Table of Contents

** Minutes

How do warehouse pick modules improve ecommerce fulfilment?

Types of warehouse pick modules

Go beyond pick modules with ShipBob’s warehousing & WMS solutions

Something as seemingly simple as being able to pick orders accurately and efficiently can be the difference between an ecommerce business that succeeds or fails. If orders aren’t packed accurately you’ll receive returns or chargebacks and if they aren’t packed efficiently customers will begin to wonder why their order is taking so long to arrive.

That’s why having the proper pick modules in place is so important. As many warehouses struggle with outdated systems and poor space use, pick modules can help you prevent damage to your brand’s reputation.

At ShipBob, we recognise these common pain points and always seek transformative solutions in pick modules. In this guide we’ll discuss how pick modules streamline the picking process, maximise space utilisation, and enhance order accuracy, paving the way for a more efficient and cost-effective operation.

What are pick modules?

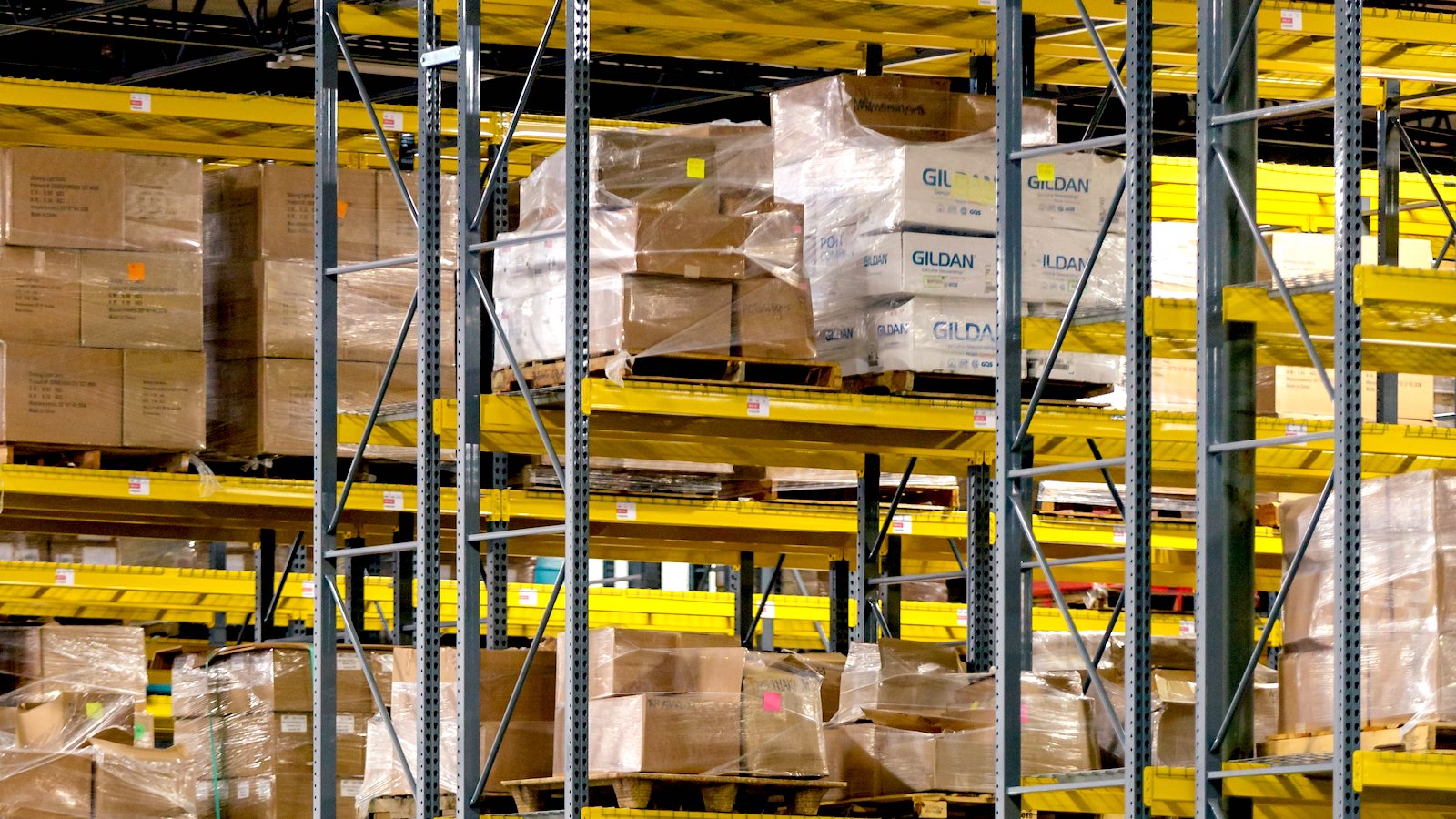

Pick modules are multi-level storage systems that boost order fulfilment efficiency in warehouses. These structures use various storage solutions, such as pallet racking, carton flow, and conveyor systems, to streamline product flow from storage to shipping.

By consolidating storage vertically, they save space and reduce picker travel distances. Pick modules support first-in-first-out (FIFO) inventory rotation and can be customised to meet specific operational needs.

Combined with advanced warehouse technologies like a warehouse management system (WMS), pick modules optimise picking rates and ensure smooth order processing.

Here’s how pick modules work

Pick modules come in various shapes and sizes. Each one is used to optimise a specific aspect of the order fulfilment process. Whether it’s for fast-moving items, high-value products, or bulk goods, each module is designed to maximise efficiency and accuracy.

Pallet racking

The primary component of a pick module is pallet racking, which provides structural support and storage for large quantities of inventory. Pallet racking systems can be configured with a pallet flow rack or push-back racks to facilitate the efficient movement of goods.

Shelving units

Shelving units are another essential element in pick modules. They offer storage for smaller items and broken-case picking areas. These units can be fitted with carton flow racks, allowing products to move seamlessly from the back to the front of the shelf. This ensures first-in-first-out (FIFO) inventory rotation and easy access for pickers.

Conveyor belts

Conveyor belts play a crucial role in automating the transportation of picked items through the warehouse. They minimise the need for manual transport, significantly reducing picker travel time and enhancing overall productivity.

Sortation devices

Sortation devices, such as automated scanners and diverters, enhance efficiency by quickly identifying items and directing them to the correct bins or containers based on their destination within the warehouse. Automated scanners read barcodes or RFID tags to gather item information, while diverters use mechanical arms or conveyor belts to move items precisely to their designated locations.

How do warehouse pick modules improve ecommerce fulfilment?

Warehouse pick modules play a key role in enhancing ecommerce fulfilment. Below, we explore how pick modules contribute to improved warehouse management and overall performance.

Increased warehouse picking efficiency

Pick modules significantly increase picking efficiency by consolidating different picking and storage methods into one cohesive system. These systems ensure that pickers move through the warehouse in the most efficient manner possible and reduce manual handling and transportation time

As previously mentioned, using these in conjunction with a WMS further enhances operations by providing real-time data and analytics, optimising inventory management, and streamlining order processing.

Optimised warehouse space usage

By consolidating storage vertically, multi-level pick modules make better use of available cubic space. This vertical integration allows you to store more inventory within the same footprint, reducing the need for additional warehouse facilities.

Pick modules also facilitate a structured and organised warehouse setup, which helps in efficiently managing different types of goods. For instance, pallet racking can be used for bulk items, while carton flow systems are ideal for smaller items or pieces.

Superior order accuracy

Technologies like WMS and barcode scanning ensure that each item is correctly identified and tracked throughout the warehouse order picking operation. Automated sortation devices further reduce human errors by directing items to their correct destinations automatically.

Scalability and flexibility

The modular nature of pick modules allows for easy reconfiguration, enabling warehouses to adjust quickly to changing demands. This flexibility ensures that your warehouse operations remain agile and responsive, no matter how your business evolves.

Types of warehouse pick modules

The choice of pick module system depends on factors such as the nature of the items stored, the volume of orders, and the preferred method of item retrieval. Below are some common types of warehouse pick modules and their unique features.

Single-level pick modules

Ideal for: Smaller operations or warehouses with limited vertical space.

These modules typically incorporate pallet racking, shelving units, and carton flow racks on a single floor level, making them simple yet effective for managing inventory.

They provide easy access to products and are suitable for operations that handle lower volumes or less diverse inventory. Single-level modules are cost-effective and relatively easy to install and reconfigure.

Multi-level pick modules

Ideal for: High-volume operations that require extensive storage capacity and quick item retrieval.

Multi-level pick modules maximise vertical space by incorporating multiple tiers of storage. These structures often include mezzanines, pallet racking, and conveyor systems that enable efficient movement of goods between levels.

They also support first-in-first-out (FIFO) inventory rotation and significantly reduce picker travel time, improving overall efficiency.

Manual pick modules

Ideal for: Handling delicate or irregularly shaped items that require careful material handling.

Manual pick modules rely on human order pickers to retrieve items from storage locations. These modules can include both single-level and multi-level configurations, depending on the warehouse’s needs.

While manual picking requires more labour, it offers flexibility and is adaptable to various inventory types.

Automated pick modules

Ideal for: Large-scale operations with consistent, high-demand inventory.

Automated warehouse picking modules leverage advanced technology such as robotics, conveyor belts, and automated storage and retrieval systems (AS/RS) to streamline the picking process.

Automated systems can handle high volumes of orders rapidly and also help reduce labour costs and error rates.

Hybrid pick modules

Ideal for: Warehouses that deal with a mix of high-volume, standardized products and lower-volume, specialized items.

Hybrid pick modules combine elements of manual and automated systems for flexibility and scalability. These modules might use automated conveyor systems for transporting goods while still relying on human pickers for item retrieval.

Hybrid modules offer a balanced approach that optimises both labour and automation.

Go beyond pick modules with ShipBob’s warehousing & WMS solutions

By minimising errors, pick modules not only enhance customer satisfaction but also reduce the costs associated with returns and re-shipments.

At ShipBob, we know firsthand that order accuracy ensures that customers receive the correct items on time, which is crucial for maintaining a positive brand reputation.

Transform your warehouse efficiency with ShipBob’s WMS

ShipBob’s WMS is designed to elevate your warehouse operations by integrating advanced technology and seamless processes. By leveraging ShipBob’s WMS, companies like Spikeball have transformed their logistics.

“We’re saving hundreds of thousands of dollars per year, just in postage. When we first got started, we estimated over $400,000 in savings. ShipBob has helped us save 40% on total fulfilment costs.”

Adam LaGesse, Global Warehousing Director at Spikeball

Scale globally with ease using ShipBob’s fulfilment network

ShipBob’s extensive fulfilment network allows you to scale your operations globally with ease. With fulfilment centres strategically located worldwide, you can reach your customers faster and at lower shipping rates.

Reduce operational costs with ShipBob’s automated solutions

ShipBob’s automated solutions streamline warehouse operations, reducing manual labour and minimising errors. Automated processes such as automated storage and retrieval systems (AS/RS) and conveyor systems enhance picking efficiency and accuracy.

Leverage real-time data for smarter inventory management

With ShipBob’s WMS, you gain access to real-time data and analytics, enabling smarter inventory management decisions. Track inventory levels, monitor order statuses, and predict demand trends to optimise your stock levels and reduce holding costs.

Get started with ShipBob

Connect with ShipBob’s team of fulfilment experts using the link below to request a quote and get started.

Pick module FAQs

Can ShipBob’s solutions integrate with other ecommerce platforms?

Yes, ShipBob’s WMS integrates seamlessly with various ecommerce platform partners. This integration helps to manage inventory in real-time, reduce picking errors, and fulfil orders faster by streamlining the order fulfilment process from storage to shipping.

What are some common pick module designs?

Common pick module designs include catwalk mezzanines, full case picking, broken case picking, and mechanized (semi-automated) picking. These designs cater to different operational needs, from small order parts and full pallets to high volume, individual item picks, incorporating components like pallet racking, carton flow, and conveyor systems.

How much does it cost to implement a pick module in a warehouse?

The cost of implementing a pick module varies widely based on the complexity and size of the system. Factors such as the number of levels, types of racking, conveyor systems, and advanced technology integrations like WMS can significantly influence the overall expense.

How do you integrate a pick module into an existing warehouse layout?

To integrate a pick module into an existing warehouse layout, start with a thorough assessment of your current space and workflow. Components like pallet racking, conveyor belts, and shelving units should be strategically placed to optimise space while minimising disruption during implementation.