Table of Contents

** Minutes

How to prevent excess stock in the first place

How technology can help with reducing excess inventory in 2023

When it comes to ecommerce inventory, you can have too much of a good thing.

Merchants need enough inventory on hand to meet demand, and some safety stock just in case. But sometimes, as you try to avoid stockouts, you might accidentally end up with more inventory than you can sell.

While excess inventory isn’t always an urgent concern, it can cause a lot of problems when left unchecked. For that reason, ecommerce merchants should know what to do with surplus inventory – and how to avoid it altogether.

In this article, we’ll cover what surplus inventory is, how it harms ecommerce businesses, tips for getting rid of it, and techniques for preventing it in the first place.

What is surplus inventory?

Surplus inventory, also known as excess inventory, refers to excess stock that your company holds. In other words, it’s any amount of product that your business has beyond the amount you need to meet demand and your safety stock.

Downsides of excess inventory

Many businesses will choose to keep a bit of excess inventory as a buffer in case of sudden demand spikes (especially during holiday seasons). However, holding too much surplus inventory can be an expensive and complicated problem for your business. Here are some of the main downsides of having surplus inventory.

Increased storage and holding costs

Inventory holding costs are already a big cost center for ecommerce businesses, and holding onto excess inventory will only raise those costs over time.

The more stock you have, the more you will have to spend on inventory storage systems, warehousing space, and labor.

Usually, selling inventory usually helps offset these costs – but because surplus inventory is often unsellable, your business ends up wasting money to store inventory that will never generate revenue.

Risk of inventory spoilage leading to unnecessary waste

Products that sit in the warehouse for prolonged periods of time depreciate in value. Moreover, they are at risk of getting damaged or expiring (particularly if products have a short shelf life), and susceptible to inventory shrinkage if they remain unsold for a long time.

As a result, your business will have to deal with higher levels of abnormal spoilage, leading to unnecessary waste.

Reduced profitability

When your company has excess inventory, it means you have capital tied up in products that you’re unable to sell.

On top of this, the surplus inventory is taking up valuable storage space (or shelf space, for products sold in-store) that could have housed more popular, fast-selling SKUs.

This makes it harder to stock up on items that are currently in demand which could potentially lead to higher sales and more profit for your business.

Moreover, the older products will depreciate in value over time. This means you’d have to lower prices if you want to get rid of the excess inventory. In some cases, you may even need to sell the old stock at a loss, which will severely cut into profit margins and damage your company’s bottom line.

Inventory obsolescence

Even if your excess inventory doesn’t necessarily expire or go through spoilage, there’s also a risk of it going obsolete if it sits on the shelves too long.

Obsolete inventory refers to products that are no longer sellable or usable, often due to changes in demand and lack of market value. This could be because trends have evolved or new technology is introduced, rendering the current product useless or inconvenient, or if the product naturally has a short life cycle.

Whatever the cause may be, inventory obsoletion may cause you to lose revenue, since your capital is tied up in inventory that won’t sell.

Increased waste from packaging

While your surplus inventory sits unsold on the shelves, there are packaging materials simultaneously sitting unused because of those slow-moving items.

In addition to disposing of the surplus items, you will also need to find a way to dispose of the packaging material for those products. This adds to your overall waste production, setting your business back in terms of sustainability.

Increased carbon emissions from unnecessary transportation

Transporting inventory to your warehouses creates a lot of carbon emissions, which adds to your overall environmental impact.

However, the transportation of excess inventory is unnecessary, and only adds to your carbon emissions, increasing your environmental impact even more.

Businesses can reduce their impact by procuring the right amount of inventory at appropriate intervals.

How to prevent excess stock in the first place

Because excess stock can cause issues for a business, it’s best to avoid it altogether. Here are some practical solutions to improve inventory control and reduce the likelihood of having surplus inventory.

Forecast inventory

Accurate demand forecasting is key to preventing surplus inventory. When you work with more accurate predictions on what SKUs will sell and how fast, you can reorder just enough inventory to meet demand, rather than guessing how much you’ll need and accidentally ordering too much.

To hone your demand forecasting, try using inventory forecasting tools to track and analyze:

- Historical sales data

- Seasonal trends

- Economic demand

- Geographic or environmental factors

- Macro-level shifts in buying behavior

Data on these qualitative qualitative analytics allows you to anticipate surges or drops in demand, so you can plan your procurement and reordering accordingly.

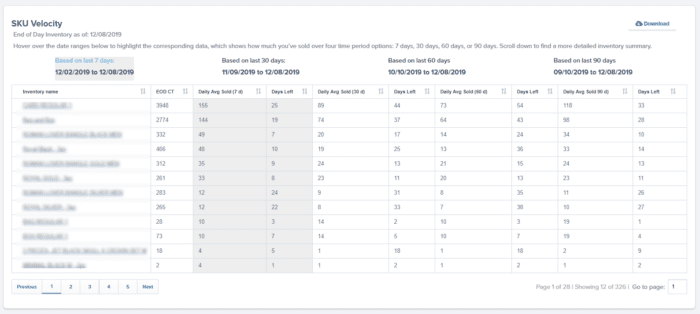

“I used to have to pull inventory numbers from three places everyday and move all the disparate data into a spreadsheet. ShipBob has an analytics tab in their dashboard with all of this information, which is great for end-of-month reconciliations.

For inventory planning, I love the SKU velocity report, daily average products sold, and knowing how much inventory we have left and how long it will last. The enhanced visibility is great. For every order I placed for years, I was ordering too much or not enough.

Between inventory forecasting tools and the ability to auto-create WROs, we don’t have stockouts much anymore. I sleep better at night.”

Wes Brown, Head of Operations at Black Claw LLC

Keep supply chains running smoothly

Disruptions and backlogs in the supply chain can also contribute to excess inventory.

For example, the COVID-19 pandemic caused a massive bullwhip effect throughout global supply chains. Retailers stocked up on products that were highly demanded in quarantine, such as air fryers and athleisure wear – but as restrictions lifted and demand quickly waned, businesses found themselves with tons of excess stock.

For this reason, even when faced with unprecedented upheaval in supply chains, it is crucial to keep your supply chain operations running as smoothly as possible.

Merchants need to maintain visibility across the supply chain, and use automation to improve supply chain efficiency where possible. That way, inventory can move seamlessly throughout the chain and minimize the risk of backlogs and disruptions.

Avoid overstocking

Overstocking is the leading cause of surplus inventory. Often stemming from the fear of stockouts, businesses may feel compelled to order more inventory than they actually need. Alternatively, they may try to meet seasonal changes in demand by stocking excess inventory.

To avoid over-ordering out of fear or uncertainty, businesses should use inventory management software (or an IMS) to track inventory levels in real-time. Working with more up-to-date information and a more accurate understanding of past sales patterns will help merchants make data-driven decisions, rather than panicked ones.

“ShipBob has given us increased visibility thanks to the dashboard that allows us to easily manage stock and orders. That wasn’t possible for us before. Our relationship with ShipBob has been a game-changer for Quadrant, and it’s made my life so much easier. ShipBob is incredibly easy to use – that’s my favorite part about it.”

Will Kerr, Apparel Lead at Quadrant

How to reduce inventory

Businesses should always try to avoid overstocking – but what if you already have surplus stock? There are a few ways to move excess inventory out of your warehouses, with some being more profitable than others.

Here are a few liquidation strategies that help you make the best use of your extra inventory.

How to sell excess inventory

Selling your surplus inventory is the best way to recover some of the money you spent on procuring it, while also getting your inventory turnover back to normal.

Start by finding ways to spotlight the products and refreshing your marketing to drive more purchases. If this doesn’t work, you can discount the excess units or even bundle them with other, more popular products to create attractive offers that will encourage customers to buy surplus stock.

How to leverage surplus to delight customers

Everyone loves a free gift – even if that gift is something the customer didn’t necessarily ask for, it’s the thought that counts.

By including surplus stock units as freebies in orders, businesses can surprise customers and deliver a better unboxing experience. This, in turn, can help drive loyalty and repeat purchases.

How and why to donate surplus stock

Even if selling your excess inventory isn’t an option, don’t dispose of it just yet. Instead, consider donating it to a good cause.

Donating your unsellable inventory is a more sustainable solution to reducing excess stock – and it offers good returns in the form of tax benefits when tax season comes around. You can leverage partnerships with different charities, or use free services such as giveNkind to donate excess inventory.

How technology can help with reducing excess inventory in 2023

Ecommerce technology has evolved to make it easier for businesses to accurately plan their procurement and avoid surplus inventory.

Best-in-class inventory management software and platforms now provide real-time visibility into stock levels, which enables your brand to see which SKU levels are running low. Some even come with reorder points notifications, which will automatically send you reminders when it’s time to place your inventory reorders.

That way, you don’t accidentally forget to replenish your stock, or overcompensate by ordering too much inventory at the last minute.

Top-tier IMS solutions also offer data tracking and insights – particularly for demand planning. A good IMS will track your order histories and SKU velocity over time, so you see which SKUs are more or less popular and leverage that data in your inventory planning.

With a better idea of how much inventory you’ll actually need, you can reorder the most strategic amount of inventory (and adjust the amounts as trends change).

Manage inventory and fulfillment with ShipBob

ShipBob is a tech-enabled ecommerce fulfillment partner that empowers you to streamline your inventory management, so you can avoid issues relating to surplus inventory. With IMS software built into our dashboard, you’ll get comprehensive and real-time visibility into your inventory, so you can keep a close eye on inventory levels at all times.

ShipBob’s software also lets you set a reorder point for your inventory, so you automatically get notified whenever stock dips below a certain level.

This gives you ample time to place your replenishment order and avoid stockouts. It also means you have the freedom to order smaller amounts of inventory more frequently, which is key to avoiding overstocking.

“ShipBob’s analytics tool is really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

To get a more accurate idea of how much inventory you need, merchants can leverage ShipBob’s powerful analytics tool that closely tracks inventory performance at the SKU level. Besides showing you your on-hand inventory, it collects historical data on inventory sales, so you can prioritize stocking fast-moving SKUs and forecast demand more accurately.

To learn more about how ShipBob’s logistics solutions can help you manage your ecommerce inventory, click the button below.

Inventory surplus FAQs

Below are answers to the most common questions about inventory surplus.

How does excess inventory affect a business?

Excess inventory ties up your financial capital in stock that is unlikely to sell, which may hinder your cash flow and cause you to lose some or all of your initial investment (or hinder you from investing in inventory that’s in higher demand).

Surplus inventory also takes up valuable warehouse space where more sellable stock could have been stored. It also inflates your storing and handling costs unnecessarily, which will decrease your profitability.

How can a company reduce or avoid excess inventory?

Accurate demand forecasts are key to avoiding excess inventory. Businesses should also consider buying less inventory more frequently instead of buying in bulk.

If you already have excess inventory, consider selling it at a discounted price, bundling it with more popular products, including it as a free gift in orders, or donating it to a worthy cause.

How does ShipBob help with inventory management?

As part of its analytics dashboard, ShipBob provides powerful inventory management software that provides merchants with real-time visibility into stock levels. This enables your brand to clearly see how much inventory you have left at a given time, and which SKUs need to be replenished.

You can even use the reorder points notification to instantly get an alert if inventory levels are running low, which will allow you to make timely replenishment orders.

Our software also tracks order data and key metrics over time, which you can use to make more accurate demand forecasts and reorder the right amount at the right time.