Table of Contents

** Minutes

Why logistics planning is important for ecommerce businesses

Logistical processes and workflows to plan for

Tips for improving your logistics planning

Planning for the known and the unknown in logistics

No army should go into battle without a plan for attack; similarly, no ecommerce merchant should go into business without a plan for handling their logistics.

While it’s not the most glamorous aspect of running an ecommerce business (nor how you thought you’d be spending your time once you opened), logistics planning is absolutely essential to your business’s success.

By taking the time to plan your supply chain, think through the details of logistical processes, evaluate resources, and budget your costs, you make more of the “unknown” quantities in your logistics known — and with fewer unknowns, you can both optimize your business operations and strengthen them against future crises.

Without logistics planning, business owners risk expensive surprises, inefficiencies, and the inability to scale their business effectively — especially when hard times hit.

In this article, we will discuss what logistics planning is, why it’s important for ecommerce, tips on how to optimize your logistics plan, and how a 3PL like ShipBob can help facilitate business growth by handling all internal and external logistics processes.

What is logistics planning?

Logistics planning is a form of logistics management in which a business owner strategizes how to deliver the right product to the right customer at the right time, at the lowest possible cost. The goal of logistics planning is to build a lean and cost-effective logistics operation that can achieve service levels at all times and withstand supply chain disruptions.

While the logistics planning process might look slightly different for each merchant, it typically involves thinking through logistics systems (such as procurement, production, and shipping) and planning all the different logistical functions involved in each system, including warehousing, fulfillment, returns, raw material handling, and inventory management. The director of logistics is usually responsible for overseeing the planning process, though other key stakeholders may have input as well.

Through logistics planning, these systems and functions are evaluated for cost, optimized for efficiency, and designed to withstand unexpected challenges.

Why logistics planning is important for ecommerce businesses

Logistics planning is vital to both the safety and longevity of your business.

Like any strategy or contingency plan, it helps protect your business from unanticipated challenges. But beyond future-proofing, logistics planning can improve the day-to-day operations of your business and position you for success in the short as well as long term.

Here are 4 of the most important benefits of planning your ecommerce logistics.

1. Chart a path for reaching long-term goals

When you first start an ecommerce business, you may not be thinking too far into the future — after all, just getting your brand off the ground is a full-time job in and of itself. But once you get established, logistics planning helps ensure that your business can continue to grow and sustain itself.

Logistics planning forces you to think about your business’s goals, both in the short- and long-term. In order to make wise decisions about how to handle your logistics, you’ll first need to set goals for how you want to grow in the future.

But to achieve those goals and generate a profit, you’ll next have to figure out how you’ll continue to meet customer demand while minimizing cost — which is impossible without thoroughly strategizing logistics processes like storage, shipping, and fulfillment.

Having a good operating plan for logistics keeps you on budget, on time, and on par with customer expectations, which enables you to work effectively towards your short-term goals.

Accomplishing those short-term goals will set you up to achieve long-term ones in the future. By creating a resilient supply chain through logistics planning now, you can worry less about fluke accidents or unexpected challenges derailing your business later on.

2. Reduce supply chain costs

When it comes to logistics, it’s easy for ecommerce businesses to go over budget. Logistics planning helps reduce silly or unnecessary expenditures that eat into your profits.

When you have a strategy for executing your logistics, you won’t be tempted to panic and settle on a more costly solution for the sake of convenience. Rather, with time and planning, you can research the most cost-effective supply chain solutions, and factor in hidden logistics costs that you might not remember to budget for otherwise (such as labor, warehouse insurance, and equipment).

If you outsource logistics, the right 3PL will also drive savings for your supply chain. As expert logisticians, these companies have mastered how to execute logistics functions quicker, cheaper, and more efficiently than most ecommerce businesses could on their own — and as your partner, their techniques will save you time and money.

A 3PL should also make logistics planning easier with predictable, transparent pricing for every service so customers know exactly what they will pay for ecommerce fulfillment, right off the bat. For example, with ShipBob additional value-adds like free standard packaging, data and analytics, and our best-in-class software are included at no extra charge to help you stay on budget and plan your logistics.

3. Meet customer demand quicker

Well-planned logistics systems are streamlined logistics systems. By scrupulously maintaining inventory levels, honing operations, and securing fast shipping options, your business will always be in a position to meet customer demand quickly.

Meeting customer demand quickly takes a lot of effort — but partnering with a 3PL lessens the business owner’s burden. 3PLs like ShipBob use their logistics expertise and resources to satisfy their customers’ end customers quickly and cost-effectively.

Touchland, an ecommerce company specializing in hand-sanitizing mists, had a similar experience:

- When the COVID-19 pandemic caused their business to grow 1200% in just a few weeks.

- With ShipBob as their 3PL, they were able to scale quickly, and pick, pack, and ship orders for 2-day delivery — a remarkable accomplishment that never would have been possible through self-fulfillment.

4. Increase revenue

Increased revenue is a natural consequence of the other benefits to logistics planning, but an important reason to plan logistics in its own right.

If your planned goals have kept you on budget and you’ve reduced supply chain costs, you’ll likely see monetary savings and higher profit margins.

Similarly, meeting customer demands builds customer satisfaction and loyalty, increases the likelihood of repeat purchases, and usually leads to more sales.

In addition, meeting those demands quickly through fast shipping lowers your cart abandonment rate and increases your AOV, making for more profitable transactions.

You must increase revenue over time if you’re going to build your business, so it is crucial that you plan logistics in order to gain as much profit margin as possible on every sale.

Logistical processes and workflows to plan for

The logistics planning process is quite an undertaking, as there are many different logistics functions within the ecommerce supply chain to plan for.

However, a holistic logistics plan — one that covers many logistical areas — both optimizes individual logistics processes for maximum efficiency, and helps them work together to improve overall supply chain management.

Here are some of the logistics functions that ecommerce businesses should plan for, and tips for planning each.

Logistical Process | Planning tips |

Procurement and manufacturing |

|

Transportation and distribution |

|

| |

| |

| |

| |

|

Tips for improving your logistics planning

No matter which area of your logistics you’re planning, there are some simple strategies that ecommerce businesses can employ to improve logistical functioning across the board. Here are some tips for streamlining your entire logistics operation which will also help future-proof your supply chain.

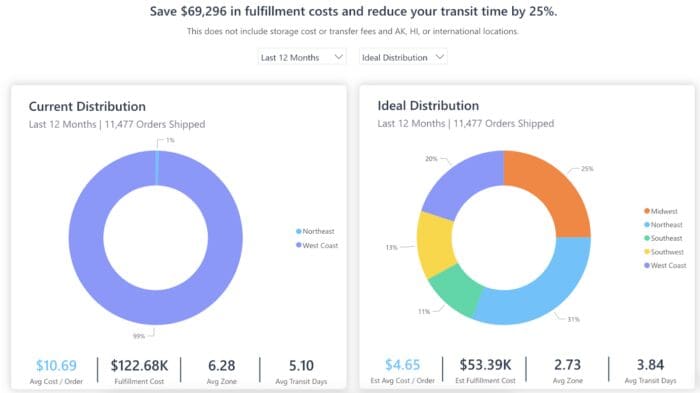

Distribute your inventory across multiple locations and regions

Splitting inventory between multiple, strategically placed fulfillment centers will place portions of your product much closer to certain pockets of customers than it was before (this is easy to do with a 3PL).

From there, orders are automatically routed to and fulfilled from the center closest to the order’s destination point.

This cuts back on shipping distance — which reduces the shipping cost — and shortens shipping time, which delights customers, increases conversions, and encourages repeat purchasing. If you can manage it, distributing inventory saves time, money, and effort for both you and your customer.

The other benefit of distributing inventory is that, by splitting your SKUs between locations, you avoid putting all your eggs in one basket. This way, you’ll protect your inventory in case of a disaster affecting a warehouse or fulfillment center (or even in severe weather events when carriers can’t pick up), and ensure that you can meet some customer demand, particularly if your products are essential.

However, before you plan your logistics around distributed inventory, there are some qualifications to consider. Distributed inventory is the best fit when:

- A business’s AOV and profit margins are high

- Products are heavy or bulky

- Customers are spread out across the country (or world) rather than consolidated in one region

If any are true of your business, you should then consider how exactly to execute your strategy. Partnering with a 3PL is often the most cost-effective option for achieving distributed inventory, as you don’t have to purchase or rent in a warehouse yourself.

“We now save a lot of money and ship faster based on distributed inventory. So far, we are shipping out of two of ShipBob’s fulfillment centers. We use the ShipBob locations that optimize and reduce the distance traveled to get our products into our customers’ hands faster. When shipping glass bottles, especially in the winter, the longer the transit time, the more likely it is to break. We see that our customers are getting their packages safer, with fewer frozen bottles exploding.”

Lindsay Louise, Fulfillment & Retail Manager at Synchro

Forecast demand to meet increased expectations

Forecasting demand is critical for logistics planning, because your ability to deliver the right product to the right customer at the right time hinges on having enough inventory to meet demand.

When you can accurately predict demand levels, you can make sure that you don’t accidentally over or understock any SKUs, both of which are detrimental to your business’s efficiency and bottom line.

Beyond meeting customer expectations, inventory forecasting affects everything from your budget to your production timeline to your storage costs to your inventory turnover. Because of this, you should always factor demand forecasts into your logistics planning so that miscalculations or assumptions don’t derail your entire operation’s efficiency.

Some 3PLs make demand forecasting easier than others. ShipBob, for example, lets you:

- Track real-time inventory counts, historical sales data, and advanced analytics to discover new patterns and identify seasonal, geographic, or product-related trends.

- Use these insights to achieve more accurate demand forecasts and guide logistics planning for the future, without the stress of tracking important metrics manually.

Don’t rely on one carrier for shipping and transportation

If you only have a relationship with a single carrier without a backup plan, unforeseen issues with that carrier could wreak havoc on your business.

When planning logistics, it is important to research different carriers — taking into account their location coverage, costs, 2-day capabilities, technology, and reputation — and use a combination.

Do not discount regional parcel carriers either, as they could be more economical than larger carriers like DHL or FedEx, and might be able to offer customizations or reach locations that bigger ones can’t.

For larger shipments or transporting finished goods to warehouses, consider all forms of distribution and transportation, including air and ocean transport. Depending on how big, bulky, or perishable your products are, one of these options may be better than standard ground transportation.

However many carriers you choose to ship with, partnering with a 3PL can usually snag you cost-savings in shipping and transportation. Because of their size, 3PLs like ShipBob can negotiate far more effectively with carriers for discounted shipping rates, which they pass on to their customers.

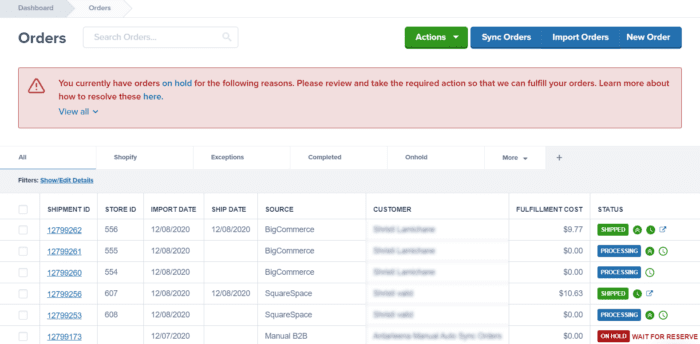

Leverage modern logistics technology and software

Modern technologies make it much, much easier to both optimize your current logistics operations management and “future-proof” your logistics going forward. Software like an IMS and WMS streamlines and digitizes critical functions like order processing, inventory management, storage, and fulfillment, which keep daily operations efficient with less effort.

These platforms also come with tools that make logistics planning simple: real-time inventory tracking, for example, helps keep demand forecasts accurate, and automation in order processing and warehouse functions lower labor costs and increase order accuracy.

These platforms should also automatically gather and record data for future analysis, and store it in one place for easy access at any time. ShipBob’s merchant dashboard was designed with this in mind — specifically, it integrates directly with your ecommerce platform so that you can see all your information in one place.

Our technology is full-stack and implemented in each of our warehouses, so you don’t have to worry about juggling different tools and platforms to manage different locations.

“We are very impressed by ShipBob’s transparency, simplicity, and intuitive dashboard. So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse. On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on. I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

Planning for the known and the unknown in logistics

With so much uncertainty in the world of supply chain, logistics planning can be challenging — but that doesn’t mean it’s impossible.

Some challenges are relatively predictable, and can be tackled in much the same way every year or season with preventative planning. Other challenges, however, are completely unexpected, and there is little you can do in the moment to prevent them from affecting your business.

Still, if you plan thoroughly and have lean logistics operations in place, chances are that you will still be able to meet customer expectations, even in unlikely or unexpected disruptions.

Here are just some of the challenges you should anticipate, as well as some that you cannot, and some practical tips for use when planning for both.

Planned challenges

| Challenge | How to plan |

Holidays |

|

Business growth |

|

Shipping costs and expectations |

|

Unplanned challenges

| Challenge | How to be prepared |

| |

Government regulations |

|

Gas price fluctuations |

|

Unanticipated delays |

|

Shipping container shortages |

|

How ShipBob makes fulfillment logistics planning easy

Logistics planning is an ongoing process of continuous optimization, and requires regular time and attention. But because their bandwidth is limited, many businesses choose to partner with a 3PL like ShipBob to have the services and tools they need.

ShipBob is a tech-enabled 3PL with years of experience in fulfillment, shipping, and other logistics services. Thousands of DTC brands trust us to help them plan their logistics and face both expected and unexpected challenges, so we have built the resources and logistics infrastructure to make sure that each of our customers can deliver the right order at the right time at the right cost, through growth spurts and disasters alike.

At ShipBob, we offer solutions for ecommerce logistics processes, beginning with storing and managing your inventory. Using a distributed inventory approach, ShipBob can store your inventory in one or many of our strategically located fulfillment centers, so that your business is positioned to ship quickly and cost-effectively anywhere.

Our merchant dashboard even includes an ideal inventory distribution tool to help you plan to allocate inventory between locations as strategically as possible.

ShipBob’s dashboard also helps you manage inventory and plan for the future. You:

- Get full visibility into real-time inventory levels.

- Can sets automatic reorder notifications.

- Track historical sales data and other metrics for use in demand forecasting.

- Have the information you need to plan inventory at your fingertips.

Once orders are automatically processed, we’ll pick, pack, and ship those orders for you — and with our transparent pricing structure, you will know exactly what your costs are, making it easy to budget your costs ahead of time.

You can also view warehouse operations at a glance through our proprietary WMS. This platform connects directly to your ecommerce store, and because all of our warehouses run on it uniformly, you won’t have to plan for different 3PLs and different SOPs.

Finally, when it comes time to ship, ShipBob offers 2-day and expedited shipping, and shipping and negotiates agreements with major carriers to get your shipments on the customer’s doorstep as cost-effectively as possible.

With ShipBob, you have the all-in-one, out-of-the-box solution that makes planning simple. With a multifunctional and long-term partner by your side, your business will be prepared to scale and withstand the unexpected in the present, the future, and beyond.

For more information, read this review or request a pricing quote below and start the conversation.

Logistics planning FAQs

Here are answers to the most common questions about logistics planning.