Table of Contents

** Minutes

What is on-time delivery (OTD)?

What makes on-time delivery tick in 2023?

How to set and measure on-time delivery KPIs

How to improve on-time delivery rates

ShipBob can help you optimise on-time delivery and delight your customers

Beyond the quality of your products and the values you maintain, ultimately customers care about the delivery — if it’s accurate, damage-free, and of course — on time.

Delivery speed is one of the main factors that will affect the overall customer experience, which has an impact on future sales.

RIFRUF, a ShipBob customer experienced increased sales since they managed to provide 35% faster shipping through ShipBob. This led to an 8x year-over-year growth for the pet accessory brand.

Another ShipBob customer, A Year of Dates, managed to save 18 days of transit time with ShipBob, which helped them to double their sales each year. With faster shipping to the U.S., the U.K.-based brand now ships 35% of their orders to the U.S. when previously, it had only been 5%.

That’s why it’s important to track on-time delivery metrics.

In this article, we take a closer look at on-time delivery, why it’s important, how to measure it, and how to improve it for your business.

What is on-time delivery (OTD)?

On-time delivery (OTD) is a metric used by ecommerce businesses to measure how many customer orders they’re able to fulfil by the expected delivery date.

By tracking this metric, businesses can identify how effective they are at fulfilling customer orders on time, and track the percentage of orders that are delivered on time to meet customer satisfaction.

On-time delivery vs. OTIF

On-time delivery is used to measure whether the delivery was completed on time, regardless if it’s only for a partial order.

On time and in full (OTIF) measures whether the delivery was completed on time and in full, meaning that the order must be delivered in full for this metric to come into play.

Let’s say a customer’s order consists of three items, which were shipped out separately. Two of those items arrive by the promised date, while one was shipped out slightly later due to it being out of stock at the time the order was placed.

Here, two of those shipments still count toward your OTD. However, this particular order wouldn’t count toward your OTIF, since it wasn’t delivered fully on time.

Why is OTD so important?

On-time delivery plays a critical role in the overall customer experience.

When customers get their orders on time, it gives them a positive delivery experience, which is a key factor in encouraging repeat purchases.

Delivering orders on time speaks volumes about the overall brand experience, which will affect your brand reputation. If customers repeatedly face issues with delayed delivery, it’s going to reflect badly on your brand.

Low on-time delivery rates also contribute to more customer complaints, meaning that your customer service team will have more tickets to deal with. This can add to the subsequent costs for your business.

Not to mention the bad reviews that will deter prospective customers from ordering again or the disappointed customers who choose to return their orders or those who will choose not to order from you again.

All of this will eventually add to significant revenue losses for your business.

On-time delivery disruptors in 2023 (and beyond)

As important as on-time delivery is, many businesses struggle to deliver orders on time. This may be due to a number of reasons, but it’s likely because they don’t have a dedicated OTD strategy.

Some may not have a strategy that’s actively monitored and optimised, resulting in inefficiencies and disruptions that contribute to delayed deliveries.

Poor inventory management

One of the leading causes of delayed deliveries is poor inventory management systems and processes. Not having a system to track inventory levels in real time can make it hard to optimise inventory to meet demand.

This can lead to delayed shipping to due stockouts and backorders.

Inventory management software can help track historical order data so you can forecast demand and replenish inventory accordingly.

Similarly, lack of inventory visibility is another reason why this type of issue occurs since companies are not updating their stock levels in real-time. This may lead to over-selling, where they sell more items than the inventory they have in stock.

Fulfilment inefficiencies

Any inefficiencies in your fulfilment process can result in significant shipping delays.

For example, if warehouse pickers have a hard time finding the items needed for an order, it will delay other aspects of the fulfilment process.

Setting up a warehouse management system that can help with lot tracking can solve for this. It can help keep warehouse employees efficient in picking and packing, as well as improve order accuracy.

Poor planning

Failure to plan ahead can result in delayed deliveries that affect your OTD.

For example, if you fail to account for lead times before placing a replenishment order, you may experience delays in getting the inventory needed to fulfil customer orders.

Similarly, a lack of route planning can lead to delivery inefficiencies since drivers are unable to follow optimal routes to deliver as many packages as possible in as little time as possible.

Having partnerships with multiple shipping couriers can help support your shipping strategy and improve delivery rate.

Supply chain disruptions

Unexpected disruptions and supply chain bottlenecks further up in the ecommerce supply chain can trickle down and affect your OTD.

Disruptions can occur at any time throughout the supply chain. A warehouse closure, bad weather, or a raw material shortage can all influence on-time delivery rates.

These disruptions may result in companies being unable to get their inventory on time, or it can cause shipping delays during the last-mile delivery.

What makes on-time delivery tick in 2023?

Now that we have a better idea of the main causes of late deliveries, it’s time to look at the factors that contribute to on-time delivery.

Machine learning

With machine learning evolving at such a rapid pace, it can effectively help to improve supply chain planning and efficiency, which subsequently contributes to timely deliveries.

Machine learning applications in demand forecasting and route optimisation are particularly useful.

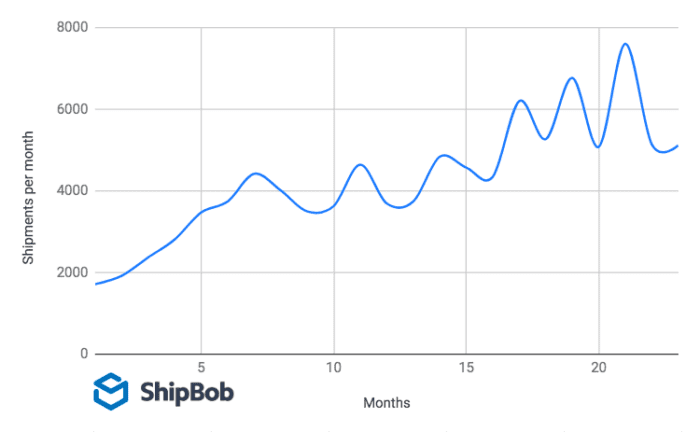

For example, machine learning will detect patterns and recognise demand signals, such as the ones in the graph below to make accurate predictions about future demand.

Moreover, it can adjust to changing situations and keep these predictions up-to-date to address demand volatility.

Machine learning can also be used to make predictions about traffic congestion and other factors that have an impact on transit time.

It can then determine the most ideal route to take that will minimise driving time and allow for efficient deliveries.

Automation

Retailers often partner with third-party logistics that offer automation solutions to speed up and improve the accuracy of their supply chain operations.

For examples, with WMS, automated picking lists are generated to allow for optimal picking efficiency. This helps speed up the picking and packing process.

Moreover, retailers can ensure timely inventory replenishment by setting up automated reorder notifications through an inventory tracking system. An alert is sent when stock dips below a certain level, so that there’s ample time to reorder inventory before it runs out.

Automation can also be used to compare rates and transit times between different shipping couriers, which will allow you to choose the best carrier option for each order.

Crystal clear communication

As inventory moves through your supply chain, it’s important to maintain clear communication throughout every stage.

This will allow you to be immediately notified in case of any issues and rectify them before things go out of hand, allowing orders to still get shipped out on time in some cases.

Similarly, this communication must be maintained even after orders leave your warehouses. Couriers must keep you informed about any possible delays so you can come up with a solution while keeping customers in the loop.

How to set and measure on-time delivery KPIs

The process of calculating on-time delivery is pretty straightforward as it only requires comparing the number of orders delivered on time against the total orders that were shipped out.

Here’s the formula to calculate your on-time delivery rate.

On-Time Delivery = (Number of Orders Delivered on Time / Total Orders Shipped) x 100

The calculation should be made based on a specific timeframe. Let’s say you want to calculate your on-time delivery rate for the month of December.

You shipped out a total of 7,000 units that month, out of which 6,500 were delivered on time. The remaining 500 either experienced delays or went missing in transit.

In this case, your on-time delivery rate would be:

On-Time Delivery = (6,500 / 7,000) x 100 = 92.8%

How to improve on-time delivery rates

Let’s break down the different ways to improve on-time delivery rates.

Set realistic goals

Start by setting an on-time delivery goal that you want to achieve, so your team can direct their efforts towards it. But make it realistic.

Holding an 100% on-time rate would be great, but it isn’t realistic since there are many unexpected events that could cause delivery delays.

Take a look at your existing performance data to see your usual on-time delivery rate. Then set a goal that’s higher than your usual numbers but still feasible.

For example, if your on-time delivery rate normally sits at 80%, your goal may be to achieve 90% on-time delivery.

Be transparent with customers

Give your customers the option to track their shipments in real time so you can maintain transparency even in case of unexpected delays.

A part of being transparent also involves providing delivery timelines that you can realistically meet.

Instead of promising to deliver exactly by a certain date, provide a date range spanning 2-3 days. This will also give you a wider on-time delivery window while improving customer satisfaction.

Optimise warehouse operations

Although every aspect of the supply chain is critical for timely deliveries, what goes on in your warehouse is perhaps one of the most vital.

Factors such as how your inventory is stored and managed, how tasks are assigned to warehousing staff, how items are located and picked, etc. are all essential for determining the timeliness of your deliveries.

So it’s important that you optimise every aspect of your warehouse operations for improved speed and efficiency. Inventory should be able to flow seamlessly through different stages of the supply chain within your warehouse.

You may need to optimise how inventory is stored and labelled to allow for easy movement and identification, which will speed up the picking process.

Additionally, you’d want to make use of warehouse automation to minimise the need for manual tasks and significantly speed up different warehousing processes.

Manage supply chain and logistical risks

Ecommerce businesses are highly susceptible to unexpected disruptions that can cause supply chain shortages and other logistical issues, which trickle down to affect your on-time delivery.

This makes it vital to improve supply chain resilience by planning ahead to manage these risks effectively so that any unexpected shortages and disruptions don’t hit you too hard.

Improving your supply chain planning is an essential step as it helps you better manage your supply chain. It also provides you with a game plan for how to respond even in case of unexpected disruptions.

Proper supply chain planning involves accurate inventory forecasting combined with a solid replenishment strategy so you can restock your inventory on time.

Moreover, you should also make strategic decisions about where and how to store your inventory.

For example, distributing your inventory between multiple distribution centres makes it easier to get your products closer to your customers for faster shipping.

It also makes for a more agile supply chain. If one distribution centre needs to close for any reason, you can transfer the order to another location, so it doesn’t delay a shipment.

Use logistics management software

The right technology can go a long way in improving the speed, efficiency, and accuracy of your logistics operations.

If you want to improve on-time delivery rate, consider investing in logistics solutions that will help you improve the way you manage your logistics.

With the right ecommerce shipping software, you can compare transit times and rates between multiple couriers, manage shipping labels, and track your shipments in real time.

Ideally, look for a modern 3PL that offers solutions for logistics automation, so you can automate activities such as order processing, picking and packing, and route optimisation to speed up the process.

Partner with a 3PL

Sometimes, a partnership with a 3PL is all you need to improve your on-time delivery rates.

“With our last 3PL, if our customers wanted free shipping, they had to have economy shipping and wait 5-8 days for delivery. Whereas with ShipBob, we can offer free shipping and customers receive their order in 3-5 days.”

Peter Liu, Co-Founder of RIFRUF

An omnichannel 3PL provides expertise, technology, and a network of fulfilment locations to manage inventory, pick and pack orders, and ship orders through the most optimised route.

You can leave all the complex and time-consuming aspects of your supply chain activities to the experts, who will then ensure that customer orders get shipped out on time.

ShipBob can help you optimise on-time delivery and delight your customers

ShipBob’s ecommerce fulfilment solutions allow you to outsource complex fulfilment logistics to the experts so you can save time and speed up your operations.

ShipBob’s fulfilment network makes it easy to distribute your inventory based on where your customers are located. Once an order comes in from any sales channel, it is sent to the nearest fulfilment centre to be picked, packed, and shipped.

Across ShipBob’s global fulfilment centres, a team of professionals will handle the picking, packing, and shipping processes on your behalf and ensure that orders get out the door quickly to reach your customers on time.

“Once we decided to implement ShipBob’s 2-day shipping for our US orders, we really saw a shift in how fast our orders were shipping.

Even when we’ve had one fulfilment centre run out of inventory, orders get pushed to a different fulfilment centre and they still arrive on the customer’s doorstep in 2 days.”

Maria Osorio, Logistics and Operations Director at Oxford Healthspan

ShipBob maintains an impressive 99.99% on-time shipping rate along with a 99.95% accuracy rate.

Moreover, ShipBob offers 2-day shipping coverage across the entire contiguous U.S. So you can ensure that orders reach customers on time in as little time as possible.

ShipBob’s fulfilment platform makes it easy to outsource fulfilment but get full visibility into fulfilment activity. All in one place, you can track inventory levels, manage SKUs, view order status, forecast demand, and much more.

On-time delivery FAQs

Below are answers to the most common questions about on-time delivery.

What is the difference between OTD and OTIF?

On-time delivery is used to measure delivery for all orders, even if it’s just a partial shipment. OTIF measures whether the delivery was completed on time and in full.

What is the importance of on-time delivery in business?

On-time delivery can help to improve customer satisfaction, which affects the overall customer experience and brand loyalty.

What is a good on-time delivery rate?

Businesses should aim to keep their on-time delivery rate above 95%.

How can ShipBob help improve OTD?

ShipBob’s software allows you to automatically process orders and speed up the fulfilment process. You can also leverage a distributed fulfilment network to shorten transit times. ShipBob even offers 2-day express shipping coverage to 100% of the contiguous US.