Table of Contents

** Minutes

Step-by-step guide to conducting a supply chain audit

Post-audit: continuous supply chain improvement

You may think your supply chain is running fine. But what if it could run better?

Maybe certain functions or tasks could be performed more efficiently, or in a more cost-effective way. Maybe your supply chain could be more agile, or better prepared for potential risks. Either way, the only way to know whether or not your supply chain operations are optimized is through an audit.

The supply chain audit process is a staple for streamlined supply chains. Through this process, you’ll map out your supply chain and examine it from top to bottom to identify what’s going well, where there are potential risks, and what functions need improving.

In this article, we’ll dive deep into a step-by-step walkthrough of a supply chain audit, why it’s important, and how an expert fulfillment partner like ShipBob can help.

What is a supply chain audit?

A supply chain audit is the process of examining and evaluating every aspect of your bsuiness’s supply chain and its associated workflows. This includes every function, activity, and procedure in every stage of the supply chain, from raw material procurement and production to warehousing, inventory management, fulfillment and last-mile delivery.

The goal of a supply chain audit is to identify inefficiencies, bottlenecks, and waste that could negatively impact your profitability and bottom line. This enables you to mitigate risks, disruptions, errors, and delays, and make changes that could improve your supply chain’s efficiency.

The role of supply chain audits for ecommerce

Supply chain audits serve many purposes for ecommerce brands and deliver a host of benefits no brand wants to miss out on. Specifically, supply chain audits:

- Boost efficiency: Supply chain audits help you pinpoint inefficiencies and bottlenecks that are holding your operations back. This allows you to target problem areas and implement solutions to maximize productivity and performance.

- Improve quality control: Through an audit, you’ll discover whether suppliers and manufacturers are meeting quality standards. You’ll also evaluate which partners are living up to their promises, and which need to up their service levels.

- Reduce risk: An audit will show whether or not your business operations are agile and resilient enough to survive disruptions. If not, you can make the necessary adjustments to make sure you’re prepared.

- Help ensure compliance: Audits give you the opportunity to make sure that you are compliant with all governmental regulations, as well as any regulations your service providers and partners require.

- Keep your brand competitive: Well-run supply chains serve as a competitive advantage. They also result in better delivery experiences for customers, which boosts customer satisfaction, encouraging loyalty and repeat purchasing.

Key components of an effective supply chain audit

A supply chain audit involves examining the workflows, processes, and partners at every stage of the supply chain. For an effective audit to improve your supply chain management, you’ll want to focus on evaluating the following supply chain functions.

Pre-manufacture procurement

This stage involves sourcing raw materials required for manufacturing goods. When auditing this stage, be sure to evaluate raw material quality, cost, and supplier performance.

Production/manufacturing

During production, the manufacturer or merchant turns raw materials into finished products that can then be sold. You’ll want to audit for production efficiency, cost, product quality, and manufacturer performance.

Transportation

Your products will physically move a lot on their journey through your supply chain. To make sure your transportation is up to snuff, consider all the different ways materials and/or goods will move (for example, from manufacturer to the merchant’s warehouse, from the merchant’s warehouse to a retailer’s warehouse, etc.). Besides speed and cost, evaluate each transportation strategy for reliability and overall efficiency.

Warehousing and storage

Many of your supply chain functions will take place in a warehouse, including inventory receiving and storage. You’ll want to assess your warehouse utilization, warehouse capacity, inventory holding costs, and inventory management, as well as the overall efficiency of every task that’s completed in your warehouse.

Distribution and sales

Your supply chain audit process should also gauge how efficiently your products are being sold and distributed across different sales channels. Quality control, customer service, and returns management should also be a part of your audit.

Fulfillment

One of the most critical aspects of the entire supply chain – and one that requires a lot of attention in an audit – is your fulfillment process.

The speed, efficiency, and accuracy of your fulfillment operations will hugely impact your customer’s delivery experience, so it’s important to optimize your fulfillment strategy for peak performance. You should measure key performance indicators, such as:

- Order accuracy rate

- OTIF rate

- Average fulfillment time

- Average fulfillment cost

- Average lead time per order

- Average storage cost

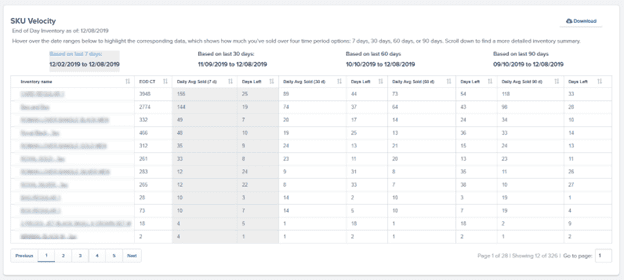

- SKU velocity

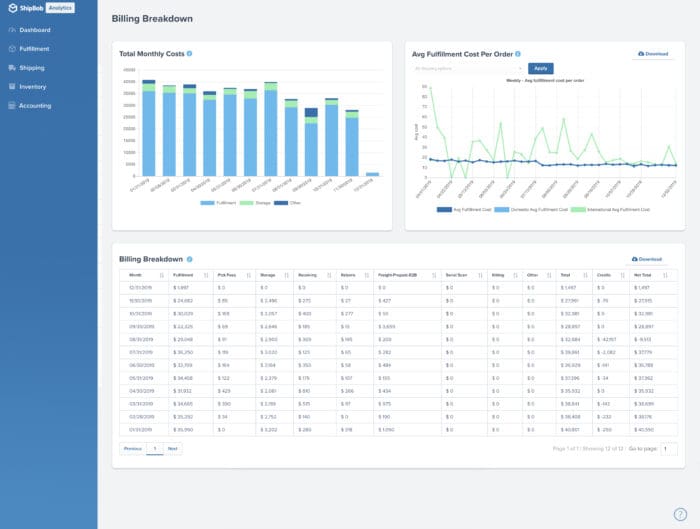

If you fulfill orders yourself, you will need to collect this data on your own. If you work with a fulfillment provider, they should be able to automatically track and present you with this data.

“I can literally go into my ShipBob dashboard and see exactly what I want to see with a few clicks. I love that it’s a quick snapshot of everything that’s going on. I can literally not look at the ShipBob platform for 3 weeks, and then log in and within 10 minutes of analyzing the data, I know exactly where we stand in the business.

Even if I had to crunch some numbers, it would be just pulling a couple of reports and putting that data together – it’s so much easier than other solutions. As a person who relies on data analytics to run my business, I want to see my analytics exactly how ShipBob displays them to me.”

Mithu Kuna, Founder and CEO of Baby Doppler

Step-by-step guide to conducting a supply chain audit

With so many areas to evaluate, conducting a supply chain audit can seem overwhelming. To help you get started, let’s walk through the steps of a standard audit.

Step 1: Initial assessment and preparation

Before you even begin your audit, you will need to do some prep work.

First, define the objectives of your audit. Once you establish specific outcomes that you wish to achieve, you will have a clearer understanding of what to focus on during your audit. This helps you target and streamline your efforts, so you don’t waste your time and resources.

For example, you may want your audit to help you cut costs. With this objective in mind, you can spend your time measuring costs, rather than spending time measuring less pertinent parameters like accuracy or efficiency.

At the same time, you should define the scope of the audit. If your supply chain is large or complex, consider focusing on a few problem areas first. For example, if you’re constantly experiencing fulfillment delays, honing your fulfillment processes is a good place to start.

Step 2: Data collection and analysis

Once you define your audit scope and objectives, it’s time to start measuring performance – and you can’t measure anything without collecting data and documentation.

To ensure that the audit is as comprehensive as possible, make sure to use all the information related to the aspects of your supply chain execution that you’re auditing. This includes all the data from your databases and systems, as well as data from apps, sensors, and IoT devices.

You may also need to look at documents such as invoices, contracts, receipts, progress report, procedures, and policies. Site visits, interviews with stakeholders, surveys, and questionnaires are additional ways to collate data for your audit.

During this stage, it’s always a good idea to look beyond internal data for performance benchmarks in your industry. Consider researching industry benchmark reports, legislative updates, and changes in best practices to help you identify new opportunities for supply chain improvement.

Step 3: Evaluating supply chain processes

After you’ve gathered the necessary data, you’ll need to analyze it to pull the insights you need. Ask yourself the following questions to help you interpret the information you’ve collected:

- Is this metric too high or too low? Why?

- What story does this data tell?

- How might the performance of one supply chain function be impacting another?

Ideally, this stage of the supply chain evaluation will reveal any issues that are impacting supply chain efficiency, such as bottlenecks, waste, and procedural delays.

Step 4: Supplier assessment

It’s also important to go beyond your internal audit and thoroughly assess your supply chain partners. Your supplier audits will typically include an assessment of all your supply chain partners, including those involved in the upstream supply chain. Look at contracts, product quality, lead times, manufacturing processes, compliance, supplier relationships, supplier diversity, and more.

Step 5: Risk identification and management

Risk assessment and risk mitigation should also be built into your supply chain audit. In addition to potential issues that you are aware of, do due diligence to identify any risks that could cause disruptions in your supply chain – or even make your existing operations more susceptible to outside threats.

Consider risks related to:

- Cybersecurity

- Geopolitics

- Non-compliance

- Natural disasters

- Macroeconomic movements (such as a recession)

- Health & safety

Proactive risk assessment enables you proactively mitigate these sorts of risks. That way, you can manage these threats before they turn into a bigger issue, or at least prepare your business for disruptions outside of your control.

Step 6: Implementing improvements

Now, it’s time to act on the insights you’ve gained from your investigation. This process will look different depending on the end goal of your supply chain audit, but it typically involves tweaking, changing, or wholly redesigning supply chain processes to improve them.

It might be helpful to create an action plan for each improvement, where you identify:

- The root issue being addressed

- The key stakeholders responsible

- A timeframe for implementing the changes

- Resources needed

Every modification you make should serve your end goal, and make your supply chain more efficient, cost-effective, and reliable.

Step 7: Monitoring and continuous improvement

You’ve changed things up in your supply chain – but how do you know if those changes are working?

To determine if your adjustments are having the desired effect on your operations, it’s crucial to monitor relevant supply chain metrics and data for improvement.

For example, say you arranged automatic reorder notifications on your inventory management software to help you time replenishment and avoid stocking out. To see if those notifications make a difference, track your stockouts and inventory levels over time. If you experience fewer stockouts and see inventory levels stay balanced, your adjustments probably worked.

Closely monitoring your performance will enable you to quickly pivot if you don’t see improvements, or continuously improve your processes for even better results.

Step 8: Reporting and documentation

As you conduct your audit, make sure to keep records of data, any changes you make, and their results. That way, you not only have it to refer back to later on, but you can share the impact of your supply chain audit with key stakeholders.

You may even compile relevant findings, supply chain KPIs, and recommendations for each department into a comprehensive audit report. This can help different parties understand the significance of your audit’s findings, and how it applies to their specific department.

Best practices when auditing your supply chain

While you are free to conduct your supply chain audit however you want, leveraging the following best practices can help you execute your audit more successfully.

- Put together an audit team: Have a proper team in place to conduct the audit. Consider including internal auditors from various departments and processes who can add vital insights and department-specific expertise.

- Plan your audit schedule: Timing is a vital element to consider when conducting your audit. This is especially true in the case of audit methodologies that involve site visits and interviews. You’ll need to create an audit schedule by coordinating with suppliers and stakeholders as needed.

- Create an audit checklist: Having a checklist in place helps you organize your audit and gives auditors a clear path to follow. It also gives everyone the opportunity to make suggestions before the audit begins. Moreover, it ensures that everyone involved in the audit has a clear idea of how it will be performed, thus reducing information gaps.

- Prioritize open communication: Communication plays a critical role in successful supply chain audits. Auditors must be able to seamlessly communicate with relevant stakeholders, departments, supply chain partners, regulatory agencies, and frontline workers. This is particularly important when operations and information systems are siloed, as the lack of visibility may impact the effectiveness of your audit.

- Take a risk-based approach: Conducting a risk-based audit will help you prioritize tackling the biggest threats and weaknesses. This allows you to strategically allocate your resources where you need them the most.

- Make the most of technology: Supply chain technology platforms can make a huge difference in your audit process by providing end-to-end visibility and automated data collection. Warehouse management systems, inventory management systems, and enterprise resource planning software help you keep track of vital supply chain data to streamline your analysis and improve accuracy.

Post-audit: continuous supply chain improvement

Improving your supply chain is a continuous process, not a one-time task. Regular supply chain optimization should be a part of your post-audit strategy.

Analyze audit results for long-term strategy

While a supply chain audit may reveal several short-term improvements, you should also consider how your audit results impact your operations in the long term.

For example, you may notice that you’re relying too much on one supplier, which is creating a rigid supply chain that’s prone to disruptions. You may incorporate this finding by diversifying your suppliers and creating backup options for when your primary supplier falls through. This will help you create a more flexible and resilient supply chain that can easily adapt as needed.

Implement changes and monitor progress

The insights you draw from your audit should be used to make improvements to your supply chain processes. Come up with a solid strategy for implementation and make sure everyone is on board to execute these changes. Once implemented, make sure to constantly monitor your progress by keeping track of your supply chain analytics.

Make use of supply chain technology that gives you real-time and comprehensive analytics insights that can be used for monitoring the impact of your improvements. This is also necessary to ensure that the changes are being implemented effectively and in accordance with your recommendations. Set milestones and timelines to review your performance so you can understand whether the results are as expected or whether you need to change course.

ShipBob’s role as your supply chain audit software

A successful supply chain audit relies heavily on supply chain visibility and reliable data. When you have accurate, real-time data on supply chain processes, you’ll have a better understanding of how your operations are running – and can make more strategic decisions.

To achieve this data and visibility, many brands choose to partner with a professional logistics platform like ShipBob. Here are just some of the ways that ShipBob can help your brand conduct a more comprehensive and successful audit.

Advanced analytics for data-backed decisions

ShipBob’s analytics reporting tool delivers comprehensive insights into your supply chain performance. It automatically tracks and records data on supply chain KPIs, including average transit time, average fulfillment cost, SKU velocity, and more.

Using this deep visibility, you can quickly identify areas of inefficiencies that need to be addressed. The powerful reporting capabilities empower you to make data-backed decisions to improve various aspects of the supply chain and improve your performance.

For instance, brands can leverage historical sales data and SKU performance to more accurately forecast demand, plan procurement accordingly, and avoid over- or under-stocking.

Leveraging technology for optimized warehousing operations

ShipBob also offers a proprietary warehouse management system (or WMS) that brands can use to power and optimize their own warehouses. It serves as a single source of truth to manage all areas of the supply chain, including warehousing, inventory, distribution, transportation, and fulfillment.

In addition to the analytics dashboard mentioned above, ShipBob WMS customers receive implementation support that helps them optimize their warehouse layout and processes for efficiency. Once it’s set up, ShipBob WMS’s easy-to-use technology keeps your operations running smoothly, so can keep performing at peak productivity even between audits.

“ShipBob’s WMS has more than doubled, if not tripled, our productivity in terms of labor hours. Our average days to ship is now only 0.8 days, so most packages are shipping same-day or next-day, with rare exceptions.

We’ve cut 4 days of lead time because orders are getting processed, fulfilled, and shipped more efficiently. When we first started with ShipBob, we were doing about 15K orders per month, and now we’re processing 30K — double what we were doing just six months ago.”

Ben Tietje, Co-Founder and CEO of Earthley

Outsourced fulfillment services for leaner supply chain performance

If your audit reveals that you’re in over your head when it comes to logistics management, it might be time to outsource to an expert. ShipBob offers outsourced solutions that enable you to hand off complex supply chain functions like inventory storage, warehousing, fulfillment, and shipping to our team, and let us take care of optimizing them for you.

Once you partner with ShipBob, you can send your inventory to one or more of our dozens of global fulfillment centers. From there, our warehousing teams will receive and store inventory, pick and pack orders, and send them out for shipping for you – all while leveraging best practices and automation to design a faster, more cost-effective supply chain.

“Fulfillment is hard, so there’s always going to be mistakes – and with our previous 3PL, we were used to having about a half of a percent error rate (meaning 0.5%-1% of the DTC orders that we shipped out were wrong in some way). With ShipBob, I feel like our error rate is a hundred times less.

I’m just stunned by how accurate our orders are, and our error rate is just vanishingly small now. Honestly, it’s been a game-changer for us, because we’re experiencing way fewer customer service issues than before, while growing 4x.

If our accuracy levels had stayed the same as they were before partnering with ShipBob, we would have had to hire more customer service members on our team just to handle all the issues and get orders out on time. If we were still with our old 3PL, we would not have been able to scale.”

Matt Crane, Co-Founder and Chief Science Officer at Semaine Health

For more information on how ShipBob can help you create a more efficient supply chain, click the button below to speak to an expert.

Supply chain audit FAQs

Below are answers to common questions about supply chain audits.

Why should I audit my ecommerce business’s supply chain?

Auditing your ecommerce business’s supply chain helps you boost efficiency, improve quality control, mitigate potential risks, stay compliant with regulations, and keep your brand competitive.

How often should supply chain audits be conducted?

Supply chain audits should be conducted periodically according to your business’s needs.

How does technology enhance the supply chain audit process?

During a supply chain audit, brands can leverage technology to collect valuable data and access real-time visibility into supply chain operations.

What are the key components of an effective supply chain audit?

An effective supply chain audit starts with thorough preparation and comprehensive data collection. This data is then analyzed for actionable insights, alongside supplier assessment and supply chain risk management. A brand then changes or adjusts supply chain processes based on the audit’s findings, and tracks key metrics to measure how those changes impact efficiency.