Inventory Accuracy Guide

Managing inventory plays an essential role in supply chain management, but it isn’t always easy. That’s why retail businesses must consistently track inventory records at the SKU level.

Even if you have a good track record with inventory accuracy, there are key things to consider to keep it that way. Read on to learn more about inventory accuracy and how to improve it.

Request Fulfillment Pricing

A fulfillment expert will get back to you shortly. Privacy Policy

What is inventory accuracy?

Inventory accuracy refers to any inconsistencies between the actual quantity or type of physical inventory and what is recorded or is supposed to be. In most cases, it is the difference between what’s recorded in an inventory management system and what you have available for sale in a store, warehouse, or storage location.

Importance of inventory accuracy

Inaccurate inventory is obviously problematic as it can translate to incorrect customer orders, a shortage of product, theft, damages, loss for your business, or even trouble selling through what you have before it becomes obsolete.

But there are also implications on the accounting side that can cause more trouble for a business.

For example, inaccurate inventory can lead to inventory shrinkage when stock is less than the recorded balance in accounting records and can throw off your inventory valuation at the end of a financial year or accounting phase.

Inventory write-offs are when you remove or reduce the value of inventory or dead stock that has no value from their accounting records and can be used to rectify inaccurate inventory.

By making sure your inventory is accounted for, your operations run more smoothly and you make more sales. Here are some of the reasons why maintaining inventory accuracy is so important.

Minimize customer loss

Having inventory inaccuracies is troublesome because it can translate to incorrect customer orders because you have a shortage of product. This can be a loss for your business as a result, or you may even have trouble selling through the inventory you have before it becomes obsolete.

When your inventory is accurate, you ensure customers are getting what they ordered instead of turning to your competitor.

Reduce operational and holding costs

If you don’t have a clear understanding of how much inventory you have, you may buy more inventory than you need. When you have a surplus of inventory that isn’t selling, it is sitting on the warehouse shelf racking up holding costs. Knowing when to move those items helps you drive down operational costs.

Prevent inventory shrinkage

When you have accurate inventory counts, you’re able to monitor how much product you have. If you have inaccuracies in your inventory records, you can experience inventory shrinkage. Inventory can easily go missing due to theft, damage, or pick errors.

Keep inventory valuation in check

If you experience inventory inaccuracies, it can throw off your inventory valuation at the end of a financial year or accounting phase. Making sure you have proper inventory results in less headaches for you and your finance team.

Why ecommerce shops struggle with inventory accuracy

Achieving inventory accuracy isn’t an easy task, but it can be made easier with the right technology, processes, and know-how. Here are the most common reasons why inventory accuracy is challenging for ecommerce brands.

They are self-storing

Many ecommerce stores prefer to be as independent and cost-effective as possible, and usually self-fulfill and self-store their products from their home. This can lead to inventory accuracy problems when it’s not being stored professionally or managed in a warehouse.

And as the business grows and expands its product line, inventory storage only becomes more difficult without the right equipment and a dedicated, experienced team.

Their inventory management system is sub-par

If your inventory management system is basic or non-existent, you may be tracking inventory on paper, spreadsheets, or not at all. Having integrated technology helps keep inventory records up-to-date, making things easier for accounting purposes, helping prevent stockouts, and streamlining purchasing from manufacturers.

“So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on. I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

If you introduce new sales channels, multichannel inventory management is needed to prevent over-stocking and under-stocking issues across stores.

How to calculate inventory accuracy

There are two common methods for calculating inventory accuracy.

1. Physical inventory counting

Inventory reconciliation, or the process of comparing physical inventory counts with records of inventory on hand, helps reduce stock discrepancies and understand why there are discrepancies in the first place.

You’ll need to perform a physical count of all the available inventory on hand and compare it against what you’re supposed to have.

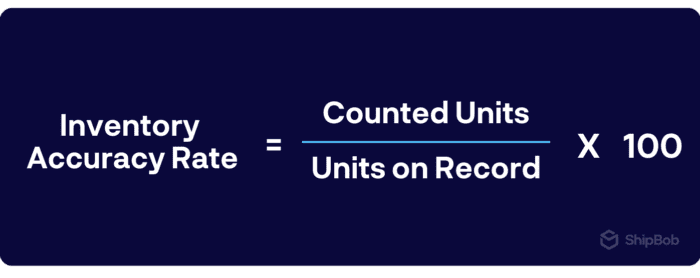

You can use this formula to calculate inventory accuracy rate:

Inventory Accuracy Rate = (Counted Units / Units on Record) x 100

If the two counts match up, then your inventory is accurate and does not have any inconsistencies. If it does not match, then there is an obvious discrepancy.

The best way to get the most out of this method is to perform weekly checks using this method. This way, you can progressively keep track of your inventory.

Try using our calculator below to find your inventory accurate rate.

Calculator: Inventory accuracy rate

Enter the values below, and hit “Calculate” to find your average inventory accuracy rate.

Note: This formula works if your total units on hand (that you count) is less than your total units on record (that you expect to be there). If you have more on hand than you expect, you can flip the order of the values to understand what % away you are from a perfect 100% inventory accuracy rate.

2. Inventory valuation

This method for calculating inventory accuracy is an inventory accounting practice and is done by counting the value of the inventory you have on hand (physical inventory), and then dividing it by the value of the inventory you are supposed to have in whatever you use to track inventory data. This method is not as accurate, as you are not comparing each item in your inventory.

If your inventory accuracy is low, you should consult your sales receipts and records. This could reveal the discrepancy (e.g., you may have sold the missing inventory).

What is the average inventory accuracy?

It is almost impossible to retain a 100% inventory accuracy rate, no matter what calculation method and technology you employ but it shouldn’t be too far from it. Typically, the average inventory accuracy is 99.6%, where the 0.4% is mostly due to human error that is inevitable for large companies. The more transactions you have, the higher the probability of a discrepancy in inventory data, and the occasional mishap isn’t something to worry much about.

7 tips to improve your inventory accuracy

After choosing an inventory accuracy calculation method and computing your inventory accuracy, you might feel that there’s room to improve your inventory control. Here are some tried-and-tested methods for improving inventory accuracy.

1. Count your inventory regularly

Inventory accuracy is a metric that should be top of mind. Inventory should be checked often to make sure your physical inventory matches your records. By doing this regularly, you’ll minimize the chance that your inventory is incorrect. And if your inventory is inaccurate for any reason, you’ll be able to fix the issue early on.

2. Adopt the cycle count program

Cycle counting is a way of managing inventory where a portion of inventory is counted in specific locations, on certain days, on a recurring schedule. Implementing a cycle count program allows you to forgo annual physical counts so you can count specific items on a more regular basis and therefore ensure your inventory is accurate.

3. Improve inventory security

Having proper inventory security ensures the safety of your products in the storage facility. By making sure your inventory is secure, you’re able to minimize theft. As a result, your inventory counts will remain accurate since theft is not a consideration.

4. Use more professional storage methods

Instead of self-storing your inventory, consider professionally storing your inventory in a proper warehouse. It’s all too easy to lose inventory in your apartment, basement, garage, or car.

Although an investment of this kind might incur higher overhead costs, you may end up saving money, in the long run, thanks to greater inventory accuracy. Of course, a good warehouse is not enough though; Proper warehouse management will help you keep tabs on real-time inventory records.

5. Work with a fulfillment partner

Rather than storing your own inventory at all, you can pair up with an ecommerce fulfillment partner that can store your inventory in its their warehouse(s) and manage it for you. Fulfillment companies specialize in picking, packing, kitting, shipping, inventory management, and warehousing.

A tech-enabled fulfillment company like ShipBob can even provide inventory forecasting tools and access to data and distribution metrics that track inventory accuracy.

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order.”

Ines Guien, Vice President of Operations at Dossier

6. Upgrade your inventory management system

Having a reliable inventory management system is necessary to help your business scale sustainably. If your inventory management system is too basic or lacking the features you need, your inventory accuracy could be suffering. In this case, you should consider investing in a better, more connected inventory management system or ERP system.

“Another ShipBob integration I love is Inventory Planner. It saves me hours every week in Excel spreadsheets, and I can raise a PO in minutes when it used to take me hours.

For every order I placed for years, I was ordering too much or not enough. Between inventory forecasting tools and the ability to auto-create WROs, we don’t have stockouts much anymore. I sleep better at night.”

Wes Brown, Head of Operations at Black Claw LLC

You can also look to use hardware and other equipment like inventory scanners to improve inventory processes within your warehouse.

7. Run frequent and randomized inventory checks

One way to improve your inventory accuracy and save time is by scheduling a frequent cycle count. A cycle counting program is an inventory auditing procedure, and conducting these frequently can prevent unchecked inventory from piling up, keeping your records consistent, and minimizing potential inventory error.

Discover more accurate inventory with ShipBob

Optimizing your inventory management and improving inventory accuracy is crucial, but it can also be difficult and resource-demanding. Fortunately, you can outsource all this to a reliable third-party logistics provider, like ShipBob.

ShipBob’s order fulfillment services help with inventory and order accuracy, and our proprietary technology helps with everything from streamlined warehouse receiving to improved warehouse picking, efficiently managing inventory turnover, and much more.

“We utilize ShipBob’s Inventory API, which allows us to programmatically retrieve real-time data on how many units of each product are currently stored at ShipBob’s warehouses. We currently use this API to generate custom reports to tie this inventory data into our accounting platforms.”

ShipBob’s industry-leading software seamlessly integrates with your ecommerce platform and our warehouse management system to streamline operations and inventory management.

This way, you can track inventory levels across all of our fulfillment centers in real-time, view order status changes, and see shipping updates from ShipBob’s dashboard.

You’ll gain useful insight into precisely what’s going on inside all ShipBob fulfillment centers you use, while letting ShipBob take on the task of preventing inaccurate inventories so you can focus on growing your business without having to manage a warehouse yourself.

Inventory accuracy FAQs

Ensuring inventory accuracy is an important task, and you probably have a lot of questions about it. Here are some answers to frequently asked questions regarding inventory accuracy:

What is the average inventory accuracy rate?

It’s nearly impossible to have perfect inventory accuracy at all times, considering the inevitability of human error and other issues that arise from managing frequent transactions, but the average inventory accuracy rate hovers around 99.6%.

Why is inventory accuracy important?

Inventory accuracy is important because it provides business owners with clear insight into their stock and inventory levels. A large number of inventory inaccuracies could mean customer get the wrong orders, you have a shortage of product, you’re experiencing theft, your products have. damages, your business is at a loss, and you can even struggle to sell through what you have before it becomes obsolete.

Do warehouses improve inventory accuracy?

Professional warehousing facilities make it easier for businesses to store and control their stock, improving the overall inventory accuracy.