Table of Contents

** Minutes

How bad is obsolete inventory?

How to identify obsolete inventory

What to do with obsolete inventory

How to avoid & reduce obsolete inventory

How ShipBob ensures inventory obsolescence is a problem of the past

For most ecommerce business, having enough inventory to meet demand is often a top concern.

So it’s tempting to order more than you need to be on the safe side.

But having too many goods can backfire.

Even though it’s always a good idea to carry some safety stock in case of emergencies (or to cover an unexpected surge in demand), purchasing too much inventory can put your business at risk of carrying a product that will lose value before it’s sold.

Known as obsolete inventory, holding on to purchased inventory that is no longer sellable can significantly harm your bottom line.

In this article, we discuss how to avoid, identify, reduce, and manage obsolete inventory to ensure a more profitable business.

What is obsolete inventory?

Obsolete inventory refers to a product that has reached the end of its lifecycle. It happens when a business considers it to be no longer sellable or usable and most likely will not sell in the future due to a lack of market value and demand. Usually, inventory items become obsolete stock after a certain time period has passed and after they reach the end of their lifecycle.

Obsolete inventory is also called “dead stock,”, “excess inventory”, or “dead inventory.”

Though any type of product can become obsolete, some industries are more vulnerable to carrying obsolete inventory such as electronics, apparel, and furniture. These types of items are more likely to go obsolete due to:

- Innovations that make the products worthless, inconvenient, or unattractive

- New technologies that disrupt the way the items are produced

- Decline in overall demand for the items (due to changes in trends)

- More competition and therefore more pressure to offer the latest and greatest (remember fidget spinners?)

How bad is obsolete inventory?

Inventory is purchased or created with the intention to sell it. Since you cannot sell obsolete inventory, it is considered a loss and can cut into profit margins.

Once inventory becomes obsolete, it is no longer considered an asset. At the end of an accounting period or fiscal year, the unsellable inventory must be reported on as an inventory write-off in accordance with the Generally Accepted Accounting Principles (GAAP).

With today’s technology and customers’ high expectations, the product lifecycle has become shorter across industries, making inventory become obsolete much faster (e.g., fast fashion).

Check out ShipBob's Warehouse Management System (WMS)

ShipBob's WMS helps your warehouse reduce picking errors, manage inventory in real time, and fulfill orders faster.

Causes of obsolete inventory

Accumulating obsolete inventory can occur for several reasons, from inaccurately forecasting demand to a lack of proper inventory management. Here are the common causes of obsolete inventory.

Inaccurate inventory forecasting

Businesses may end up with obsolete inventory when they fail to accurately forecast demand based on historical sales data, market trends, and other factors.

As such, they might predict a much higher demand and end up ordering an excess amount of inventory.

Though inventory forecasting is rarely 100% accurate, it becomes even more challenging when there isn’t enough historical order data or market insights to help make the best decisions.

If that’s the case, you can avoid over-ordering by buying less inventory more often rather than purchasing inventory for an entire year.

Poor inventory management

Obsolete inventory can also be a result of poor inventory management. Without proper inventory planning — including the tools and technology to help track inventory in real time — optimizing inventory levels can be a challenge.

For instance, if you don’t have any insight into what items are slow-moving and taking up storage space, then it will be harder to identify how much obsolete inventory you’re accumulating.

By implementing technology to easily track inventory activity, you’re given insights into key metrics, such as average days of inventory on hand or inventory turnover rate, which can help you quickly identify products that might become obsolete due to a slower sales cycle.

Lack of inventory transparency

Not only can a lack of visibility cause obsolete inventory to go unseen (and therefore increase carrying costs), you also risk stockouts of your high-demand products.

Along with inventory management, having visibility over your inventory at all times is key. Without inventory visibility, it will be hard to understand how much of each product you need to restock and when (and what product(s) might be worth discontinuing).

With more visibility, you can find ways to optimize inventory to meet demand and avoid common inventory issues, such as overstocking.

Lack of supply chain data

Inventory is at the heart of an online business, so it’s important to have access to data that provides insights into how well your supply chain is performing.

Supply chain forecasting involves using data and research to make predictions on all aspects of the supply chain to ensure a business runs smoothly and continues to grow. This includes having insights into production lead times, labor needs, warehousing, order fulfillment, and shipping.

Having access to supply chain data can help you improve supply chain efficiency, including how well inventory is managed.

How to identify obsolete inventory

The best way to identify obsolete inventory is by implementing the right tools, technology, and processes to identify slow-moving inventory on hand.

For instance, conducting regular inventory audits can quickly identify obsolete inventory before it eats away at your profits. From there, you can make a decision on when to run a flash sale or donate items so you’re not overpaying in storage fees.

The right technology can also help. By implementing an inventory tracking system, you can get a closer look at inventory days on hand, sales, and buying trends. This way, you have the insights needed to make better decisions on when to repurchase more inventory (or even discontinue an item).

What to do with obsolete inventory

Though there are several ways to help avoid accumulating obsolete inventory, carrying any type of dead stock is inevitable. Here is what to do if you end up carrying inventory that has become unsellable.

Writing off obsolete inventory

Since obsolete inventory is no longer sellable, it’s no longer considered an asset since it can’t be sold. In this case, your excess stock can be written off as a loss on your financial statements.

An inventory write-off can help you reduce your tax liability, which involves taking the inventory off the books when it is identified to have no value and, thus, cannot be sold.

Putting items on sale

If the products still have potential, you could also sell them at a discount by running a promotion, such as a flash sale.

Though obsolete inventory can still impact ideal profit margins, putting items on sale can help replenish some of the costs by attracting bargain shoppers.

Alternatively, you can try product bundling obsolete items with a fast-selling item (and even offer free shipping).

Remarketing items

There’s also the option of remarketing items that are at risk of becoming obsolete.

If items still have sales potential in a specific market, you could rethink your marketing strategy. This could include changing your target audience or geographic locations in marketing ads or selling the items on a different sales channel.

Note: While remarketing has the potential to generate some value, it will require additional investments (such as ad spend), which can lead to a low return on investment.

How to avoid & reduce obsolete inventory

Proper planning and inventory management can significantly mitigate the risks associated with obsolete inventory. Here are a few tips you can use to avoid or reduce obsolete inventory.

Forecast demand for inventory

By taking a look at historical data, you can predict future demand for each SKU and make informed decisions to avoid purchasing too much of an item that might become obsolete faster than it can be sold.

Though there are several great inventory forecasting solutions on the market, you can always rely on a 3PL to provide the insights you need to better forecast demand without the extra cost.

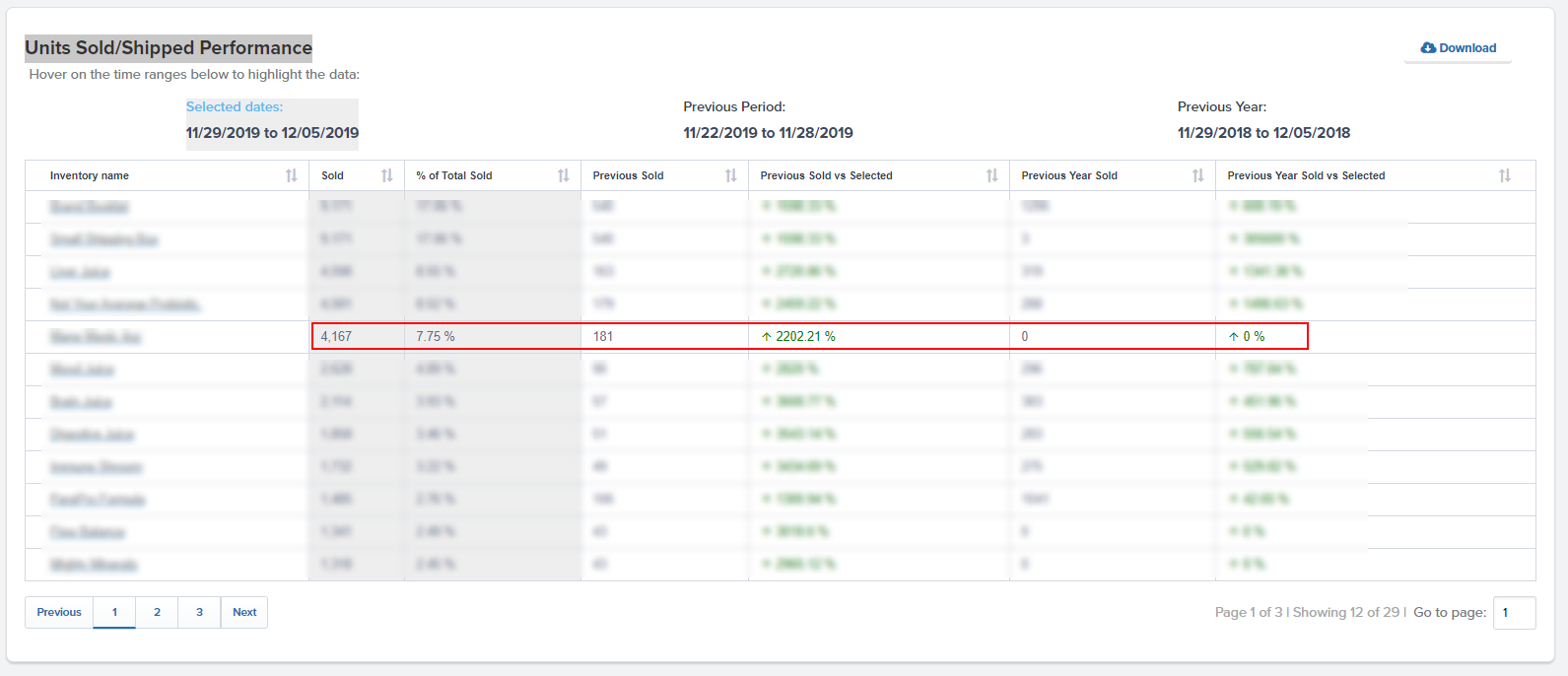

For instance, ShipBob is a 3PL that offers analytics and reporting that help you understand:

- How quickly products are selling and which items are slow-moving

- How many days of inventory you have until you are expected to run out based on SKU velocity

- How your current demand compares to a previous time period

- How your sales are affected by different seasons and months

- And much more

Utilize inventory management software

Having robust inventory management softwarecan help you track inventory, predict future selling trends, and identify slow-moving items before you put in your next repurchasing order.

ShipBob’s order fulfillment solution offers built-in inventory management tools, data, and reporting that offers insights into demand forecasting, order management, and more to help you make better decisions on how to manage your inventory.

Perform regular inventory audits

Consistent and accurate inventory audits can also help you avoid and reduce obsolete inventory by understanding how much you’re paying in holdings costs to store slow-moving items that are at risk of going obsolete.

Slow-moving items and dead stock can take up valuable storage space that could be used to store a higher volume of faster-selling products.

By performing regular audits, you can quickly remove inventory that is unsellable or unlikely to sell.

“I used to have to pull inventory numbers from three places everyday and move all the disparate data into a spreadsheet. ShipBob has an analytics tab in their dashboard with all of this information, which is great for end-of-month reconciliations.”

Wes Brown, Head of Operations at Black Claw LLC

Get real-time accurate supply chain data

Real-time access to data across the supply chain is beneficial for real-time inventory management. This gives you the most current information about inventory levels along with other details, such as warehouse receiving and production time lines.

With access to the right supply chain data, you’re given the insight needed to effectively optimize stock availability, maintain the right amount of buffer inventory, and know exactly what items need to be repurchased and when to meet future demand.

“We utilize ShipBob’s Inventory API, which allows us to programmatically retrieve real-time data on how many units of each product are currently stored at ShipBob’s warehouses. We currently use this API to generate custom reports to tie this inventory data into our accounting platforms.”

How ShipBob ensures inventory obsolescence is a problem of the past

ShipBob is a tech-enabled 3PL that operates a robust logistics network powered by a best-in-class retail fulfillment technology.

With ShipBob, you can split inventory across our international fulfillment network and easily track and manage inventory in real time all through ShipBob’s user-friendly merchant dashboard.

ShipBob offers full transparency and visibility into operations by providing essential insights, analytics, and data needed to control stock, manage SKUs, and replenish inventory on time, so you never run out of your high-demand products.

“We roll out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each week. It’s really easy to create new SKUs and restock existing ones using ShipBob’s technology, which is especially important with high inventory turnover.”

Carl Protsch, Co-Founder of FLEO

To learn more about how ShipBob can help you optimize your supply chain, click the button below to start the conversation.

Improve inventory management with ShipBob’s WMS

For brands looking to improve inventory visibility and tracking within their own warehouses, look no further than ShipBob’s warehouse management system (WMS).

Ecommerce merchants can now leverage ShipBob’s WMS (the same one that powers ShipBob’s global fulfillment network) to streamline in-house inventory management and fulfillment. With real-time, location-specific inventory visibility, intelligent cycle counts, and built-in checks and balances, your team can improve inventory accuracy without sacrificing operational efficiency.

Obsolete inventory FAQs

Here are the top questions about obsolete inventory.

Is obsolete inventory bad?

Accumulating too much obsolete inventory can be bad for business since it cuts into profit margins. Inventory is considered an asset since it’s purchased with the intent to sell. If inventory goes obsolete, it’s considered a financial loss. Though carrying some obsolete inventory is inevitable, it’s important to help avoid accumulating too much inventory that is at risk of losing its value.

How do you identify obsolete inventory?

There are several ways to identify obsolete inventory. One way is to use an inventory management system that helps track inventory throughout its lifecycle. This way, you have data to calculate inventory days on hand and inventory turnover rate, which are key inventory metrics to track. You can also use lot tracking to group different batches of inventory.

With the right data, you can identify slow-moving items and make decisions on whether to discontinue certain items or run a promotion to sell slow-moving items faster before they completely lose their value.

Are damaged goods obsolete inventory?

Damaged goods is a type of dead stock and is sometimes considered obsolete if the product is unfixable and therefore, loses its value.

What do I do with obsolete inventory?

There are several ways to handle obsolete inventory. You can sell them at a discount, bundle them with other products, liquidate them through surplus resellers, try to remarket them to a different audience, or do a complete inventory write off.