Table of Contents

** Minutes

Strategies for managing inventory backlog

Imagine you’re in a very busy restaurant where you seat yourself. You spot a table in the back corner – but when you approach, you realize that it has a “reserved” sign on it. Even though the table is empty, you know not to take it because it is technically already committed to someone else.

Inventory backlogs work the same way. While all the inventory in a brand’s warehouse or fulfillment center is physically present and technically pickable, some of it is already committed to orders that haven’t been fulfilled yet.

An inventory backlog is an inevitable part of running an ecommerce business. However, an accumulation in your inventory backlog can result in supply chain bottlenecks and overwhelm your operations. That means it’s important to keep it in check, and pick, pack, and ship inventory quickly and efficiently.

In this article, we’ll cover what causes an inventory backlog, strategies for managing them, and how expert fulfillment partners like ShipBob can help you tackle an excessive inventory backlog.

What is inventory backlog?

Inventory backlog refers to inventory that has been ordered by a customer and therefore technically spoken for, but has not been shipped to the customer yet. In other words, it refers to the orders that are awaiting fulfillment as well as the inventory units that are allocated to fulfill those orders.

Receiving orders grows your inventory backlog, while fulfilling and shipping out orders reduces it. For example, say you receive 100 orders in one day, each of which require a single unit of inventory. If you do not fulfill any orders by the end of that day, you would have 100 inventory units in your backlog. The next day, you receive no new orders but fulfill 60 of yesterday’s orders. Your inventory backlog would be reduced to 40 units.

Backlogs are a typical part of order management, and will happen as long as your business is receiving orders.

Causes of inventory backlog

Inventory backlogs are a regular part of ecommerce operations, and can be caused by many different factors, including:

- Preorders – One of the most common causes of inventory backlogs is preorders. Businesses may open preorders for upcoming product releases or ahead of the holiday season. As a result, they may accumulate a lot of orders that can’t be fulfilled until inventory arrives from a manufacturer or supplier.

- Demand surge – When demand spikes suddenly, a brand may struggle to efficiently fulfill orders that come in due to capacity and workforce limitations, or they may run out of inventory to fulfill orders with. Both of these scenarios result in inventory backlogs.

- Supply chain disruptions – Businesses may experience inventory backlogs if there are disruptions that create shortages and supply chain bottlenecks. Production delays, transportation issues, natural disasters, and political issues are some common types of disruptions that can lead to backlogs further down the line, and that stall supply chain velocity.

- Internal issues – Businesses may also face internal challenges that inhibit their ability to fulfill orders. For instance, accidents, equipment malfunction, and other unexpected issues can disrupt order fulfillment operations and cause an inventory backlog. Similarly, operational inefficiencies can also be a leading cause of inventory backlogs.

- Inventory tracking errors – Errors in your inventory tracking can increase your inventory backlog. For instance, if your inventory management system fails to update inventory levels as orders are picked and packed, you may mistakenly think that you have more available inventory than you actually do. This not only increases your inventory backlog, but can also lead to costly stockouts and backorders.

- Inaccurate forecasting – Inaccurate demand forecasting may leave you without enough stock to meet customer demand. If your inventory estimate is less than what you actually need, you will run out of stock running out sooner than expected. As a result, you may face an excess inventory backlog, as you don’t have the stock to fulfill those orders.

Implications for ecommerce businesses

An inventory backlog isn’t necessarily a bad thing – in fact, it can be a sign that your ecommerce business is receiving a lot of orders and is growing.

However, problems occur when your inventory backlog becomes excessive. Too much inventory backlog can negatively impact your business in a number of ways.

Lower customer satisfaction

Shipment delays and late deliveries are some of the biggest ways in which unaddressed inventory backlogs can affect your business. If you’re failing to get your customer orders fulfilled fast enough, it means that shoppers will have to wait longer to receive them. This not only impacts your overall fulfillment performance, but also reduces customer satisfaction.

Higher costs

Excessive inventory backlogs are not cost-efficient. The longer inventory sits in your warehouse (rather than being picked, packed, and shipped to customers), the higher your holding costs will be. Additionally, taking longer to fulfill orders only increases your labor costs.

Ecommerce businesses with large inventory backlogs are also more prone to accidentally miscounting or overselling their stock, which can lead to expensive stockouts and lost loyalty from putting customers on backorder.

Slower growth

When your brand can keep inventory moving through your supply chain and fulfill orders at a fast clip, it’s easier for you to grow. Inventory quickly delivers its ROI, efficient processes keep costs down, and customers receive their orders quickly – all of which combine to boost margins and revenue.

A lengthy inventory backlog slows your entire operation down, because inventory gets stuck in limbo. That means your brand cannot recoup its investment as quickly, supply chain processes that require inventory grind to a halt, and customers don’t receive the short wait times they expect. This makes growth much harder and slower.

Strategies for managing inventory backlog

It’s important to keep your inventory backlog in check so that you know how much inventory is available to sell, and so that orders are shipped out on time. Here are some best practices for managing your inventory backlog effectively.

Adopt a robust inventory management system

The most effective way to prevent an excessive inventory backlog is to optimize your inventory management process. As mentioned earlier, inaccurate stock count and demand forecasting are some of the leading causes of a large inventory backlog. When you improve these processes, it helps shorten your backlog and lower the accompanying risks.

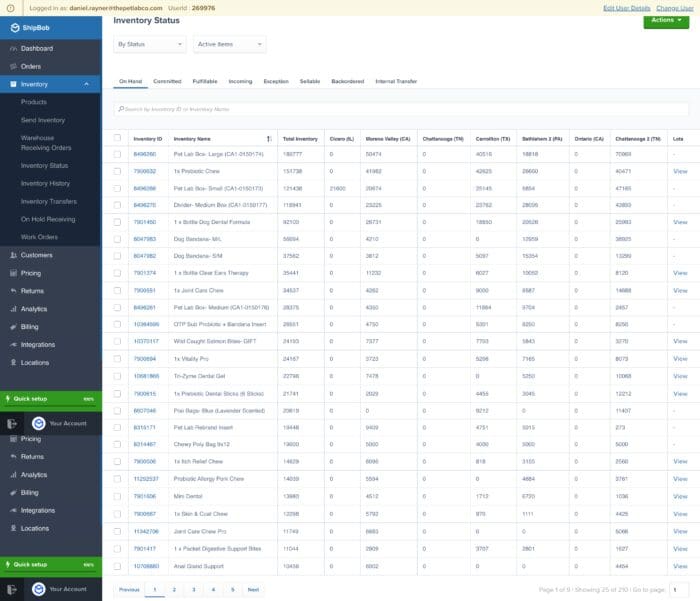

It all starts with implementing a robust inventory management software system that gives you an accurate understanding your inventory levels. Having real-time inventory visibility enables you to correctly assess your stock levels, so you can understand your true inventory needs. This way, you can effectively time replenishment, forecast demand, and prevent issues such as stockouts and surplus inventory.

Your inventory system should be able to tell you exactly when you’re running low on stock for a particular item, send you notifications when stock levels reach a specific reorder point, and automatically track inventory and order data for you over time.

Enhance supply chain communication

Inventory is a critical part of most supply chain processes, so to minimize the impact the inventory backlog has on the rest of your operations, you’ll need to establish transparency and communication between different functions and parties.

Make sure you can get realistic timelines so you know how to plan for replenishment. Proactively communicate with suppliers regarding your inventory levels and replenishment needs. Similarly, ensure that they proactively update you regarding possible shortages and delays as well as unexpected disruptions that could eventually lead to inventory backlogs.

This will give you ample time to plan ahead for possible inventory shortages by finding alternative suppliers. In the event of stockouts, you can also clearly communicate with your customers by marking out-of-stock items so you don’t accidentally sell items that you can’t yet ship out.

Additionally, you should maintain transparency with your customers regarding delivery expectations. This involves sending them timely updates on their shipment status and providing them with real-time ecommerce order tracking. That way, even with inventory backlogs, you can avoid customer frustration by setting realistic expectations and providing visibility.

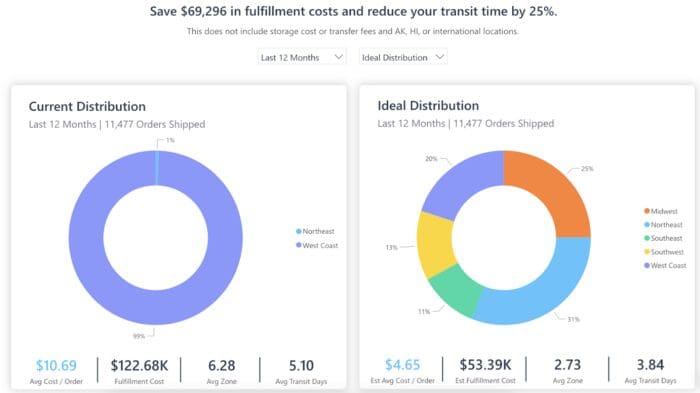

Partner with a fulfillment provider

The easiest way to keep your inventory backlog under control is to outsource logistics to a professional logistics partner that will handle fulfillment on your behalf. This allows you to leave most aspects of inventory management to the experts, including storage, counts, and audits. When you have experts handling these processes, you can streamline the order fulfillment process, improve efficiency, and get orders out the door faster to reduce the size of your backlog.

Expert fulfillment platforms like ShipBob will also be able to integrate with and pull orders from all your channels (DTC, B2B, retail, marketplace, etc.) into a single system, so you know exactly how many orders you have and how much inventory you’ll need to fulfill them.

The right partner will also leverage automation throughout its operations to improve your inventory and order management. For example, ShipBob’s dashboard enables merchants to set up and receive automatic reorder point notifications for each SKU, so you know exactly when you need to reorder and have enough inventory to support your backlog.

How ShipBob tackles backlogs and inventory management

With industry-leading fulfillment services and proprietary technology, ShipBob provides ecommerce merchants with solutions to effectively manage inventory and prevent excessive backlogs.

Real-time inventory management

ShipBob’s inventory management system comes with real-time inventory tracking capabilities. This helps you keep track of your inventory levels across your entire supply chain. With this level of visibility, you can get an accurate picture of your actual inventory needs and plan your supply chain and procurement accordingly.

Combined with reorder point notifications, this type of real-time inventory visibility helps you make timely replenishments, so you always have sufficient stock to meet customer demand.

Moreover, ShipBob’s dashboard provides you with inventory analytics to deliver SKU-level insight into inventory performance. Based on this data, you can better forecast demand more accurately, optimize your product mix, and allocate inventory strategically across ShipBob’s network.

Fast and accurate fulfillment

Getting inventory picked and packed correctly and clearing orders from your queue quickly are ShipBob’s specialties. With 99.95% accuracy rate in fulfilling orders, your brand can trust ShipBob’s combination of best practices, technology, and expertise to fulfill your orders the right way – and with 99.8% of orders shipping on time within their SLA, you can also trust that inventory will get out of your backlog and into customers’ hands quickly and cost-effectively.

Success stories: How ShipBob helps

Here’s how real ecommerce brands used ShipBob’s solutions to reduce inventory backlog and scale their businesses to new heights.

Taste Salud

When Taste Salud sold their first 500 units within a couple of hours, the co-founders were thrilled – until they realized they had to fulfill them all by hand. Their inventory and order backlog were sizable, and once they realized that self-fulfillment wasn’t going to be a scalable option, they partnered with ShipBob.

Within the first six months, ShipBob helped Taste Salud fulfill $350k worth of orders. In 2022, this scaled to $4 million in sales, which more than tripled in 2023. Throughout all this, ShipBob managed to fulfill these orders with zero hiccups.

“I’ve been to multiple ShipBob locations, and I’ve seen how much they’ve invested into automation and how organized everything is. It’s no wonder that orders get out within 24 hours of being received – ShipBob is really good at what they do.”

Tyler McCann, Co-Founder of Taste Salud

Earthley

When Earthley was fulfilling a few thousand orders per month, they were able to handle everything themselves. But as the business scaled to more than 10,000 orders per month, they started experiencing issues as the system they were using couldn’t handle the complexity and scale of their operations.

The brand hit their breaking point in 2022 when they took an average of five days to prepare their orders for shipping. They sometimes even needed to touch the same order 10 times, and shipping each package required too much labor.

Since they started using ShipBob’s WMS to power their in-house operations, the Earthley team has been able to double (if not triple) their warehouse productivity. Because orders are getting processed, fulfilled, and shipped more seamlessly, they’ve been able to cut four days of lead time, with orders taking only 0.8 days to ship on average.

When they initially started using ShipBob’s solutions, they were shipping out about 15,000 orders per month. Now they’re processing 30,000 orders per month, with no signs of slowing down.

Food Huggers

In January of 2021, Food Huggers appeared on The Today Show. This led to a 786% increase in weekly average order volume, which threatened to hugely increase their inventory and order backlog – but because they partnered with ShipBob for fulfillment, they were able to fulfill 97.3% of their orders on time despite the crunch.

After the sudden spike, the brand continued to see an increase in orders. Even then, ShipBob’s fulfillment pace remained consistent, with an OTIF fulfillment rate of 98.2% for the rest of the month. This meant that inventory wasn’t sitting on shelves in a backlog, orders weren’t dawdling in queues, and even resulted in a 497% growth in sales month over month.

“Spikes in order volume can happen at any time, so knowing that our 3PL partner is able to manage huge peaks in business and fulfill thousands of orders in a short time if needed is priceless. With ShipBob, we’re not afraid of going viral! We’re not afraid of blowing up, because we know that ShipBob will be able to handle surges in demand.”

Juliana Brasil, Director of Operations at Food Huggers

Want to learn how ShipBob can help you cut your brand’s inventory backlog? Click the button below to get in touch with someone on our team.

Inventory backlog FAQs

Below are answers to the most commonly asked questions about inventory backlogs.

What’s the difference between backlog vs. backorder?

Backlogs refer to inventory that has been ordered and is therefore “spoken for,” but has not been shipped out yet.

Backorders occur when a customer places an order, but the business does not have one or all of the inventory items in stock (or the units are in-stock, but already committed to earlier orders), and thus cannot yet fulfill the order.

This means that all backorders are a part of inventory backlogs, but all inventory backlogs aren’t necessarily backorders.

How does an inventory backlog affect business operations?

An inventory backlog isn’t necessarily a bad thing, but if it is too large, it can lead to fulfillment and delivery delays, which impact customer satisfaction. Excessive backlogs also slow down your operations and increase your overhead due to higher storage and labor expenses.

How does ShipBob help manage inventory backlog?

ShipBob helps manage inventory backlog for merchants by providing real-time inventory visibility that shows accurate inventory levels, so you know when to reorder so you can stay stocked. ShipBob’s inventory analytics and metrics also help you forecast demand, optimize your product mix, and manage your inventory to minimize your backlog.

Can ShipBob integrate with my existing ecommerce platform?

ShipBob integrates with several major leading ecommerce platforms and marketplaces. Check out the full list of ShipBob integrations to see if ShipBob integrates directly with your existing ecommerce platform.