Table of Contents

** Minutes

Understanding inventory movement in ecommerce

Inventory movement challenges facing ecommerce brands

How to track and report on inventory movement

Imagine this: you run a two-for-one sale on your ecommerce store. Your most popular SKU is selling quick, but you’re not recording sales as they happen. As a result, customers end up placing orders even after you’ve sold your last piece of inventory, leaving them on backorder and disgruntled.

To avoid scenarios like this, it’s important for ecommerce businesses to track inventory movement. When you know exactly how your inventory is moving through your supply chain – from the moment it’s received to the moment it’s delivered to the customer’s doors – you can manage your inventory more effectively and make more strategic business decisions.

In this article, we’ll take a closer look at how brands can track inventory movement, its challenges, and how experts like ShipBob can help.

Understanding inventory movement in ecommerce

Inventory movement in ecommerce refers to any movement of inventory items that occurs throughout the supply chain. This includes when inventory is:

- Received at the warehouse from manufacturers or suppliers

- Transferred between warehouses

- Stored

- Sold

- Picked

- Packed

- Handed off to last-mile carriers

- Shipped

- Delivered to the end customer

- Returned

Inbound inventory movement will increase the quantity of available inventory in your inventory records, as it accounts for the movement of inventory into your warehouse. Conversely, outbound inventory movement will decrease the quantity of available inventory in your inventory records, as it accounts for inventory depleting or leaving your warehouse.

Inventory movement reporting refers to the act of recording all inventory transactions, including receiving, transfer, sale, shipping, and return. This report typically includes a code that indicates the movement type, along with the source and destination location, so ecommerce warehouses can accurately follow an inventory piece’s journey.

How does inventory movement relate to inventory management?

To effectively manage your inventory, you need to have an accurate understanding and record of how much inventory you have – and to achieve accurate inventory counts, you’ll need to track inventory movement.

As inventory moves in and out of your warehouse and undergoes various warehousing processes, your inventory count can fluctuate. If you fail to keep track of these inventory transactions, these fluctuations can easily fly under the radar and lead to inaccurate inventory counts – so it’s important to track inventory movement at all times, so you can prevent costly discrepancies in inventory levels.

The role of inventory movement reporting in ecommerce

Inventory movement reporting is key to keeping your operations running smoothly and efficiently. When you know exactly how your inventory is moving and how much stock you have at which stage of your supply chain, you can:

- Prevent overstocking and stockouts: By tracking inventory movement, you will know when products you are running low on and which you have plenty of. This enables you to replenish inventory in time (to avoid stocking out) without ordering too much.

- Catch inventory shrinkage: If you consistently track inventory movement, you will be able to quickly notice discrepancies that come up due to lost, damaged, or stolen inventory.

- Balance inventory distribution across your network: If your brand uses multiple fulfillment centers, keeping a record of what inventory is sent to which facility allows you to forecast ideal inventory levels for each location. You can then make sure that every fulfillment center has enough inventory to operate.

- Avoid overselling and backorders: By tracking inventory as it’s sold, you know when you’ve run out of stock. That way, you can close sales for that product and avoid accidentally selling stock you don’t have.

Inventory movement challenges facing ecommerce brands

Tracking inventory movement is important – but it can also be tricky. There are several challenges that many ecommerce brands face when monitoring and recording inventory movement.

Lack of visibility

A lack of inventory visibility hinders your ability to track inventory movement in real time. Often resulting from the use of outdated technology and warehouse management systems, a lack of visibility means you’re unable to see where stock is or how it’s moving at all times.

If you can’t see how many units are available at different areas of the warehouse or which units are transferred to a specific department, you can’t accurately report on inventory movement.

Before partnering with ShipBob for order fulfillment, we had a lot of trouble getting visibility into inventory movement. We worked with some large fulfillment providers as well as some smaller 3PLs, and none of them gave us unified data, let us look at inventory holistically, or enabled us to see which inventory was moving and where.

Partnering with ShipBob finally gave us the visibility and analytics we were looking for. We get real-time insight into how much inventory to allocate to a specific warehouse, our current on-hand inventory levels, and how long each SKU is going to last by location. ShipBob provides a lot of distribution metrics, and everything presented is useful.

Mithu Kina, Founder and CEO of Baby Doppler

Manual tracking errors

Many brands try to track inventory movement by hand, using programs like Excel or even pen and paper. However, manual inventory tracking comes with a high risk of inaccuracies in your inventory movement reporting.

Mismatches between your inventory records and your physical inventory levels are easy to make or even miss, and can lead to backorders, stockouts lost sales, cancellations, and stockout costs that could affect your bottom line.

Any inventory discrepancy we have is easily traced back to human error and our shipping costs remain lower than before we started with ShipBob.

Tom Wall, Vice President of Global Warehousing & Logistics at Beachwaver Co.

Inefficient warehouse layouts

If your warehouse has a busy, crowded, or confusing layout, it can be hard to track inventory movement across various stages or functions.

For instance, if your warehouse setup requires inventory to constantly move back and forth between different areas of the warehouse, there’s a higher risk that the movement will get recorded inaccurately. You might end up failing to record or double-recording some transactions as you transfer stock items between these locations.

Onboarding with ShipBob’s WMS was our first time connecting to a warehouse management system, so we had to get data and SKUs synced with the platform, do warehouse mapping, and get our various integrations (like Shopify and NetSuite) set up. Once everything was in place, we just had to flip a switch to start fulfilling orders. The ShipBob team even came out to our facility for a week to show us how to do everything. It was a super straightforward process. It’s a very plug-and-play solution that is also customizable to our workflows.”

– Jourdan Davis, Operations Manager at Pit Viper

How to track and report on inventory movement

Tracking and recording every inventory transaction isn’t always easy, but there are ways that brands can make monitoring inventory movement simpler, more streamlined, and more accurate. Here are some vital tips to help you track and report on stock movements.

Adopt lean inventory practices

Keeping your supply chain lean simplifies inventory movement reporting, as it helps eliminate unnecessary activities or processes involving inventory. With fewer movements to keep track of and more straightforward processes, it is much easier to maintain accurate inventory records.

For example, adopting lean inventory practices may involve buying just the right amount of inventory to meet demand (so there is less inventory to keep track of overall), or implementing a cross-docking strategy to eliminate putaway and storage processes.

In both of these cases, you’re reducing the amount of time inventory sits idle in your warehouse. Meanwhile, the only movements that take place are vital for your ecommerce operations, which simplifies the tracking process. You’re also minimizing the risk of dead stock that could complicate your inventory movement reporting.

Warehouse layout optimization

Optimizing your warehouse layout helps you streamline the movement of goods across your warehouse. When inventory moves in a logical flow through distinct, proximal areas in a warehouse, tracking that movement is much simpler.

A warehouse layout conducive to inventory tracking often features:

- Distinct areas that house each function or activity, with each station located nearby the next logical activity’s area (for example, receiving docks being located nearby the storage area)

- A clear, intuitive labeling system

- Adequate space to separate and distinguish one area from another, and to ensure that workers can navigate the floor quickly and safely

If your warehouse layout is optimized accordingly, you can reduce the back and forth between different processes that could otherwise confuse your tracking efforts. Layout optimization allows your warehouse staff to move seamlessly between different locations, which also simplifies the process of tracking inventory movement.

Moreover, layout optimization improves the efficiency of your warehouse operations so inventory can quickly move through the supply chain. Staff can easily find and retrieve the items they need, and deliver them to the correct areas without hassle or confusion.

Leverage automation and robotics

Manual inventory tracking is prone to error and could create inaccuracies in your inventory movement reporting. This makes it crucial to adopt more sophisticated technology to help you automate the inventory tracking and recording processes as much as possible.

Consider using inventory scanners to automatically capture inventory data as an item moves through the supply chain. These scanners read information on barcodes that are attached to products or packages, so every time the inventory gets transferred or reaches a particular destination, the scanner automatically records the change and sends that information to a central database. This significantly reduces the need for manual work while reducing human errors and paperwork.

RFID tags can also be used for tracking inventory movement. They can store more information than barcodes and can be read from a distance. They’re ideal for tracking bulk inventory movement, providing you with automatic and real-time visibility to improve traceability.

You may also make use of sensors and IoT devices to further improve visibility while boosting inventory control. For example, GPS trackers can show you exactly where your in-transit inventory is located. Meanwhile, temperature sensors can provide you with alerts in case inventory is exposed to extreme temperatures so you can quickly take action to prevent damage.

Many warehouses also make use of robotics to automate their inventory movement and tracking processes. Some robots are even equipped with advanced sensors to scan barcodes and RFID tags and provide you with real-time inventory tracking as they transport products between different warehouse locations.

Implement an inventory management system

Finally, it’s crucial to have a centralized inventory system for recording and managing all your data. An inventory management system provides a single dashboard where you can track all sorts of important inventory functions, including inventory movement.

Look for a cloud-based solution that runs on the internet rather than on a local server or computer so you can easily sync all your inventory movement data from across the warehouse. The software should also integrate directly with your barcode scanners and RFID tags (as well as other data sources) so any inventory movement data that’s captured across various channels, locations, and platforms is automatically recorded and tracked in one place.

ShipBob: Your inventory management partner

As a leading ecommerce enablement platform, ShipBob offers brands powerful cloud-based inventory management software to streamline inventory tracking and accurately record your inventory movement. Here are just some of the capabilities that ecommerce brands can unlock by leveraging ShipBob’s solutions.

Inventory management and distribution

There are so many different facets to inventory management, and ShipBob helps your brand with them all.

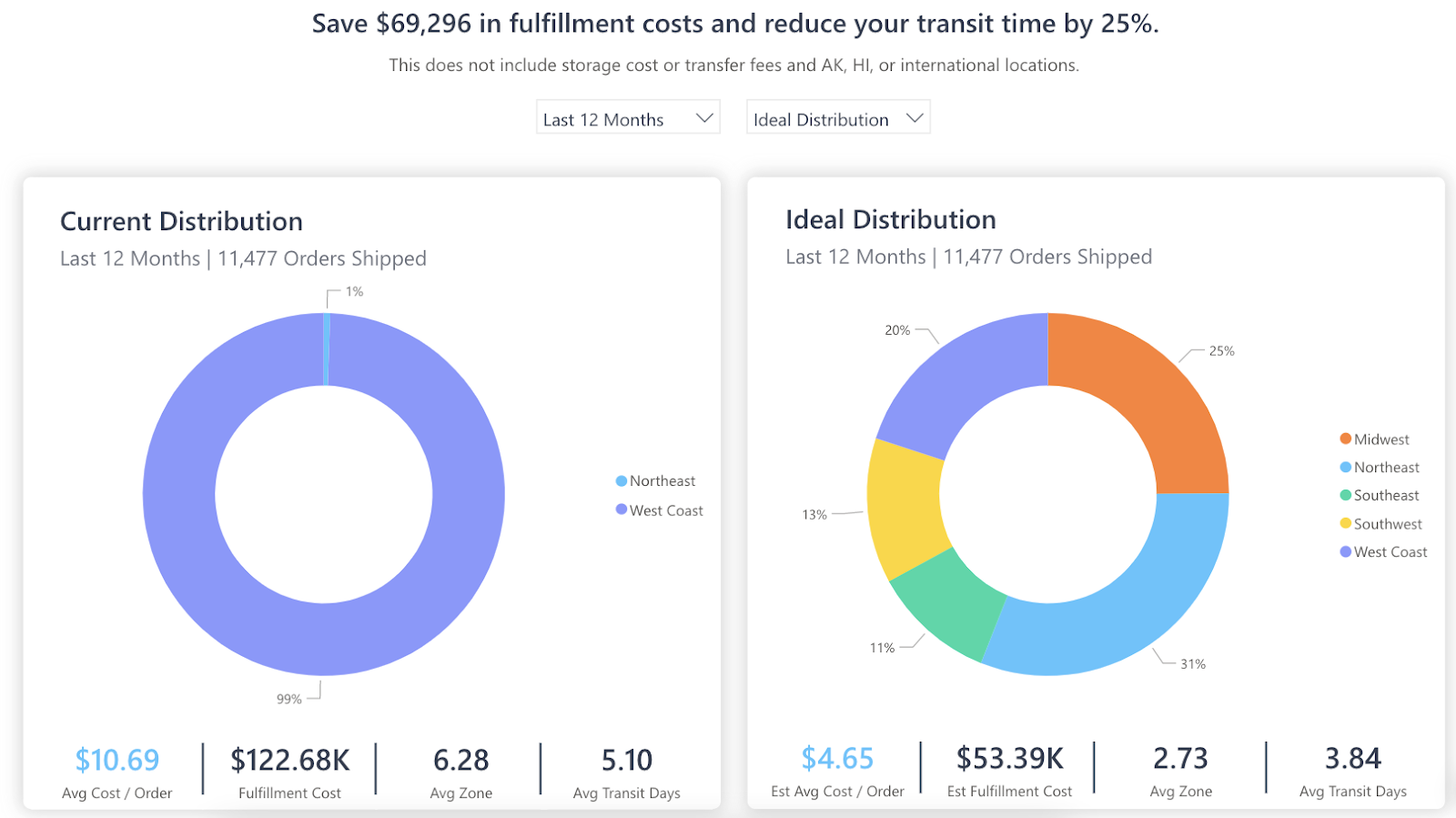

Before your inventory even reaches a warehouse, brands can leverage ShipBob’s Ideal Distribution tool to determine the most strategic allocation and distribution of inventory across ShipBob’s fulfillment network (and through ShipBob’s Inventory Placement Program, ShipBob will even physically distribute that inventory for you).

Once your inventory arrives at a ShipBob fulfillment center, ShipBob’s team takes care of receiving, storage, picking, packing, and shipping on your behalf – all of which you can monitor through your ShipBob dashboard.

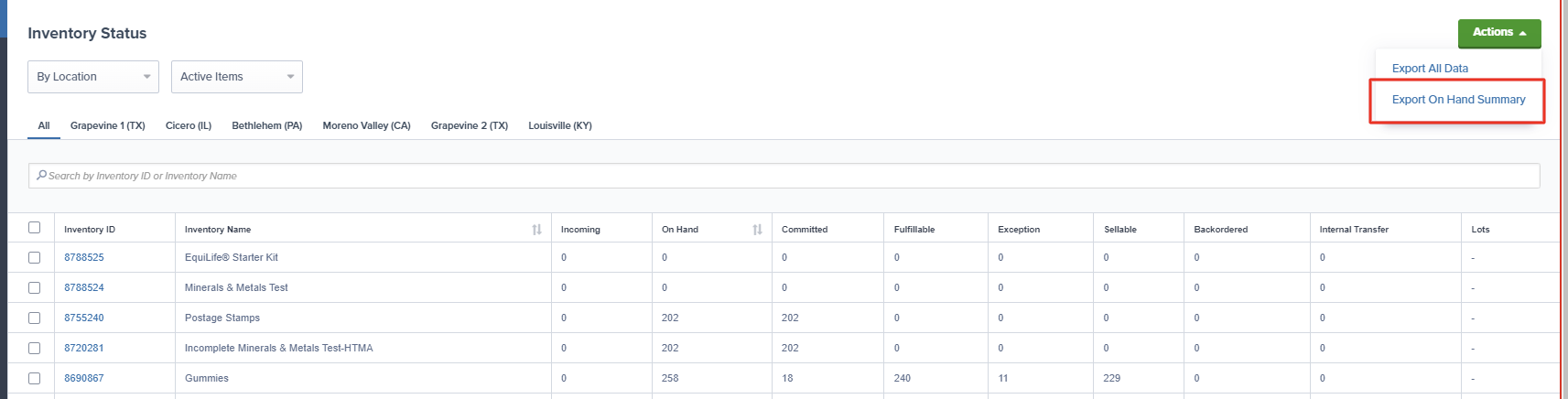

ShipBob’s dashboard offers advanced inventory management functionality that goes beyond simply tracking inventory levels. It enables you to:

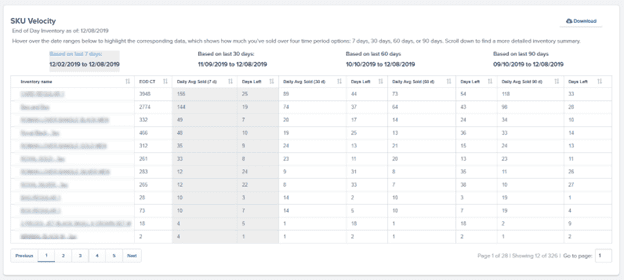

- View SKU velocity to easily understand which SKUs are performing well and which ones are moving slow, and manage product assortment accordingly.

- Set automatic reorder point thresholds for each SKU and receive automatic reminders to time purchase orders, production orders, and replenishment perfectly.

- Track SKU performance across locations and channels.

- Monitor inventory spend, including storage and average fulfillment costs.

Real-time inventory tracking and forecasting

ShipBob’s dashboard provides real-time insights into inventory levels across all locations. You’ll be able to see how many units are in stock, and see inventory counts at each stage of the fulfillment process. This goes a long way to ensuring that your inventory records are accurate, allowing you to proactively manage your inventory levels and prevent stockouts.

For example, even if you have a certain number of units left in stock physically, some of those units may already be wrapped up in orders that are shipping out soon. Without this granular degree of visibility, it’s easy to accidentally sell inventory you don’t have – but ShipBob’s dashboard gives you the up-to-date data you need to make strategic inventory decisions and stay stocked.

Additionally, ShipBob’s dashboard automatically records historical sales data that your brand can use to help you forecast demand more accurately in the future. That way, you can avoid ordering too much or too little inventory while replenishing inventory at just the right time.

Industry-leading warehouse management system (WMS)

ShipBob’s industry-leading warehouse management system (WMS) is designed to streamline inventory movement in not just ShipBob’s warehouses, but also a merchant’s.

The system serves as a single source of truth to help manage every aspect of your warehouse, ensuring that orders are fulfilled accurately and swiftly by minimizing manual processes and giving real-time visibility into your warehouse operations. It also helps to reduce mis-picks by allowing workers to easily cross-check their inventory picks for accuracy, thus minimizing discrepancies and significantly improving your inventory accuracy.

For more information on how ShipBob’s outsourced and in-house solutions can help you track, manage, and optimize inventory movement, click the button below.

Inventory movement FAQs

Below are answers to the most common questions about inventory movement.

What are the types of inventory movement?

Inventory movement refers to inventory receiving, transfer between warehouses, storage, sale, picking, packing, shipping, delivery, and returns.

How does ShipBob help with inventory movement?

ShipBob helps with inventory movement by providing real-time visibility into your stock levels at the SKU level across various locations. This visibility helps you track inventory movement in real-time and automatically records the information, minimizing the need for manual tracking and reporting.

Can ShipBob integrate with my ecommerce platform?

ShipBob offers direct integrations with leading ecommerce platforms, including Shopify, BigCommerce, Magento, WooCommerce, and more. Check out the full list of ShipBob partners to see if it integrates with your ecommerce platform.