Table of Contents

** Minutes

What is just-in-case inventory?

The role of just-in-case inventory in ecommerce (+ strategies)

Upgrade your inventory management strategy with ShipBob’s JIC solutions

In an age of influencer marketing and internet virality, it’s never been more important for ecommerce merchants to expect the unexpected. Savvy brands know that demand could spike at any time – and how to prepare their inventory accordingly.

Having just enough stock on hand to meet regular demand often leaves brands scrambling when there’s a sudden demand surge, and with no inventory reserves, they lose out on potential sales and damage customer satisfaction.

To avoid this, many brands employ a just-in-case (or “JIC”) inventory strategy.

Just-in-case inventory ensures that you have more inventory in stock than you technically need, so that you’re equipped to meet surprise surges in demand. It also helps you prepare for stock shortages resulting from unexpected supply chain issues that could disrupt production and procurement.

In this article, we explore what just-in-case inventory means, what role it plays in ecommerce, and how you can improve your inventory management with this approach.

What is just-in-case inventory?

Just-in-case inventory, or JIC, is an inventory management strategy that involves maintaining safety stock in addition to your forecasted inventory needs. This enables ecommerce businesses to have sufficient stock on hand to fulfil orders even if something unexpected happens. In other words, they have additional on-hand stock “just in case” they need it.

For example, say your business:

- Is featured on an influencer’s TikTok account, and receives a flood of customer orders as a result.

- Experiences a supply chain disruption (such as the Suez Canal blockage in 2021, which held up hundreds of cargo ships for six days and held up almost $10 billion in trade each day).

- Loses some of its inventory to a tornado, hurricane, or other natural disaster.

These issues could cause stockouts and backorders unless you have safety stock to tide you over until the replenishment stock arrives. As such, a just-in-time approach can help you avoid expensive stockout costs and prevent lost sales.

JIC vs. JIT inventory

With the prevalence of lean manufacturing practices, many businesses have opted for a just-in-time inventory management (or “JIT”) method. Businesses that use the JIT system only keep just enough inventory on hand to meet their needs. Replenishment is made “just in time” to avoid unnecessary inventory holding costs and prevent issues like dead stock.

This is in contrast to the JIC method, in which businesses keep more than enough inventory on hand so they are prepared for unforeseen demand surges and unexpected disruptions.

Both methods have pros and cons. JIT inventory helps avoid unnecessary holding costs and prevent issues like dead stock, but requires close monitoring of inventory levels and precisely-timed replenishments. It also leaves you susceptible to supply chain disruptions and unexpected demand surges. JIC inventory, on the other hand, is often considered a safer approach, but may result in higher inventory storage costs and dead stock.

As such, just-in-time management is most suitable for businesses that see consistent demand levels and can forecast demand accurately. They should also have well thought-out contingency plans and ample flexibility to face disruptions.

JIC inventory is most suitable if you’re working with suppliers that have long lead times or are inconsistent in delivering orders. Additionally, businesses that frequently see demand fluctuations can benefit from JIC inventory. You should also consider this approach if raw materials frequently go out of stock or are susceptible to price surges.

The role of just-in-case inventory in ecommerce (+ strategies)

While setting aside safety stock sounds simple enough, properly executing the JIC strategy is a more involved process than one might think. To use the JIC method successfully, you’ll need to understand how JIC affects all your inventory management activities, and how to tweak your processes to make the strategy work.

Assessing inventory needs

Brands leveraging JIC are susceptible to overstocking, so it’s crucial that you have an accurate understanding of how much inventory you have on hand most of the time. That way, you can maintain an amount of safety stock that makes sense given your regular inventory needs, and not hold on to massive amounts of inventory out of over-caution or fear.

To get a sense of your inventory needs, look first to your inventory management system (or IMS). These solutions often present real-time data on order volume, inventory levels, and other crucial metrics to help you understand your inventory turnover. In addition, perform regular inventory audits to compare your physical inventory levels against your inventory records.

This will provide you with an accurate idea of your actual inventory needs, so you can secure the perfect amount of safety stock.

Understanding demand forecasting

The JIC method gives brands a safety net, but it doesn’t mean they can forgo forecasting altogether.

On the contrary, JIC is most effective when brands meticulously review past order history, sales data, and seasonal trends to determine how much inventory they expect to sell in a given period. With this estimate, brands can better plan procurement, maintain optimal inventory levels, and prevent costly stockouts while minimising holding costs.

Optimising safety stock levels

Just like your forecasts for regular demand levels, your calculations for your safety stock needs should be educated and precise. This is a key aspect of successful JIC execution, as you can’t have too much or too little safety stock.

Instead of simply relying on assumptions, optimise your safety stock levels using the safety stock formula. This involves accounting for your maximum daily usage and average daily usage as well as maximum lead time and average lead time. Use ShipBob’s safety stock calculator to quickly determine how much inventory you need to keep as safety stock.

Evaluating supplier reliability

While many ecommerce businesses use the JIC strategy as a backup plan to unreliable suppliers, it won’t solve the problem. You still need a certain level of reliability to successfully implement JIC, as you still need suppliers to provide you with timely replenishments with minimal lead time.

If your suppliers or manufacturers are too inconsistent in their performance, you face an increased risk of stockouts and delivery delays. In some cases, you may even end up with dead stock because the replenishment stock arrived late as demand starts to dwindle.

While maintaining a good supplier relationship is vital to ensure better reliability, it all starts with the evaluation process. You should be working with reliable suppliers and supply chain partners right from the start.

Properly evaluate your suppliers and manufacturers and their production processes for reliability and quality control, even if you have an existing agreement with them. If any of your suppliers raise red flags, such as failing to communicate delays, making late deliveries consistently, or making lots of mistakes, consider looking for alternative options.

Balancing cost and efficiency

Although JIC inventory management provides you with more stability and agility in case of unexpected supply chain issues, it comes with a few cost implications.

First of all, a significant portion of your capital is tied up in inventory, leaving you with less working capital and cash flow. Additionally, keeping more inventory than required means you’re spending more money on holding costs and managing your excess inventory, which can hurt profitability.

This means that brands using the JIC approach will need to maintain a bit of a balancing act to keep your inventory costs minimal while still carrying sufficient stock.

To balance cost and efficiency, you’ll need up-to-date data and analytics on inventory spend, turnover, and more. Consider partnering with an expert solution like ShipBob, which offers brands an inventory analytics dashboard to closely monitor inventory performance at the SKU level while analising your per-unit storage costs.

With this type of insight, you can easily adjust your procurement strategy so that you can reduce low-performing SKUs while stocking up on high-performing ones. Similarly, you can quickly identify when you’re spending too much on inventory storage and adjust your safety stock strategy accordingly. That way, you can avoid overspending on carrying costs while still maintaining sufficient safety stock just in case.

Supporting and protecting supply chains

With volatile supply chains in fast-paced market environments, resilience and agility are vital for a brand’s survival. JIC inventory is key to staying flexible and still meeting customer demand when faced with natural disasters, supplier failures, global pandemics, and sudden demand spikes.

That said, JIC shouldn’t be the only element of your contingency plan. Consider finding backup suppliers or vendors, operating out of multiple fulfilment centres, and other fail-safes to keep your entire supply chain up and running in the event of unforeseen issues.

Upgrade your inventory management strategy with ShipBob’s JIC solutions

If your brand is going to implement the JIC strategy, it helps to have an expert partner to help you do it. ShipBob is that partner for thousands of brands, and offers merchants the data, technology, and best practices to optimise inventory management and set themselves up for success.

Here are just some of the ways that ShipBob helps brands execute the JIC inventory management strategy.

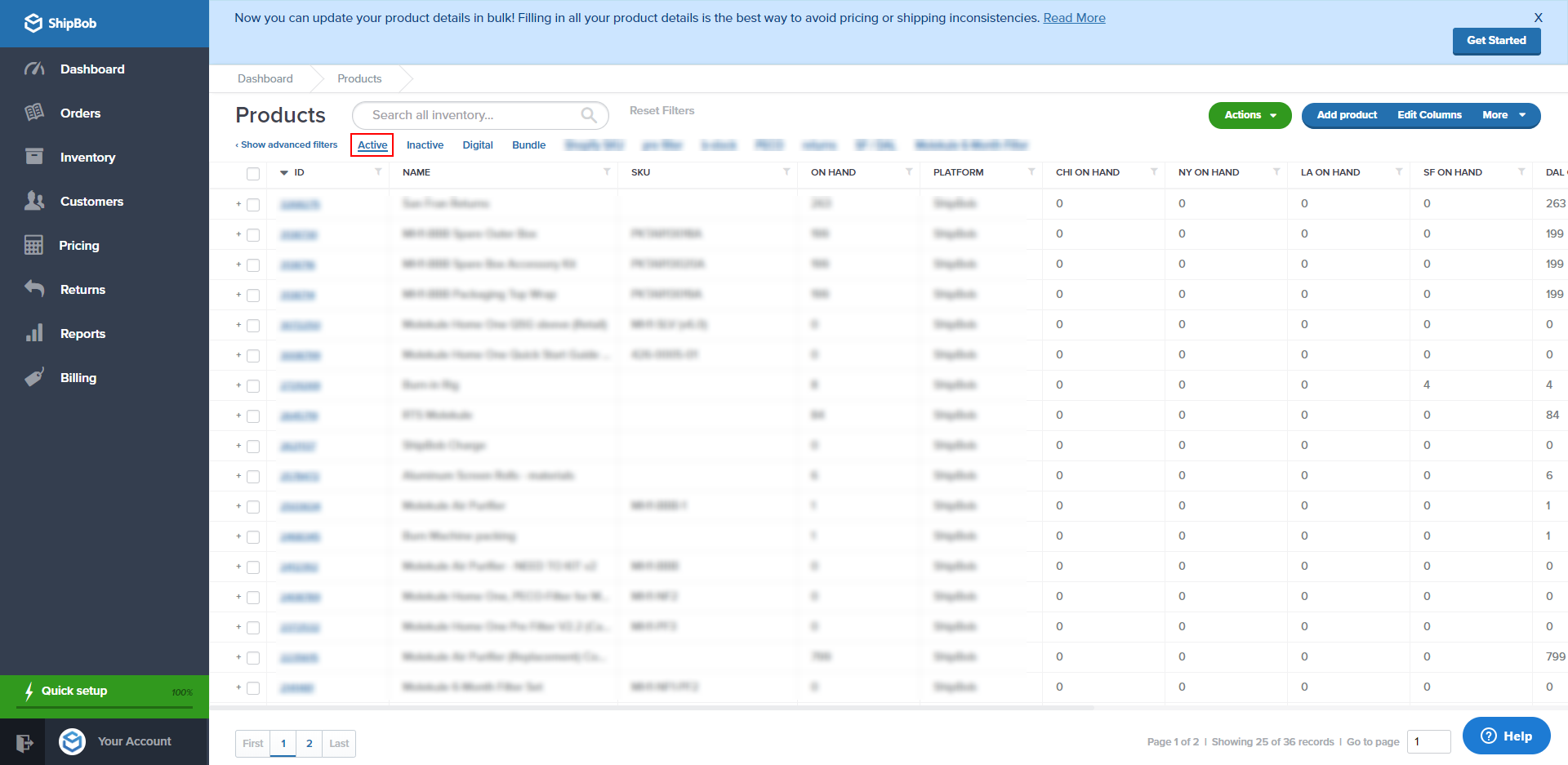

Real-time inventory tracking and analysis

ShipBob’s dashboard features built-in inventory management software, and provides real-time inventory tracking capabilities so you can see exactly how much of which SKUs you have on hand at any given time. This lets you know when you’re running low on a particular item, so you can reorder in time and never deplete your safety stock.

Additionally, the comprehensive inventory analytics show you which SKUs are performing well and which ones are slow to sell. This enables you to make informed decisions on how much JIC inventory to keep for each SKU, so you can avoid overstocking and high holding costs.

“Our fulfilment data feeds into our ERP, but a lot of times, we’ll go to ShipBob’s dashboard because the data is instant and real-time. We know ShipBob’s data is accurate as of this minute, so we can utilise ShipBob’s software as our real-time source of truth.”

Jessica Cedarleaf, VP of Operations at Tonies

Distributed inventory for JIC efficiency

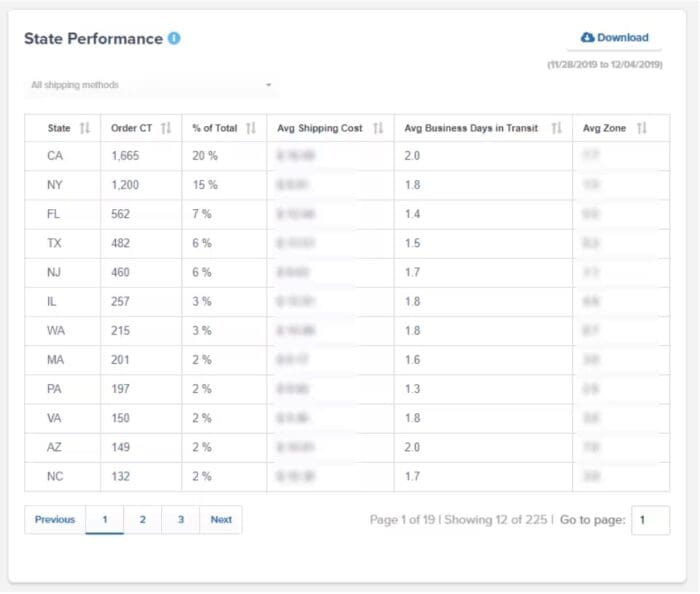

To reduce risk and meet customers’ expectations for fast and affordable shipping, it helps to store your inventory in multiple, strategically placed fulfilment centres. Leveraging ShipBob’s extensive US network (as well as global locations in the UK, Europe, Canada, and Australia), you can do just that – store your inventory closer to customers to minimise shipping costs and times while maximising inventory availability.

Through our Inventory Placement Program, ShipBob will even take care of allocating and distributing your inventory across our network for you. Merchants can use our Ideal Inventory Distribution tool to calculate the optimal split of inventory (based on order data that ShipBob automatically records), and send all their inventory to just one hub, from which ShipBob will distribute it to regional fulfilment centres. This saves you both the hassle and expense of doing it yourself, and frees up time to focus on other priorities.

“We’re using ShipBob’s Inventory Placement Program to manage inventory allocation and distribution, and it’s been super helpful for us. We send our inventory to one hub location, and from there, ShipBob determines the most strategic split of inventory across its fulfilment centre network and distributes our inventory for us. Having the ability to reduce shipping costs through distributed inventory is probably the difference between profitability and unprofitability for most businesses in the DTC space – so the fact that ShipBob’s network enables brands to do it so easily is a huge differentiator.”

Neil Blewitt, SVP of Operations at Bloom Nutrition

Advanced forecasting tools

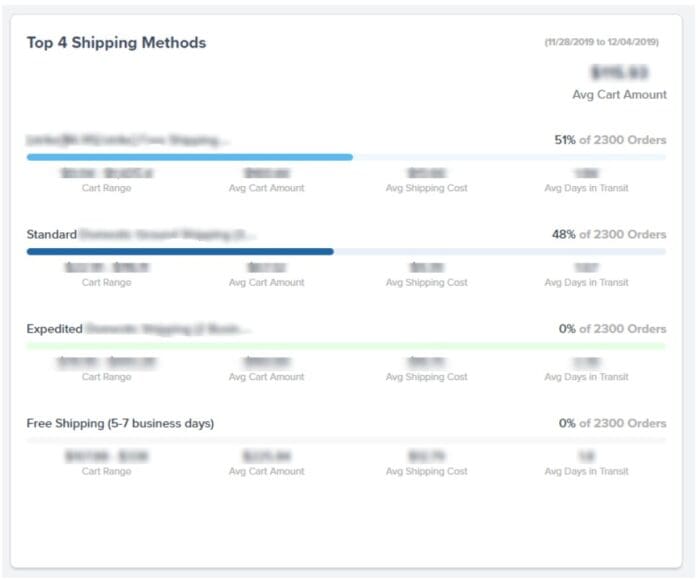

ShipBob’s dashboard delivers a free analytics reporting tools to make it easy for you to access comprehensive data and improve forecasting accuracy.

Through the dashboard, brands receive accurate inventory forecasting analytics, including historical order data, top selling states and shipping methods, fulfilment performance, and more. These insights allow you to effectively plan for demand fluctuations, determine optimal JIC inventory levels, figure out safety stock needs accordingly, so you are always ready to meet demand.

“The ShipBob dashboard is great for real-time information with their built-in reporting. It’s one of the things that really separates ShipBob from the rest of the solutions on the market. I’ve oftentimes leveraged the data and analytics ShipBob provides when I’m preparing for sales meetings. I can see what our top selling states are, what our average fulfilment time and cost is, how much inventory we have on hand at each fulfilment centre – a lot of different metrics that are very helpful when you’re selling B2B. ShipBob has all of that information ready for us at any time.”

Tyler McCann, Co-Founder of Taste Salud

For more information on how ShipBob can help you execute and optimise the JIC inventory method, click the button below.

Just-in-case inventory FAQs

Below are answers to the most commonly asked questions about just-in-case inventory.

How does just-in-case inventory differ from just-in-time inventory?

Just-in-case inventory involves stocking more inventory than required. Just-in-time inventory involves keeping just the right amount of stock on hand to meet demand.

What are the main advantages of adopting a just-in-case inventory strategy?

Just-in-case inventory allows you to prepare for unexpected demand surges and unforeseen supply chain disruptions. It also allows you to mitigate the risks associated with stockouts and backorders, and helps you avoid lost sales.

How do you calculate the optimal level of just-in-case inventory for a business?

You can calculate the optimal level of just-in-case inventory using the safety stock formula or using ShipBob’s safety stock calculator.

How can ecommerce businesses effectively implement a just-in-case inventory system?

Ecommerce businesses can effectively implement a just-in-case system by accurately forecasting demand, understanding their specific business’s requirements, and accounting for safety stock needs.