When it comes to your ecommerce brand’s inventory, meticulous record-keeping is very important. But no matter how diligently you track inventory, sometimes things don’t turn out the way you expected.

Maybe you discover some of your inventory has gone missing, or a sudden flood damages stock beyond repair. Suddenly, the inventory amounts and levels you have recorded don’t match the inventory amounts and levels you actually have.

In this scenario, you’ll need to perform an inventory adjustment. Regularly adjusting your inventory helps ensure that your inventory data is accurate and representative of your actual, physical inventory on hand.

Let’s walk through what an inventory adjustment is, when you need one, how your business can benefit from it, and how to adjust inventory correctly and efficiently.

What is an inventory adjustment?

Inventory adjustment is the process of adjusting inventory levels in your inventory records to match the actual amount of stock you have on hand. These adjustments may involve decreasing or increasing the quantities to match the physical inventory count, or adjusting the value of inventory in your system to reflect your actual inventory value.

If you identify any inventory discrepancy, performing an inventory adjustment allows you to resolve it and ensure that your records are accurate and updated. Having accurate, up-to-date inventory counts is crucial, as it enables your brand to:

- Make more informed, data-driven decisions

- Correctly identify when you’re running low on stock and make timely replenishments to minimize stockouts

- Avoid ordering excess inventory and prevent dead stock, surplus inventory, and unnecessarily high holding costs

When do you need to adjust inventory?

You’ll need to adjust inventory whenever the actual number of items you have on hand does not match the amount of inventory you recorded. Typically, the mismatch is because instead of being used to fulfill orders, something else has happened to inventory.

This is called inventory shrinkage, and there are many potential causes.

Theft

One of the most common reasons to adjust inventory is shrinkage due to theft. Your physical inventory count may be lower than the levels in your inventory system if unscrupulous employees or third parties are stealing stock.

Loss/misplacement

Misplacing inventory is a common occurrence, especially if your warehouse layout is disorganized. Whether this is temporary or permanent, it still decreases your physical inventory count, resulting in discrepancies. Similarly, if those misplaced items turn up after you’ve already made adjustments, you’ll need to account for them again and make additional adjustments.

Damage/breakage

Accidents can happen in the warehouse, and these sometimes result in inventory damage. Since this damaged inventory can no longer be sold, it needs to be written off and excluded from your inventory counts.

Waste

Similarly, when your inventory expires or becomes obsolete, it counts as waste and needs to be removed from your viable stock. Waste is common when selling food and consumer goods and perishable items.

Internal use

Sometimes, inventory items may also be used internally by the company. In this case, you should update your inventory records to ensure that the usage of that stock is accounted for.

Returns

If you don’t have a proper system in place to account for returns, then you’re likely to face discrepancies in your physical stock levels. You may end up having more physical stock than what’s recorded in your system.

Counting errors

Human errors in the physical inventory counting process can also lead to inaccuracies. This can either decrease or increase your inventory quantity in your records or in actuality.

Clerical errors

There can also be clerical errors resulting in discrepancies in your inventory value. For example, some items may be accidentally recorded with a higher cost of goods sold (COGS), leading to an overestimation of your inventory value.

Types of inventory adjustments

There are three kinds of inventory adjustments brands can make: decreasing inventory quantity recorded, increasing inventory quantity recorded, and inventory revaluation.

Decreasing quantity

This is a type of quantity adjustment that helps you account for inventory shrinkage and loss as well as waste, damage, and internal use. It involves reducing the on-hand quantity of inventory you state in your records.

Increasing quantity

On the other hand, you could have more inventory units on hand than you had recorded because of counting errors and returns. In this case, you’ll need to adjust recorded inventory to increase your inventory counts.

Reevaluation

Whenever you increase or decrease your recorded inventory count, you will also need to increase or decrease your inventory value.

You will also need to revalue your inventory when you encounter changes in the cost of goods sold (often due to fluctuations in production cost and raw material prices), abnormal spoilage, fluctuations in exchange rate, and inventory obsolescence.

The ripple effect of inventory adjustments

Inventory adjustments may seem like a hassle or a nuisance, but they ultimately benefit your brand. Here are some of the positive effects that inventory adjustments can have on your brand’s operations and supply chain.

Enhanced operational efficiency

Inventory adjustments give you ideas for how to improve your operational efficiency. For example, if you are regularly adjusting inventory due to theft, that is a good indication that you need to improve your security measures. Similarly, failing to account for your returned items may point you towards improving your returns management process.

Improved customer satisfaction

When you consistently adjust your inventory, you ensure that you’re always working with the most up-to-date and accurate inventory counts. This means that you can trust your data when it indicates you’re running low on certain SKUs, and you can therefore restock your inventory on time without accidentally overstocking. This also helps you prevent expensive stockouts and backorders, since you can maintain adequate stock levels to satisfy your customers.

Accurate financial statements

For most ecommerce brands, inventory is their largest investment – so it’s important that your financial statements accurately reflect the true value of that investment. Performing regular value adjustments on your inventory helps keep your financial statements accurate and orderly.

More informed business decisions

Inventory impacts so many of your business decisions, so you want to be working with the most accurate inventory data possible. By adjusting your inventory regularly, you can have more confidence in your inventory records and make more data-driven decisions regarding reorder quantity, pricing, product mix, and more.

How to make inventory adjustments (expert tips)

Performing an inventory adjustment is relatively simple. First, you must conduct a physical inventory count to establish how much inventory you have on-hand. Next, compare that number with the amount of inventory you have recorded. If they do not match, identify the cause of the discrepancy and adjust your records to reflect the actual amount of inventory you have.

Beyond those essential steps, here are a few expert tips to help you improve your inventory adjustment process.

Adopt real-time inventory management software

The easiest way to simplify your inventory adjustment process is to minimize the need for adjustment in the first place. That’s why it makes sense to invest in inventory management software that can update inventory counts in real-time as units are received, stored, picked, packed and shipped.

Using a real-time inventory management system, a barcode on every inventory item is scanned as it moves through every touchpoint within your warehouse. This enables the system to update your records automatically. As a result, you are far less likely to lose inventory to misplacement or counting and clerical errors, which reduces the need to adjust your inventory later on.

“ShipBob’s reporting is very robust and meets all of our needs. We get visibility into receiving, order volume, SKU availability – everything from inbounds and inventory transactions to individual order statuses (whether it’s on hold, in processing, an exception order, and other detailed descriptions). All this data is real-time, meaning that we’re always seeing the most accurate, up-to-date information. Having this real-time data is crucial for my team, so the fact that there’s not hours of lag time waiting for data to update is huge.”

Ryan Steffenson, Senior Manager, Channel Operations at Tonies

Conduct regular inventory audits

The longer you put off investigating your inventory records for discrepancies, the longer those discrepancies can wreak havoc on your inventory data. For that reason, it’s important to regularly audit your inventory by:

- Performing physical inventory counts at every warehouse or inventory storage location and comparing those counts to your records

- Investigating any mismatches and pinpointing their causes

- Double-checking your purchase orders and invoices against receiving logs to make sure the correct amount of inventory was delivered to you

- Determining whether to prioritize auditing certain SKUs (suitable for a regular audit) or to audit the entire product catalog (best if you have not performed an audit in a while)

- Hiring outside experts to audit your inventory without bias

Leverage inventory analytics

With access to detailed inventory analytics, it is easier to identify inventory discrepancies and nip them in the bud.

By tracking metrics over time, you can begin to discover patterns in how inventory moves through your supply chain. If a metric is suddenly atypical, you can investigate the abnormality and correct any issues before those issues result in you having to adjust inventory.

For instance, say the inventory turnover rate for one of your most popular products drops very low one month. After investigating, you discover that the warehouse workers are not scanning each unit’s barcode when picking it for an order, so your inventory turnover is higher and your records are off as a result.

Adjust to your heart’s content with ShipBob’s inventory management solution

As an expert ecommerce fulfillment partner, ShipBob’s solutions are designed to make inventory management easy and keep inventory counts accurate. Here are just some of the ways that ShipBob can help you minimize inventory adjustments while improving your entire ecommerce supply chain.

Real-time inventory visibility

The ShipBob dashboard provides real-time visibility into your inventory balance across fulfillment centers, locations, and channels. Through direct integration with major ecommerce platforms, your inventory counts are automatically updated as orders are picked, packed, and shipping to customers. This level of inventory visibility means you always have up-to-date data on where each item is stored and how much of it you have left.

Comprehensive analytics

ShipBob’s free analytics reporting tool gives you comprehensive insight into your inventory performance at the SKU level. Leveraging key inventory analytics, you can forecast demand, plan procurement, time replenishment, and improve your overall inventory management.

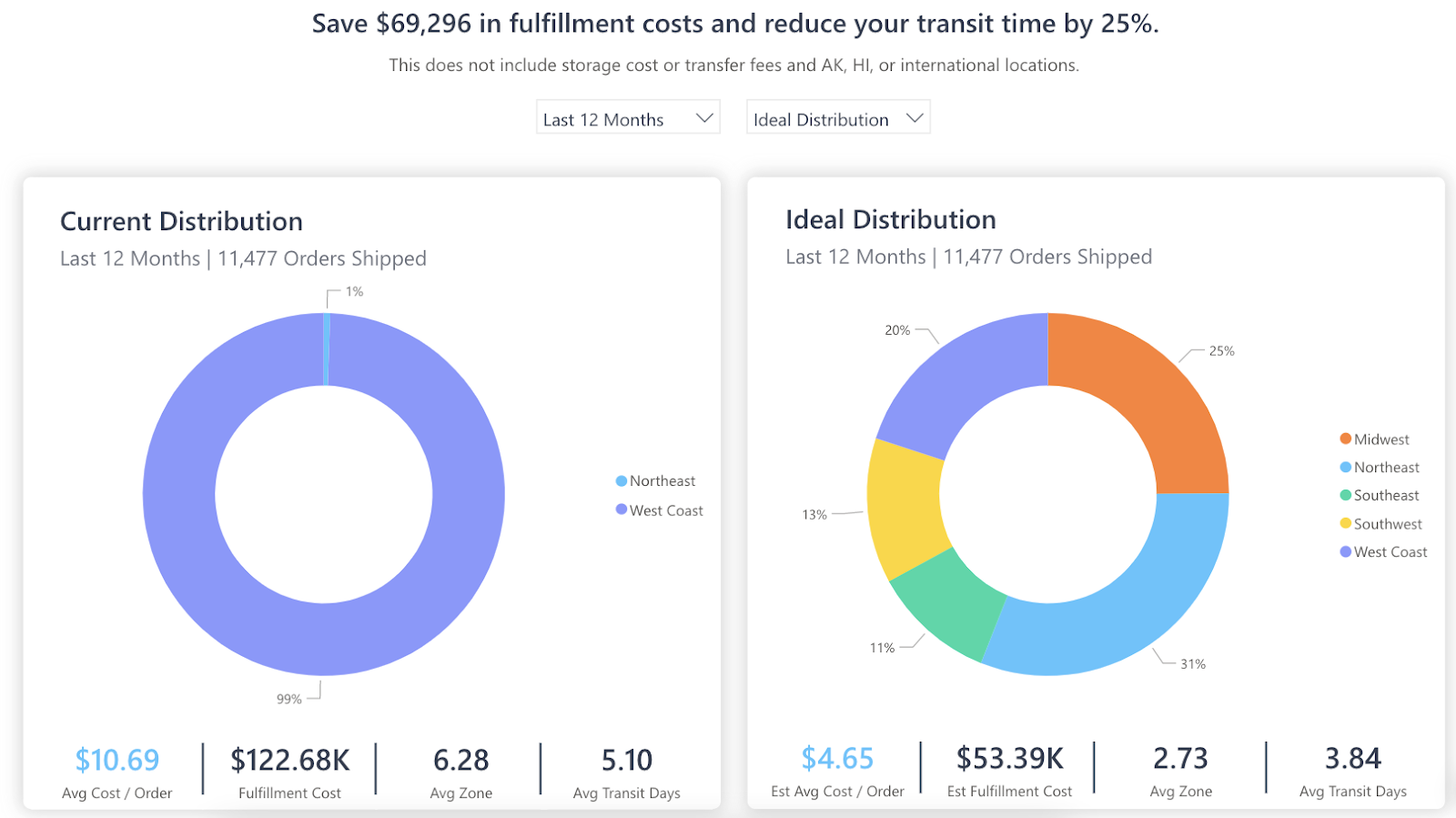

Brands can even use ShipBob’s Ideal Inventory Distribution Tool to calculate the most strategic split of inventory across ShipBob’s fulfillment center network to reduce shipping times and costs. (ShipBob can even physically distribute your inventory for you through our Inventory Placement Program.)

Outsourced inventory management

Between renting warehouse space, receiving, stowing, picking, packing, and shipping, physically managing inventory can be time consuming and exhausting. ShipBob takes care of all of that for you, so you get time back to focus on your business.

ShipBob’s inventory management solutions are designed to scale as you grow into new countries and channels, and to always give you deep visibility into and control of your inventory.

“Personally, when I hear about people trying to do their own fulfillment, I’m kind of skeptical. Having gone through that experience of packing orders, I would tell anyone that’s thinking about starting a business that it’s really, really well worth your time to consider partnering with a professional like ShipBob.

A lot of people think, “I don’t need that,” or “I don’t want to waste money on a fulfillment provider.” But in reality, partnering with an expert like ShipBob will free up so much of your time, speed up shipping, and lead to a better customer experience.”

Tyler McCann, Co-Founder of Taste Salud

How Baby Doppler adjusts inventory across regions with ShipBob

Before Baby Doppler started working with ShipBob, they had worked with some large fulfillment providers along with smaller 3PLs. None of them were able to provide them with unified data to get a holistic view of their inventory, so they couldn’t see which inventory was moving and where.

Each fulfillment provider had a different reporting format, each of them incomplete. This meant that Baby Doppler was tasked with the nightmare of piecing all the data together from all these different sources to figure out what was going on.

After partnering with ShipBob, Baby Doppler opted into the Inventory Placement Program. Immediately, they got the visibility and analytics they were looking for: real-time insight into how much inventory to allocate to a specific warehouse, their current on-hand inventory levels, and how long each SKU is going to last by location.

With easily accessible information on inventory movement, Baby Doppler has been able to distribute inventory across 6 ShipBob fulfillment centers without losing track of it. Distributing inventory this way lets them ship 87% of their orders from Zones 1-4, speeding up deliveries and reducing shipping costs.

“I don’t want to have to ask multiple people for information or wait for reports on stock levels at various locations – and with the Inventory Placement Program, I don’t have to. Now, I can literally go into my ShipBob dashboard and see exactly what I want to see with a few clicks.

I love that it’s a quick snapshot of everything that’s going on. I can literally not look at the ShipBob platform for 3 weeks, and then log in and within 10 minutes of analyzing the data, I know exactly where we stand in the business.

Even if I had to crunch some numbers, it would be just pulling a couple of reports and putting that data together – it’s so much easier than other solutions. As a person who relies on data analytics to run my business, I want to see my analytics exactly how ShipBob displays them to me.”

Mithu Kuna, Founder and CEO of Baby Doppler

To learn more about how ShipBob can help your brand track, manage, and optimize inventory, click the button below.

Inventory adjustment FAQs

Below are answers to the most commonly asked questions about inventory adjustments.

What triggers the need for an inventory adjustment?

Theft, damage, misplacement, waste, counting errors, returns, and clerical errors are some of the situations that necessitate an inventory adjustment.

How often should inventory adjustments be made?

Inventory adjustments should be made periodically, either in response to inventory audits, after major sales and promotions, or at least at the end of every financial year.

Can inventory adjustments affect business profitability?

Yes. Accurate inventory counts help prevent stockouts and overstocking, saving a brand money and impacting its bottom line.