Table of Contents

** Minutes

Common transloading challenges

ShipBob’s winning approach to shipping and logistics

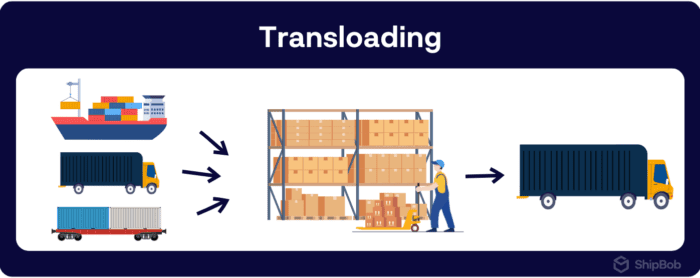

When it comes to the long-distance transfer of goods, you probably want the best of both worlds: economical rail transport and flexible over-the-road trucking. With transloading, you get just that. Transloading involves completing the transit with unloading of goods from rail cars and loading them onto trucks or vice versa.

At a time when cross-border commerce and shipping are booming, using multiple means of transport can complicate your operations and require the implementation of sophisticated shipping processes.

This isn’t a process ecommerce companies want to focus on. It’s much more important to focus on selling their goods rather than managing transloading end-to-end. That’s why many businesses outsource shipping to third-party logistics (3PL) providers like ShipBob.

Interested to know more about this form of long-haul transportation? This article is perfect for businesses or individuals looking for information on what transloading is, how it works, and the benefits of using transloading services of logistics companies.

What is transloading?

Transloading is process of moving goods between different modes of transportation. As the term suggests it involves the unloading of freight from one transport vehicle and loading it onto another.

Typically, transloading happens between rail cars/containers and trucks. When the location isn’t rail-served, planes and ocean freight containers may also be used as a method of transportation.

Transloading is used in the shipping and logistics industry for its ability to reduce costs of shipping, while offering a lot more flexibility.

Transloading vs. other shipping terms

You might be wondering how transloading is different than cross-docking, drayage, or other modes of transport.

In this section, we compare and contrast transloading with other shipping terms.

| Transloading | Cross-docking | Drayage | Intermodal | |

| What is it? | In-transit shipment is unloaded from one mode of transportation and loaded onto another. | Goods are received from trucks and sorted at a cross-docking facility. Then, they are loaded directly onto outgoing trucks for last mile shipment. | Goods in shipping containers are moved to their final destination (short-haul) via truck. | Entire shipping containers of goods are transported via more than one mode, including truck, train, ship, airplane, or pipeline. |

| Example | A single shipment of books, from Canada, lands in California and is sent to a local warehouse. It is then trans-loaded onto a truck for last-mile delivery to a small town not easily accessible by rail. | A shipment of glass bottles from San Francisco reaches a cross-docking facility in Seattle. It is offloaded, split based on geography, and immediately loaded into trucks that are headed to different delivery locations. | A shipment arrives at a port and is transported to a nearby location via trucks. | A container of office supplies is sent from India via flight to California, USA. And from there, it’s loaded onto a cargo train and moved to New York station. And from there it is sent to a stationary shop in NYC via a truck. |

| Benefit | This is a good option for when the goods are impractical to send only via rail containers. It also is useful when you need to combine shipments into the final truckload. | This transportation method helps distribute products more efficiently, by doing away with the need for long-term warehousing costs. | This tends to be a part of a large transportation mix. | Intermodal shipping is great for businesses that need more flexibility in the movement of large containers of goods. And there is no need to “trans-load” between transport modes. |

The benefits of transloading

The benefits of using transloading services range from supply chain versatility to lowered logistics and transportation costs, and freight consolidation. Ultimately, it can help businesses overcome common logistical challenges and streamline their shipping operations.

- Enables supply chain versatility: Since there are multiple modes of transportation involved, it’s possible to get our goods delivered in different ways. It also has almost unending capacity and cross-border reach, to handle more freight shipping as your business expands. This adds to the flexibility that you can leverage.

- Lowers costs: You can use the modes of transport that are most economical to get your goods from point A to B. For example, if you are able to use rail cars for the majority of the route, your fuel costs are lowered significantly. Once the goods have reached the region where they’ll be stored and shipped, shippers can then use trucks for the remaining route, making transportation faster and more cost effective.

- Promotes freight consolidation: If you have a lot of freight situated in different locations, but the end destination is the same then you may transport all of it in fewer rail cars. You can send the trucks from each location to transload facilities along the rail line and freight can be consolidated into the same rail car as it moves closer to the destination.

- Overcome logistics challenges: Whether there is a lack of direct shipping routes or limited road access along the transport route, transloading can offer a way to still deliver the goods using multiple modes of transport.

How does transloading work?

Each transloading workflow depends on the freight’s origin and destination, the type of goods being transported, how it’s packed, timelines, the budget, and so many other factors. But overall, here are some of the basic steps to how transloading works:

- Load freight onto a truck for transport to a transload facility.

- At the transloading facility, the goods are sorted and organized based on the destination, size, weight, and other factors.

- Transfer freight to rail cars, using cranes, forklifts, or other equipment, at the transload facility. The type of transfer method and type of rail car (e.g., tank car, flat car, or boxcar) depends on the type of product being transported.

- The freight may be loaded from the rail cars back into trucks if the final delivery location is not accessible by train.

Any type of freight, from lumber and metals to liquids, frozen foods, and heavy machinery, can be transloaded. Here is how various products can be transloaded.

| Product type | Transloading process |

| Palletized goods | A forklift may transfer goods from a truck to a rail car |

| Heavy products, like steel beams, rebar, pipe, and wind components | A crane may lift goods off a rail car and place them on a flatbed truck. |

| Products like rock, salt, and other minerals and aggregates | A front-end loader is used to lift the goods off a rail car and place them on a truck |

| Products like plastic pellets and liquids | A pump/pneumatic transfer is used to lift the goods off a rail car and place them on a truck |

| Bulk products like sand, soda ash, grains, flour and sugar | A conveyor is used to move bulk goods from one location to another, especially if the next mode of transportation is not situated close to the current mode of transport |

Note: Today, since most goods are shipped in standardized (intermodal-friendly) rectangular steel containers, transloading has become a lot easier.

Common transloading challenges

In this section, we discuss the common challenges businesses face during the transloading process.

Managing multiple transportation modes

Transloading is a very complex process. Coordinating different modes of transportation during the transloading process can be very challenging. Businesses need to ensure that each mode of transportation is properly synchronized and communication lines between all relevant parties remain open to avoid delays and additional costs.

You may also be slapped with additional handling costs, such as storage costs, extra packaging and labeling costs, and labor costs for loading and unloading goods. This can reduce the cost-effectiveness of the transportation process.

Ensuring product safety and security

It’s very important to ensure the safety and security of products during the transloading process. To prevent theft of products during transportation, you must have a strict tracking process in place, it would also help to install security cameras in the cargo holds.

Damage to the freight can happen due to handling, transfer, and storage – especially in the case of fragile goods. To avoid such issues, develop and implement standard operating procedures (SOPs) for transloading and conduct regular training sessions on the same.

Transloading can also pose safety risks to the workers handling and transporting the goods. To avoid this, you must conduct inspections and audits to identify and address potential safety hazards and ensure all machinery is working properly.

Navigating customs and regulations

When a package gets stuck in customs, it’s is a headache for retailers. Navigating customs clearance formalities and regulations when transloading products for international shipping can be overwhelming. It is important to understand and comply with customs requirements to avoid delays and penalties.

ShipBob’s winning approach to shipping and logistics

Transloading requires a lot of meticulous planning and coordination. ShipBob’s use of technology can help businesses optimize their transloading operations and improve efficiency. This explains why ShipBob is a well-recognized as a leader in the ecommerce fulfillment space.

If you want to stop stressing about transportation, and focus on growing your business, consider outsourcing fulfillment to ShipBob. We streamline shipping and logistics operations so that you can concentrate your efforts on what really matters: business innovation, strategy, and growth.

Our services are tailored to meet the needs of direct-to-consumer brands, selling to customers located anywhere in the world.

The importance of tech-enabled shipping in ecommerce

ShipBob has created powerful technology to provide brands with best-in-class inventory, order, and warehouse management. In the shipping and logistics industry, such a technology is essential to helping businesses optimize their shipping operations and improve efficiency.

Our platform offers brands with a real-time look at inventory and orders, predictive data and analytics, and optimized shipping.

ShipBob’s platform acts as a single source of truth across fulfillment centers, no matter which facilities you’re using within ShipBob’s global fulfillment network. It tracks inventory and orders in real time and allows users to manage, edit, and customize orders. You can even set reorder points to alert you when its time to restock.

ShipBob even has built-in supply chain-related reports and analytics to give you a competitive advantage.

How ShipBob helps businesses grow

Are you looking to grow global? ShipBob offers international shipping and global fulfillment solutions so you can reach your customer base no matter where they’re located.

ShipBob has a global network of fulfillment centers with facilities in the US, Canada, the UK, EU, and Australia. Our fulfillment network of over 50 warehouses can help businesses seamlessly scale their operations and meet the demands of a growing customer base.

Our proprietary technology and team of proven experts work together to get orders to customers safely and on time.

Ecommerce champions outsource fulfillment to ShipBob

If you want to secure maximum benefits from transloading and other fulfillment processes, ShipBob can help. This is why so many ecommerce businesses outsource their supply chain management to us.

We help you get the best transport rates and maximum flexibility when transporting your freight.

“ShipBob’s advanced software helps us quickly understand shipping costs and how to improve shipping times by being closer to where our customers are.”

Andrea Lisbona, Founder & CEO of Touchland

ShipBob is constantly evolving and adding new features to enhance the merchant experience and create a streamlined supply chain. Here are some of ShipBob’s features that can help make your logistics more efficient.

Inventory receiving in hub and spoke model

ShipBob’s hub spoke distribution model allows you to send inventory to a dedicated receiving facility where products are inbounded and then sent out to spoke fulfillment centers. ShipBob’s inbound receiving and distribution process has quick WRO creation and receiving for designated hub sites.

Orders are fulfilled at the spoke facilities located closer to your end customer. This model allows for quick and accurate receiving and faster, more cost-effective shipping.

By placing goods closer to the end customer, you reduce transloading transit times.

Inventory transfer between ShipBob warehouses

Inventory transfer between two ShipBob warehouses offers faster shipping options for your customers and helps you save on shipping costs.

To ensure that inventory transfers are planned and executed without any glitches, our platform offers tracking throughout every stage and full visibility into inventory levels throughout your supply chain.

Brands can leverage our Inventory Placement Program where we place your inventory in our fulfillment centers on your behalf based on ideal distribution. This program takes the burden of distributing inventory off of your team, allowing you to focus on other aspects of your business.

Cross-docking for inventory distribution across ShipBob warehouses

To enable faster distribution, we de-consolidate containers or LTL shipments. And then, ShipBob distributes them to multiple warehouses or a cross-regional fulfillment center of your choice. Thus, we offer a factory-floor-to-customer-door cross-docking solution for your brand.

Get started with ShipBob

Interested in leveraging ShipBob’s fulfillment solution? Connect with our team to learn how we can streamline your order fulfillment and logistics.

Transloading FAQs

Below are answers to common questions about transloading.

How does ShipBob’s fulfillment process work?

When you leverage ShipBob’s outsourced fulfillment solution, the entire journey from the factory floor to the customer’s door can be fully managed by ShipBob. Our best-in-class technology, team of supply chain experts, and network of fulfillment centers play key roles in making order fulfillment seamless.

How does transloading help businesses save on shipping costs?

By using the rail car for shipping goods, at least for some part of the way, you save on fuel and transport costs.

In case goods are not in the same location but are going towards the same destination, distribute the goods to warehouses along the rail route, so that they can be transloaded and consolidated into the same rail car.

What are the common challenges faced during the transloading process?

Challenges faced during transloading range from issues managing multiple transportation modes to product safety and security, and navigating customs. And these challenges impact the efficiency and cost-effectiveness of shipping operations.

How does ShipBob handle international shipping?

ShipBob offers crossborder solutions that include access to the best rates and timelines for international shipping and a network of fulfillment centers across the globe. When required, we also support clearing customs.

What’s more, our proprietary technology and team of proven experts help you get orders to global customers safely and on time.