Table of Contents

** Minutes

What is a stock keeping (SKU) number?

Where do you find a SKU number?

How to create SKU codes for products

How are SKU numbers used within ecommerce?

Whether you have 3 products or 300, SKU numbers are one of the most useful tools for your business.

There are so many benefits: they simplify inventory management and control, increase visibility into inventory levels and sales data, and even improve the customer experience.

That said, there’s no one-size-fits-all way to create SKU numbers — and when it comes to finding SKU numbers, you’ll find that different brands use them in different ways. Without understanding their purpose, adopting a SKU system can get messy quickly.

In this article, we will discuss what SKUs are and how they can be found, as well as everything you need to know about how to create SKUs for products missing them, the best way to manage SKUs, and how you can find the right fulfillment partner to help you seamlessly manage the entire process.

What is a stock keeping (SKU) number?

SKU (or stock keeping unit) numbers are custom alphanumeric codes that merchants assign to every unique product or product variety.

SKUs are typically 8-10 characters long, with each character (or sets of characters) representing a particular feature of the product that SKU is assigned to.

There are no standardized rules for creating SKU numbers. Rather, every business is free to create SKU numbers using whatever characters and referencing whatever features make the most sense for their operations. However, SKUs are most useful when they are simple and easy to understand.

Merchants typically print each product’s unique SKU number on the product’s label to help identify that product and track it through the supply chain.

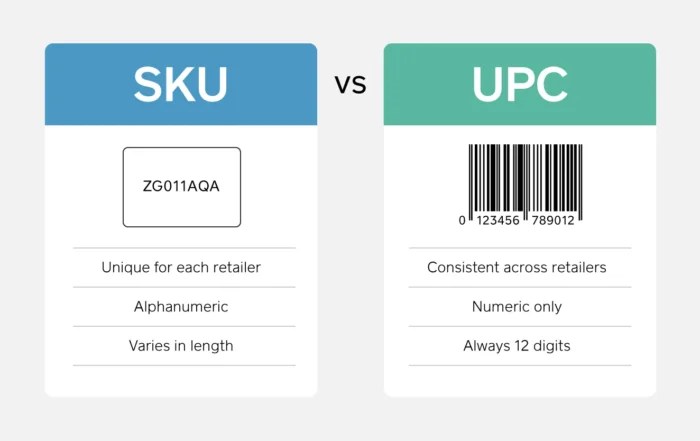

SKU numbers vs. UPC codes

Typically, as a merchant creates their SKU numbers, they will assign a unique barcode to each SKU number. However, these SKU numbers and their corresponding barcodes are not the same as Universal Product Codes (UPCs).

While a UPC is also a numerical code and corresponding barcode assigned to a specific product, UPCs are used universally across businesses and industries. This means that, if a particular product has a UPC, every business will use the same number and barcode to refer to it.

A SKU, on the other hand, is unique to the business that creates and uses them. This means that each retailer has its own variant of SKUs.

SKU number examples

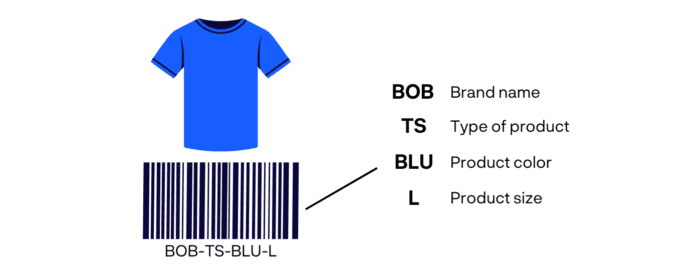

As an example, let’s say there is a small business that sells t-shirts, dresses, and shoes.

After auditing their inventory, the business decides that they want each SKU to communicate information about the following features:

- Type of clothing (t-shirt, dress, or shoes)

- Size

- Color

- Collection the item was released in (Fall, Spring, Summer, or Winter)

With this in mind, the business creates the following coding system for their SKUs:

| Type of Clothing | Code | Size | Code | Color | Code | Collection | Code |

T-Shirt | TS | 8 | 8 | Red | RE | Spring | 10 |

Dress | DR | 9 | 9 | Blue | BL | Summer | 20 |

Shoes | SH | 10 | 10 | Green | GR | Fall | 30 |

| Vest | VE | 11 | 11 | Yellow | YW | Winter | 40 |

Using this coding system, the business can create and assign SKUs to their existing products. For instance:

ITEM: A T-shirt, size 10, in blue, released in the summer collection

SKU: TS-10-BL-20

ITEM: A dress, size 8, in green, released in the winter collection

SKU: DR-8-GR-40

Because the coding system was designed to fit the needs of the company that created it, the coding system can be modified when new items are added or when old items are deleted.

For example, if the company decides to introduce a pair of yellow shoes, they can simply add a code for the color purple to their system (such as YE or YW).

When creating SKUs, there are a few best practices to follow:

- Try not to start SKUs with a 0, or include two lookalike characters that could easily be confused for one another (e.g. “0” and “O”, or “1” and “I”)

- Avoid using special characters like &, %, or #.

- Start SKUs with a letter whenever possible.

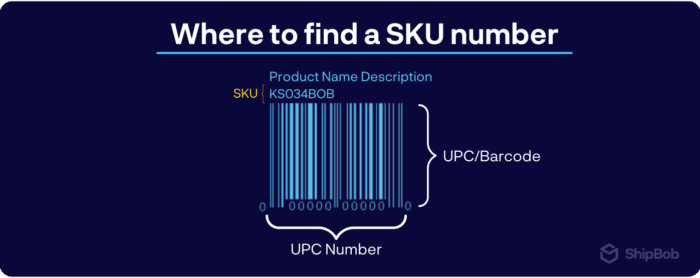

Where do you find a SKU number?

SKU numbers can be found in a variety of internal and customer-facing places.

Typically, SKU numbers are listed on the product’s packaging — usually above the product’s barcode, as seen below.

In this example, while the 12-digit numeric code on the bottom is the product’s UPC (Universal Product Code), the alphanumeric code at the top is the SKU number (which is different from the UPC).

SKU codes are also sometimes located on the price tag of the product, especially for items like clothing and toys.

In physical stores, SKUs are occasionally listed on the shelves where their products are placed instead of being printed on the product itself. This allows the retail store workers to efficiently locate and manage the in-store inventory.

Products are not required to have SKUs — so if a product does not have an SKU printed anywhere on it or the packaging, the product either has not been assigned one yet or may only be listed online.

How to create SKU codes for products

SKUs are customizable — that is, there is no one set of conventions or rules that every business follows when creating SKUS. Rather, each business is free to create SKUs according to whatever system and criteria best suits their needs.

While it is possible to use a SKU generator to create your SKUs, there are certain aspects of the process that you’ll need to think through yourself. Here are a few tips and best practices to follow when creating SKUs.

1. Create a standard naming convention

Before doing anything else, your business should first establish a standard set of conventions for creating and assigning SKUs.

Decide what attributes you’ll want the SKU to catalog, and what order you’ll present those attributes in. Typically, top-level attributes like the type of item come first, and progressively specific identifiers (such as product name, part number, and/or model numbers) follow.

2. Make sure every SKU is unique

It is very important to ensure that every product has its own unique SKU. The point of giving every item a unique number is to distinguish each product from every other product, so having identical SKUs for two different products defeats the purpose.

If a product is ever retired or discontinued, its item number should not be reassigned to a different product. Additionally, businesses should not simply adopt manufacturer’s SKUs or the UPC numbers — especially if you are a wholesaler, sell through B2B channels, or list products on online marketplaces such as Amazon or Walmart — as doing so may cause confusion.

3. Showcase SKUs that are alike

One of the best benefits of implementing SKUs is that it allows you to identify similar items and present them together, both in physical locations and on your online store.

Grouping similar SKUs not only keeps inventory organized, but could also provide quick and easy alternatives and close a sale if a customer’s desired item is sold out.

4. Add SKU basic information

When creating a SKU system, remember to record the dimensions and weight of each SKU. Many businesses tend to skip this step, but it is necessary to accurately estimate your inventory capacity size.

5. Create an SKU management system

Creating and assigning SKUs doesn’t do much good unless you also have a SKU management system in place. SKU management systems streamline SKU tracking over time, both in physical storefronts or warehouses and for accounting purposes.

6. Implement SKU software

Implementing an inventory management system that lets you name, monitor, and track different SKUs is a game changer for inventory management.

The right software will automate much of the SKU management process, and view individual SKU levels, order histories, sales records, and shipment confirmations in detail.

You should also look for a solution that lets you set up reorder points for each SKU and bundles different SKUs together when needed.

“We’ve always had a pretty low fulfillment error rate. But keeping that number low has become harder the larger we get. When we were small, everyone knew what products were called and where they were in the warehouse. But now we have over 200,000 SKUs on our website, 190,000 of which are stowed in our warehouse. It became difficult to make sure everyone was doing fulfillment in the right way.

ShipBob’s WMS makes it almost impossible to do things wrong. Eliminating the potential for human error during picking and packing has been great. That was our biggest problem before. Last time I checked, our error rate was less than 1%. We’re shipping out over 10,000 orders per month.“

Clint Sanders, VP of Operations of Bunker Branding

How to find SKU number for products online

To find a SKU online, try going to the product page on the business’s website. Many times, the SKU will be listed in the product description or in the other information provided.

However, it’s important to note that the customer-facing version of a SKU is not always the same internal SKU number that a brand uses to organize products for storage and restocking purposes.

How are SKU numbers used within ecommerce?

There are several ways to leverage SKU numbers in ecommerce and retail. Here are just a few of the top reasons why ecommerce businesses utilize SKUs across their inventory.

Efficiently track all inventory

Because each SKU is unique, it gives you a way to distinguish between items. This, in turn, makes it easier to track the amounts, movements, and sale levels of individual products.

With SKUs codes, you can easily track the status of your inventory and how much you have in every storage and fulfillment location, which helps you to make more informed supply chain decisions. Consider printing your SKU list in a poster size to display in your workspace for easy reference and streamlined inventory management.

Provide SKU product data

By adding SKU codes to all products, you are able to collect data from your inventory processes and better understand which products are selling well and which need a bit of a push.

In this way, SKUs provide much more detailed inventory data and can even help you audit your inventory and discover deadstock.

Forecast future sales

By making inventory tracking easier, SKUs subsequently enable you to forecast future demand and sales more accurately.

With every specific product segmented and tracked, you can study each product’s performance across a given period and analyze customer trends.

You can also observe order values and volume across different products, determine which products are the most profitable for your business, and make future purchasing decisions accordingly.

This lets you predict and prepare for customer demand and set your business up for success.

Set reorder points

Without a system for tracking and distinguishing products from each other, it can be hard to know when to reorder what products. By assigning each product a SKU, you gain a new level of inventory visibility, and can quickly identify which stock levels are running low.

Segmenting specific products via SKUs also enables you to set reorder points for each unique item. This helps ensure that you don’t run out of an item while you wait for its inventory to be replenished.

Create a better customer experience

Assigning SKUs to each product variety facilitates better inventory tracking, provides more detailed sales data, and helps you time replenishment correctly — all of which combine to better the customer experience.

Tracking SKU data helps you identify trends so that you can meet customer demand. Insight into SKU quantities at various locations helps prevent stockouts and backorders that drive customers to away from checkout and towards cart abandonment.

If you do stock out, SKUs can also be used to suggest similar items to customers.

How ShipBob’s SKU management works for retailers

SKU creation and management can be a tedious and time-consuming process — but partnering with an expert supply chain platform like ShipBob can help you focus more on core competencies while freeing up your time.

Here are just some of the benefits of outsourcing inventory storage and order fulfillment to ShipBob.

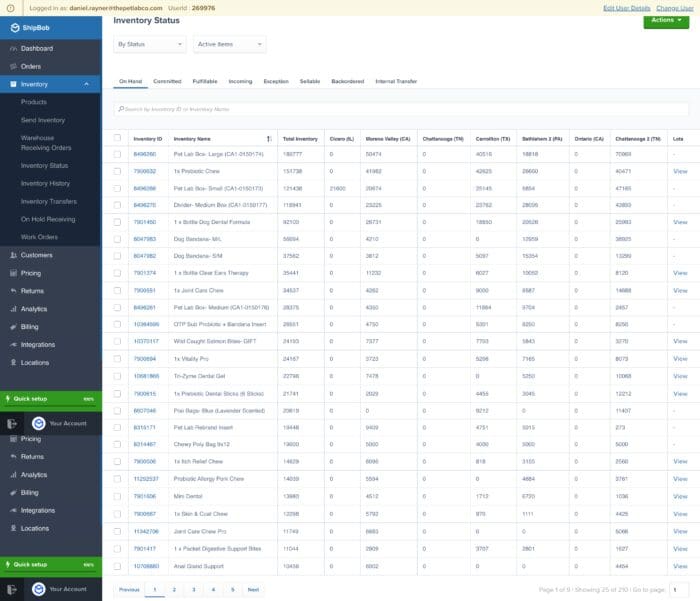

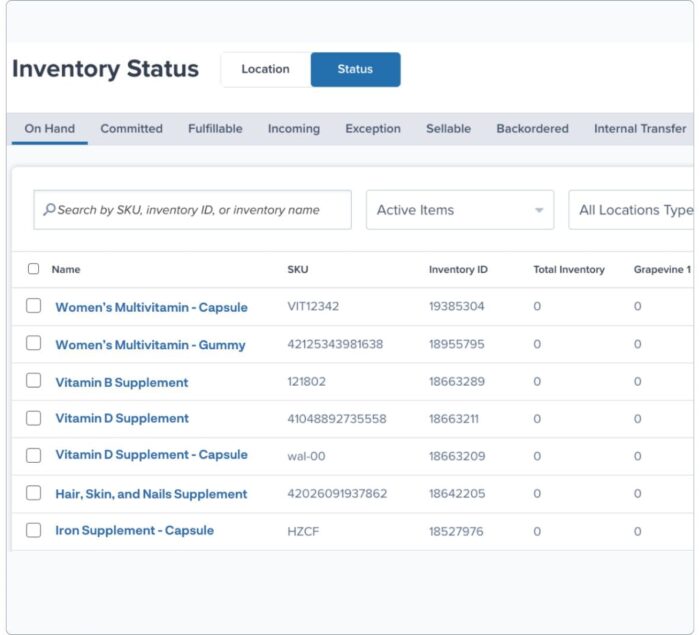

Allows retailers to view inventory levels in real-time

ShipBob’s software allows its users to track inventory levels in real time at any of ShipBob’s fulfillment centers, so that you can access up-to-date data at any time across your distribution network.

With a more accurate understanding of inventory levels and movement, your business can more effectively forecast inventory demand and study purchasing patterns for each SKU to make better supply chain decisions.

Over time, this will help you achieve greater customer satisfaction and prevent stockouts and backorders.

“Partnering with ShipBob, we get real-time insight into how much inventory to allocate to a specific warehouse, our current on-hand inventory levels, and how long each SKU is going to last by location. ShipBob provides a lot of distribution metrics, and everything presented is useful.”

Mithu Kuna, Founder and CEO of Baby Doppler

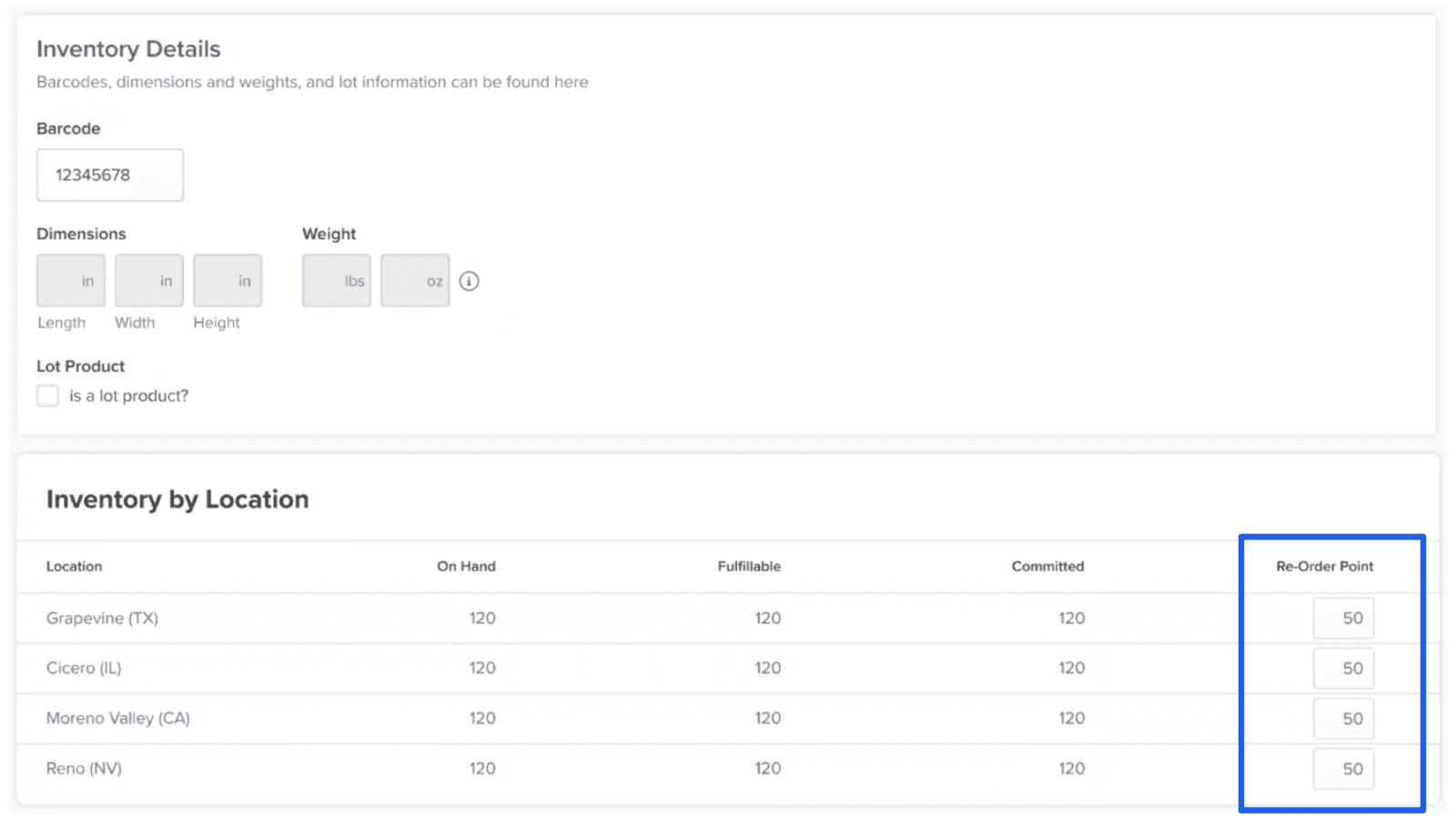

Set automatic reorder points

ShipBob software allows you to set up reorder points for every one of your SKUs so that you are automatically notified whenever an inventory item reaches its reorder threshold.

Not only does this save you the trouble of manually tracking many different SKUs, it also enables you to time replenishment perfectly across store locations so that customer demand is consistently met.

“Trying to figure out how much of what inventory to send where could be wildly complex for our supply chain managers – but since ShipBob automatically tracks our order and shipping data for us, that data basically tells us our optimal inventory distribution. We also get automatic reminders notifying us well before inventory levels are getting depleted, so we don’t have to constantly be checking our stock levels.”

Tyler McCann, Co-Founder of Taste Salud

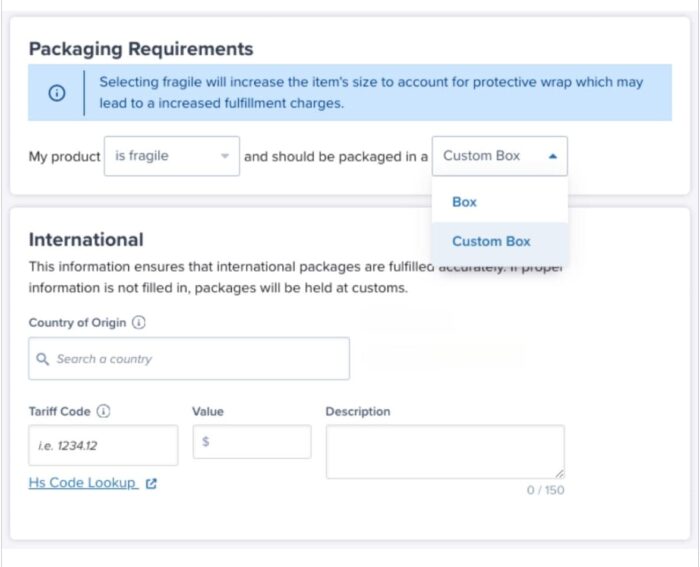

Set SKU packaging preferences

Sometimes, SKUs have specific packaging or handling needs. ShipBob’s interactive dashboard lets you add custom details to your products, including packing and shipping details.

Through ShipBob’s dashboard, you can choose whether each SKU is fragile, foldable, a poster, a book, or something else entirely. After choosing the product type, ShipBob will automatically adjust the packing process based on your preferences.

“We love ShipBob’s technology. The dashboard is very intuitive. I like that we can create our own rules, such as adding marketing insertions to orders, which makes it super easy. For each product, I can choose the packaging preferences and requirements, which is the same with retail preferences. That’s what I like with ShipBob — there are lots of things I can do myself in the dashboard which wasn’t the case with my previous 3PL.”

The IZIMINI team

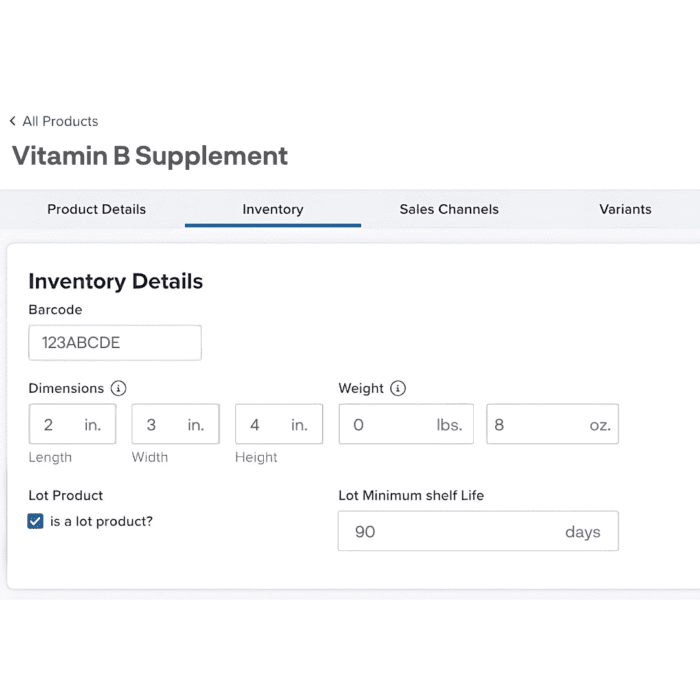

Manage perishable SKUs with lot tracking

If you have SKUs that expire by a certain date, ShipBob’s lot tracking capabilities can help you ensure inventory freshness during the fulfillment process.

Through ShipBob’s dashboard, you can quickly and easily assign a lot number to any SKU that is perishable. When you send ShipBob your inventory, simply list that lot number, and ShipBob will store each lot separately to save time and keep your stock organized.

From there, ShipBob uses the FIFO (First In, First Out) approach to pick and ship items with the nearest listed expiration date first. This way, you can use up your inventory while it’s still fresh and avoid deadstock – all without having to manually check each product’s expiration date yourself (or pick and pack orders).

“Many of our products have expiration dates, so it’s incredibly important for us to track and maintain inventory freshness – and ShipBob’s lot control features make that really easy.

When we send new inventory to ShipBob, all we have to do is mark it as a lot product in the ShipBob dashboard and list the lot number and expiration date for each lot on the warehouse receiving order (WRO). From there, ShipBob handles receiving and stores each lot separately for trackability and so there’s no confusion when it’s time to pick.

At our scale, it would be impossible to manually check the expiration date of every single unit we ship, so leveraging ShipBob’s lot capabilities gives us much more peace of mind.”

Neil Blewitt, SVP of Operations at Bloom Nutrition

How to find SKU number FAQs

Here are answers to the most common questions about how to find SKU numbers.

Is the SKU number the same as the product number?

Despite being used interchangeably at times, SKU number and the product number are not the same thing. While SKUs are developed internally to manage inventory and are unique to them, product numbers are the manufacturer codes universal across all the retailers of the said product.

What is the best way to manage SKUs?

SKU management can be both challenging and time-consuming. To save time and work, a growing ecommerce brand should consider partnering with a tech-enabled 3PL like ShipBob that allows them to focus on growth areas while still maintaining control of their inventory operations.

Is SKU management important for retailers?

Yes. SKU management is important for both offline and online retailers because it gives them specific details about every item in their inventory, which can significantly improve order accuracy during the warehouse picking and packing process.

How do you calculate the number of SKUs in your inventory?

To calculate the number of SKUs in your inventory, you will need to consider all of the different product variations you offer. This includes variations in color, size, price, and more. The number of SKUs in your online store will be equal to the number of product variations.

If you are a small clothing retailer, your SKU calculations might look like this:

You have a t-shirt that comes in 2 styles, 2 colors, and 3 sizes. Red or blue; V-neck or crewneck; and small, medium, or large. Here are all of the possible product variations:

- Red, V-neck, Small

- Red, V-neck, Medium

- Red, V-neck, Large

- Red, Crewneck, Small

- Red, Crewneck, Medium

- Red, Crewneck, Large

- Blue, V-neck, Small

- Blue, V-neck, Medium

- Blue, V-neck, Large

- Blue, Crewneck, Small

- Blue, Crewneck, Medium,

- Blue, Crewneck, Large

2 colors x 2 styles x 3 colors = 12 variations; you will have 12 SKUs.