Table of Contents

** Minutes

What is on-demand warehousing?

What’s causing the rise of on-demand warehousing?

Why on-demand warehousing falls short

Grow with a partner, not just a warehouse

What do you want to learn?

Running an ecommerce business involves a lot of moving pieces. Supply chain management is rarely the driving force of getting into ecommerce, but it is a critical piece of the puzzle that affects everything from customer deliveries to inventory management.

Ecommerce businesses have a few methods to choose from when it comes to ecommerce warehousing, fulfillment, distribution, and shipping. These include:

- Self-fulfillment: When you keep inventory storage, packing boxes, and shipping orders in-house (either in your home or leasing your own warehouse space).

- Dropshipping: When the merchant never touches inventory but rather has the manufacturer control the entire retail supply chain, sending orders from the factory directly to the customer.

- Third-party logistics (3PL): When you outsource fulfillment to a company that specializes in storing your inventory and picking, packing, and shipping your orders from their warehouses.

- On-demand warehousing: When you partner with a technology company that contracts warehouses that have excess, shared warehouse space to store your inventory.

Outsourcing fulfillment to a 3PL or an on-demand warehousing company allows you to keep your product closer to your end customer while freeing up time and space without needing to invest in your own warehouse.

Below we’ll jump into a few core differences and for whom each option is best suited.

What is on-demand warehousing?

On-demand warehousing is a platform that connects businesses that need to store inventory and fulfill orders on a temporary basis with warehouses that have excess space.

In other words, on-demand warehousing is outsourcing fulfillment to a company that doesn’t perform fulfillment services itself but outsources it to others.

Common examples of on-demand warehousing solutions include: Flexe, Stord, Ware2go, Flowspace, Shopify Fulfillment Network, and Deliverr.

Some small 3PLs are contracted by on-demand warehousing solutions, but some on-demand warehousing companies simply use garages and other buildings that aren’t designed for fulfillment.

It begs the question, do you really want to put your inventory — an important part of your business — in the hands of strangers contracted through a middleman who doesn’t actually own and operate any warehouses?

What’s causing the rise of on-demand warehousing?

We can partially thank Amazon for the rise of on-demand warehousing, which seeks to replicate FBA’s reach without owning the warehouses themselves. Similar concepts also include marketplaces such as Uber and Airbnb, where they find and rent out available vehicles or homes with space for a particular time frame. We have seen the “Uberization” of just about everything, which has been a big trend in the VC world.

Lack of warehouse space

While you don’t typically think about real estate when you think of ecommerce, a lack of warehouse space and vacancies nationwide has caused more businesses to look into temporary solutions like on-demand warehousing.

Warehouse space is also a very expensive capital investment. On-demand warehousing allows for warehouse slotting or organizing a warehouse to maximize space while monetizing underutilized space. Best of all, there is less waste.

Continued ecommerce success

With more successful ecommerce shops comes the need for more warehousing space. Though demand forecasting isn’t always predictable, ecommerce continues to increase its share of total retail sales. Ecommerce during COVID-19 demonstrates this firsthand with sales trends increasing across verticals.

A desire for greater flexibility in warehousing

With no long-term commitments, on-demand warehousing offers flexibility especially for products that are only sold seasonally, those that need a one-time pop-up warehouse or ecommerce fulfillment space, and other agile, short-term needs for empty space.

If you have a bunch of excess inventory that would be too expensive to store with a regular 3PL, warehousing or on-demand warehousing can be a solution until you work through units from overflow or bulk buying.

Some on-demand warehousing solutions help large enterprises and renowned names in brick-and-mortar retail (e.g., Walmart, Staples, and other retailers that require millions of square feet). It’s not the best option for small to mid-sized ecommerce brands that don’t need access to a dozen or more locations at any given time.

On-demand warehousing is especially beneficial for retailers who:

- Have thousands or millions of SKUs

- Are so large that they need millions of square footage

- Require hundreds of pallets over a short period of time

- Primarily need B2B fulfillment

- Sell very large products (e.g., mattresses and items with oversized shipping needs) that require much more warehouse space than a brand that sells cosmetics or supplements would.

Need for speed

On-demand warehousing can help provide same-day shipping such as one-hour delivery and more easily cover the last mile of delivery. Retailers can search on a provider’s platform for shared warehouse space in a location within miles of a customer base.

On-demand warehousing can also be beneficial if you want to use a city center in a very specific location that you can’t find elsewhere or that you need immediately for a short period of time. This was seen during the COVID-19 pandemic, where brick-and-mortar retailers were forced to change how they use real estate, given what became considered an ‘essential’ business by local governments.

Check out ShipBob's Warehouse Management System (WMS)

ShipBob's WMS helps your warehouse reduce picking errors, manage inventory in real time, and fulfill orders faster.

Why on-demand warehousing falls short

While on-demand warehousing can be great for people who need a specific storage location immediately or Fortune 500 companies that have budgets to compete with Amazon, the average Shopify store likely won’t require this type of model.

Most ecommerce brands want a partner and not just a platform to input new space as needed. Unlike working with a 3PL, on-demand warehousing is more transactional in nature and isn’t as common for a growing brand looking to find a long-term partner that will scale with them.

Here are a few reasons why on-demand warehousing doesn’t equate to long-term, continuous ecommerce success:

1. Temporary space + open marketplace = short-term solution

Similar to Uber and Airbnb, on-demand warehousing doesn’t guarantee a long-term spot to store your products or ensure that you’ll be able to use the same space over time.

By matching supply and demand, the likelihood of getting the same Uber driver twice is low, and that Airbnb you stayed in may have been a summer home for the tenants and unavailable the next time you try to book it. Same goes for on-demand warehousing. It is based on what’s available for a specific point in time.

If you’re looking for a long-term solution, a 3PL will be a better option for you.

2. Inconsistent warehouses + lack of expertise = more fulfillment errors

Not all warehouses are created equal or even have experience with fulfillment logistics. Some on-demand warehousing platforms don’t work exclusively with fulfillment centers. They may have warehouses with varying levels of safety procedures, security, standardized processes, storage options, packaging materials, relationships with carriers, and more.

Warehouse management in one facility to the next can vary greatly when it’s not managed directly by the same fulfillment expert. Providing a consistent experience to all customers becomes difficult. Not only are the warehouses not always up to par, but many on-demand warehousing platforms have no operations expertise or experience managing a fulfillment center themselves.

Order fulfillment will inevitably have errors — even the top fulfillment companies do. If a warehouse isn’t a fulfillment expert themselves, you’ll experience significantly more errors that can damage your reputation with customers.

When evaluating on-demand warehousing, consider:

- How do they manage low performers across their network?

- Can you tour their fulfillment centers? How different is one fulfillment center from the next?

- Do they use the same racking, technology, packaging materials, tools, and more so you are charged fairly and receive the same service warehouse to warehouse?

- How do they handle damages, support, and other issues that need boots-on-the-ground escalation?

- How will they conduct an inventory audit?

Don’t assume just anyone could solve your logistics problem. You need professionals. Instead of on-demand warehousing, a 3PL with multiple fulfillment centers can cultivate a deeper understanding of your business, products, and fulfillment needs.

“A newer fulfillment network sold us on their solution, but they clearly did not think much through. We experienced a huge surge in fulfillment errors and countless complaints about orders being inaccurately fulfilled. Errors will inevitably happen when you fulfill orders at large volumes, but not like this. We also had 1,500 units of missing inventory that they couldn’t find. It was a terrible experience. They don’t understand the fulfillment game like ShipBob does.”

Gerard Ecker, Founder & CEO of Ocean & Co.

3. No operational oversight + lack of quality control = poor customer support

By not operating fulfillment centers and only providing a layer of technology, on-demand warehousing leads to a lack of visibility and a lot of uncertainty around what’s actually going on inside warehouses. It’s very difficult to keep close ties with dozens or even thousands of warehouses without the ability to conduct a warehouse audit or test out new processes in your own warehouse first before rolling them out to the masses.

“Overall, there is more transparency with ShipBob that even helps our team manage customer service better. I can see the granular stage the order is in — if it’s being picked, packed, in transit, etc. That enhanced visibility is great. No other 3PLs offer that in my experience. Tracking our costs and how much we’re spending on storage is a lot easier to understand.”

Wes Brown, Head of Operations at Black Claw LLC

There are too many parties to keep track of with literal moving pieces. Coordinating basic information with a large number of warehouses is chaotic at best — even without a major issue popping up.

Consider the following scenario around inventory control:

- What happens if one warehouse loses some of your inventory?

- How will it get resolved?

- Do you call the on-demand warehousing support team, then they have to call the warehouse, and you get stuck in the middle of playing a game of phone tag?

- What if the warehouse you happen to be in isn’t a priority for the on-demand warehousing company you contracted through that has a thousand other warehouses to keep tabs on?

Without any direct employees of their own managing operations on the ground floors, on-demand warehousing companies struggle to get answers and resolutions in a timely manner.

“With an on-demand fulfillment network we briefly worked with, each process relied heavily on someone else rather than feeling like we have control of our store. We couldn’t actually see what their warehouse associates were picking. We always had to play detective. Their response to any issues were very slow with lots of uncertainty. It was the exact opposite of our experience with ShipBob, where you can outsource your fulfillment while still maintaining full control.”

Gerard Ecker, Founder & CEO of Ocean & Co.

The importance of scalability

If you aim to run an ecommerce brand that is long-lasting, choosing a fulfillment solution that scales with your company at each stage of growth through seasonal ebbs and flows or rapid growth is key. This means a partner that can support you when you are doing 10 orders per day to 1,000 orders per day, and not just with more space but more tools, resources, and expertise.

A tech-forward 3PL that focuses on the entire fulfillment process puts you in control of what happens with your products and orders in their fulfillment center(s). You won’t lose space but can continue to expand into additional space and locations. Efficient 3PLs work on continuously optimizing their warehouses, whether it’s through batch picking or other supply chain optimizations.

Hear from a few fast-growing ecommerce brands who partnered with ShipBob to scale fast.

Blackclaw

“We talked to a 3PL that looked promising but quickly realized their model is just renting space inside of other fulfillment centers with different warehouse management systems used at each. This provided no visibility into operations or ability to maintain their SLAs. Then, we found ShipBob.”

Wes Brown, Head of Operations at Black Claw LLC

Prymal

“A lot of entrepreneurs and companies underestimate the cost-savings and power of choosing your entire supply chain and partner network wisely. These choices will make or break your business. After switching to ShipBob, we grew 300% and started saving $8,000 per month in fulfillment costs. I’m proud to be a ShipBob partner.”

Courtney Lee, founder of Prymal

EnduroSport

“Having confidence in scaling fulfillment is hypercritical for us. With ShipBob, we find comfort in knowing we can scale and have orders fulfilled in a quick manner. From day one, I felt like ShipBob was a partner on our team.

They answered all of my questions quickly, walked me through the solution to get started and how the partnership could evolve in the future, and proactively proposed more considerations for us to think through that related to our business and plans.”

Tim Fink, Co-Founder of EnduroSport

Grow with a partner, not just a warehouse

A fulfillment partner should be much more than ‘the Airbnb for warehouse storage.’ True partners work with you to find solutions before problems arise and implement them for added supply chain efficiency. On-demand warehousing has limitations that prohibit much of that, and you don’t always know who you’re actually working with.

ShipBob is the tech-enabled 3PL that gives you more

ShipBob isn’t your typical 3PL. Rather than having dozens of clients, we have thousands.

In 2014, our co-founders decided to build a long-term fulfillment machine. Compared to on-demand warehousing, our approach takes a lot longer to build up, is more time-intensive, and requires more capital — but that’s how we believe we’ll build a world-class operation for years to come. Here’s why:

ShipBob owns the entire tech stack

We don’t use anyone else’s software. We built our own warehouse management system (WMS), which acts as a control center to compile all fulfillment metrics across all elements of our fulfillment centers. Our WMS tracks everything — from how many orders per hour a picker can pick to how long it takes to receive, count, and stow new inventory that arrives — to identify opportunities for improvement and learn from each of our fulfillment centers.

We also created a proprietary merchant dashboard that connects to our WMS and gives each merchant deep insights into fulfillment performance, how we’re hitting our SLAs, visibility into order status and inventory counts, and much more. The algorithm selects the fulfillment center with available inventory that’s closest to the end customers. Rather than requesting someone to create a report for you, you can automatically pull them on-demand, eliminating back and forth while increasing transparency.

Owning this deep of a tech stack increases the velocity and scale at which we can make any type of change to our technology based on real-time customer feedback.

“With our old fulfillment solution, because of a lack of ownership of the entire fulfillment stack, it was difficult to rectify, unlike with ShipBob who owns the entire stack: inventory and order management system, warehouse management system, and their fulfillment centers.”

Gerard Ecker, Founder & CEO of Ocean & Co.

ShipBob’s roots are in owning and operating warehouses as well as technology

ShipBob’s first five years were spent running our own fulfillment centers. We opened nine fulfillment centers and learned how to perfect operations in a scalable way. We then began partnerships with a few leading fulfillment centers to bring our efficiencies and technology to them and expand our reach. We give all fulfillment centers in our network the blueprint for how operations are to be run so that we can drive the same customer experience across every site and scale out operations.

We have ten fulfillment centers in our network today, all of which are powered by the same technology and follow the same SLAs and fulfillment best practices. We control what goes on inside our warehouses to ensure every merchant is given the same retail fulfillment experience no matter what ShipBob fulfillment center location(s) they store their inventory in.

We continuously roll out new changes to our fulfillment centers to improve efficiencies and collectively be better. By focusing on controlling our costs, we’re able to pass those savings back on to our merchants.

ShipBob’s software drives upstream and downstream improvements

Between our software and our people, it’s very easy to make process changes, train on new technologies, and manage expectations and performance. Without this, it’s difficult to ensure packages are fulfilled according to the customer’s preferences and using the same standards, packaging, and timelines.

Merchants don’t need to work with five different tools, you can use ShipBob’s all-in-one order and inventory management software, analytics tool, fulfillment services, inventory storage, and more.

“With my prior fulfillment provider, I felt sidelined because all I could think about was troubleshooting errors and reconciling with the high costs. ShipBob really wants to help solve my unique problems and continues to shares a lot of the ways that they can help.”

Courtney Lee, founder of Prymal.

Large, growing fulfillment network

ShipBob operates a robust, growing fulfillment network with locations in different countries. Since every fulfillment center location is powered by the same technology, you can track inventory and fulfillment performance across multiple locations. Using the data we provide, you can choose optimal locations to split inventory across any combination of our fulfillment centers and continue to grow with us.

And you’ll never have to worry about losing space with us as we continue to expand into additional locations and capabilities.

Best-in-class support

From custom packaging to other more customized fulfillment services, ShipBob offers support every step of the way. Our merchant care team is available when you need them to answer any questions or concerns you may have at any time. Enterprise merchants are given access to a dedicated merchant success manager at no extra cost.

We listen closely to our customers’ needs and continue to implement changes and improvements to our processes. That way, we evolve alongside the growth of our customers.

“Having a helpful, dedicated account manager at ShipBob who responds quickly and has a good understanding of our products and company is really important to us. It’s given us extra support we wouldn’t have with a different fulfillment provider.”

Oded Harth, CEO & Co-Founder of MDacne.

Transparent fulfillment data

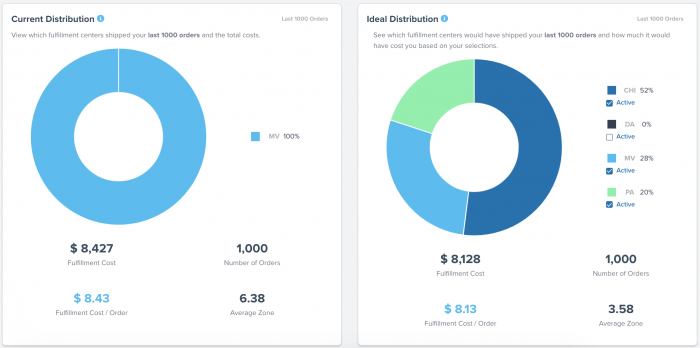

ShipBob works with you to help save cost and drive efficiencies. We provide all our merchants with data to make smarter decisions on which fulfillment center locations to store inventory in and how much inventory to store in each. That way, orders get to the end customer quickly no matter where they’re located.

“Off the bat, I liked that I would be able to control multiple warehouses through one page with ShipBob. With my old 3PL, I could never just open a page and get the info I wanted. I had to click several times, then export it, and try to make sense of it. ShipBob lets you manage your inventory while providing important data in a very digestible way.”

Wes Brown, Head of Operations at Black Claw LLC

With our free analytics and reporting tool, you get answers to questions like:

- How much money would I save on shipping if I changed the fulfillment center locations my inventory is in?

- How should I distribute my inventory across ShipBob’s fulfillment network?

- What would my shipping costs be if I went from one fulfillment center to two (or two to three, and so on)?

- How many days of inventory do I have left before I run out?

- Where are my customers shipping to most often?

“We strive to be very data-driven, and ShipBob gives us access to different views of our business. Their analytics tool has been great to have. We can see inventory reconciliations and easily view SKU velocity, transit times, and inventory distribution recommendations.”

Pablo Gabatto, Business Operations Manager at Ample Foods.

Conclusion

While you might have gotten comfortable with getting into a stranger’s car with Uber, or staying in a stranger’s house with Airbnb, are you comfortable with having just any shared warehouse space storing your ecommerce inventory?

Outsourcing fulfillment is a difficult enough task. It’s hard to give up control. With ShipBob, we take in pride in providing a transparent 3PL experience with full visibility into the fulfillment process from real-time inventory tracking to free distribution metrics reporting.

If you’re looking to build a long-term relationship with a fulfillment partner that will help you grow your business, consider ShipBob. To request a quote, click the button below.