time. These are:

1. Inventory visibility

Real-time inventory visibility and analytics are the foundation of an automated replenishment system. Through barcode scanning technology that feeds data to an online dashboard, brands can monitor inventory levels and movement in real time, and get an accurate understanding of their current inventory status. This visibility helps you see which SKU levels are low at any given time.

2. Sales forecasting

Accurate demand forecasting is necessary to time replenishment correctly and avoid stockouts. An auto-replenishment system should use historical sales data and past demand trends to help you make more predictions about how many units of each SKU you can expect to sell in a given period. This will give you an idea of when you need to reorder each SKU, and help you calculate the reorder threshold (the number of units you need on-hand when you place a purchase order to ensure that you have enough inventory to fulfill orders while waiting for the new stock to arrive).

3. Automatic ordering/reorder points

Most auto-replenishment systems give you the ability to set up reorder point notifications. With these notifications enabled, the software will automatically alert you when a SKU level depletes to a threshold you set. This is your signal to reorder stock, and helps you time replenishment to prevent stockouts. Some systems will even place auto-replenishment orders on your behalf, further automating the process.

How do ecommerce businesses benefit from automatic replenishment?

Automated replenishment is a relatively small aspect of your brand’s operations as a whole, but it can make a world of difference. Here are just some of the biggest benefits to implementing an automated replenishment system.

Better inventory management

Automated replenishment enables you to reorder inventory when you actually need it – not before, not after, but just in time. This helps prevent you from ending up with excess inventory (from ordering too soon) or a stockout (from reordering too late). With optimal inventory levels, you are better equipped to meet demand effectively.

Brands can also take note of how often they receive automated reorder notifications for different SKUs to determine which SKUs are their fastest- and slowest-selling items. This insight into inventory turnover is extremely valuable, as you can use it to adjust your procurement strategy and adjust your product catalog to devote storage space to your best-sellers (rather than inventory that will collect dust on your shelves).

Enhanced customer satisfaction

Customers hate when their favorite products are out of stock – or worse yet, when the products they’ve already purchased are put on backorder. This experience can do a lot of damage to customer satisfaction, so it’s important to ensure that you always have enough inventory to meet demand.

By leveraging an automated replenishment system, you can maintain optimal inventory levels at all times so that customers can always get what they want when they want it. This helps you avoid disappointments and lost sales, and simultaneously drive revenue for your brand.

Lower operational costs

With an auto-replenishment process in place, you both reduce the need for manual work and streamline your supply chain operations. Automating inventory tracking and replenishment eliminates the need for paper-based accounting and other manual work that is prone to human error. This not only reduces labor costs, but also helps prevent costly mistakes.

Moreover, when you strategically auto-replenish items in your inventory, you can avoid overstocking on goods that are already sufficient in stock. This helps you cut down on unnecessary spending and reduce high inventory holding costs.

By reducing your spending on inventory holding and avoiding stockout costs, you’re also lowering your overall inventory costs. These cost savings will eventually reflect in your bottom line, allowing you to maximize your revenue.

How ShipBob optimizes auto-replenishment for ecommerce success

Automated replenishment features are typically built into professional providers’ top-notch inventory management systems, and ShipBob’s software is no exception. With proprietary technology and best-in-class fulfillment solutions, ShipBob helps you automate your inventory replenishment and optimize your inventory management for long-term ecommerce success.

Reduce manual workload and stockouts

ShipBob’s inventory management software helps you ditch manual, paper-based methods of tracking, counting, and reordering inventory. Instead, you can view real-time inventory levels through ShipBob’s dashboard, simplifying your life and reducing the time and manual effort required to manage inventory (as well as the likelihood of human error in inventory accounting).

This data and visibility enables you to quickly identify when you’re running out of stock, even if you’re not physically near your inventory to count it. That way, you can reorder inventory before you run out, minimize the stockouts and backorders, and keep customers happy.

ShipBob’s dashboard also enables you to set up automatic reorder point notifications on the SKU level. You will then get email reminders when the SKU depletes to the threshold you set, reminding you to make timely replenishment orders – all without having to make last-minute calculations or manually count your stock.

Focus on growth and the customer experience

With the mental burden of monitoring inventory levels and remembering to replenish inventory eased, you can get back to focusing on other priorities – namely, scaling your brand and delighting your customers.

Automating replenishment makes it far easier to grow into new sales channels and markets, especially when you partner with an omnichannel fulfillment provider like ShipBob. ShipBob’s platform delivers inventory levels and analytics across all your DTC, B2B, marketplace, and retail channels for seamless visibility into your overall inventory management, so you can allocate enough inventory to each channel and avoid accidentally overselling inventory you don’t have.

“Having the same partner handle both direct-to-consumer and business-to-business orders is crucial. Managing separate inventory pools for DTC and wholesale can be challenging, making it essential to maintain unified inventory across all channels.

ShipBob enables us to serve both our direct-to-consumer (DTC) customers and our business-to-business (B2B) clients, which include Nordstrom, Target, Bloomingdales, and Saks. This encompasses direct vendor shipments and B2B wholesale operations, all managed seamlessly across ShipBob’s warehouse network.”

Ali Shahid, COO of Our Place

ShipBob’s global fulfillment network also allows you to easily expand into new geographies and countries. Through our Inventory Placement Program, ShipBob will use historical order data to take care of allocating inventory across our 50+ fulfillment centers for you, plus handle physically distributing it to regional locations. Allocating and placing inventory this way puts your stock closer to the people who are ordering it, minimizes shipping costs and times for customers and helping you deliver the best experience possible.

“The way ShipBob has set up the Inventory Placement Program is pretty straightforward. We ship all of our products to the Moreno Valley, California facility and ShipBob’s real-time data analyzes our recent inventory positions across locations to decide how much of the new inventory to move to each fulfillment center. This is a great process because it takes a load off of our team, making inventory replenishment simpler and more up-to-date.”

Michael Mullaney, VP of Supply Chain at ZBiotics

Handle larger volumes and multiple fulfillment centers with our WMS

Even if you choose to manage your inventory in-house, ShipBob helps you optimize the process with our powerful warehouse management system (WMS). This system (the same one that powers warehousing and fulfillment operations across ShipBob’s 50+ fulfillment centers) serves as a unified platform to give you inventory visibility across multiple facilities, making it easier to get streamlined data from different locations.

As a result, you get accurate inventory data that will inform your replenishment strategy. You can easily see which fulfillment centers are running low on stock and how to redistribute inventory to prevent stockouts. This also helps you avoid overstocking, since you can shift your inventory distribution to get stock to the locations where it’s in the highest demand.

Ensure optimal inventory levels with real-time analytics

The inventory data merchants view through their ShipBob dashboard is real-time, meaning that every time an inventory unit’s barcode is scanned as it moves throughout the supply chain, that interaction is recorded, and inventory counts and statuses are updated accordingly. This delivers an un-to-date and accurate representation of inventory levels in ShipBob’s platform that you can use to inform your replenishment decisions.

ShipBob’s dashboard also displays key inventory analytics, which brands can leverage to:

- Check inventory days on hand and stay apprised of how long their inventory is predicted to last

- Calculate the ideal safety stock amount and reorder quantity for each SKU to help you time replenishment

- View historical order data to identify demand patterns and sales trends and improve inventory and demand forecasting

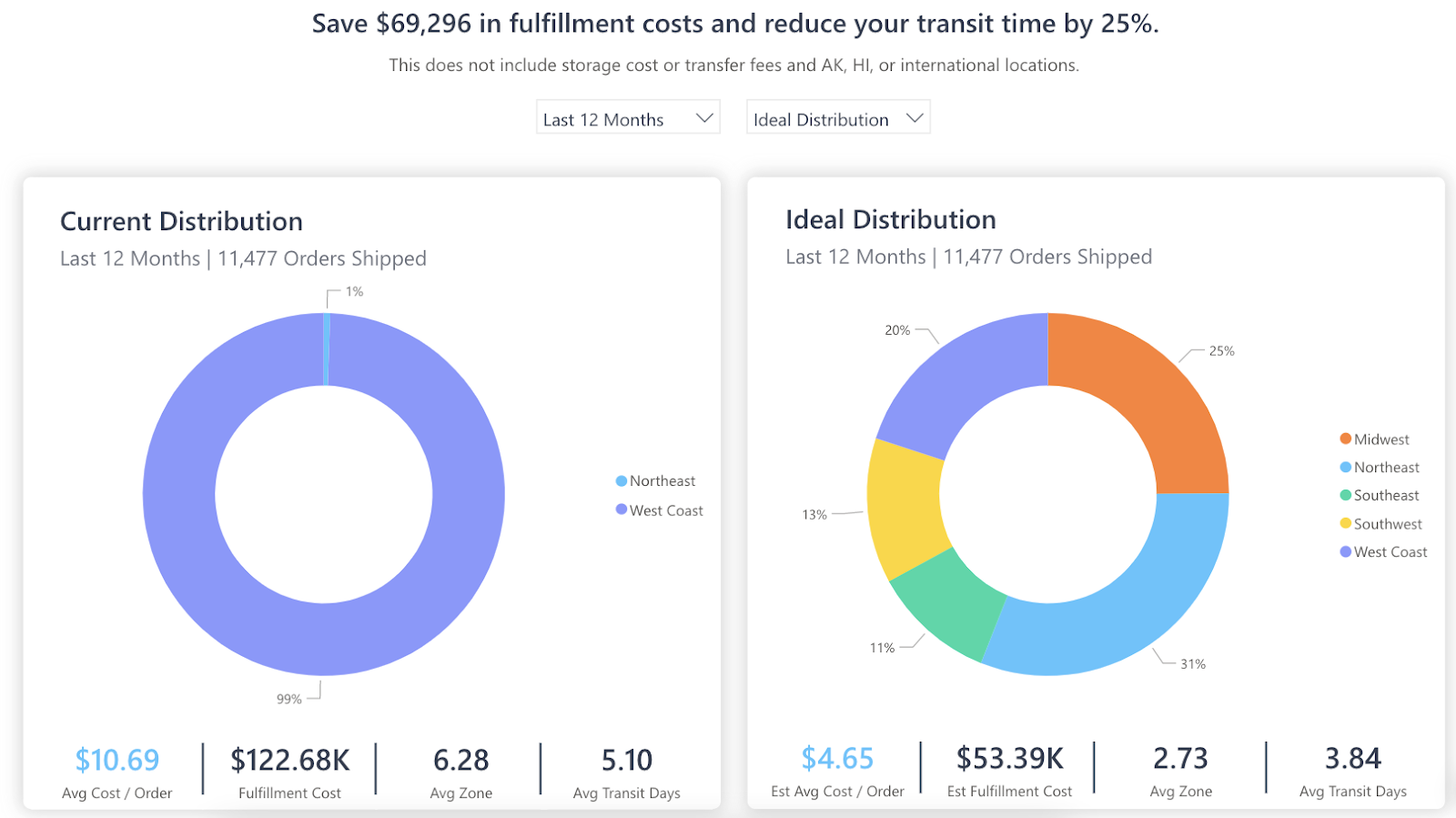

- Compare their current inventory distribution with ShipBob’s Ideal Inventory Distribution Tool’s recommendation based on their order data that’s designed to minimize shipping costs and times

Integrate with your favorite ecommerce platforms

ShipBob’s platform integrates seamlessly with major ecommerce platforms including Shopify, BigCommerce, Magento, WooCommerce, as well as retail marketplaces such as Amazon and Walmart. This ensures that your inventory data is synced in real-time with order information across all your sales channels.

Through these direct integrations, you get an accurate idea of your inventory levels based on the latest sales placed across these channels, and a unified picture of your omnichannel inventory management strategy.

Don’t just take our word for it: ShipBob’s auto-replenishment in action

Take a look at how ShipBob’s inventory management solutions have helped several ecommerce clients master the art of replenishment, plus how they’ve used ShipBob’s fulfillment solutions to save time and money.

IZIMINI

When IZIMINI was originally launched, they were handling all their storage as well as packing and shipping themselves. But when they went viral just a couple of weeks after an influencer posted about their products, they ran out of stock within the first six months and had a lot of preorders that they weren’t able to immediately fulfill. They realized they needed a partner to help them fulfill orders and stay stocked.

After unsuccessfully partnering with a different 3PL, the children’s brand turned to ShipBob – and after seamlessly integrating ShipBob’s platform with their Shopify store, they achieved the unified view of inventory they needed.

Through ShipBob’s analytics dashboard, IZIMINI’s team sees exactly what they have in stock. With real-time data across multiple channels and scalable fulfillment support to tackle surges in demand, they’ve been able to achieve 70% growth YoY with ShipBob.

“We love ShipBob’s technology. The dashboard is very intuitive. That’s what I like with ShipBob — there are lots of things I can do myself in the dashboard which wasn’t the case with my previous 3PL. The integrations are also very good.

I like to look at the analytics in the ShipBob dashboard, knowing exactly what I have for storage. I can also set up alerts to know when I’m low on inventory for certain products to make replenishment easier. The bundling process is really good. Before ShipBob we would do it with an Excel table, which was a lot to manage.”

The IZIMINI team

For more information on how ShipBob can help automate inventory replenishment for your brand, click the button below.

Automatic replenishment FAQs

Below are answers to the most commonly asked questions about automatic replenishment.

What are the benefits of using auto-replenishment in ecommerce?

Auto-replenishment helps ecommerce businesses to maintain optimal stock levels and prevent stockouts. This helps them to avoid lost sales while ensuring greater customer satisfaction.

How does ShipBob integrate auto-replenishment into its services?

ShipBob’s real-time inventory tracking provides you with the most up-to-date stock levels. The analytics dashboard offers key metrics that help you accurately forecast demand and strategically plan your replenishment strategy. Moreover, you can set up automatic reorder point notifications to ensure timely replenishment when a SKU hits its reorder threshold.

Can auto-replenishment help reduce operational costs for ecommerce businesses?

Auto-replenishment minimizes the need for manual, paper-based tracking, helping you avoid costly human errors. This also improves efficiency and accuracy, which can reduce your operational expenses.

Additionally, stocking up on time helps you avoid expensive stockout costs and cancellations resulting from backorders. You can even ensure that you’re reordering the right amount of inventory, which prevents overstocking and reduces the costs associated with it.