Table of Contents

** Minutes

Why understanding pipeline inventory is important to your business

Decoupling stock to reduce stockouts

The phrase “in the pipeline” implies something is coming soon. In the context of inventory management, this can refer to additional product lines, new scents or colours, and even just stock replenishment.

For many brands, it’s easy to overlook the first-mile delivery and drayage process (when purchased inventory is in transit), but it’s an important part of ecommerce operations as it ensures new inventory arrives at the right place at the right time.

Known as pipeline inventory, inventory in transit should be tracked alongside physical inventory on hand to provide a holistic view of how much inventory is tied up in capital versus how much inventory is readily available to sell.

In this article, we will focus on what pipeline inventory is, why it’s essential to managing inventory, and how to calculate and optimise it.

What is pipeline inventory?

Pipeline inventory refers to the value of finished goods ordered from a supplier or manufacturer that is currently in transit and has yet to reach a physical store or distribution centre.

How pipeline inventory works

Whether or not a brand has received their new products, once they pay for the inventory, these units are no longer owned by the supplier and are considered an asset owned by the buyer.

In some cases, pipeline inventory refers to raw materials purchased from a business used to create finished products (also called production inventory). When it’s received, it’s labelled as “work-in-process” inventory and considered an asset on a company’s balance sheet if products sold to the end user are designed and produced in-house.

Most ecommerce brands will always have some volume of pipeline inventory coming in if their products are being turned over and sold. As part of their inventory replenishment process, brands will look at inventory performance, production lead lines, and warehouse receiving times to order inventory according to a specific timeline, so it’s more likely to arrive, be accounted for, and be ready for fulfilment when needed.

Of course, the larger and more complex an ecommerce supply chain is, the more pipeline inventory there is in terms of order volume and total SKUs. It also can become more complex to track when there are multiple sales and distribution channels involved.

Even if it’s on the buyer’s books, if any issues arise during transit (slowdowns, shipping damages, or misplacement of goods), you need to have a strong contingency plan in place. This could mean planning for different crisis scenarios or decoupling inventory (more on this later).

Why understanding pipeline inventory is important to your business

Knowing how much pipeline inventory is incoming helps you plan better for customer demand. It also provides a holistic view of how much inventory is in currently in each stage of the supply chain.

Calculating and tracking pipeline inventory value can improve your inventory management process and reduce common issues, such as accumulating too much deadstock. For instance, if you’re only thinking about how much inventory you need based on what’s on hand, you might overthink the fact that you already have inventory in transit.

Ordering inventory from overseas can also make the process more complex due to import duties, taxes, and longer delivery times (on top of typically long transit times, the pandemic has led to severe port congestion, significantly extending timelines).

How much pipeline inventory you should have in transit depends on past inventory performance trends and activity. For example, your pipeline inventory value will more likely increase during the holidays and peak shipping season.

If you know how long it usually takes for new inventory to arrive, it would wise to adjust your restock value and delivery timelines to account for carrier delays.

Pipeline inventory formula

Calculating pipeline inventory uses demand forecasting and average production lead times to determine the value of inventory that should be in transit.

Once you have the information needed, calculating pipeline inventory is simple:

Lead Time x Demand Rate = Pipeline Inventory

In the equation, lead time refers to how long it takes for inventory to be received from a supplier (which has drastically increased lately for many brands shipping freight overseas). Demand rate refers to the average number of SKUs sold between each replenishment cycle.

Calculation of pipeline inventory example:

Assume that a dog food business sells 100 units of dog food at $30 a week. Their supplier takes 2 weeks to deliver the goods. So their pipeline inventory amount would be:

2 x $3,000 = $6,000

This means that their supply chain should have about $6,000 worth of goods in transit from the supplier to meet demand.

This is important to know for inventory accounting purposes and calculating inventory valuation by taking into account all inventory purchased, rather than focusing solely on physical inventory on hand.

Decoupling stock to reduce stockouts

Loss or delays in inventory purchases due to production closures, shipping delays, other other events can impact the rest of your supply chain, from order fulfilment to shipping.

Therefore, it can lead to lower customer satisfaction due to stockouts, backorders, and sometimes split shipments if you can’t meet demand in a timely manner. Even if a customer order can still be fulfilled eventually, any delays in shipping can impact the customer experience.

There are plenty of ways to reduce risk in inventory planning and build a more resilient supply chain. One of the most common ways is to store additional stock.

Also known as “safety stock” or “buffer inventory,” decoupling stock refers to inventory set aside exclusively for supply chain errors, delays, or unexpected events that can cause a reduction in stock availability.

Decoupling stock is also helpful if, for some reason, there is a sudden influx in demand. But no matter where the issue arises, having decoupled stock reduces risk.

However, there are few things to keep in mind before you decide how much inventory to set aside.

For one, you have to consider carrying costs and the amount of storage space you have. Warehousing fees can rise fast if you’re not careful, so be sure to calculate how much you can afford in storage.

A great tool is the Economic Order Quantity (EOQ) formula, which can be used to calculate the optimal amount of inventory to purchase in a given time period based on both COGS and customer demand. The formula for EOQ is:

EOQ = square root of: [2SD] / H

S = Setup costs (per order, generally including shipping and handling)

D = Demand rate (quantity sold per year)

H = Holding costs (per year, per unit)

Calculating EOQ can optimise your pipeline inventory value and determine how much decoupled inventory you can afford.

Improve your inventory management with ShipBob

Inventory is the heart of a fast-growing online brand. Without it, you can’t meet demand. But with too much of it, you can’t reach revenue goals.

So how does a brand optimise inventory to meet the needs of both their business and their customers?

ShipBob offer premium fulfilment technology, a global fulfilment network, expertise, and best-in-class customer support to help direct-to-consumer brands better manager their inventory management by saving time and money, while also gaining transparency and visibility into their supply chain.

Here is an overview of how ShipBob can help you improve your inventory management process.

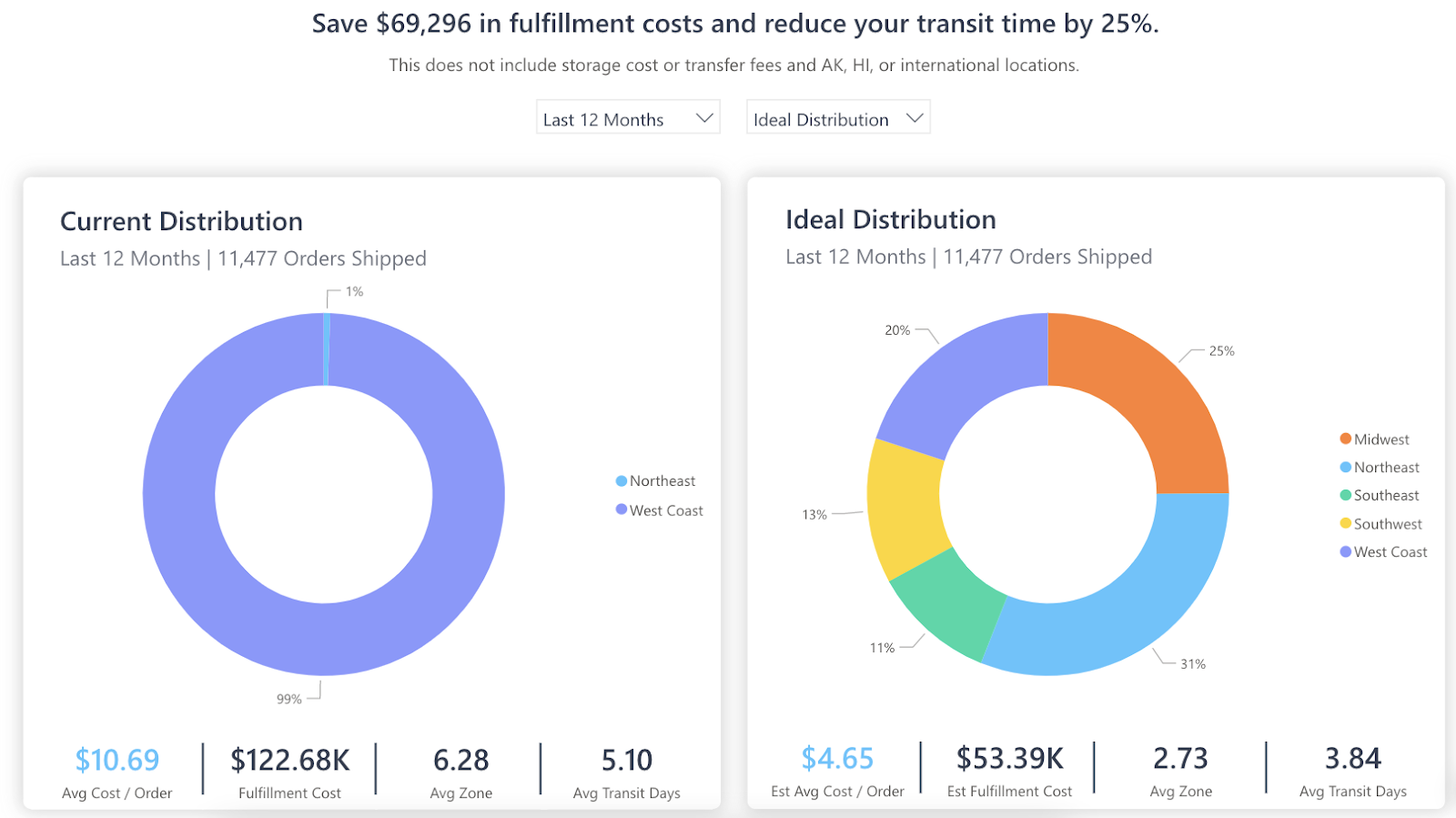

Strategically distribute inventory

ShipBob’s native technology can help you strategically split inventory across our network of fulfilment centres based on where your customers are located.

Allocating product across locations is a great way to reduce shipping costs by lowering the number of shipping zones a shipment must travel through to reach its destination (not to mention reducing transit times as well).

Optimised inventory allocation can be hard to determine without the right tools, data, and inventory analytics. With ShipBob, you gain access to real-time inventory management insights that showcase:

- Real-time inventory levels across locations

- Average fulfilment cost per order

- Average shipping cost per shipping method

- Where your customers are located

- And much more

Having this insights readily available makes it easier to optimise your supply chain, so you can offer affordable 2-day shipping for your customers.

Track inventory in real-time

ShipBob’s supply chain technology automatically tracks all inventory that is ordered, en route, and enters or leaves our fulfilment centres.

Since ShipBob’s warehouse management system (WMS) is integrated with inventory tracking technology, the ShipBob dashboard provides historical and current inventory data in real time.

This level of inventory automation can free up your time, so you can focus more on revenue-driving initiatives. You can also maintain control by setting automatic reorder points notifications, easily managing SKUs, and forecasting demand more efficiently.

“ShipBob’s analytics tool is also really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

Proactively manage warehousing and shipping

Be it packing boxes, shipping orders, managing stock, or running a warehouse, ShipBob can do it all for you. When you outsource fulfilment to ShipBob, your ecommerce warehousing and shipping workflows are on autopilot.

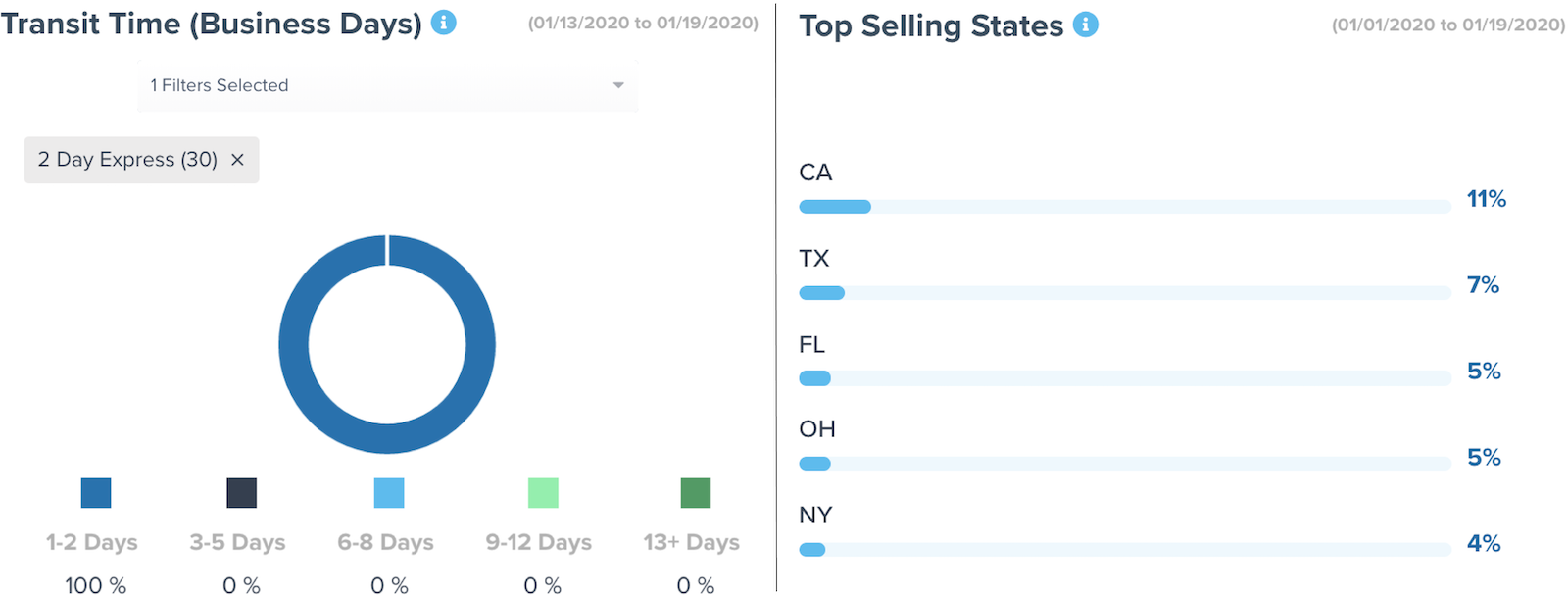

Our technology allows us to aggregate transit times, cart values, shipping methods, and shipping destinations to help you optimise your costs and test different shipping strategies.

You can track warehouse and shipping activity all in one place from the ShipBob dashboard at any time.

“We are very impressed by ShipBob’s transparency, simplicity, and intuitive dashboard. So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on. I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

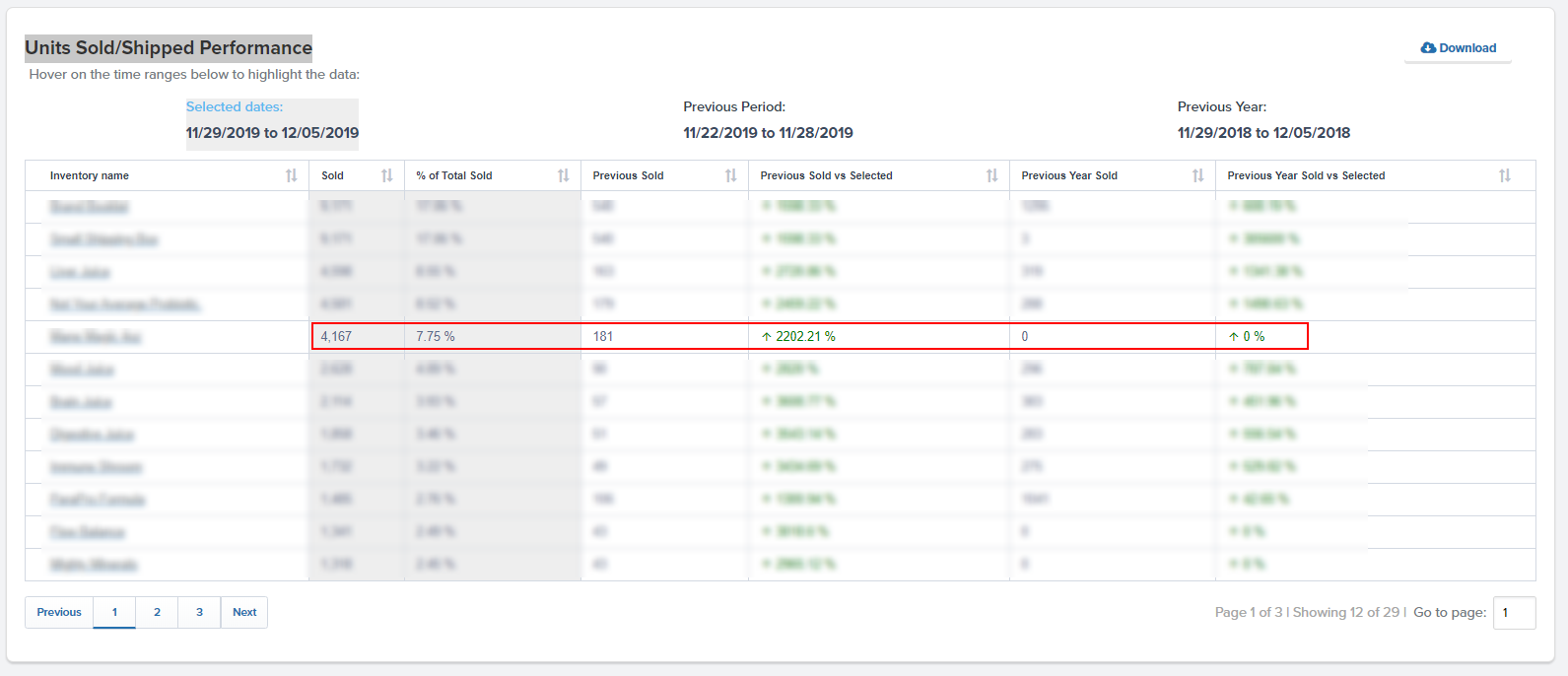

Discover inventory management trends to drive growth

ShipBob’s data and analytics reporting tool provides real-time inventory metrics by tracking activity and trends over time.

Without the need to rely on multiple spreadsheets, ShipBob makes it easier to forecast demand, optimise inventory levels, avoid stockouts, and reduce deadstock, so you can improve profit margins and increase customer satisfaction.

This level of inventory visibility also helps keep inventory records up-to-date, so you have more visibility over your ecommerce inventory at all time as you expand your logistics operations to include multiple sales channels and fulfilment centres.

“Another ShipBob integration I love is Inventory Planner. It saves me hours every week in Excel spreadsheets, and I can raise a PO in minutes when it used to take me hours.

For every order I placed for years, I was ordering too much or not enough. Between inventory forecasting tools and the ability to auto-create WROs, we don’t have stockouts much anymore. I sleep better at night.”

Wes Brown, Head of Operations at Black Claw LLC

To learn more about how ShipBob can help build a sustainable supply chain, click the button below for more information and custom pricing.

Pipeline inventory FAQs

Here are answers to some of the most common questions about pipeline inventory.

How do you calculate pipeline inventory?

To better track inventory and avoid stockouts, understanding pipeline inventory value is essential. A simple formula to follow is: Lead Time x Demand Rate = Pipeline Inventory

How can 3PLs optimise pipeline inventory?

By improving supply chain visibility, a good 3PL helps you decide how much investment to make in inventory cost by providing historical insights and real-time inventory data that provides information such as inventory days on hand, demand forecasting, production lead times, warehouse receiving SLAs, average storage cost per unit, and more.

What is transit stock?

Transit stock, also known as “pipeline inventory” refers to purchased inventory that is currently in transit from the supplier to the retailer or fulfilment centre. This inventory is not ready to be fulfilled at time of purchase, but it is considered in asset since its inventory that’s been paid for.