Table of Contents

** Minutes

The benefits of implementing inventory pooling

Challenges and considerations in inventory pooling

Your ecommerce business is ready to expand into new channels and locations. You decide that every time you enter a new state, you’ll set up a warehouse in that state to serve those customers. Similarly, every time you start selling on a new channel, you’ll open up a dedicated warehouse that holds inventory for just that channel.

But very quickly, you realize you’re in over your head. Running all these facilities is expensive, you have a ton of surplus inventory, and managing different inventories is eating up all your time.

This scenario is why many ecommerce brands pool their inventory. Inventory pooling keeps inventory management simple, streamlined, and cost-effective, making it easier for you to run a successful business.

In this article, we’ll dive deep into what inventory pooling is, its benefits and challenges, and how an omnifulfillment partner like ShipBob can help you execute it.

What is inventory pooling?

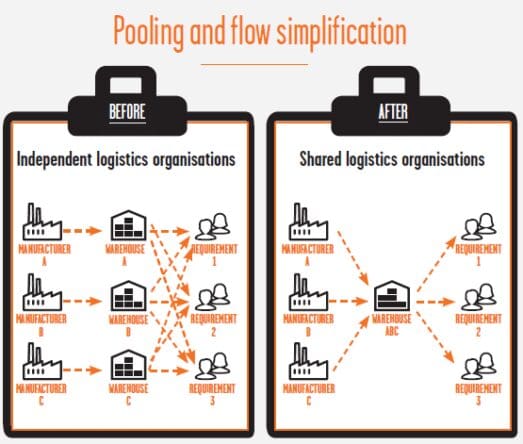

Inventory pooling is an inventory management strategy in which a brand maintains a “pool” (or supply) of stock that serves multiple different locations and sales channels. In other words, orders bound for multiple different locations and orders placed across different channels are all fulfilled from the same shared supply of stock.

Through inventory pooling, businesses can ensure better stock availability while keeping less inventory on hand. This helps prevent stockouts and keeps warehousing costs low simultaneously.

How does inventory pooling work?

In inventory pooling, multiple distribution points (particularly delivery locations and sales channels) share the same supply of inventory. Instead of having to maintain a separate warehouse space for each distribution, you’re fulfilling orders from one big pool of inventory.

If an ecommerce brand has multiple manufacturers or suppliers, every vendor sends the inventory to this centralized pool. The ecommerce brand then distributes the inventory across various sales channels, stores, and locations, according to demand. This streamlines the flow of inventory and reduces the complexities associated with supply chain management.

Say, for example, an online shoe brand receives orders from customers in New York, Los Angeles, and Chicago. Rather than operating three separate facilities (one in each state), the brand instead pools its inventory in a single, centralized warehouse in Chicago and fulfills all its orders from this warehouse.

This same online show brand also sells across multiple channels, including its ecommerce store, through online marketplaces, and through social media platforms. When it pools its inventory, the brand fulfills all orders from the Chicago facility, regardless of which channel the order came through.

Centralized vs. decentralized inventory pooling

There are a couple ways to implement inventory pooling in your own ecommerce business. The two most common inventory pooling models are centralized and decentralized pooling.

Centralized pooling

Many businesses centralize their inventory in the literal sense, meaning that they store their entire inventory in a single location, even if they have a multi-channel distribution strategy.

From a single fulfillment center, they ship inventory as needed to various end destinations. Orders on ecommerce websites and marketplaces may also be fulfilled to the end consumers directly from this one warehouse.

Decentralized pooling with centralized management system

Alternatively, some businesses may also distribute their inventory across multiple warehouses or fulfillment centers. Each of these facilities acts as its own mini inventory pool, and usually serves customers across multiple cities, states, and channels.

However, this pooling approach only works if the brand uses a centralized inventory management system or software to track, record, and manage their total inventory across all locations. This ensures that, even if you leverage multiple fulfillment centers, you’re still getting a comprehensive view of your whole inventory.

The benefits of implementing inventory pooling

There are several advantages to inventory pooling, particularly when it comes to efficiency, cost, and customer satisfaction.

Enhanced efficiency and cost control

One of the biggest benefits of inventory pooling is its efficiency. Having a shared warehouse for all your distribution points allows you to streamline your processes to save time and minimize complexities.

Moreover, there’s a huge cost benefit to storing your inventory in just one place. It means you don’t have to spend money on holding costs and warehouse space at each and every distribution point, which would be extremely expensive.

If you take a decentralized approach to inventory pooling, you will have to pay more to run multiple fulfillment centers. However, if your order volume, average order value (AOV), and margins are high enough, the money you’ll save on shipping costs can offset the extra storage and transportation costs.

Greater customer satisfaction

Inventory pooling also helps brands maintain better inventory availability to meet consumer demand. Even if one location or channel experiences higher demand than the others, you won’t have to worry about stocking out – since all units are coming from the same supply, you can keep fulfilling orders as long as the pool has enough inventory.

Similarly, inventory pooling prepares you for demand uncertainty since you can quickly respond to any fluctuations using this pool. This allows for fast fulfillment and helps you avoid stockouts, thus enhancing customer satisfaction.

Challenges and considerations in inventory pooling

As beneficial as inventory pooling may be, it also comes with a few challenges that you’ll need to consider before you implement it in your own retail inventory strategy.

Initial setup costs

Since your inventory is shared between multiple locations and distribution points, you’re naturally going to need a large pool of stock to satisfy all available channels. This means your initial inventory investment may be much higher when you’re pooling inventory, not to mention the added costs associated with maintaining an expansive warehouse space to store all this inventory.

Increased management complexity

Another key consideration is the added complexity that comes with multichannel inventory management. You need to ensure that inventory levels are balanced and updated in real time according to orders placed across all your sales channels, so that you don’t accidentally oversell your stock and create lengthy backorders.

Often, an effective omnichannel order management solution can help you streamline this process and keep orders flowing through your supply chain efficiently.

Demand forecasting requirements

You’ll need accurate demand forecasting to ensure that you have enough inventory on hand to meet demand across locations and channels from a single pool of inventory.

To achieve accurate forecasts, closely monitor the sales history, market trends, and demand patterns across all distribution points to make an educated guess as to the ideal amount of inventory you’re going to need.

ShipBob is the ultimate inventory management advantage

When implemented correctly, inventory pooling is a highly effective way to maintain stock availability and prevent stockouts while reducing inventory costs – but to pull it off, many brands turn to experts like ShipBob.

Here are just some of the ways that ShipBob’s industry-leading inventory management software and outsourced fulfillment solutions can help you optimize your inventory strategy while saving money and time.

Distribute inventory across 50+ global fulfillment centers

When you partner with ShipBob, you can pool and store your inventory in one or multiple of our dozens of fulfillment centers across the US and around the world.

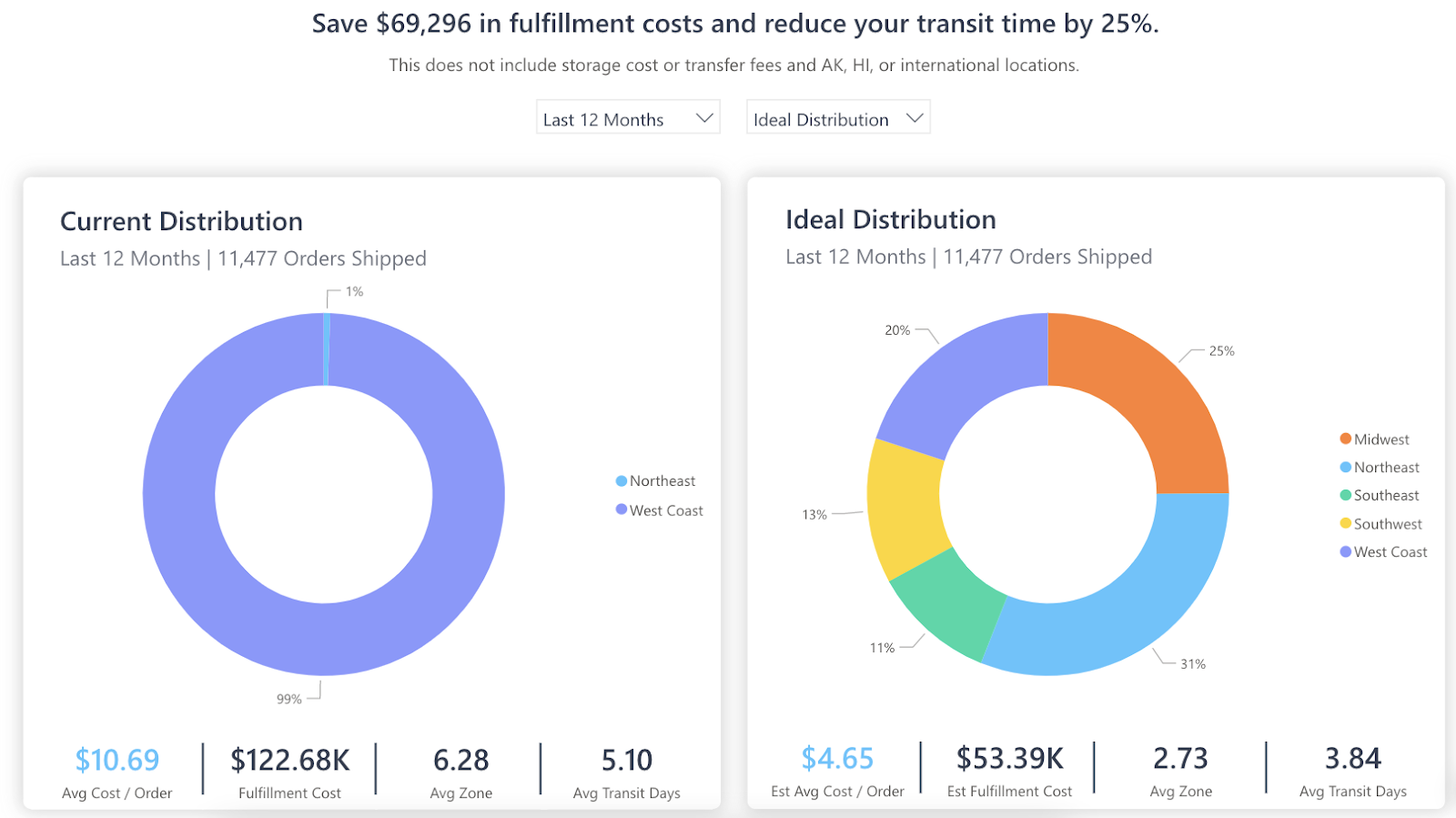

Leveraging this network, you can place your inventory pools closer to end customers. This allows you to lower the average shipping zone you ship to, minimizing both shipping costs and times to help you deliver a delightful experience for customers while achieving cost savings.

Through the Inventory Placement Program, ShipBob will even physically receiving and distributing your inventory across our network. Simply send your inventory to a single ShipBob hub facility (saving you the cost of multiple inbound freight shipments), and we’ll take care of sending it to regional fulfillment centers for you.

Since launching in the program, we’ve been able to allocate our inventory across 4 of ShipBob’s fulfillment centers in the United States, which cut our shipping times by a third – from 5.2 days down to about 3.6 days. Not only has transit time dropped, but at the same time we reduced fulfillment costs by over $2 per order compared with our old 3PL. This combination has been key to profitable growth this year.

And the cost to split inventory this way? It’s a no-brainer. It costs less for us to deliver all inventory to one location that’s close to our manufacturer partners in NJ, and let ShipBob take care of splitting the inventory between the four different warehouses than it would for us to ship and handle logistics ourselves.

Matt Crane, Co-Founder and Chief Science Officer at Semaine Health

Strategic inventory allocation

ShipBob won’t just help you distribute your inventory to pools – we’ll help you decide how much to pool where.

Using ShipBob’s Ideal Inventory Distribution tool, you can calculate the most strategic and cost-effective allocation of inventory based on your past order data. That way, you can send inventory to the right locations to not only meet demand, but also fulfill orders from the most optimal fulfillment center locations and reduce your average cost per order and average transit time.

One of the best parts of the Inventory Placement Program is how easy it makes inventory allocation. ShipBob manages inventory distribution for us, meaning, they choose the best locations for us, cross-dock our inventory, and see that it arrives at the ideal locations. All we have to do is send inventory to one ShipBob location through a WRO (or warehouse receiving order, which lets ShipBob track our inbound inventory, mark it as arrived, and stow it away), and they do the rest!

The program even recommends our ideal inventory split across fulfillment centers over time as our customer base shifts, based on our order data and inventory levels. It’s made things really simple and streamlined, because we can make sure that the right products and quantities are shipped without having to do the calculations ourselves. It also reduces a lot of man hours on our side, which allows us to focus on other strategic priorities.

Mithu Kuna, Founder and CEO of Baby Doppler

Real-time inventory tracking

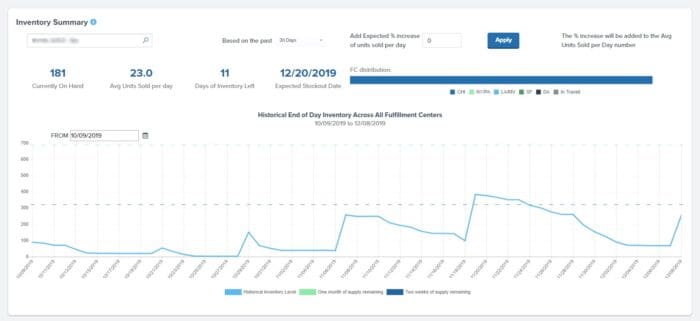

ShipBob’s dashboard provides real-time inventory visibility, so that you always know what’s going on with your inventory at any time, in any facility.

With real-time inventory tracking, you can improve inventory control and see exactly how many units of you have in stock. That way, you can quickly identify when you need to replenish different products to avoid stockouts.

Being able to see how much inventory you have at all times also helps prevent overstocking. ShipBob’s inventory management system keeps track of your inventory levels at various parts of the warehouse including your safety stock and buffer inventory, which means you can avoid ordering excess inventory that could quickly turn into dead stock.

Automated reorder points

With so much else on your plate, ShipBob helps brands leverage automation to streamline key aspects of inventory management such as inventory replenishment.

Once you calculate the ideal order quantity using the reorder point formula, ShipBob enables you to set automatic alerts so you’re instantly notified when stock levels reach a certain threshold. This way, you can reorder stock at the perfect time and avoid costly backorders and stockouts.

To learn more about how ShipBob can help you optimize your inventory pooling and management, click the button below to get in touch.

Inventory pooling FAQs

Below are answers to the most commonly asked questions about inventory pooling.

What is risk pooling in inventory management?

Risk pooling in inventory management refers to the pooling of inventory resources to reduce risks associated with uncertainties and demand variabilities.

Can inventory pooling be applied to all types of products?

Inventory pooling may not necessarily be applicable to all types of products. For example, inventory pooling may not be wise for perishable products, as there’s a higher risk of spoilage.

How does inventory pooling impact order fulfillment times?

Inventory pooling can sometimes reduce fulfillment times as it helps to maintain inventory availability, which allows businesses to quickly fulfill orders.