Table of Contents

** Minutes

Common causes of warehouse overflow

Challenges of managing warehouse overflow

Preventative strategies to avoid warehouse overflow

A well-stocked warehouse is every ecommerce business owner’s dream; an overstocked warehouse, on the other hand, is a logistical nightmare. Whether it’s because of a miscalculation, capacity constraints, unexpected demand shifts, or just bad luck, warehouse overflow presents a number of challenges for ecommerce businesses.

In this post, we’ll break down the common causes of warehouse overflow, share some best practices for preventing it, and how experts like ShipBob can help you manage your inventory and storage.

What is warehouse overflow?

Warehouse overflow occurs when your inventory levels exceed your maximum warehouse capacity.

In other words, warehouse overflow happens when you have too much excess inventory, to the point where you can’t store it all in your current warehouse space. This excess could result from:

- Supplier or manufacturer error

- Inventory obsoletion

- Inaccurate demand forecasting

- Unexpected demand shifts

- Supply chain disruptions or bottlenecks

Whatever the root cause, warehouse overflow often leads to warehouse congestion and disorganization, both of which present safety hazards and can lower your operational efficiency.

The impact of warehouse overflow on business operations

To get an even better understanding of why warehouse overflow is such a major concern for ecommerce businesses, let’s take a look at how it impacts your operations.

Increased storage costs

When you’re trying to store more inventory than your warehouse space can hold, it won’t just be physically cramped; it’s also going to increase your inventory carrying costs. The more inventory you have, the more space it takes up – and since storage fees are usually charged per bin, per pallet, or per shelf, warehouse overflow naturally raises your storage costs.

Even if you’re running your own warehouse, warehouse overflow may force you to spend more money on storage infrastructure. The cost of procuring additional shelves, bins, and pallets to accommodate the inventory overflow can add up to impact your overall storage costs.

Delayed shipments

Overflow can lead to disorganization and warehouse congestion, which could make it more difficult for your warehouse staff to find and pick items needed for fulfillment. This slows the entire order fulfillment process, which in turn lengthens lead times, delays delivery, and ultimately negatively impacts customer satisfaction.

Reduced operational efficiency

With inventory spilling over its allotted warehouse space, your staff will experience challenges navigating and moving across the warehouse. It becomes difficult to seamlessly move between smaller aisles and overloaded shelves without posing a risk to warehouse safety. This prevents workers from efficiently performing their tasks, which directly impacts your logistics efficiency.

Common causes of warehouse overflow

Lots of different factors can lead to warehouse overflow. Here are some of the most common reasons why ecommerce businesses may experience overflow problems.

High seasonal demand

Demand typically spikes during peak seasons, which means businesses tend to stock up to meet this increased demand. However, as peak shipping season ends, they may not always sell off their seasonal stock. This excess inventory takes up valuable space and limits your storage capacity, contributing to overflow.

“In Q3 of 2022, ShipBob provided us with a roadmap to order management going into peak season and we decided to place inventory in some of ShipBob’s US fulfillment centers, in addition to our warehouse in Illinois.

We started out by having ShipBob only ship limited SKUs but when Black Friday rolled around, we were overloaded with orders. We were 10x over forecast and a top-5 Shopify product during Black Friday Cyber Monday (BFCM).

We weren’t able to manage all of those orders in our own warehouse, so we again turned to ShipBob. We shipped several trailers full of inventory from our warehouse to ShipBob’s fulfillment centers in Illinois, Texas, and Nevada, so our customers could get their presents in time for Christmas. ShipBob offered solutions on the fly that ultimately saved the season for us and our customers.

Tom Wall, Vice President of Global Warehousing & Logistics at Beachwaver Co.

Inaccurate forecasting

A common culprit of overflow inventory is inaccurate demand forecasting. If you overestimate how much demand you’ll see for a certain product and you end up selling much less inventory than you’d originally anticipated, the unsold inventory turns into deadstock. When this happens repeatedly, it can reduce your available storage space and lead to overflow.

Limited storage space

For some brands, the problem is not that they have too much inventory; they just have too little space. If you know you ordered the right amount of stock to meet demand but are still dealing with overflow issues, it’s probably time to think about expanding capacity.

That said, sometimes brands experience overflow because they aren’t making the best use of their physical space. For instance, a business might run out of storage space on warehouse floors, but not realize there’s plenty of free vertical space that they could use by installing warehouse racks. Warehouse slotting solutions allow them to make use of all available space in the warehouse and increase capacity.

Business growth outpacing infrastructure

While every business strives for growth, its existing infrastructure may not be able to support said growth. If you’re stocking up on more inventory to meet growing customer demands but still rely on the same storage facilities that you used when you started out, chances are you’ll run into overflow problems.

“Growing so fast has really underscored for us the importance of having a partner that can scale as fast as you do. Scaling is great, but it also comes with certain headaches – and while it’s a good problem to have, you need a partner that can handle your volume, even as it’s skyrocketing to over a million orders. With ShipBob, that capacity was never in doubt – and that was huge for us.”

Sergio Tache, Founder and CEO of Dossier

Challenges of managing warehouse overflow

While warehouse overflow won’t doom your business, it does present several challenges that can be costly and time-consuming to overcome.

Disorganized inventory

If your racks and shelves are already full, there’s no place to store additional incoming inventory during the warehouse putaway process. This leads to disorganization, which will negatively impact your warehouse inventory management.

Delayed order picking

In a disorganized warehouse, it’s much easier for items to get stored in the wrong places. This slows down your warehouse picking process, as your fulfillment staff may have a harder time locating the items they need – and when they do locate the items, retrieving them may be difficult if the warehouse is congested.

Temporary storage solution costs

Even if a business makes use of on-demand warehousing for overflow storage, this type of temporary storage solution is unsustainable. The high costs of leveraging these short-term solutions will eventually add up to eat away at your bottom line – not to mention that there’s no guarantee the warehouse will support your needs during peak seasons.

Health and safety hazards

Warehouse overflow can very easily lead to warehouse congestion. In a congested warehouse, racks and shelves may be overloaded, which could collapse and threaten worker safety. Congested aisles also pose a risk of accidents and collisions.

Additionally, boxes stored on the floor may become a tripping hazard. Meanwhile, congestion also prevents accurate inventory tracking, which means that some items may expire, leak, or spill, which may threaten the health and safety of your warehouse staff.

Preventative strategies to avoid warehouse overflow

The best way to manage warehouse overflow is to prevent it from occurring in the first place. Here are some of the best preventative strategies to avoid and reduce overflow issues.

Optimize your warehouse layout

To boost warehouse capacity and avoid overflow, try assessing and improving your warehouse layout. Optimize your warehouse setup to maximize your available storage areas, and consider investing in shelving systems that will help you make the most of any vertical space. You can even look for ways to reorder shelves and storage to hold more inventory (and even make picking more efficient).

Invest in real-time inventory management

Having real-time inventory visibility is crucial to get a realistic understanding of your actual inventory needs. When you can see exactly how much stock you have, it’s easier to plan your replenishment order so that you’re not reordering more inventory when you already have sufficient stock.

A top-notch warehouse management system (WMS) or inventory management system can deliver this level of visibility and help you monitor inventory levels. For instance, ShipBob’s WMS features built-in inventory management capabilities – including real-time inventory tracking and automatic reorder notifications – which you can leverage to accurately plan your procurement and avoid overstocking.

Learn demand forecasting and inventory placement

While your current stock levels give you some idea of your inventory needs, it’s only one side of the coin. To get an even more precise understanding of how to plan your replenishment orders, you need accurate demand forecasting.

To forecast demand correctly (and avoid overstocking), look at your brand’s sales history, inventory performance, and any current demand trends. In addition, consider where your customers are and what locations are seeing the most demand for which products. Armed with this information, you will be in a better position to predict demand and allocate inventory accordingly.

Solve overflow with ShipBob’s warehousing solutions

Whether you’re looking for more storage space, better inventory management, or even to outsource warehousing altogether, ShipBob can help. As an expert supply chain and fulfillment partner, ShipBob optimizes inventory storage and management for thousands of ecommerce brands to minimize costs while maximizing efficiency.

Here are just some of the ways that ShipBob’s solutions can help you avoid warehouse overflow, plus streamline your inventory and ecommerce warehousing operations as a whole.

Outsource overflow to ShipBob’s fulfillment network

ShipBob offers scalable solutions to warehouse overflow that help you store and manage large amounts of inventory. With 50+ fulfillment centers across the globe, you can strategically distribute your inventory to avoid overflow at any one location, equip each fulfillment center to meet demand, and even improve shipping speeds.

“We’ve recognized the importance of having a network of warehouses spanning the United States, as it’s crucial for us to be geographically close to our customers. Setting up four warehouses has been remarkably straightforward from a technological standpoint.

ShipBob’s technology streamlines inventory management across our network, ensuring optimal inventory allocation. Once the inventory is allocated correctly, passing orders to ShipBob is seamless. ShipBob automatically routes orders to the nearest warehouse to the customer. We receive notifications confirming the warehouse selected for shipping, eliminating inventory discrepancies between the warehouses.

Efficient inventory allocation significantly impacts our outbound shipping costs, and with ShipBob, managing this has been effortless.”

Ali Shahid, COO of Our Place

Distribute and place inventory for efficient storage

ShipBob helps brands leverage a distributed inventory model, which reduces the risk of overflow. This involves splitting stock across multiple fulfillment centers so that no one facility overflows with excess inventory.

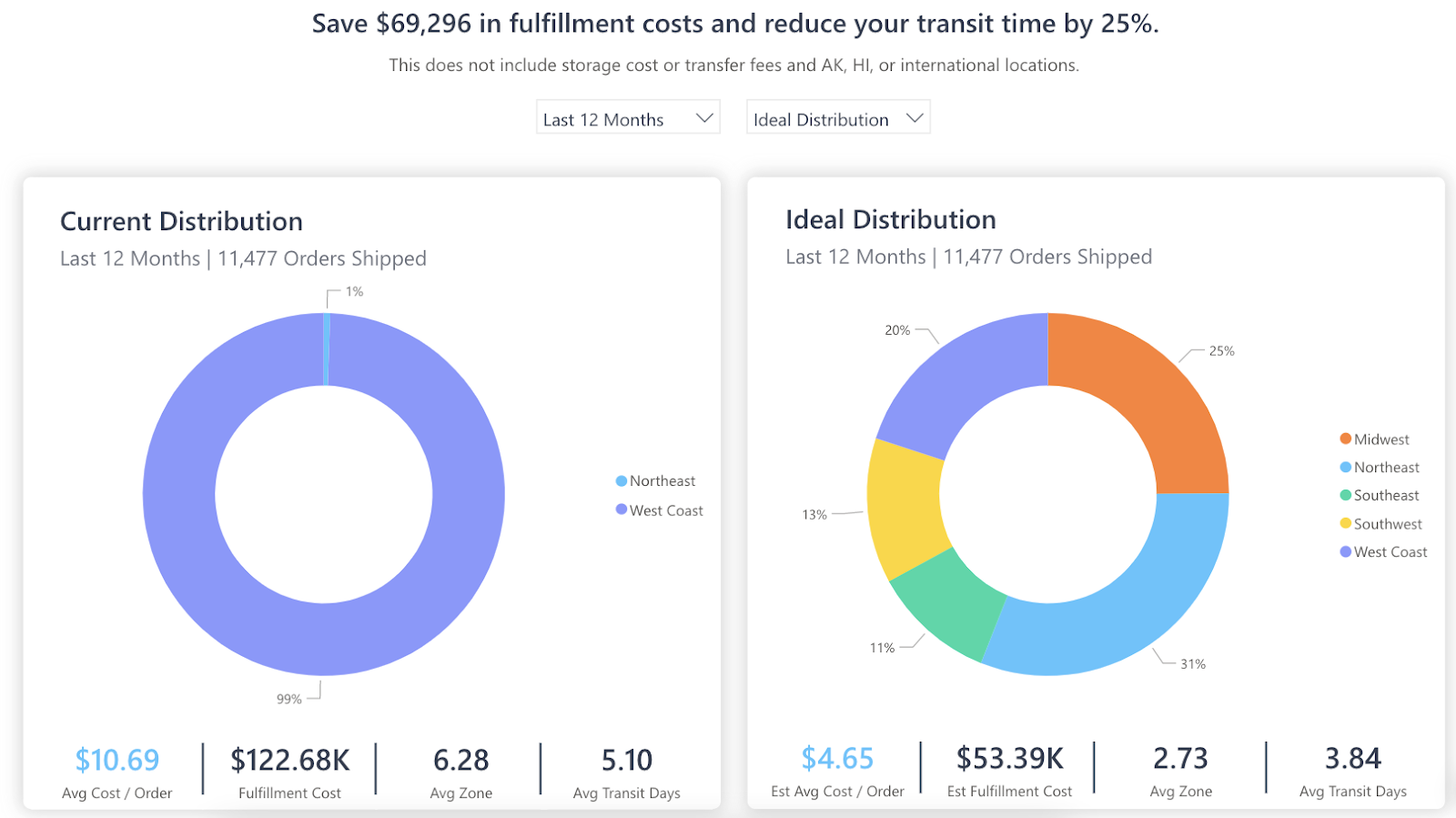

Using ShipBob’s Ideal Inventory Distribution tool, you can calculate the optimal amount of inventory to send to each fulfillment center based on your past order data. Not only does this ensure that every fulfillment center you use has enough stock to meet demand, but it also places inventory closer to end customers to reduce shipping times and costs.

ShipBob will even physically distribute your inventory for you through the Inventory Placement Program. Simply send your inbound inventory to a single ShipBob receiving hub, and ShipBob will take care of distributing it regionally to save you time, money, and effort.

“I ran the numbers to see what it would cost to ship pallets directly to different fulfillment centers, and it’s so much more expensive than sending it to one hub and letting ShipBob distribute it for us. The Inventory Placement Program’s model is much cheaper, and we don’t have to think about distribution. It’s saved us so many headaches, and now we just arrange one pickup from a manufacturer and one delivery. It’s so cheap, and so easy.”

Matt Crane, Co-Founder and Chief Science Officer at Semaine Health

Get on-demand storage flexibility

ShipBob’s flexible storage solutions give you the flexibility to scale up or down as you need. This can support your holiday inventory preparation, helping you effectively handle increased demand during peak shopping seasons with the freedom to scale down during slower months.

To learn more about how ShipBob can help you manage your inventory, click the button below to get in touch with an expert.

Warehouse overflow FAQs

Below are answers to the most commonly asked questions about warehouse overflow.

What are the best practices for managing warehouse overflow during peak seasons?

Some best practices for managing warehouse overflow during peak seasons include:

- Reworking your warehouse layout to maximize existing storage space (including vertical space)

- Conducting an inventory audit to move out deadstock and obsolete inventory

- Distributing inventory across multiple fulfillment centers to ease capacity pressure and put inventory closer to end customers

- Outsourcing fulfillment and storage to a flexible warehousing and fulfillment provider that offers dynamic storage solutions

Can ShipBob’s fulfillment network reduce my warehousing costs?

ShipBob’s fulfillment network can help reduce your warehousing costs. By strategically distributing your inventory across multiple of ShipBob’s facilities, you can minimize the high holding costs that result from warehouse overflow and reduce your shipping costs by placing inventory closer to customers.

What are the risks of not managing warehouse overflow?

Not managing warehouse overflow leads to warehouse congestion and disorganization, which can slow down your operations, increase safety risks, and delay shipments.

What is an overflow warehouse?

An overflow warehouse is a backup storage facility that a business uses to store inventory when the primary warehouse reaches capacity.