Fulfillment Costs Explained

In an ecommerce supply chain, fulfillment is where the magic happens. The faster orders can be fulfilled and shipped, the happier your customers will be.

But fulfillment comes with a cost, and the process isn’t as simple as picking and packing boxes. Keeping fulfillment costs low while also meeting customer expectations around fast, affordable shipping can seem impossible – but luckily, there are several ways to reduce costs while delivering a great customer experience.

This article covers the different line items associated with fulfillment and how to easily calculate fulfillment costs.

So what do you want to learn?

- What are order fulfillment costs?

- Order fulfillment costs with a 3PL & fulfillment center pricing

- 3PL order fulfillment costs & pricing explained

- How to calculate fulfillment cost per order

- Common 3PL pricing models

- ShipBob’s 3PL pricing explained

- The cost of inefficient fulfillment

- Lower your fulfillment costs and scale your business with ShipBob

- FAQs

Request Fulfillment Pricing

We’ll get back to you within 24 hours. Privacy Policy

What are order fulfillment costs?

Order fulfillment costs are the total charges & expenses calculated for receiving inventory, storing products, processing orders, picking, packing, and shipping of all orders and inventory. Common retail order fulfillment costs vary by provider, the number of orders placed, pricing models, and any additional services used.

What is a 3PL?

A 3PL (short for “third party logistics provider”) is a logistics services provider that allows merchants to outsource fulfillment, which includes warehousing, inventory management, and fulfillment. 3PLs take care of all fulfillment-related tasks – tasks that can often be too costly and unproductive to manage in-house.

Partnering with a 3PL can help your business save money and time, freeing up resources and attention so you can focus instead on product development, marketing, and business growth.

However, not all 3PLs are created equal, especially when it comes to digital fulfillment pricing models and 3PL costs.

To help figure out which 3PL is best for your ecommerce business, it’s important to familiarize yourself with the different expenses and pricing models involved.

Read on to learn how to calculate fulfillment costs for your ecommerce business.

Order fulfillment costs with a 3PL & fulfillment center pricing

Below is an example of a common 3PL pricing model and the associated costs.

| Service | Pricing model | Cost (in USD) |

| Receiving | Flat rate | $35 for the first two hours, and $45/hour for each subsequent hour |

| Storage | Per bin, shelf, and pallet | $40/pallet/month $10/shelf/month $5/bin/month |

| Pick and pack fees | Included in total fulfillment cost | A set number of picks included, then $0.26 for each subsequent pick |

| Standard packaging materials | Included in total fulfillment cost | Free |

| Kitting fees | Per-project basis | A flat fee for the kitting project (e.g., $25) and each additional touch at $0.04 – $0.50 per unit or kit |

| Shipping | Carrier pricing passed directly on to client | Varies based on order destination, weight, dimensions, shipping speed, etc. |

Just like there is no one-size-fits-all fulfillment solution, there is no one pricing model that fits all businesses. Reach out directly to ShipBob team for custom pricing that takes into account your business’s size, needs, and budget.

“What we love about ShipBob is we have fulfillment pricing information so much ahead of time that we know exactly how much to build into our COGS. We couldn’t do this with our prior fulfillment providers. We’ve been able to build a proper pricing forecast and models, and do so much cost analysis because ShipBob makes it easy to calculate what our actual costs will be, which helps us continue to run profitably.”

Kayleigh Christina, Co-Founder and CMO at CLEARSTEM

3PL order fulfillment costs & pricing explained

While there are several different fulfillment pricing models, there are many common costs across fulfillment providers. Here are some of the expenses you may encounter when working with a 3PL and what to know before you sign an agreement.

Onboarding costs

When getting started with a new fulfillment partner, you may encounter onboarding costsor setup fees to get ecommerce fulfillment services up and running. Onboarding is worth the investment, since it is designed to help reduce headaches and confusion as you get started with a fulfillment provider.

“I was considering a couple fulfillment providers, but I noticed that ShipBob ranks really highly among the competition, so I decided to give ShipBob a try. The onboarding process was really, really easy – and that’s coming from someone that didn’t understand shipping at all!

We were assigned an Implementation Specialist, and she helped us with everything: integrating our Shopify store to ShipBob’s dashboard, getting all of our inventory sent and stored in our first ShipBob fulfillment center, and making sure we had what we needed. It was all very seamless.

Now that the business has grown, I’m out of the role where I’m managing fulfillment or connecting with ShipBob’s team day-to-day, but I really appreciate how simple it was to get started with ShipBob.”

Tyler McCann, Co-Founder of Taste Salud

Inventory receiving costs

Before a fulfillment partner can start processing and fulfilling orders from your online store, they first need to receive your inventory.

In inbound and outbound logistics, receiving refers to the acceptance and storage of incoming inventory. Different 3PLs charge for receiving in different ways, including per-unit, per-pallet, flat rates, or per-hour. At ShipBob, we charge a flat USD fee for the first two hours of receiving and storing inventory (then an additional USD surcharge per hour after that). For more information on ShipBob’s receiving pricing, click here.

Inventory storage costs

When you store your inventory at a 3PL’s fulfillment center, you will be charged for storage space. Warehousing fees can range from per-SKU or per-unit storage fees to a fixed fee for each bin, shelf, or pallet used.

ShipBob charges for ecommerce warehousing on a per-shelf, per-bin, and per-pallet basis, so you only pay for the space you use on a monthly basis. You can also view your storage costs at any time through ShipBob’s dashboard.

Order pick and pack costs

Some 3PL providers’ models include pick and pack pricing. Once your customer places an order, the fulfillment process begins with picking, or collecting each ordered item from its designated storage location using a picking list. Many fulfillment providers charge on a per-pick basis, meaning you pay a fee for each item included in an order.

Kitting costs

Some 3PLs offer kitting and assembly services. Kitting refers to any unique accommodations for the way in which items are assembled, arranged, or packed before shipping. Common applications for kitting include assembling multiple SKUs or preparing inventory in a particular way during the packing process. Because this service is so specific to each individual client, kitting fees can vary.

Packaging costs

Your packaging is often a customer’s first in-person impression of your brand. Some 3PLs will charge for packing materials (such as standard boxes) as a separate line item, while others include them as part of their fulfillment services.

At ShipBob, for example, standard packing materials — brown boxes, yellow bubble mailers, white poly bags, packing tape, and airfill — are included at no extra cost. Merchants can use custom branded packing materials at an additional cost.

“When we first started out, our packaging process was really simple – we just picked the product, stuck it in a brown box, and shipped it. Because ShipBob can support custom packaging, we’ve leveled up our strategy to include Bloom-branded boxes, marketing inserts, and the ability for customers to add personalized gift notes to their orders.

The level of customization that ShipBob supports helps us reinforce our image as a premium-quality product, and lets us curate a branded experience at scale for customers as soon as their package arrives on their doorstep.”

Neil Blewitt, SVP of Operations at Bloom Nutrition

Shipping costs

Finally, ecommerce shipping costs: the amount a fulfillment provider charges to ship an order from their fulfillment center to your customer’s doorstep. Many 3PLs have relationships with major shipping carriers that allow them to pass bulk volume discounts onto their clients. Shipping fees take a variety of factors into account, including shipping speed (such as two-day shipping), shipping zones, and dimensional weight.

“Our subscribers are some of our closest, most valued customers, so we want to give them the option of receiving their first order in 2 days. With ShipBob, we can make that happen. Not only that, we can make it happen without compromising on cost. Because of ShipBob’s overall order volume, they can negotiate bulk discounts with carriers that we simply couldn’t. By partnering with ShipBob, we get better quality fulfillment and shipping for a better price.”

Maria Osorio, Logistics and Operations Director at Oxford Healthspan

How to calculate fulfillment cost per order

Fulfillment costs vary depending on what 3PL and distribution center you partner with and their pricing model, but standard pick and pack fees usually start around USD $0.20 per pick.

Along with pick and pack fees, there are other costs to consider when you look at the entire fulfillment process.

To calculate total fulfillment costs, you’ll need to add up the following expenses:

- Warehouse receiving: Labor costs associated with receiving new inventory, calculated using an hourly rate.

- Storing and managing inventory: A monthly cost, including the amount of pallets, shelves, and bins being used to store items, as well as any technology fees associated with using or leasing inventory management software.

- Warehouse picking and packing: Labor costs associated with picking and packing items, calculated by the number of items being picked over time.

- Standard or custom packaging: The price of standard packaging (e.g., generic poly mailers and boxes) or the use of branded packaging (e.g., eco-friendly packaging).

- Kitting (if applicable): Pre-assembly of separate pieces into a single offering or the arrangement of a package a certain way, which is offered as an additional service by most 3PLs.

- Return management and processing: Costs associated with restocking or disposing of returned items.

- Automated shipping: Carrier rates for shipping packages to end customers (costs vary based on destination, weight, dimensions, carrier used, shipping speed, etc.).

Since there are so many variables associated with fulfillment costs, it’s always best to use fulfillment software that can track your average fulfillment cost per order.

For instance, ShipBob’s fulfillment technology makes it easy to break down fulfillment costs by activity. Through ShipBob’s dashboard, you can get insights into:

- What is my average storage cost per unit?

- What is my average fulfillment cost per order?

- How much are my customers spending by shipping method?

- What is my average shipping cost per shipping method?

- What is the total number of bins/shelves/pallets I’m being charged for?

- What is the average shipping cost by shipping method and order?

- What is your average US shipping zone?

- What is your average billable weight by shipping method?

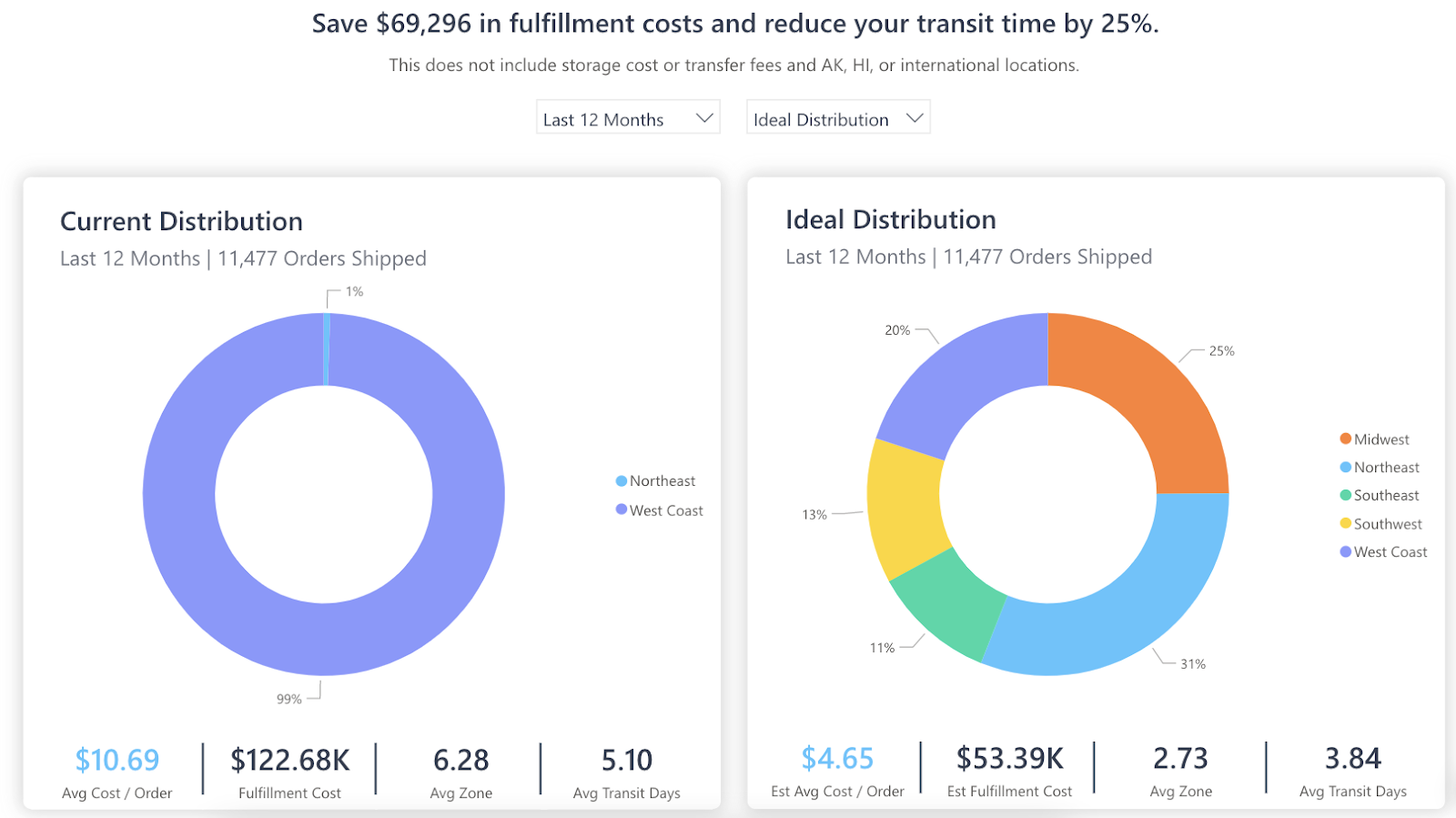

With deeper insights into fulfillment performance, you can find ways to optimize fulfillment costs, such as moving inventory into a fulfillment center location closer to your customers.

This inventory allocation method reduces the average shipping zones of shipments by keeping inventory closer to your end customers, therefore reducing the cost of shipping while speeding up delivery). ShipBob even offers an Inventory Placement Program that will not only help you calculate the most optimal inventory allocation plan to minimize shipping costs and times, but will also handle regional inventory distribution for you.

“Right after we partnered with ShipBob, we joined their Inventory Placement Program, which streamlines inventory distribution across the US, taking multi-location inbound shipments, inventory allocation, and rebalancing off merchants’ plates.

Since launching in the program, we’ve been able to allocate our inventory across 4 of ShipBob’s fulfillment centers in the United States, which cut our shipping times by a third – from 5.2 days down to about 3.6 days. Not only has transit time dropped, but at the same time we reduced fulfillment costs by over $2 per order compared with our old 3PL. This combination has been key to profitable growth this year.”

Matt Crane, Co-Founder and Chief Science Officer at Semaine Health

Common 3PL pricing models

Third-party fulfillment pricing and cost structures can be confusing – especially depending on the model that your fulfillment partner uses. Some models are also more prone to include hidden additional fees, which can add up quickly and squeeze your profit margin, so it’s important to figure out which 3PL pricing model is simplest and most transparent for your business.

Here are three of the most common 3PL pricing models, and how they work.

Total fulfillment cost (ShipBob)

ShipBob’s pricing model is reflective of a total fulfillment cost for standard, direct-to-consumer order fulfillment. Rather than cluttering your invoice with line items or hidden fees, this pricing model simplifies fulfillment costs by only charging a single fulfillment fee for picking, packing, shipping, packaging materials, and labor (along with separate fees for receiving inventory, monthly inventory storage, and other add-ons like kitting and returns).

This simple pricing model helps ensure that retailers avoid any hidden fees or surprise costs during the fulfillment process.

“There have been obvious cost benefits in working with ShipBob — their cost structure is much more favorable than any 3PL we’ve worked with. With our multipick orders, we were getting slammed by pick fees all over the world. Our 3PLs before ShipBob also were a total black box when it came to pricing — we’d just get one invoice with no line items, which made it impossible to work out what was what. With ShipBob, it’s very transparent billing and pricing, and now we know exactly what we’re being charged.”

Jonathan Byrt, Director & Co-founder at memobottle

Pick and pack

As the name suggests, the pick-and-pack pricing model includes charges for each individual item picked in the process of assembling an order. This model is generally favored by fulfillment companies, as it makes it easier for them to track and charge for every touchpoint in a package’s fulfillment lifecycle.

For each individual pick, there usually is between a USD $0.20 and $5.00 fee depending on the fulfillment center. If you ship several items in one order, these fulfillment costs can quickly add up.

Amazon FBA

Fulfillment by Amazon (FBA), the outsourced fulfillment service for products that are sold via the Amazon marketplace, uses a unique pricing model.

Amazon is able to charge discounted fulfillment fees because they also receive a cut of every sale, called the seller fee. Seller fees mean that merchants often take home less profit on each sale than they would by selling on their own website. Sellers also lose the ability to highlight their brand when they ship via FBA — all packages are shipped in Amazon-branded boxes, and the entire customer experience and communication will take place via Amazon.

The Amazon FBA pricing model also includes several conditional fees, including (but not limited to):

- Aged inventory surcharge

- Inventory storage overage fee

- Unplanned services fees

- Manual processing fees

- Inbound placement service fee

- Low-level inventory fee

- Inbound defect fee

Amazon FBA costs are complex, varying based on seasonality, the type and size of the item, and a variety of other factors.

ShipBob’s 3PL pricing explained

Since there is no one-size-fits-all fulfillment solution, there is no one pricing model that fits all businesses.

However, that doesn’t mean you should be left in the dark on how much you’ll be paying for fulfillment costs when partnering with a 3PL.

Unlike many fulfillment partners and supply chain technology platforms, ShipBob offers transparent, custom pricing with no hidden fees. Our pricing model is reflective of a total fulfillment cost for direct-to-consumer fulfillment, so you’ll know exactly what your costs will be.

Please refer to ShipBob’s Help Center for the most up-to-date fees, including:

The cost of inefficient fulfillment

Because fulfillment is generally a huge cost center, it’s normal for brands to look for cost-savings opportunities. But more often than not, cutting corners in fulfillment only leads to more problems and expense down the line.

For instance, many brands assume that keeping fulfillment in-house is cheaper and better than outsourcing to a professional partner – but this approach leaves you prone to errors, takes up all your time, and isn’t scalable in the long run.

“We are willing to pay a premium for a premium product. In our initial call with the new fulfillment network, we were told that our average fulfillment cost would be around USD $0.15 to $0.20 higher than ShipBob. In actuality, our costs were around 50% higher than that of ShipBob, and the new fulfillment solution was not a superior product in the slightest.

They even overcharged us with billing errors. While many 3PLs utilize a complex pricing model that makes forecasting expenses nearly impossible, ShipBob has a clear pricing model so we know exactly what we’re going to be billed.”

Gerard Ecker, Founder & CEO of Ocean & Co.

For brands that do partner with a 3PL, the temptation is to focus on price – but the cheapest 3PL isn’t always the best option for your business. Even if their prices are low, many fulfillment platforms don’t offer the infrastructure, modern technology, visibility, expertise, and customer support that ecommerce brands need to build a high-quality, reliable and scalable fulfillment strategy.

Without taking the time to evaluate and choose the fulfillment solution for your needs, there is a lot at risk that can hinder the growth of your business.

Here are some of the most common results of selecting the wrong fulfillment strategy or a sub-par fulfillment partner.

Inefficiencies and roadblocks

Whether you’re fulfilling orders yourself or outsourcing to a provider, doing things manually is inefficient and often results in more errors. Following outdated processes or using old of clunky technology also imposes other limitations, like:

- No bulk discounts: If you’re not shipping millions of packages each year, you don’t have the leverage to negotiate shipping rates with major carriers. Plus, if you’re only working with one carrier, you may be missing out on the strengths of another, such as discounted international shipping costs. If you’re just starting out and shipping a low volume, you’ll also be paying commercial prices for packing materials.

- Lack of integrated systems: If your processes aren’t connected to the technologies you already use, you lack automation, data to drive decisions, and transparency for customers. This can slow down and even impair your operations.

- Only shipping from one location: If you are stuck shipping orders out from a single location, you may have to pay higher postage for packages that travel across multiple shipping zones.

- Trips to the post office: Making several trips to the post office each week is time-consuming and expensive.

- High overhead: Choosing to invest in the operational infrastructure to fulfill orders yourself is expensive. This set of fulfillment costs includes warehouse space, forklifts and other equipment, warehouse management software, recruiting and labor, workers comp, liability insurance, and other logistics costs — not to mention the time it takes to get this all set up.

Keeping customers waiting for their deliveries

When shipments take too long to reach your customers, you may be jeopardizing future business.

Today’s consumers expect Amazon-like service everywhere they shop online. Nobody likes to wait. Slow delivery times can fail to meet customer expectations. When this happens, they are less likely to become repeat customers. So if you’re constantly making trips to the post office, or if your 3PL partner is taking days to get orders out for delivery, you won’t be providing the quick and affordable delivery experience that wins repeat business.

“In the world of ecommerce, making sure the customer has a good experience is a top priority. We want to do everything we can to ensure a customer will continue to order from us, so we must impress them. We do that by using ShipBob for fulfillment because they receive and fulfill orders on-time, provide communications about tracking, and offer speedy delivery.”

Cesar Contreras, Head of Supply Chain of Wholesome Goods

Only focusing on fulfillment

When it comes to growing a successful ecommerce business, time is money. While your to-do list is never-ending, some tasks deserve your time more than others.

Whether you’re making phone calls or emailing back and forth with a traditional 3PL, constantly checking for new orders, or packing your items and waiting in line at the post office to wait in line, you’re missing the opportunity to grow your customer base, develop new products, market your business, and much more.

In other words, you may be losing money by not outsourcing operational tasks to an experienced, affordable fulfillment provider. Outsourcing fulfillment can help you dedicate valuable time to performing tasks that require more attention and provide higher value to your business.

“Our order volume has grown immensely since we started the business, to where fulfillment doesn’t leave time for us doing anything else. At the scale we’re starting to operate at, keeping everything in-house would mean that we would be picking and packing orders all day! We have even bigger ambitions for our business going forward, including launching new products and increasing stock. So we wanted to free up our time to focus on growing our business, and knew it was time to outsource fulfillment to experts like ShipBob.”

Adelina Zotta & Connor Westby, Co-Founders of NutriPaw

Lower your fulfillment costs and scale your business with ShipBob

As an expert supply chain and fulfillment platform, ShipBob has helped thousands of ecommerce brands reduce their fulfillment costs, improve their fulfillment quality, and build a fulfillment strategy that scales with them.

Brands like yours can save on fulfillment by leveraging ShipBob’s services and capabilities, including:

- Transparent billing and easy-to-understand invoices (with each individual line item broken down to prevent mystery fees).

- Intuitive software that features built-in inventory and order management capabilities

- An analytics dashboard where you can view key inventory, order, and fulfillment performance metrics and data in real-time, plus insights to help you optimize your operations for cost.

- Inventory distribution across 50+ global fulfillment centers (including locations in Canada, the UK, Europe, and Australia) to shorten shipping time and reduce shipping costs.

- Omnichannel fulfillment for retail dropshipping and distribution, marketplaces, and social channels to streamline operations through a single provider.

- Seamless integrations with dozens of major ecommerce platforms and tools (so you don’t have to pay for and juggle multiple partners).

- Customization options such as gift notes and marketing inserts to delight customers and drive engagement

“For me, the cost of fulfillment is completely outweighed by the level of service and the commitment that ShipBob shows to merchants. Even if I were spending my own personal money, I would pay double – the fulfillment quality and support are that good.”

Kelly Bond, Operations Manager at Elle Sera

Get a fulfillment quote from ShipBob below and learn if we’re a good fit for your business.

Fulfillment cost FAQs

Below are answers to some of the most common questions about fulfillment costs.

How much does ecommerce fulfillment cost?

It varies based on the 3PL you partner with. For general pick and pack fees, it can cost around USD $.20 – $1.00 per pick. With ShipBob, it varies by country of fulfillment and when you start fulfilling with ShipBob. Please find more here.

Are fulfillment costs under COGS?

Yes, fulfillment costs are usually factored into an ecommerce brand’s COGS calculation. This is because the cost of fulfilling orders is considered a part of the overall cost of creating and selling those goods (since without fulfillment, it would be impossible to get goods to the end customers who purchased them).

How do fulfillment costs impact overall profitability for an online store?

Fulfillment costs are typically a big cost center for ecommerce businesses and can mean the difference between profitability and unprofitability. If your fulfillment costs are so high that they eat into your bottom line, you will need to find ways to lower your fulfillment costs in order to stay profitable.

What percentage of ecommerce fulfillment costs comes from order picking?

Order picking is usually just one of many costs in ecommerce fulfillment, especially if you work with a 3PL partner that has its own pricing model for various outsourced services. Other cost-drivers in ecommerce fulfillment include:

- Inventory receiving

- Inventory storage

- Kitting and assembly

- Packaging (particularly custom branded packaging)

- Labor

- Technology (such as software, scanners, and forklifts)

- Shipping

- Returns processing