Table of Contents

** Minutes

What is the order to cash (O2C) cycle?

What makes the order-to-cash cycle so important?

7 key processes in the order-to-cash cycle

Best practices to improve your order-to-cash process

Common problems in the O2C cycle and how ShipBob addresses them

When a customer places an order, does it count as a sale?

It’s easy to assume that once a customer completes checkout, it magically turns into cash. But there’s a lot that happens “behind the scenes,” and it all must run smoothly for an order to turn into profit.

This concept is known as the “order-to-cash” process (or O2C). For direct-to-consumer (DTC) brands, it involves several steps, from processing an order to shipping it out.

In this article, you’ll learn how the order to cash process works, why it’s important, and what you can do to ensure a smooth O2C process.

What is the order to cash (O2C) cycle?

The order-to-cash (O2C) cycle refers to a set of business processes involved in turning an order into cash — or in other words, profit.

Once an order is placed online, it must be processed. Once the customer’s information is validated, items in the order must go through the retail fulfilment process before they’re ready to ship.

During the O2C cycle, some inventory management and accounting tasks must occur, such as locating items in the available inventory to fulfil the order and receiving customer payments.

A healthy O2C cycle requires order management software to track orders and record data, which is used to analyse O2C performance.

What makes the order-to-cash cycle so important?

The O2C cycle plays a critical role in your business operations. There are several key order metrics that are tracked to ensure customer satisfaction, including order accuracy and on-time shipments — which all relate to establishing an efficient O2C process.

Once orders are placed, you will need to process and validate order information, including delivery location, as soon as possible before you begin picking and packing orders.

As orders move throughout the O2C cycle, systems and processes should be in place that give visibility into the process, including the ability to track orders at every stage.

This way, you can keep your customers in the loop on their orders and track, analyse, and optimise the ecommerce fulfilment process.

7 key processes in the order-to-cash cycle

To create an efficient O2C cycle, below we cover seven key processes that must be developed and evaluated over time.

1. Order management

The order management process begins as soon as a customer places an order and continues until their shipment has been received (or even sent back). It involves tracking the entire O2C process, from processing orders to managing returns and analising performance.

The process requires several moving parts, often controlled by separate entities, that are often integrated to create an efficient operation.

Keep in mind that without the right software and technology, tracking a high volume of orders can be difficult and time-consuming.

Before anything, you will want to consider implementing order management software that can help track all orders by status, let you view order tracking details, and more, so you have all the data and information you need to track and manage the O2C process.

If you sell across multiple sales channels, a more robust solution like a multichannel retailing system can be integrated to automatically push the relevant information (order details, shipping details, delivery address, etc.) from your ecommerce store to a centralised system, such as 3PL’s software.

2. Payment processing and credit management

Payment processing involves receiving payment for orders. After a customer submits an order online, a secure payment gateway captures their credit card details (or other payment method) and sends the info to your payment processor.

The card-issuing bank then verifies the legitimacy of the transaction, either declining or approving the sale. If the transaction is declined, all relevant parties get notified about it.

If it’s approved, the payment goes through and the order is confirmed. The funds from the sale will get credited to your store or merchant account within the next few days, completing this part of the transaction.

In situations where credit is applicable, a thorough credit management process is also necessary to minimise issues toward the final stage of the process.

3. Order fulfilment

Order fulfilment refers to the warehouse picking and packing stage of the order. Once orders are placed and processed, the correct items must be located, then picked and packed before shipment.

Early on in an ecommerce business’s history, this step in the O2C process is often done in-house or from an office. However, in-house fulfilment is time-consuming and can be costly if not done right. That’s why DTC brands often delegate order fulfilment to a 3PL like ShipBob.

You can connect your online store to ShipBob’s technology and send inventory to one or more fulfilment centre locations based on where your customers are. Your ecommerce inventory is then retrieved to ensure accuracy and avoid inventory shrinkage before items are stored.

4. Order shipment

Ecommerce shipping is a vital stage in the O2C cycle. This stage requires more thought than simply packing orders and shipping them out.

The shipping experience directly impacts customer satisfaction. Since most customers expect fast and affordable shipping, taking the time to establish a shipping strategy is essential.

The attractiveness of your shipping options can reduce cart abandonment and increase average order value and customer loyalty.

When thinking through a strategy, you will need to decide the ecommerce shipping methods you will offer, as well as any shipping incentives (affordable 2-day shipping and/or free shipping), and choose which major and/or regional parcel couriers you’ll partner with.

Once orders are shipped, order tracking must be generated and sent to the customer, so they can track last-mile delivery.

5. Customer invoicing

Be sure to send your customers a digital receipt. For DTC orders, once an order is processed, a receipt is automatically sent to the customer via a transactional email.

However, there are some cases in which an online store would have to generate a more detailed invoice to send to a customer. This is common for B2B ecommerce transactions that require it for accounting purposes.

Some customer invoices, especially for wholesale or bulk orders, might also include information on what was purchased, who was involved in the transaction, when it occurred, and which payment method was used.

Customer invoicing is crucial when dealing with large, international shipments. For instance, if you sell bulk orders to another company overseas, the destination country could estimate the value of the package incorrectly without the proper paperwork, which could potentially cost your customer more in import fees.

6. Accounts receivable

Accounts receivable involves keeping track of and managing unpaid invoices of finished goods provided.

It is a record of: the date of sale, to whom, the amount of money owed, and when payment is due. Depending on the circumstance, credit terms (when applicable) may vary from a couple days, to a week or up to one year.

In many cases, one-off customer purchases receive payment at the point of sale. However, tracking accounts receivable is always required, especially if you offer subscription box orders or a pay-later service, such as Affirm.

Pay-later services are becoming more common, which allows a customer to choose a payment plan for often bigger purchases. In this case, partial payment is collected at point of sale and a reminder (via text or email) is sent to the customer to avoid missing additional payments.

No matter if you solely offer point-of-sale purchases, special financing, or net days, implementing an accounting software like Quickbooks is a must for managing accounts receivable.

7. Reporting and data management

A proper O2C process would be hard to manage and improve on if there isn’t any data being collected.

Once your O2C process is in place, you will want to ensure that your supply chain technology stack is well-connected and is pulling in the right data sources and information, including insights into orders, inventory levels, shipments, and returns.

Referring back to the first step, having an order management system will allow you to see all sales order data in one place, making it easier to analyse the available information and make data-driven decisions.

“We utilise ShipBob’s Inventory API, which allows us to programmatically retrieve real-time data on how many units of each product are currently stored at ShipBob’s warehouses. We currently use this API to generate custom reports to tie this inventory data into our accounting platforms.”

Best practices to improve your order-to-cash process

If your current O2C process needs a bit of revamping, here are some best practices to help you decide on next steps and where to optimise.

Upgrade your order management software

The right order management software solution will make it easier to identify real-time problems because you can see the whole process from a birds’ eye view instead of as separate fragments.

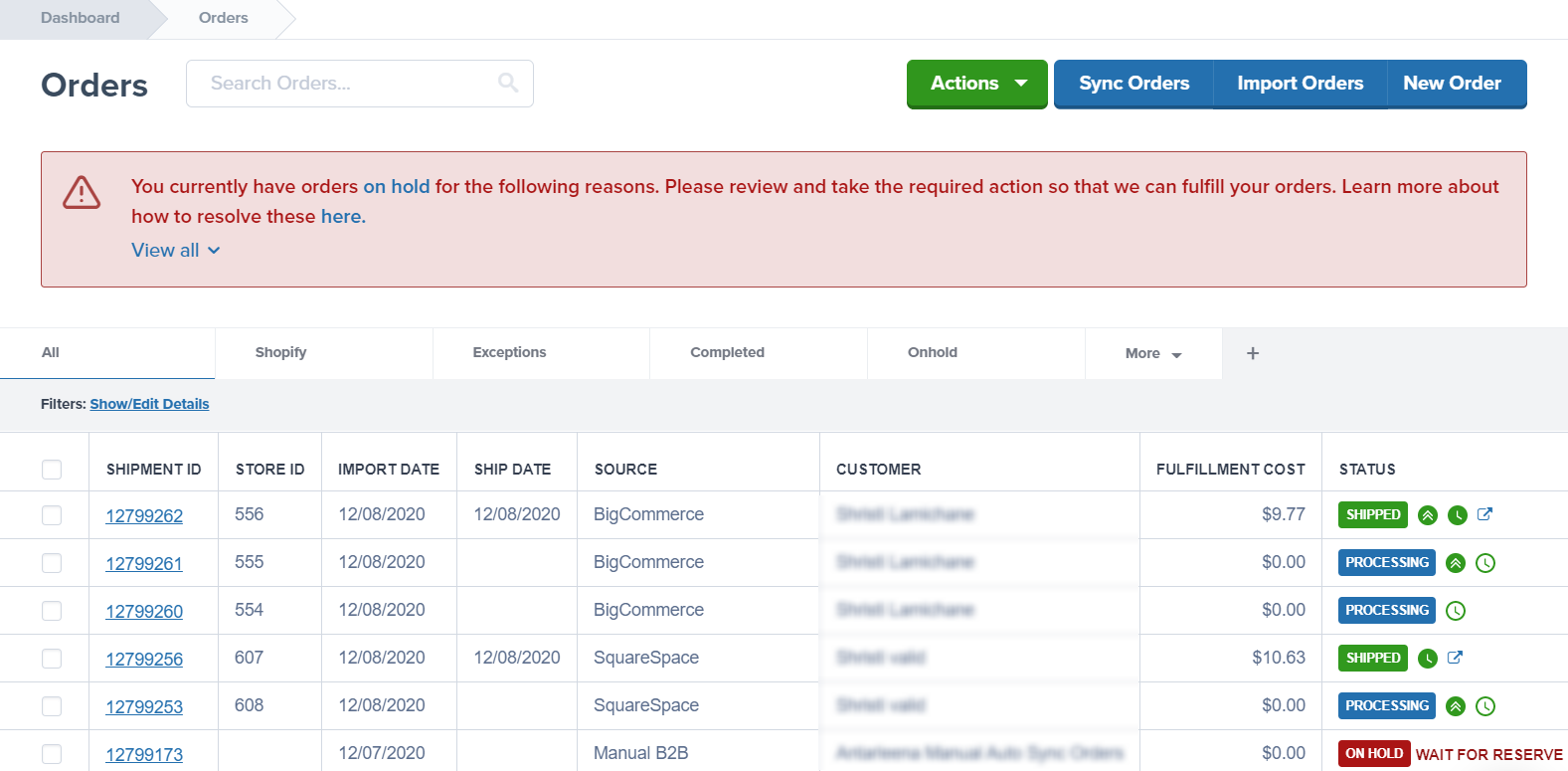

For example, ShipBob’s built-in order management system (that’s part of our overall outsourced fulfilment solution) makes it easy to filter orders by status, search for a specific order, edit orders post-purchase up until they are being picked, and shows how your customers’ orders are distributed geographically.

Upgrading your order management software to integrate with your entire logistics operations minimises the risk of human error, fulfilment delays, and orders being placed when items are out of stock while improving speed, accuracy, and delivery.

“I love that you can view orders based on when they are processing, completed, on hold, and in other stages. It is super helpful for us to have that and track the order every step of the way.”

Ines Guien, Vice President of Operations at Dossier

Automate as much as possible

Ecommerce automation is key to creating a streamlined O2C process. Automation is used to put time-consuming, error-prone tasks on autopilot to create a more efficient supply chain.

Automation can be implemented in any stage of the process, from order processing to shipping.

For instance, an automated order processing system integrates with your sales channels and automatically processes and verifies orders as they come in. Orders can’t be fulfilled until orders are processed, so automating the order processing step is a surefire way to enable faster fulfilment.

Though there has been tremendous advancements in logistics innovations, implementing automation into your operations can be costly.

Another approach is to work with a tech-enabled 3PL like ShipBob that automates fulfilment and uses best-in-class technology to streamline your logistics operations, saving you time and money in the long run.

Access and analyse data in real time

To improve your O2C process, you will need real-time access to relevant data so you can respond quickly before problems escalate.

For example, real-time updates on stock availability can let you know when to stop accepting orders for a particular product (and update stock counts accordingly). That way, you can avoid the risk of getting new orders for out-of-stock items that can’t be fulfilled right away.

Another great advantage of partnering with a 3PL like ShipBob is the ability to access fulfilment data and pull reports on fulfilment performance, which impacts your O2C cycle. For instance, from the ShipBob dashboard, merchants can get answers to questions like:

- How many of my orders are fulfilled on time (and what’s the breakdown of orders placed, processed, and shipped)?

- How many and which orders can’t be fulfilled because of inadequate stock levels?

- How many days does it take for my orders to be delivered?

Optimise for your customer first at every step of the way

At each step of the O2C cycle, the customer experience should always be top of mind. With the right systems and processes in place (e.g., automation, order management software, and data and reporting), you will have enough visibility and insights to find ways to optimise the journey.

Sometimes, there are hiccups during the purchasing process. To reduce the chance of this happening, be sure there aren’t any barriers to purchase by evaluating your store’s cart. Then review order confirmations to ensure they are sent right away to the customer. You can always create test orders instead of completing actual purchases.

During the fulfilment process, look for ways to optimise speed without compromising accuracy. This helps ensure that customers receive their shipment on time. You can also consider custom packaging to further enhance the unboxing experience.

Most importantly, customers want timely updates about their orders, so be sure to set up a system that automatically sends order tracking to your customers.

Common problems in the O2C cycle and how ShipBob addresses them

Partnering with a 3PL like ShipBob can help you improve the O2C cycle by providing a robust fulfilment infrastructure and technology solution that helps you save time and money.

Here is an overview of how we solve common problems DTC brands face during the O2C process.

Problem: Inaccurate data for orders across sales channels

If you’re selling through multiple channels, you might face challenges like getting accurate order data across all those sales channels (that also feed into one view of total available inventory).

This could mean that an item that you no longer sell on Amazon might look as if it’s still in stock on a different marketplace or on your store. Or, your online store may not update stock levels in real time, which then displays inaccurate stock counts. This can cause an influx in backorders and negatively impact customer satisfaction.

Without a system built specifically to manage an omnichannel retail strategy, you will struggle with matching current inventory counts with accurate stock information across channels.

Solution: ShipBob offers an omnichannel order management system

ShipBob makes it easy to connect your online store(s) and get started with new sales channels through our fulfilment technology, so you can get accurate order data across all sales channels.

Once all channels are integrated, from the ShipBob dashboard, you can:

- Sync, import, and create orders.

- Merge the same SKUs that are sold on more than one store.

- Search orders and create filters according to the data you wish to see.

- Perform actions on a specific order or a segment of orders.

- View fulfilment cost per order.

This will allow you to efficiently manage multichannel inventory levels and view order activity in one place. Since ShipBob’s entire network is powered by the same warehouse management system (WMS), the data is aggregated in real time.

For a more robust solution, ShipBob’s technology integrates with leading order management solutions that specialize in multichannel logistics.

Problem: Slow or delayed shipping times

All online retailers face challenges when it comes to shipping.

Failing to meet today’s customer expectations around fast, affordable delivery can result in lost business and a negative brand perception. If you can’t meet expectations around premium shipping, your shoppers will look elsewhere.

Unfortunately, not all retailers have the capital to invest in technology and the fulfilment infrastructure to meet these high standards.

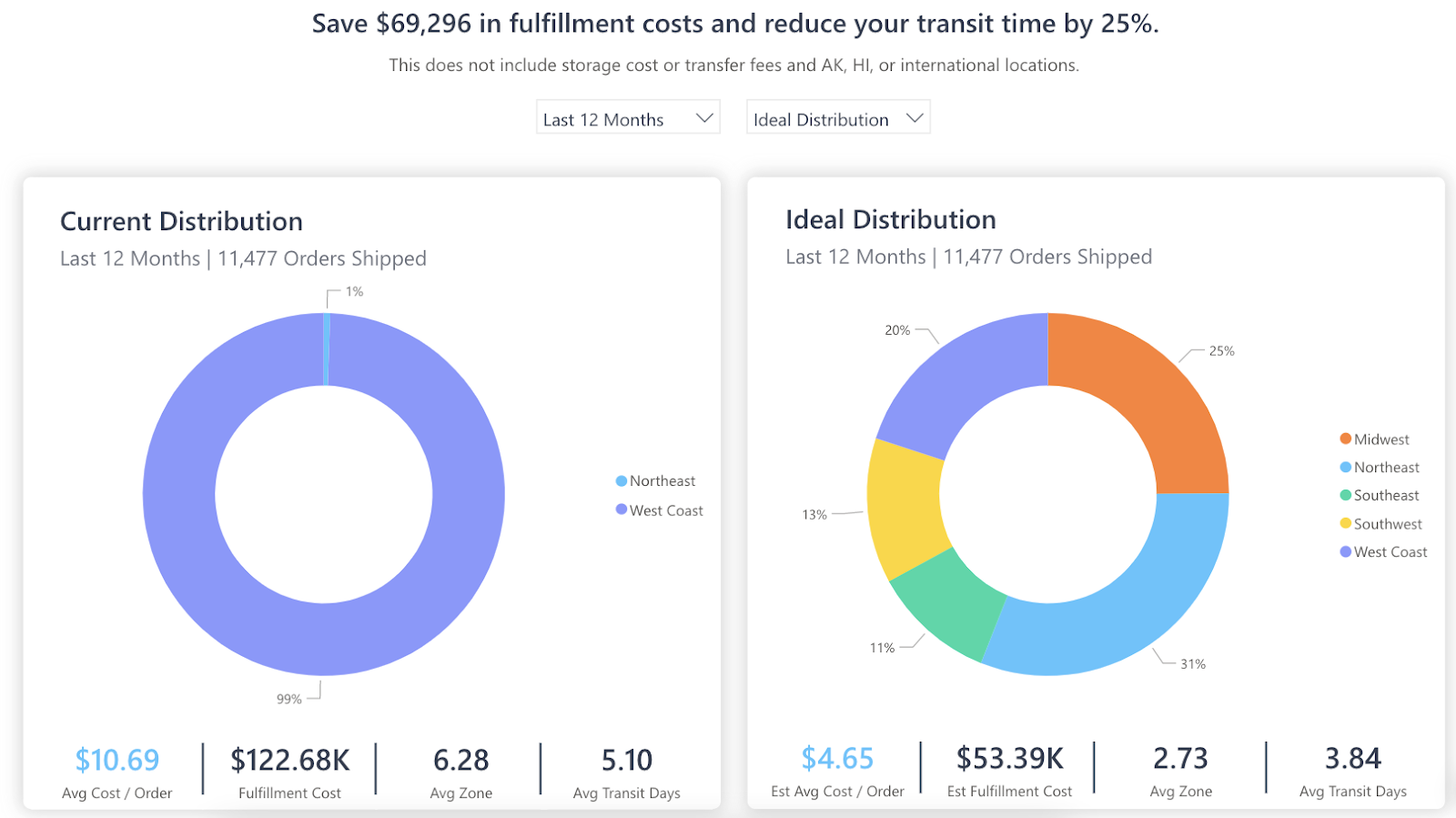

Solution: ShipBob offers 2-day delivery + the ability to distribute inventory for faster turnaround times

ShipBob operates from multiple fulfilment centres across the globe, allowing you to ship out orders from the nearest fulfilment centre to reach customers quickly.

ShipBob also provides recommendations for optimal inventory distribution across our fulfilment network (which reduces shipping costs and time-in-transit times) based on demand forecasting data and where orders are coming in from.

Problem: Reporting on different steps within the O2C cycle is time-consuming

Businesses also have to tackle the challenge of getting accurate reports on different stages of the O2C cycle as they often have to pull in data from multiple sources.

This can be time-consuming process and prone to error.

Solution: ShipBob offers accurate, real-time analytics on your inventory & order metrics to make more informed decisions

ShipBob offers free analytics reporting that provids real-time inventory updates and order status. This enables you to make more informed decisions on how to manage your inventory and enhance your fulfilment strategy.

You can also subscribe to receive order updates via email for a specific order and export an order report that provides details for an entire order.

“ShipBob has an analytics tab in their dashboard with all of this information, which is great for end-of-month reconciliations. It’s really nice to not have to operate three 3PLs.

For inventory planning, I love the SKU velocity report, daily average products sold, and knowing how much inventory we have left and how long it will last.

Overall, there is more transparency with ShipBob that even helps our team manage customer service better. I can see the granular stage the order is in — if it’s being picked, packed, in transit, etc. That enhanced visibility is great.

No other 3PLs offer that in my experience.”

Wes Brown, Head of Operations at Black Claw LLC

To learn more about how ShipBob works, take a virtual tour of our operations:

Ready to move forward with a 3PL to streamline your O2C cycle? Click the button below to get in touch with ShipBob.

Order-to-cash FAQs

Here are the top questions about order-to-cash (O2C):

What is an example of order-to-cash?

Here’s an example of the order-to-cash cycle: Let’s say Holden Industries offers both wholesale and one-off purchases. Both types of orders come in, which need to be processed and verified before they move to the fulfilment process. For one-off purchases, customer payment is often completed at point-of-sale. Once the order is confirmed, an automatic email is sent right away to the customer, including a receipt. Once the order’s details and information are verified, items are located, then packed and shipped.

For the wholesale order, there might be more paperwork involved, such as invoicing that provides more details than a simple purchase receipt. To help manage the O2C cycle, Holden Industries uses an order management system to oversee the order-to-cash process, which makes it easy to track orders, shipments, and returns.

Can you outsource the O2C process?

You can outsource many parts of the O2C process. For instance, you can work with an accountant to track accounts receivable (i.e., customer payments) and partner with a 3PL to take care of inventory tracking and fulfilling orders, as well as sending out shipments. Many 3PLs like ShipBob also provide data and reporting to help you maintain control over the process and find ways to improve it.

What is the order-to-cash process flow?

For DTC stores, a customer places an order and pays using a debit or credit card. The order is then processed and verified before it moves to the fulfilment process. Once payment is received, confirmation is sent to the customer, and orders are then picked, packed, and shipped. Order tracking information is sent to the customer, so they can track the delivery. Order management software is also used to oversee the order-to-cash process by tracking orders, shipments, and returns.