Inventory Visibility Guide

Managing and maintaining healthy inventory levels across your supply chain network can be a full-time job.

As you expand your ecommerce business, you might be concerned on how to maintain visibility as you allocate product across multiple locations and channels.

In this article, you will learn why inventory visibility is important, how to implement tools and systems to improve visibility, and how a fulfillment provider like ShipBob can help you maintain visibility to improve your supply chain.

So, what do you want to learn?

Request Fulfillment Pricing

Let’s talk. Our experts can help you boost your order volume by 30% year over year.

A fulfillment expert will get back to you shortly. Privacy Policy

What is inventory visibility?

Inventory visibility refers to the ability to view and track inventory in real time, and gain insights into exactly how many units of each SKU are in stock at each location, and where it’s stored within a warehouse or fulfillment center.

Why does ecommerce inventory visibility matter?

For an ecommerce business to scale, it’s crucial to have visibility into inventory levels at all times, along with the ability to gain insights into how to better manage inventory to meet customer expectations.

Having full inventory visibility enables you to prepare for the unexpected and provides you with the data and analytics you need to make better business decisions, such as how to efficiently allocate inventory across your distribution network to reduce shipping costs and speed up transit times.

When online retailers have the tools they need to manage, view, and optimize inventory levels in real time, they are able to act quickly to ensure demand is met.

“ShipBob’s Inventory Placement Program provides visibility into inventory movement that’s absolutely key for anyone running a business. The data is easily accessible, and it shows exactly how inventory is being split across ShipBob’s network of warehouses. It’s also really great for our product reconciliation, because you can see what’s received at the hub locations and individual fulfillment centers. There’s a lot more clarity, and it’s so much simpler to check that our shipped inventory was received.”

Mithu Kuna, Founder and CEO of Baby Doppler

8 benefits of increasing inventory visibility throughout your supply chain

Increasing inventory visibility can significantly improve your supply chain velocity, increase efficiency, meet customer demand, and more. Here are some of the biggest benefits of increasing inventory visibility throughout your supply chain.

1. Increase overall efficiency

When you have oversight of your ecommerce inventory across multiple channels, you can leverage valuable historic and current inventory data to improve internal processes and boost supply chain efficiency.

If you lease and manage a warehouse, you can implement inventory apps and other types of tools to help you track inventory and increase visibility, which can eliminate the need to do manual inventory audits.

Or, you can partner with a tech-enabled 3PL company that offers the visibility and data you need to run an efficient and lean supply chain at a fraction of the cost.

2. Maintain healthy inventory levels

Part of inventory management is figuring out how much inventory you should have on hand, at each location, at all times. Increased inventory visibility helps you maintain healthy inventory levels across all channels.

With so many locations, and not to mention the transportation and movement of inventory, it can be hard to know the exact quantities of each product, and where it’s all currently stored. If you can’t account for each product, you risk not getting orders delivered on time, lost inventory, and even inaccurate financials.

3. Boost demand forecasting

With more visibility, you have an opportunity to collect historical order data to help you make better inventory decisions around forecasting demand across all channels.

Being able to see the time and date of orders, SKU(s) ordered, their destinations, and on which sales channel will help you forecast growth and trend projections on a more granular level (plus, you can look back to see how your forecasts matched up to reality).

Through forecasting demand will never be 100% accurate, having visibility gives you greater accuracy, which can also help you improve production lead times and increase operational efficiencies.

4. Improve the customer experience

The more inventory visibility you have, the easier it is to monitor stock levels across channels and maintain enough inventory to meet customer demand. With improved visibility, you have the ability to:

- Optimize stock levels across your network.

- Save on logistics costs to offset the cost of shipping or any promotional incentives like free shipping.

- Calculate safety stock to avoid stockouts.

- Reduce last-mile delivery by storing inventory closest to your customers.

5. Enhance internal communication

Inventory visibility improves overall supply chain management by providing your team with the real-time inventory data they need to make better decisions and take action quickly.

With more visibility, your team can communicate more effectively when they’re given full transparency into how much inventory is arriving at or leaving a warehouse at any given period of time.

6. Reduce supply chain costs

Inefficient inventory storage, poor geographic locations, high shipping costs, and unoptimized labor and operations can add up over time and kill your margins.

Having a comprehensive view of inventory on hand across your supply chain ensures that you’re not paying too much in logistics costs or warehousing fees, accumulating dead stock that is unsellable, and/or storing too much inventory in locations where there isn’t as high of demand for your products.

7. Promote real-time inventory visibility data

It can be hard to know the exact quantities of each product and where it’s all currently stored. And as orders are placed, inventory levels can change in a blink of the eye. By manually managing inventory, you risk not getting orders delivered on time.

That’s why having the ability to access real-time inventory data is key. Inventory automation plays a huge role here, and many times, businesses lean on a third-party logistics (3PL) company that provides visibility into real-time tracking and inventory performance.

8. Improve order accuracy rate

A lack of inventory visibility can also impact your fulfillment process and order accuracy rate. For instance, if an order is placed with multiple items, customers expect it to be received within the same delivery.

But with poor inventory management, you risk the chance of one item from the order being sold out, causing a backorder and/or a split shipment (or shipping multiple items from a single order out separately).

With more visibility, you can ensure that you have an optimal amount of stock in every location to full orders accurately and on time (or backups in other locations so customers don’t have to wait).

How ShipBob uses inventory visibility software within their supply chain

Since inventory ebbs and flows constantly, having the ability to view real-time inventory insights is key to efficiently replenish inventory to meet demand.

When an ecommerce business considers partnering with a 3PL like ShipBob, they are often concerned about their ability to maintain inventory visibility and control since the storage and fulfillment process takes place outside their business’s four walls.

ShipBob’s premium fulfillment technology and services are designed to provide the visibility you need to view and track SKU quantities, inventory turnover, days sales in inventory, SKU performance, and much more.

“I used to have to pull inventory numbers from three places everyday and move all the disparate data into a spreadsheet. ShipBob has an analytics tab in their dashboard with all of this information, which is great for end-of-month reconciliations.”

Wes Brown, Head of Operations at Black Claw LLC

Since ShipBob’s entire network is powered by the same tech stack, if you decide to split inventory across multiple fulfillment centers, you are able to manage and track inventory all in one place.

Here is a deeper dive into how ShipBob’s technology works and how it provides full inventory visibility to help you optimize your supply chain.

Real-time dashboard updates

ShipBob offers real-time insights and a full view into inventory performance by providing access to distribution metrics needed to plan for demand (and replenish inventory accordingly).

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order.”

Ines Guien, Vice President of Operations at Dossier

Below is an overview of the different data and analytics tools you have full access to through ShipBob’s dashboard.

Inventory planning

From the ShipBob dashboard, you can:

- Visualize SKU velocity and days of inventory remaining on hand.

- Input changes in projected order volume or scenarios to calculate changes in inventory turnover.

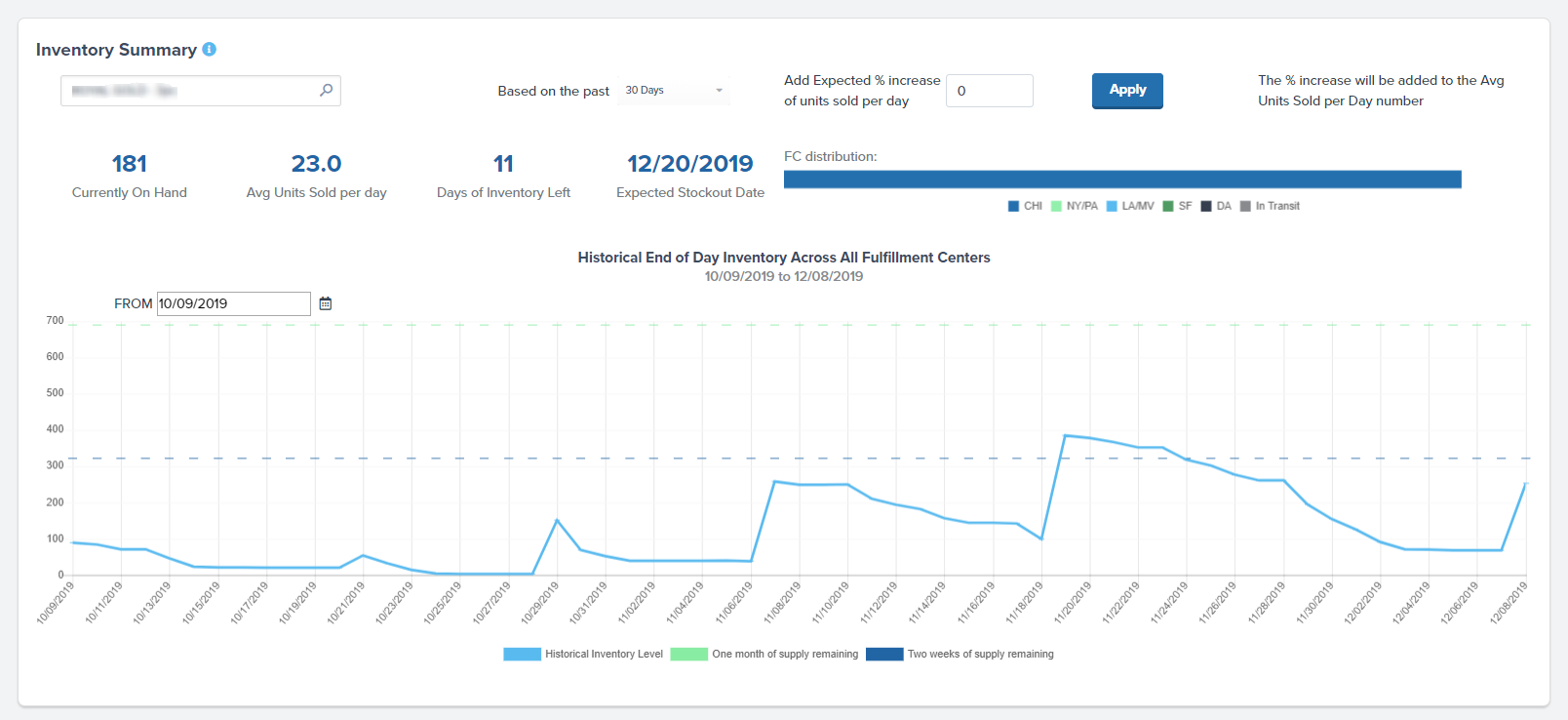

Below showcases the ‘Inventory Summary’ page which visually shows historical inventory levels and how much inventory is remaining at each distribution center:

You can check real-time inventory levels at each fulfillment center at any time and set automatic reorder levels, so you are notified when stock is running low. This helps take the guesswork out of the inventory reordering process.

This type of insight also gives you the data you need to calculate inventory turnover rate, which measures the amount of times inventory is sold then replaced in a designated time period.

“We roll out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each week. It’s really easy to create new SKUs and restock existing ones using ShipBob’s technology, which is especially important with high inventory turnover.”

Carl Protsch, Co-Founder of FLEO

SKU performance

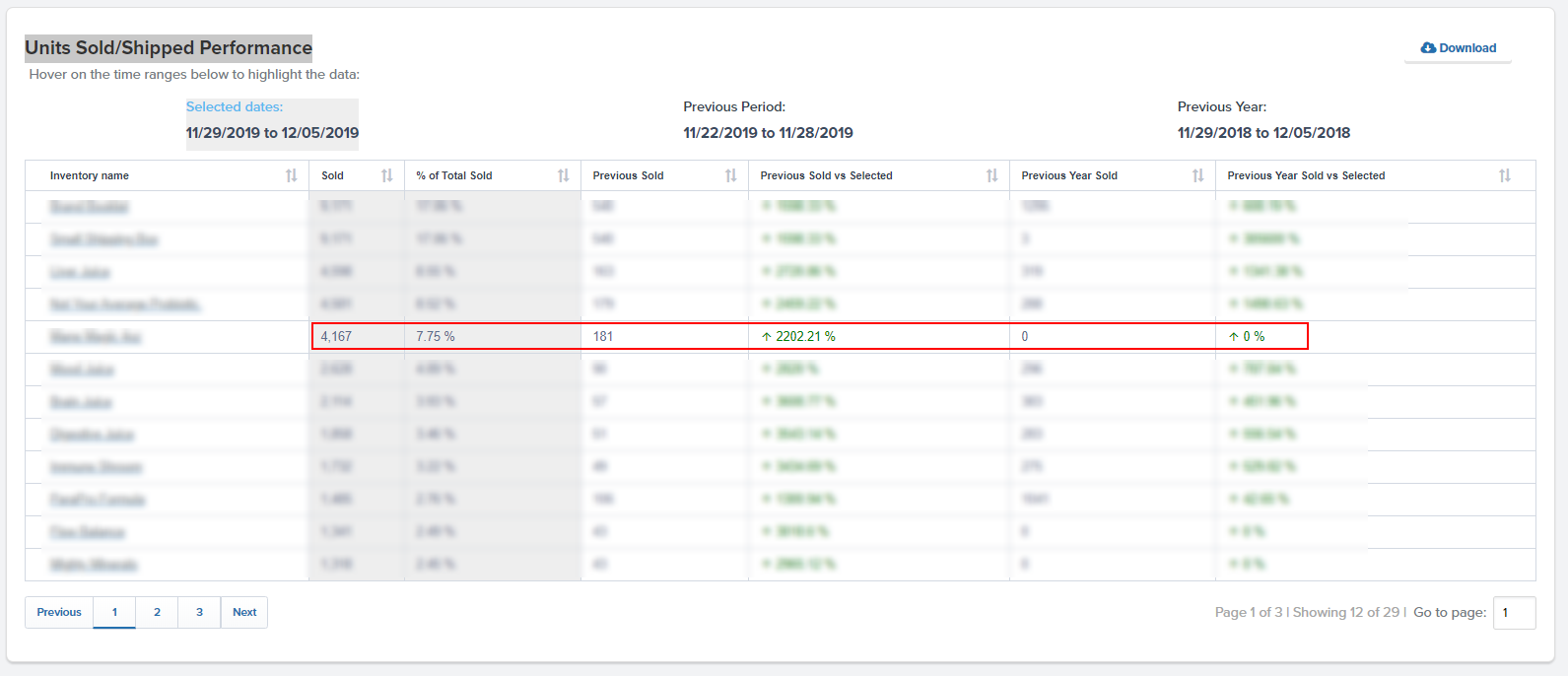

By viewing the ‘SKU Performance’ page from the ShipBob dashboard, you can look at performance of your product(s) over time by channel sold.

In the example below, you will see that during the week of 11/29/2019 to 12/05/2019, a merchant sold 4,167 units of a SKU, which accounts for 7.75% of all items sold by that merchant.

“ShipBob’s analytics tool is also really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

Daily inventory history

Easily access daily inventory history at any point in time. Using ShipBob’s ‘Daily Inventory History’ page, you can search by item, filter by specific lot number, and account for inventory in transit.

Inventory on hand

From the ShipBob dashboard, you get a comprehensive view of inventory on hand in real time. Review your current, available inventory levels by ShipBob fulfillment center, and see if you have any inventory in transit to another location.

“We utilize ShipBob’s Inventory API, which allows us to programmatically retrieve real-time data on how many units of each product are currently stored at ShipBob’s warehouses. We currently use this API to generate custom reports to tie this inventory data into our accounting platforms.”

Waveform Lighting Team

Inventory map and distribution

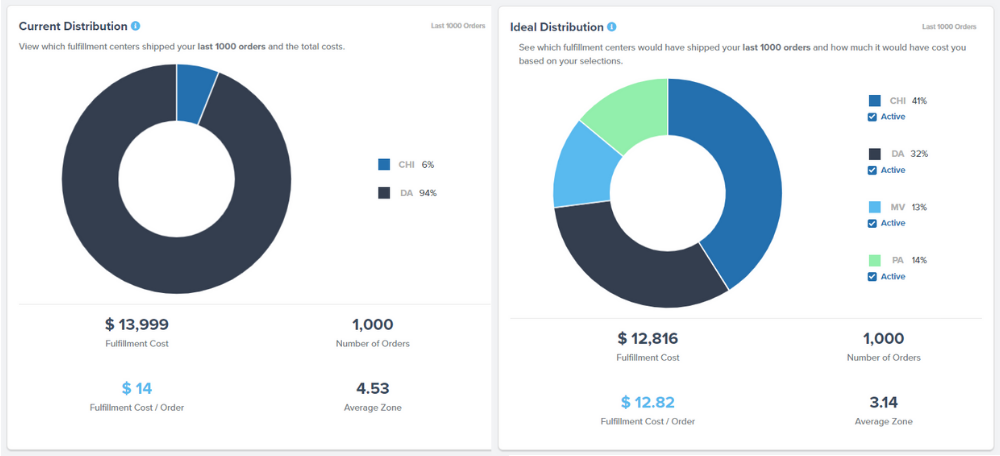

ShipBob makes it easy to take a data-driven approach to inventory distribution. By aggregating historical order data, you get an analysis of which logistics centers you should stock to best leverage ShipBob’s network of fulfillment centers for the most cost-effective and fast deliveries.

You can easily visualize where your customers are, and compare your current and ideal distribution to optimize product allocation.

With this type of visibility, you get get answers to questions like:

- How should I distribute my inventory across ShipBob’s fulfillment network?

- What would my shipping costs be if I went from one fulfillment center to two (or two to three, and so on)?

- How many days of inventory do I have left before I run out?

- What is my SKU performance over time?

- Where are my customers shipping to most often?

“Storing inventory in different regions is key to reducing costs and transit times. From expanding into a second ShipBob fulfillment center, we are excited to be able to offer 65% of our customers with 2-day ground shipping, up from 32% by only having a single West Coast facility. Soon, this will be 100%. Not only is this better for our customers but we also gain a 13% savings to our bottom line.”

Pablo Gabatto, Business Operations Manager at Ample Foods

Benefits of a tech-enabled 3PL for your inventory management

Inventory visibility has the power to enhance your entire supply chain, which leads to higher profit margins, better inventory forecasting, and ultimately a higher customer satisfaction rate.

That’s why many fast-growing ecommerce businesses partner with ShipBob, a tech-enabled 3PL that offers a global fulfillment network, premium technology, inventory management tools, and full visibility into your inventory.

When you outsource fulfillment to ShipBob, you get full visibility and transparency into the entire fulfillment process, which allows you to maintain control, track inventory and orders at all times, and get access to advanced data and analytics to make better business decisions.

“So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on. I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

With ShipBob, you can expand and scale your business with ease, and optimize your logistics operations efficiently.

Inventory visibility FAQs

Here are answers to the most commonly asked questions related to inventory visibility.

How do you increase inventory visibility?

Investing in inventory tools such as an inventory management system or other types inventory apps is a great way to increase inventory visibility. These tools are designed to help you keep track of inventory across your supply chain in an automated way, from one single dashboard. This way, you can see real-time inventory numbers at a glance and get insights on how better manage your inventory to meet demand across your distribution network.

What is a supply chain inventory visibility system?

A supply chain inventory visibility system (SCIV) is often used by enterprise businesses to track inventory across a global distribution network. A SCIV system also has the ability to set reorder notification alerts, view order status, and more. Many 3PLs like ShipBob offer built-in inventory management tools that provide the same level of visibility into inventory levels.

How do you monitor inventory levels?

Monitoring inventory levels is a tedious process if you still use card systems, Excel sheets, or physical ledgers or paper. But by implementing an inventory tracking systems, you can monitor inventory levels in real time from a single dashboard. Inventory tracking systems enable you to make better decisions on where to allocate inventory, when to reorder, and where to store to meet demand.

How does ShipBob implement full inventory visibility?

ShipBob offers real-time inventory visibility with a built-in inventory management system and analytics tools. ShipBob’s entire international fulfillment network is powered by proprietary technology, which allows you to view inventory levels from different locations all from one single dashboard. With ShipBob, you can track inventory levels of each SKU in each location in real time for better inventory control across your sales channels.