Inventory Storage Guide

Storing inventory is a necessary part of running any business that sells physical goods. The storage needs will vary from business to business, based on sales volume, product attributes, and locations sold.

As an ecommerce business, it can be tough to know which inventory storage system is the best for your business. Between self-storage, warehousing and third-party logistics (3PL) providers, how exactly do you know which option is right for you?

A cost-effective inventory storage system helps you manage your inventory to meet customer expectations, while allowing room for your business to grow.

So, what do you want to learn?

Request Fulfillment Pricing

Let’s talk. Our experts can help you boost your order volume by 30% year over year.

A fulfillment expert will get back to you shortly. Privacy Policy

What are inventory storage solutions?

Inventory storage solutions are systems that help businesses store, manage, and track inventory. These systems typically involve physical equipment, such as racks, shelves, pallets, and bins.

Inventory storage also involves strategic planning, as every business will need to decide on their approach to storing inventory.

For example, a business may adopt the “first-in, first-out”, or FIFO method of storing inventory, where the oldest inventory in storage is always sold before newer inventory. Alternatively, a business may use the “last-in, first-out”, or LIFO approach, where the newest inventory is always sold first.

Which system a brand uses affects how and where a brand stores its inventory (in easily-reachable warehouse locations vs. less trafficked, less easily-accessible areas, for instance), and for how long inventory is stored – so before purchasing any equipment, brands will need to consider their overall strategy.

There are several different ways to store inventory and properly manage it: self-storage, traditional warehouses, and partnering with a 3PL.

3 inventory storage solutions

The inventory storage system you pick will depend on the size of your business. When you are first starting out, you will likely store your inventory at home: in your garage, basement, or somewhere else. For more established businesses, storing inventory in a warehouse or partnering with a fulfillment provider is a better option. Here are pros and cons to all three inventory storage options.

1. Self-storage

When you are first starting your business, self-storage is a likely choice. Since you won’t have the funds to pay for ecommerce warehousing (or massive amounts of products to store), you’re going to store your inventory however way you can. It could be anywhere, such as your place of business, your closet, a storage facility, or at home.

Pros

- Cheap (or “free”)

- Easy to access

- Great for starting out

Cons

- Inefficient and frustrating

- Leads to storage miscalculations

- Risk of damage and loss

- Doesn’t scale as you grow

Overall, as your business starts to grow, self-storing becomes more of a challenge. Once you start to fulfill more orders per month, you’ll want to consider other options.

2. Traditional warehousing

Traditional warehousing is used by growing ecommerce businesses. You pay for a location where you can send your inventory before it gets picked for shipping. This can be in a storage unit, small warehouse, or even purchasing land and building a facility yourself.

Pros

- More professional than self-storage

- Full control over handling your inventory

Cons

- In 2023, logistics warehouse tenants can expect to see a 10% rate hike.

- Must hire a workforce to fulfill orders.

- Might quickly outgrow the space or never fully grow into it

- Might not be the most optimal location to reach the majority of your customers

Overall, you’re still responsible for acquiring inventory tracking and other order management tools, certifications, equipment, insurance, shipping supplies, and fix and maintain everything.

Taking traditional warehousing a step further is on-demand warehousing, or a technology platform that helps you find excess warehouse space but doesn’t run any fulfillment centers.

3. 3PLs

When you outsource fulfillment to a 3PL, you’re able to store your inventory and pick, pack, and ship your direct-to-consumer orders. 3PLs do the work for you and you’re not responsible for running a full-scale operation.

3PLs are inventory and fulfillment experts that have years of experience and the resources available to store your inventory, while managing other aspects of your shipping and retail fulfillment to maximize efficiency and get orders out as soon as possible.

Pros

- They store your inventory and perform all fulfillment services on your behalf

- Most 3PLs have multiple fulfillment centers to optimize your deliveries and save on shipping costs

- Access to inventory tracking and management tools

- Fast shipping and ability to affordably reach your customers

- Inventory warehousing security

- Easy implementation and likelihood of supply chain optimizations

- Provide fulfillment expertise, resources, and partners

Cons

- You give up control over inventory

- More expensive than doing everything yourself

Overall, you don’t have to become a logistics and warehouse management expert, and you get more time back to focus on growing your business rather than dealing with inventory and packing boxes.

The best inventory storage option

There are several options when it comes to storing inventory. With self-storage, warehousing, and 3PLs offering a variety of pros and cons, it can be tough to know which option is the best for you. Many businesses start with self-fulfillment and then move to a 3PL.

[Related article: Should You Invest in Your Own Warehouse, or Outsource to a 3PL?]

Unlike self-storage and warehousing, storing inventory with a 3PL puts your inventory exactly where it needs to be when shipping to customers. Thus, minimizing steps in your system to get packages out and improves overall efficiency.

3PLs like ShipBob offer leading shipping services and inventory management, while being easy to work with due to their technology and general expertise in all things shipping, inventory and warehousing.

7 types of inventory storage & methods

Once you decide what your brand’s storage strategy will be, you will also need to consider what type of inventory storage you need. There are many different varieties of inventory storage, each of which may involve different procedures and equipment.

Here are some of the most common inventory storage methods for ecommerce businesses.

1. Warehouse storage

Warehouse storage is the go-to solution for most brands that have outgrown their initial launching space (usually a garage, office, or living room). Most ecommerce warehouses are full of racking or shelving systems, which store inventory on pallets, shelves, and bins. Some warehouses may also double as fulfillment centers and reserve space for other functions, such as receiving areas and packing stations.

A business may own its own warehouse, but purchasing an entire warehouse can be extremely expensive. Instead, many brands opt to rent warehouse storage space. As a result, they share the warehouse with other brands, but are allotted dedicated space to store their inventory to prevent mix-ups.

2. Just-in-time (JIT) storage

Using the “just-in-time” storage method, a business times inventory procurement and/or production so that they get finished goods at the moment they’re needed, rather than well in advance.

For example, a candle company might only order a particular SKU from their supplier only after a customer places an order for it, rather than ordering multiple candles in advance and storing them in case someone orders one.

JIT inventory storage is ideal for brands that have limited storage space, as inventory doesn’t sit on shelves or take up space for very long. However, for the JIT method to work, you will need to make sure your procurement cycle is short, and that you can obtain inventory quickly enough to satisfy customer demand.

3. Distribution center storage

A distribution center is a facility that is designed to hold inventory temporarily before it is distributed elsewhere, such as a retail storage location, carrier facility, or fulfillment center.

While both distribution centers and fulfillment centers are almost always warehouses, the two are not necessarily synonymous. Distributions centers typically do not house any sort of fulfillment activity (like picking or packing consumer orders), and instead serve as hubs to coordinate the transit of goods across a brand’s network and channels.

4. Retail storage

Warehouses dedicated to retail storage hold inventory that will eventually end up on shelves in brick-and-mortar retail locations. Retail storage can also include storage areas within the retail locations themselves.

5. Cross-docking

Cross-docking is the process of unloading cargo from one vehicle (usually a truck or railroad car) and immediately reloading it onto another vehicle for transportation elsewhere. Essentially, a cross-docking space is just a quick stop for inventory on its journey to its final destination.

This means that cross-docking usually involves very little storage space, if any at all. While workers may store products in a cross-docking space for a few hours while sorting, consolidating, or consolidating shipments, those products definitely won’t sit on shelves for an extended period of time.

As a result, any cross-docking storage is not designed to serve as a long-term storage solution.

6. Climate-controlled storage

Climate-controlled storage is specially designed to regulate the climate inside the facility, including temperature and humidity.

This type of storage is a necessity for brands that sell perishable products, especially if those products have short shelf lives. These can include:

- Food and beverages

- Supplements

- Certain types of cosmetics

- Medical devices and equipment

Using climate-controlled storage, companies that sell these types of products can avoid inventory spoilage, and make sure their product stays safe to sell.

7. Outdoor storage

Brands selling products that benefit from open air (such as plants) might want to consider outdoor storage options, such as open-air warehouses.

Open-air warehouses have racks like regular storage warehouses, can be covered or uncovered by a roof, and may or may not have walls for protection from sun, rain, wind, snow, heat, or cold. A business may also cover inventory with tarps or protective material to keep inventory safe.

Just as with more traditional storage solutions, brands should also evaluate the safety risks involved with exposed storage, including risk of theft, the land’s stability and integrity the facility is built on, and how to keep the space clean, well-lit, and safe for workers.

4 tips for inventory storage

What are things to keep in mind with inventory storage? Having worked with thousands of ecommerce businesses, here are four tips and best practices for inventory storage.

1. Set reorder points for all SKUs

Reordering inventory is always a priority for your ecommerce business. With the right technology, you can automatically set notifications so you know when it’s time to replenish inventory for each SKU.

3PLs like ShipBob let you do this easily with their software, using accurate historical data and even help with inventory forecasting. Best sellers tend to sell out faster than the rest of your inventory, so adjust your reorder point and reorder quantity accordingly.

2. Implement inventory management and tracking

If you’re doing self-storage or warehousing, you can find software that manages and tracks your inventory easily, including the ability to conduct inventory audits and warehouse audits.

You can still use spreadsheets to manage inventory reports, but this has fallen out of favor as affordable apps and tools now provide inventory management software that’s affordable for most businesses. If you’re working with a 3PL like ShipBob, this is already included!

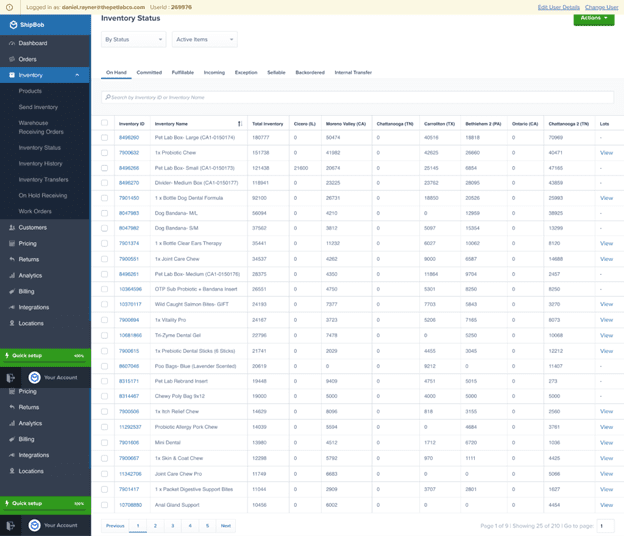

Through ShipBob’s dashboard, you can track inventory movement in real time, and gain visibility into inventory levels across channels and storage locations. This way, you can always know how much inventory you have left, and how inventory is moving through your supply chain.

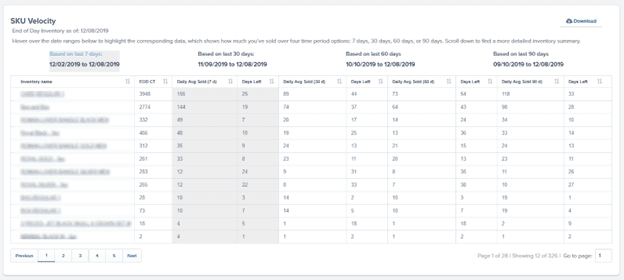

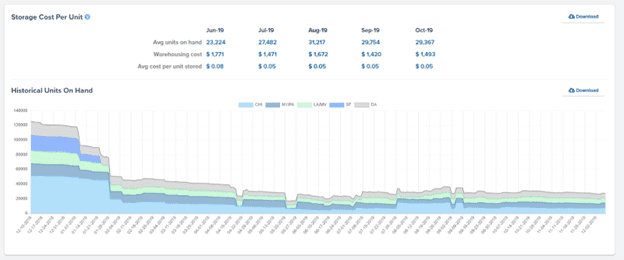

The dashboard also lets you monitor key inventory metrics over time, such as SKU velocity and storage cost per unit. Leveraging that data in your inventory planning and demand forecasting, you can avoid overstocking and stay on budget for your storage.

3. Know when to upgrade

If your storage solution isn’t working for you, it’s important to upgrade to a better one before your brand grows any bigger. It may be time to upgrade your system if you’re experiencing:

- Lack of space for inventory

- Difficulty physically reaching or accessing items because of the storage system’s design

- Disorganization or frequent mixing of SKUs

- High storage costs

These struggles will only get harder as your order volume grows – but investing in a high-quality storage system sooner rather than later enables your brand to scale more efficiently and with less hassle.

4. Perform inventory checks often

It’s much easier to store inventory efficiently when you know exactly how much inventory you have. Regular inventory audits ensure that you have an accurate idea of on-hand inventory levels, and that all inventory you’re storing is in good condition and accounted for.

These periodic audits typically involve physically checking every storage location, cleaning them, and disposing of spoiled, damaged, or obsolete inventory. Doing so helps keep equipment and inventory sanitary and in good condition, and moves deadstock out to keep storage costs in check.

Audits also involve inventory reconciliation, or checking that actual inventory levels align with recorded inventory levels. This helps you stay up to date with inventory accounting, and helps catch theft and honest accounting mistakes.

Premium Inventory Storage Systems with ShipBob’s WMS

Managing inventory and storage can be challenging – especially if you run your own warehouse. A warehouse management system, or WMS, can help brands optimize their in-house inventory strategy, as well as improve efficiency and accuracy across all warehousing operations.

ShipBob’s WMS powers a network of 50+ fulfillment centers across the world – and now, brands can implement that software in their own warehouses. Here are just a few of the ways ShipBob’s WMS streamlines inventory management for the ecommerce brands leveraging it.

Enhanced inventory visibility and accuracy

ShipBob’s WMS gives you location-specific inventory visibility throughout your warehouse, so you can stay organized, and so that pickers know exactly where every SKU is stored at all times. A built-in system of checks and balances improves picking accuracy, while intelligent cycle counts keep inventory records accurate and help you make better purchasing decisions.

Brands like coffee creamer substitute Prymal have used this visibility to improve quality control in warehouses, and even achieve 10% cost-savings.

A single source of truth

Stitching together multiple tools to understand your inventory only creates confusion, and makes it harder to scale your operations. ShipBob’s WMS offers one platform through which you can manage your inventory, order, transportation, and fulfillment, so that you can keep managing your operations simple, and still achieve deep visibility.

For example, netball game phenomenon Spikeball uses ShipBob’s WMS to monitor all of their facilities through a single platform, which gives them the connectivity they need.

Maximized pick and pack efficiency

With ShipBob’s WMS organizing and optimizing your inventory storage, the efficiency of other functions improves. Your brand can leverage flexible picking options (including batch, auto-cluster, custom cluster, and single-order picking) and visual, step-by-step packing flows to minimize errors and maximize fulfillment efficiency.

Sunglasses brand Pit Viper, for example, leveraged ShipBob’s WMS to improve picking accuracy from 92% to 99.7%, resulting in 2,100 less mispicks a year on average.

Real-time analytics at your fingertips

Using ShipBob’s dashboard, your brand can access real-time data on inventory and fulfillment, and continuously optimize operations based on those insights. ShipBob WMS users get up-to-date metrics on inventory – including inventory turnover, on-hand levels, SKU velocity, and storage costs – as well as fulfillment performance across all warehouses and breakdowns of order counts at different stages.

ShipBob WMS customers like Bunker Branding use these analytics to monitor data and performance at a person-by-person level, and easily determine which order should be prioritized for fulfillment.

Check out ShipBob’s Warehouse Management System (WMS)

ShipBob’s WMS helps your warehouse reduce picking errors, manage inventory in real time, and fulfill orders faster.

Don’t know how to get started? ShipBob can help

At ShipBob, we pride ourselves on being the best fulfillment partner for ecommerce merchants. With our integrations with major ecommerce platforms, best-in-class technology, fulfillment centers across the country, and our inventory and order fulfillment services, your inventory is in good hands.

ShipBob gives you the tools you need for inventory control, order management, and 2-day shipping. To save on overall inventory storage costs, partner with the ShipBob team. Request a quote for our outsourced fulfillment solution by clicking the button below.

Inventory Storage FAQs

Here are some of the most common questions about inventory storage.

What are the benefits of an inventory storage system?

An inventory storage system helps ecommerce brands keep inventory organized, which minimizes spoilage, obsoletion, and waste. This, in turn, makes it easier for brands to find the right items when they’re needed, pack them in customer orders, and deliver those orders quickly – all of which is key to customer satisfaction.

What are the pros and cons of using the first-in, first-out inventory storage system?

In terms of accounting, the FIFO method often results in a higher valuation for ending inventory and a higher net income. On a more practical level, the FIFO method helps prevent inventory spoilage and obsoletion by ensuring that the oldest inventory (usually at highest risk for spoilage and obsoletion) are sold before newer inventory.

Some of the cons of the FIFO method include a higher risk of accounting discrepancies if a brand’s cost of goods sold spikes unexpectedly, and higher taxes in some cases.

What is the cheapest way to store inventory?

The cheapest way to store inventory will depend on your brand’s products, needs, and plans for the future. For many brands, partnering with a 3PL enables them to flexibly scale their warehouse space without investing a lot of capital in a warehouse of their own (which they are then totally responsible for).

How do I keep track of my inventory in storage?

The best way to keep track of inventory is to invest in an inventory management system, or IMS. A good IMS software solution will automatically update inventory levels as inventory moves through the supply chain, so that merchants always know how much inventory they have left throughout their channels and storage locations.

Ideally, this software will also provide insight into metrics like SKU velocity and inventory turnover over time, so your brand can pick up on sales and storage patterns.

You can purchase and implement an IMS independently, or partner with a tech-enabled 3PL like ShipBob that offers it as part of their services.

What is a perpetual inventory system?

A perpetual inventory system refers to software that supports a business’s perpetual inventory accounting. The perpetual inventory method of inventory accounting involves continuously tracking inventory levels in real-time, so that a business’s inventory counts are highly accurate.

What is the difference between a warehouse and a storage room?

A storage room typically refers to a small space that may hold anything a business wishes to store. A warehouse, on the other hand, is almost always an independent building that has much more floor space, and higher ceilings to accommodate more storage.

Most ecommerce brands use warehouses to store inventory specifically, and warehouses may also house supply chain activities, such as inventory receiving, order fulfillment, and cross-docking.

Written By:

Rachel Hand

Rachel is a Content Marketing Specialist at ShipBob, where she writes blog articles, eGuides, and other resources to help small business owners master their logistics.

Read all posts written by Rachel Hand