No supply chain is foolproof. While every ecommerce brand strives to build a strong one, even the most resilient supply chains have vulnerabilities. Some are avoidable, and some aren’t – but a strategic approach to supply chain planning can help you mitigate their impact and position your brand for success.

In this guide, we’ll discuss the most common supply chain vulnerabilities, how to detect them, strategies for protecting your business, and how a supply chain enablement partner like ShipBob can help strengthen your operations.

What are supply chain vulnerabilities?

Supply chain vulnerabilities are weaknesses that could disrupt the flow of goods within your supply chain.

Supply chain vulnerabilities include any risk or fragility in your supply chain processes, infrastructure, or suppliers that could potentially interrupt your supply chain operations.

To avoid your supply chain breaking or grinding to a halt, it’s crucial to identify these vulnerabilities during your supply chain risk management and find ways to mitigate them.

Common ecommerce supply chain vulnerabilities

There are many types of vulnerabilities that can lead to supply chain bottlenecks and disruptions. Some of the most common kinds of vulnerabilities include:

- Natural disasters – Earthquakes, floods, hurricanes, and other naturally-occurring disasters can cause damage and prevent supply chains from functioning seamlessly.

- Geopolitical risks – Political disturbances, sanctions, trade disputes, and regulatory changes lead to blocked communication, uncertainties, and supply chain delays.

- Cybersecurity threats – Cyberattacks and data breaches could result in loss of information and operational disturbances.

- Supplier instability – Delays, bankruptcies, and quality issues on the supplier’s end are one of the leading causes of supply chain disruptions, especially for brands that rely heavily on just a handful of suppliers.

- Inventory management issues – Poor inventory management and inaccurate forecasting often results in stockouts or overstocking, which could disrupt your supply chain operations.

- Lack of visibility – Limited visibility into your supply chain makes it difficult to track inventory, monitor supplier performance, and keep up with your schedules.

- Logistical disruptions – Accidents, port congestion, infrastructure failure, and strikes can cause delays or interruptions in transportation.

How global dependencies heighten supply chain risk

The globalization of ecommerce has had many benefits – but at the same time, a global supply chain can be more prone to vulnerabilities.

Ecommerce businesses that rely on international suppliers, stakeholders, and networks are particularly vulnerable to external forces, such as global disasters and geopolitical unrest. Any disturbances in these factors could lead to uncertainties, interruptions, and delays that impact fulfillment timelines.

For instance, brands that source their products in China may experience delays in freight shipping due to port congestion. Worse yet, a global health crisis such as the COVID-19 pandemic has the potential to completely halt business operations around the world, leading to labor shortages, suspended operations, and rampant stockouts and backorders.

Regulatory changes could also complicate logistics or increase costs for international shipments. In more serious cases, businesses may have to look for alternative suppliers due to trade wars and sanctions preventing them from working with their existing vendors.

Supply chain cyberattacks are running rampant

As supply chain technology has evolved, supply chains are becoming increasingly digitized. Although this convergence introduces a lot of automation and usually boosts supply chain efficiency, it also poses greater risks for cybersecurity.

Ransomware and malware attacks could lead to the loss of sensitive data and expensive “ransoms” in addition to disrupting your operations. They could even result in reputational damage and legal issues, which can severely harm your business.

Many of these attacks specifically target supply chains, as the use of third-party vendors and suppliers leaves ecommerce businesses more vulnerable to data breaches. Despite having advanced cybersecurity systems in place within their own organizations, many ecommerce businesses may work with smaller suppliers who lack the sophisticated security needed to thwart these attacks.

“We’ve had some perfect storms – when forecasts were off, there were weather delays, etc. – but our team and ShipBob’s came together to work some magic and make it happen. When things came down to the wire, ShipBob’s team was always there to support and problem solve with us, and we still managed to make it all go perfectly.

During peak season one year, there was flooding in California, and things were a bit of a mess. We never expected or planned for our containers to be flooded – nobody thought we were going to be able to recover. But with ShipBob’s support, we were able to get our inventory live and online in time to meet the demand surge! We feel really good about how we handled that peak, and we could not have done it without ShipBob’s team.”

Molly Noonan, Senior Manager, Supply Chain at Tonies

How to detect vulnerabilities in your supply chain

It’s impossible to create a supply chain that is 100% free from vulnerabilities. What you can do is identify those vulnerabilities, so that you can prevent them from causing major supply chain disruptions.

Here are some of the ways you can pinpoint the vulnerabilities in your own supply chain.

Invest in supply chain visibility

When you know what’s going on throughout your supply chain, it is much easier to identify where its weaknesses are. Investing in supply chain systems that give you real-time visibility into how various aspects of the supply chain are performing will help you pinpoint any weaknesses that could threaten your operations. By increasing your supply chain visibility, you gain access to essential performance data and information to easily detect any deviations and abnormalities.

Be sure to invest in systems that let you maintain an open line of communication with key supply chain partners, like your suppliers or 3PL. This will allow you to increase transparency and stay informed about possible issues that could turn into vulnerabilities down the road.

“Before partnering with ShipBob for order fulfillment, we had a lot of trouble getting visibility into inventory movement. We worked with some large fulfillment providers as well as some smaller 3PLs, and none of them gave us unified data, let us look at inventory holistically, or enabled us to see which inventory was moving and where. The reporting formats for every fulfillment provider were different yet incomplete, and taking all of that data and piecing it together to figure out what was going on was a nightmare. I got to a point where I just couldn’t operate like that any more.

Partnering with ShipBob, we joined their Inventory Placement Program, which helps us distribute our inventory to strategic hubs across the US so we don’t have to manage multi-location inbound shipments or identify the most optimal fulfillment center locations ourselves. This finally gave us the visibility and analytics we were looking for.

Through the program, we get real-time insight into how much inventory to allocate to a specific warehouse, our current on-hand inventory levels, and how long each SKU is going to last by location. ShipBob provides a lot of distribution metrics, and everything presented is useful.”

Mithu Kina, Founder and CEO of Baby Doppler

Employ risk assessment techniques for supply chain resilience

Conducting a comprehensive risk assessment to identify possible vulnerabilities and threats will help you mitigate those risks and make necessary optimizations to boost your supply chain resilience.

Start by thoroughly mapping your internal risks – in other words, the weak points that are likely within your control. Consider your cybersecurity, your tech stack and infrastructure, and your logistics operations and processes for inefficiencies that could leave you susceptible to disruptions.

You’ll also need to assess external risks, like geopolitical changes, regulatory updates, supplier relationships, and other factors outside of your control that could impact your supply chain. Staying on top of these updates allows you to quickly identify potential risks.

As you map these risks, create contingency plans for your most vital transportation hubs, vendors, and warehousing facilities. This will help your supply chain stay agile and continue operations even if disruptions arise.

Tools for monitoring and auditing supply chain risks

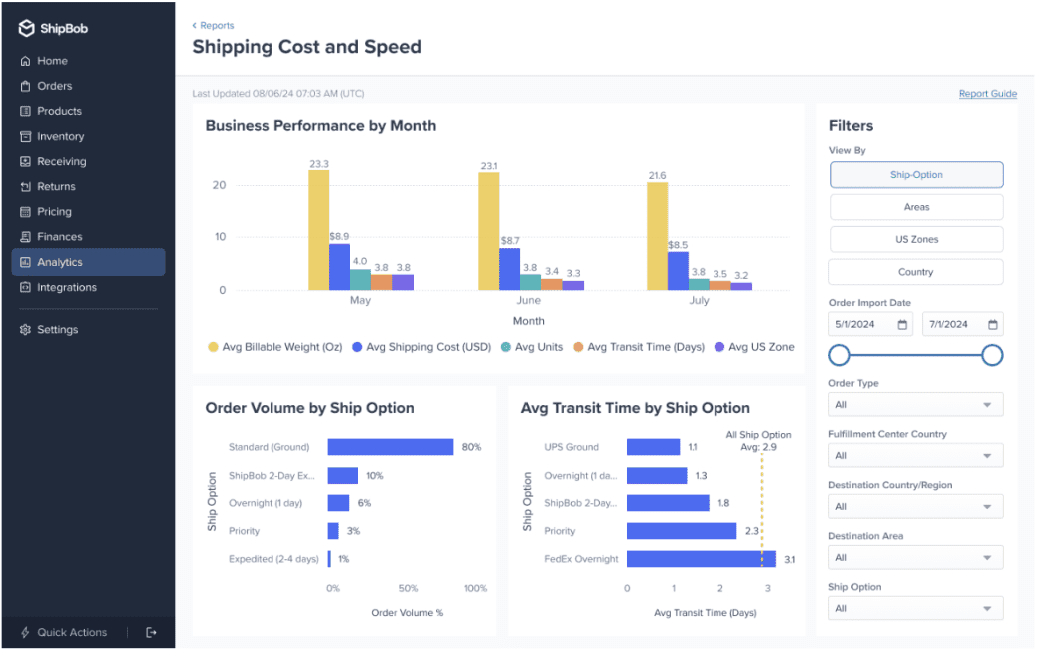

Fortunately, there are supply chain software solutions that can enhance visibility and simplify the process of identifying vulnerabilities. Consider leveraging relevant supply chain analytics tools to monitor performances at key nodes across your supply chain network.

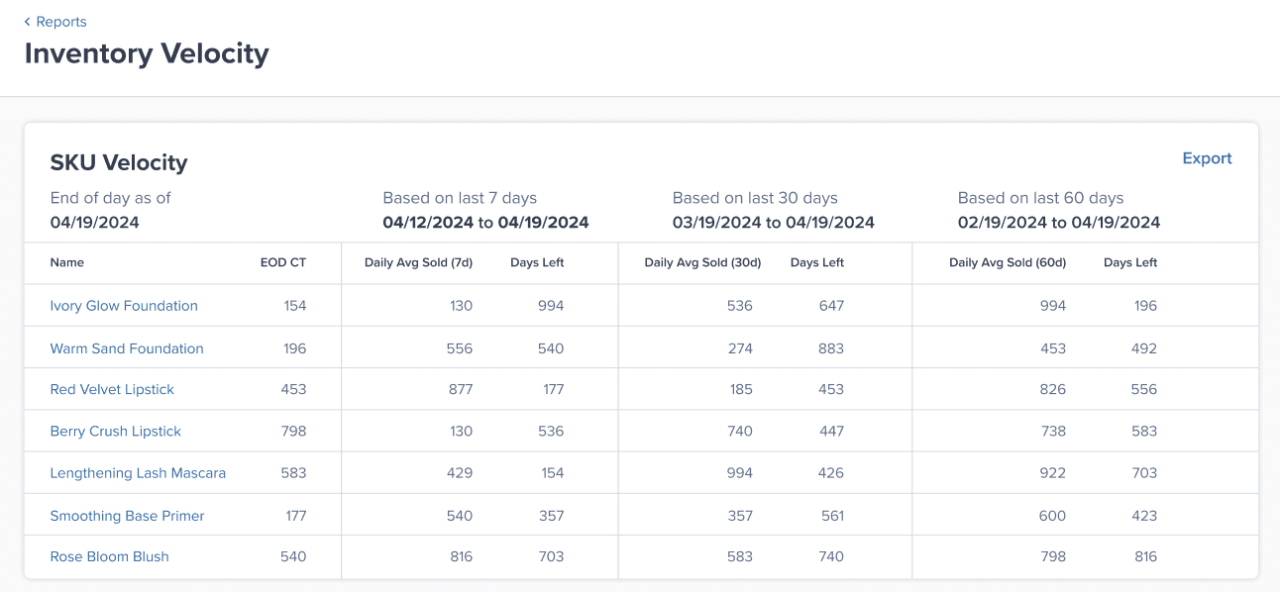

ShipBob’s merchant dashboard, for instance, gives you real-time insights into your inventory and supply chain performance. Its inventory management capabilities let you track inventory levels in real time, telling you exactly how many units you have available for each SKU. This makes it easier to plan your procurement and make timely replenishment orders so you can avoid stockouts and backorders.

You can view inventory data to see how specific SKUs are performing, track historical sales, and make accurate forecasts about future demand, as well as track warehouse management metrics to detect internal issues and backlogs before they escalate.

3 strategies to protect your ecommerce business from supply chain vulnerabilities

Although it’s impossible to completely eliminate risk from your supply chain, there are a few best practices to help you minimize your supply chain vulnerabilities and mitigate their impact.

1. Diversifying your supplier base

Relying on a single or a few suppliers leaves your supply chain vulnerable, as even a single snag or disruption could have a major impact on your operations and leave you without alternatives. For instance, if a fire were to occur at the supplier’s warehouse, you’ll immediately feel the impact through inventory shortage and procurement delays.

On the other hand, if you work with several suppliers, you always have backup options in case something goes wrong with one supplier, and can rely on them to continue operations without affecting the customer’s experience. In the previous example, you could obtain backup inventory from other suppliers to tide you over while the affected supplier recovers from the damage, without having to pause sales or put customers on backorder.

2. Leverage distributed inventory for risk reduction

In the same vein, diversifying your inventory distribution is another great way to protect your business against vulnerabilities.

When you rely on just one warehouse to store your inventory, regional disruptions or factors could easily impact your entire inventory. If a natural disaster flooded your only warehouse, for example, you could lose your entire stock, leaving you unable to fulfill outstanding customer orders. Similarly, if regional power outages were to temporarily disrupt your fulfillment center’s power, you would instantly be unable to ship out any remaining customer orders.

But by distributing inventory between multiple fulfillment centers, you always have backup options in case of disruptions affecting one region. This way, even if one storage facility or fulfillment center is impacted, you still have enough inventory and fulfillment capacity to continue operations.

“In 2023, we were hit with another unexpected issue: our products were being delayed at the ports and customs. ShipBob was able to expedite receiving those containers of product. ShipBob receiving inventory throughout all of peak season and BFCM once again saved the season for us and our customers. By distributing our inventory across ShipBob’s US fulfillment centers, we have seen our own warehouse’s order flow drop to manageable numbers while maintaining peak sales during peak season.”

Tom Wall, Vice President of Global Warehousing & Logistics at Beachwaver Co.

3. Strengthen your supply chain with cybersecurity measures

In addition to the loss of sensitive information, cyberattacks could put you at risk for huge financial losses and serious reputational damage. As a result, it’s crucial to have strong cybersecurity protocols in place throughout your supply chain network.

This means following strong encryption protocols and fostering a culture that prioritizes cybersecurity, as well as holding your supply chain partners accountable to follow these protocols and ensure better data protection.

Additionally, you’ll want to implement a layered security approach for the systems used across your supply chain network. This includes the use of powerful firewalls, intrusion detection systems, and anti-malware software.

How ShipBob helps mitigate supply chain vulnerabilities

As an expert logistics and supply chain enablement partner, ShipBob has helped thousands of ecommerce brands strengthen their supply chains and optimize their operations for cost-savings and efficiency.

Here are just some of the ways that your brand can leverage ShipBob’s solutions for a more agile, resilient supply chain.

Avoid disruptions with multi-location inventory placement

Optimizing your inventory distribution is one of the key steps to building a resilient supply chain that’s less vulnerable to disruptions. However, maintaining multiple warehouse spaces across different locations can be expensive, not to mention complex. Even if you do have the space, how do you decide how much inventory goes where?

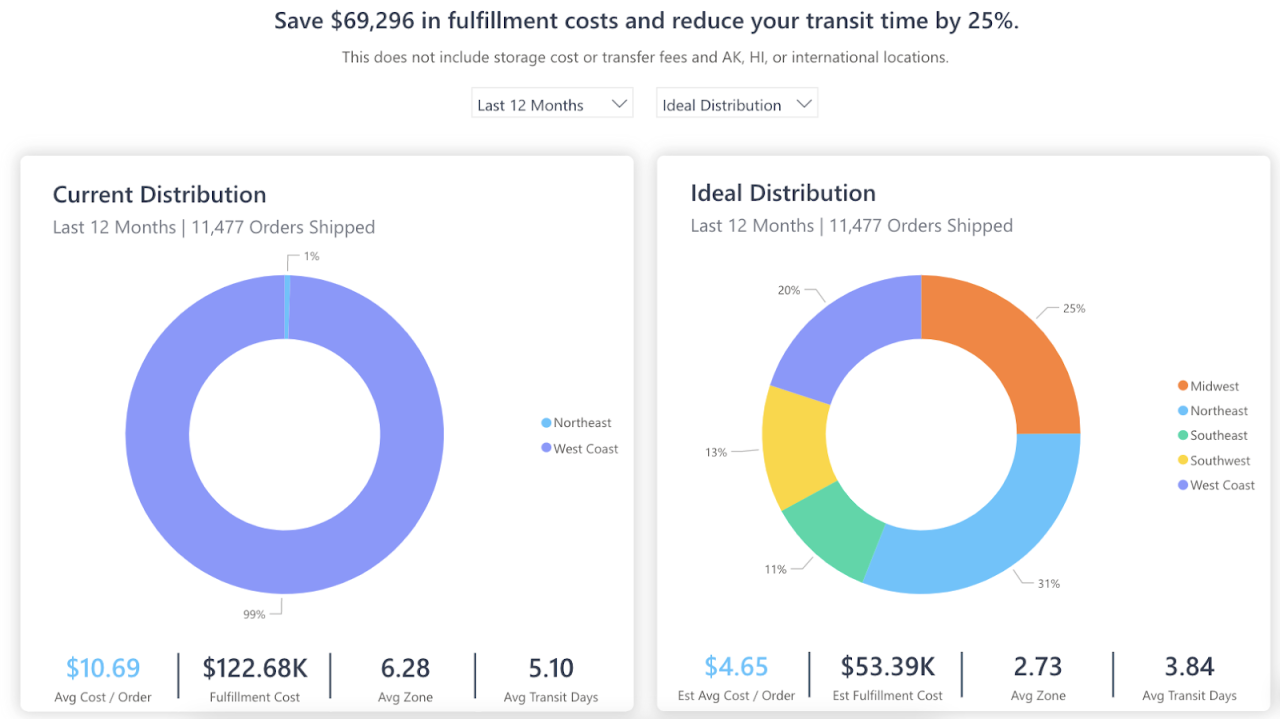

ShipBob’s Inventory Placement Program is designed to streamline the inventory distribution process. The program uses a proprietary algorithm to determine the ideal split of inventory across dozens of ShipBob’s fulfillment centers, allowing you to store your inventory to meet demand more effectively across regions, maintain optimal stock levels, and minimize shipping costs and times.

Moreover, you only need to send your inventory to one central hub. ShipBob will then distribute the inventory for you based on the recommended distribution strategy. This saves you time and money while helping you reduce vulnerabilities.

Prevent vulnerabilities with end-to-end visibility and real-time insights

Your supply chain becomes vulnerable when you’re only reacting to issues after they occur. By the time you solve the problem, it may have already interrupted with your operations enough to result in losses and delays.

ShipBob’s real-time visibility tools enable you to proactively monitor key data and metrics, providing you with timely insights to prevent issues before they turn into major disruptions.

You can leverage the various inventory tracking and warehouse monitoring tools to improve end-to-end supply chain visibility. For example, ShipBob’s dashboard lets you:

- Track your inventory movement in real time to easily identify delays before they create serious bottlenecks.

- Monitor warehouse activities like receiving to quickly detect interruptions and solve them before they escalate.

- Stay on top of your order fulfillment processes and deliveries to identify possible delays and maintain transparency.

Run a tight ship with ShipBob’s warehouse management system

ShipBob’s powerful WMS helps you maintain a single source of truth to better manage your supply chain operations within your own four warehouse walls. The cloud-based software is capable of powering multiple warehouses, enabling teams to update information and monitor warehousing activities in real time. This makes it easy to have additional checks and balances at every stage, which reduces errors and boosts inventory accuracy.

“When we implemented ShipBob WMS in our Nevada warehouse, we saw how well it worked compared to the software we created. It helped us a lot with inventory. Previously, we were having so many issues with not seeing where inventory was so the ShipBob WMS gave us greater inventory visibility. Additionally, the software helped us improve picking accuracy, inventory counts, and forecasting.”

Cesar Contreras, Head of Supply Chain of Wholesome Goods

For more information on how ShipBob can help you strengthen your supply chain, click the button below to get in touch.

Supply chain vulnerability FAQs

Below are answers to the most commonly asked questions about supply chain vulnerability.

Why are supply chains so vulnerable to cyberattacks?

Supply chains are especially vulnerable to cyberattacks because they involve multiple stakeholders with varying levels of security and infrastructure. This makes it easy for attackers to launch an attack by exploiting the weakest points of a supply chain.

How can supply chain vulnerabilities impact freight forwarders and logistics service providers?

Transportation delays, natural disasters, and port congestion are some of the biggest supply chain vulnerabilities that could impact freight forwarders and logistics service providers. These weaknesses could lead to delays, disruptions, and increased costs.

What recent examples have highlighted global supply chain vulnerabilities?

Trade restrictions, labor shortages, lockdowns, and closures resulting from the COVID-19 pandemic are some key examples highlighting vulnerabilities in the global supply chain. The Suez Canal blockage in 2021 that resulted in massive delays, operational disruptions, and financial losses is another key example.

What percentage of breaches start with supply chain software?

About 75% of recorded breaches start with an attack on the victim’s supply chain software.