Table of Contents

** Minutes

What are supply chain analytics?

What is supply chain analytics software?

What supply chain analytics can do for your business

5 types of supply chain analytics

What kind of data is used for supply chain analytics?

Supply chain analytics tips and best practices

If you can’t measure something, how can you improve it?

This concept applies to many areas of business, and the supply chain is no exception.

From how quickly you can fulfil orders to how cost-efficient your logistics operations are, supply chain efficiency is a crucial part of growing a sustainable online business.

Finding ways to optimise your supply chain can make all the difference in delivering an exceptional customer experience and increasing profitability.

As a result, efficient supply chain management that optimises for costs, accuracy, and speed should always be a priority.

However, optimising isn’t always the hard part. The challenge often lies in understanding what parts of the supply chain require improvement.

Fortunately, modern supply chain technology is designed to help online brands optimise their supply chain through greater visibility, including access to advanced data and analytics.

In this article, we’ll discuss the importance of tracking supply chain analytics and how you can better track supply chain activity and performance to make informed business decisions.

What are supply chain analytics?

Supply chain analytics refers to the collection of data and information that provide insights into logistics performance, from inventory management to fulfilling and shipping orders.

With the continuous growth of ecommerce, there is more pressure to establish a lean supply chain while also meeting customer expectations around fast, affordable shipping.

By implementing technology, tools, and other resources to collect real-time data across everything from inventory flow to shipping performance, online brands are able to make better decisions on how to manage their supply chain to save on costs, speed up operations, and improve accuracy.

What is supply chain analytics software?

Supply chain analytics software refers to a technology solution that integrates data from different sources and parts of the supply chain, including third-parties.

Many times, it provides not just raw data but visualizations that can be easily viewed and interpreted from a single dashboard, as well as custom reporting tools.

A typical supply chain analytics solution offers insights into inventory forecasting, product allocation, fulfilment performance, logistics costs, order accuracy rates, and more.

What supply chain analytics can do for your business

Supply chain analytics can help a business better plan for the future, as well as the unexpected, and ultimately build supply chain resilience. Below is an overview of what supply chain analytics can do.

Help predict future demand

Supply chain forecasting is key to building a strong supply chain. And you need supply chain analytics to provide insights into future demand and trends by collecting and aggregating historical inventory and order data.

This way, you can understand how much inventory on hand you need at a given period of time, whether it’s month-by-month or by season.

Demand forecasting is essential if you want to avoid both stockouts and accumulating a large amount of excess inventory (such as dead stock, which can increase carrying costs).

Reduce risks in your supply chain

By implementing tools that help you get a clearer picture of how your supply chain is running, you can see patterns form and identify potential risks.

The key to reducing risk is proper supply chain planning, so if something happened unexpectedly, then you and your team will know how to respond efficiently and keep your supply chain afloat. However, better planning always requires access to more data and analytics.

For example, with the right data, you might notice a shift in production lead times that are causing longer turnaround times for inventory receiving and ultimately fulfilment.

By using data to gain more insight into the first-mile delivery and drayage phase, you can respond quickly either by having a conversation with your supplier, adjusting lead times, or deciding to diversify your supplier network.

Optimise your supply chain

Supply chain analytics allow you to keep a close eye on supply chain performance, from warehouse receiving to shipping.

Finding ways to optimise your supply chain are much easier when you have access to the right analytics. With the right mix of technology and improved business processes, you can make supply chain improvements in a short amount of time.

By making an effort to consistently look for ways to optimise processes, you will significantly reduce inefficiencies and save on overall costs, whether it’s through improved operations and warehouse management or a reduction in overall costs.

5 types of supply chain analytics

With access to real-time data and accurate information, how you analyse supply chain performance and efficiency is endless. To help you get started, there are five common types of supply chain analytics that you’ll see in the ecommerce industry.

These supply chain analytics all provide deep insights that lead to better decision-making.

1. Descriptive analytics

Descriptive analytics are statistical measures of past events or data that you already have. This type of analytical measurement looks at historical data to identify patterns, enabling you to identify trends and measure return on invested capital.

For instance, you can look at historical order data to decide which products are best-selling or even slow-moving. With this insight, you can decide whether you want to discontinue a product or increase the reorder amount for your most high-demand products.

2. Predictive analytics

Predictive analytics use historical data, statistical algorithms, and machine learning to help predict possible trends.

Predictive analytics can help businesses identify any potential changes or disruptions, allowing them to proactively prepare and create a more agile supply chain.

An example of predictive supply chain analytics is to use historical inventory data to determine a pre-set time to reorder more inventory while keeping inventory levels and holding costs optimised.

Many inventory apps and other tools not only provide inventory forecasting insights, but they also provide an option to set automatic reorder points to save on time and get reminded at the proper time.

3. Prescriptive analytics

Perspective analytics uses massive amounts of data run through computer software to help make decisions.

You can use these supply chain analytics to strategize the best possible move for your business. For example, many times brands use prescriptive analytics to determine when it’s time outsource fulfilment.

It might make sense to launch an online brand and fulfil orders in-house at first, but as your business grows, spending your time fulfilling orders turns into an opportunity costs. You might find that your time is better spent on revenue-driving initiatives, rather than on order fulfilment.

When brands reach a high order volume, they often turn to a tech-enabled 3PL (like ShipBob) to save on costs and time in the long run.

4. Cognitive analytics

Cognitive analytics use machine learning and artificial intelligence to help make human-like reasons and decisions, but with massive amounts of data. This makes the process a lot more efficient, enabling businesses to speed up their decision-making process.

For ecommerce supply chains, AI enables more visibility and integration across networks, which allows brands to expand their supply chain while keeping everything streamlined.

Much of AI for ecommerce is still in development, but for the major brands that have been able to already implement new advances in AI into their supply chain, 61% of executives reported reduced costs and 53% stated increased revenues.

5. Diagnostic analytics

Diagnostic analytics refers to overlooking overall performance in pursuit of understanding why mistakes, errors, and delays occur.

This type of supply chain analysis helps online brands understand the reason(s) behind issues such as shipment delays, procurement disruptions, and reduced carrier capacity.

While each type of supply chain analytics may have a separate function, they all play a critical role in increasing your supply chain efficiency.

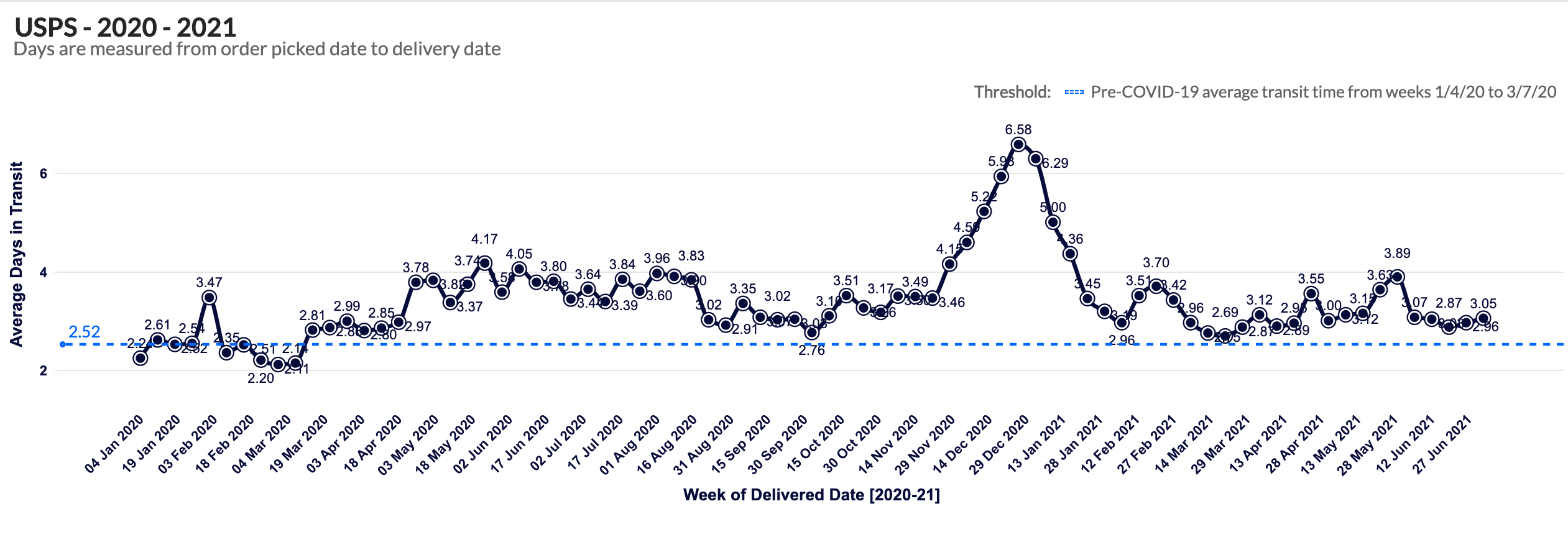

For instance, at the beginning of the pandemic, ShipBob started aggregating shipping carrier data trends to help online brands easily track carrier performance each week. (Below showcases USPS average days in from January 2020 to June 2021.)

With this insight, brands are able to be proactive in communicating with their customers about potential last-mile delivery delays and why.

What kind of data is used for supply chain analytics?

Supply chain analytics makes use of all sorts of data that directly relates to inbound and outbound logistics performance.

This data can include anything that relates to supply chain performance, such as inventory turnover rate, warehouse receiving turnaround times, order accuracy rates, on-time shipments, and average fulfilment cost.

Supply chain analytics can also pull insights from external applications that provide visibility across the entire supply chain, including third-party performance (suppliers, couriers, and 3PLs), as well as distribution metrics related to multiple sales channels and distribution centres.

Supply chain analytics tips and best practices

If you’re looking to implement supply chain analytics for your business, here are a few tips and best practices to give you a head start.

Ensure your tech stack is connected

Supply chain analytics rely on data from multiple sources. For ecommerce businesses, this could include information from your inventory management software, store(s), manufacturer(s), warehouse(s), fulfilment operations, and more.

To get a clear picture of how your supply chain is operating, you will need to integrate all of these data sources, so you get accurate supply chain analytics that relate to performance and tell the full story.

Even if you’re not handling your supply chain in-house, make sure you work closely with you supply chain as a service (SCaaS) provider or 3PL partner to connect all your data sources.

“I used to have to pull inventory numbers from three places everyday and move all the disparate data into a spreadsheet. ShipBob has an analytics tab in their dashboard with all of this information, which is great for end-of-month reconciliations. It’s really nice to not have to operate three 3PLs.

For inventory planning, I love the SKU velocity report, daily average products sold, and knowing how much inventory we have left and how long it will last.

Overall, there is more transparency with ShipBob that even helps our team manage customer service better. I can see the granular stage the order is in — if it’s being picked, packed, in transit, etc. That enhanced visibility is great.”

Wes Brown, Head of Operations at Black Claw LLC

Gather sentiment data from social media

Customer reviews, comments, and discussions on social media can be also be a great supplement to quantitative data as they sometimes provide qualitative data on supply chain performance that directly impacts a customer’s experience.

Gathering data from social media can give you insights into the minds of your customers, enabling you to find opportunities to further optimise your supply chain and strengthen your social commerce strategy.

For example, are people talking about their intentions to buy a specific product for the holidays? This could complement demand forecasting tools to make more accurate predictions about future demand.

Visualise your data to make it easier to digest

To help make it easier to digest a plethora of supply chain data, implementing tools to visualise the information can help.

A visual overview of your supply chain allows you to easily interpret the data, make connections and assumptions, and share easy-to-understand information with your team, so you can spend more time making improvements, rather than spending too much time analising it.

For instance, ShipBob’s advanced data and analytics reporting provides digestible tables and charts, so you can easily get a glance on how your supply chain is operating, including insights into:

- Fulfilment performance and SLAs

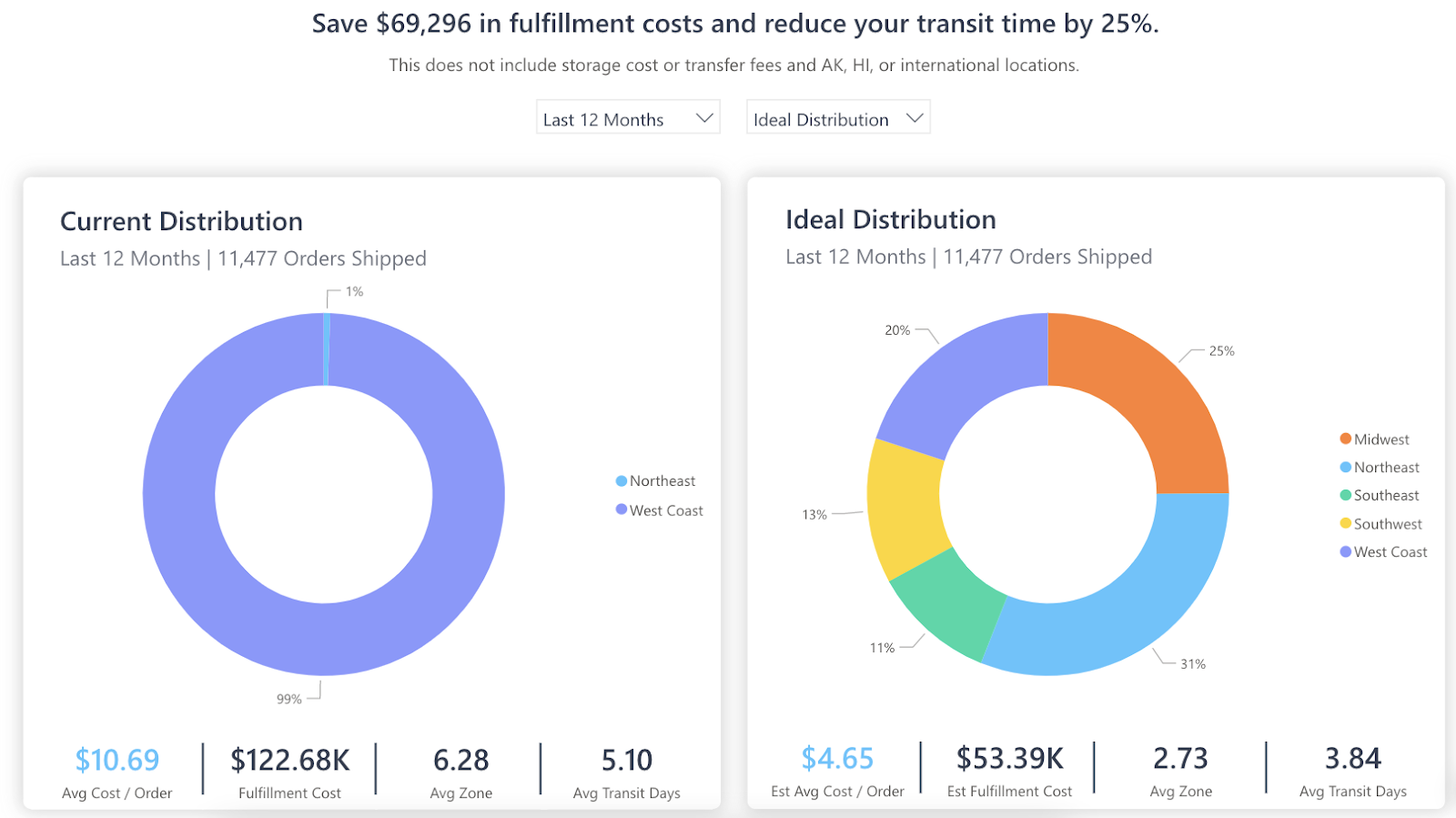

- Current inventory distribution vs ideal distribution

- Transit times, shipping methods, and destinations

- Historical stock levels

- Logistics costs associated with storage, fulfilment, and shipping

“I am a bit of an analytics nerd, so I love the ShipBob dashboard because I didn’t have access to this level of visibility before.

ShipBob’s technology integrates with Shopify and Bold Subscriptions, and it is so cool to see how all the shipments move through the process so quickly and how fast the whole fulfilment process happens.

I also love the ability to see remaining inventory — that’s so huge. Before, we were counting one by one in my house, but that’s being taken care of by ShipBob now.”

Andrea Hamilton, founder of The Finer Things 1920

Look for location-specific insights

If you’re distributing your inventory across multiple warehouses, extracting insights based on location can be extremely effective.

Accessing data to support distribution will allow you keep track of how a specific location is performing, the unique challenges it’s experiencing, and the appropriate solutions that may not always apply to other locations.

ShipBob’s logistics network is powered by the same warehouse management system (WMS), which automatically pulls inventory allocation data on current distribution and provides insights on the ideal distribution strategy.

Moving towards an ideal inventory distribution based on where your customers are can speed up delivery, reduce shipping costs, and enable affordable 2-day shipping for more of your customers.

“Last July, Prymal reached $40,000 in revenue. After switching to ShipBob just four months later in November, we are reaching $160,000 a month in revenue — that’s 300% growth. We’re also saving $8,000 per month in fulfilment costs.”

Courtney Lee, founder of Prymal

Use predictive analytics to set ideal minimum inventory levels

Managing inventory while trying to save on costs is a challenge without the ability to forecast demand. Though forecasting is never 100% accurate, it does provide the information you need to optimise inventory levels.

Other data that can help you better forecast demand include:

- Average units sold per day

- Production lead times

- Receiving turnaround times

You can combine these insights to predetermine reorder quantitiesand set automatic reorder points to streamline the inventory restocking process.

ShipBob’s technology makes it easy to set optimised reorder points by providing all the data and insights you need in one dashboard.

“ShipBob’s analytics tool is really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

See what your ERP or SCM software already offers

Many enterprise resource planning (ERP) and supply chain management technology already have robust supply chain analytics and reporting built in. So you might not need to invest in a separate software solution just for analytics.

However, ERPs and other robust supply chain management solutions are costly. While it can be worth the investment to aggregate supply chain analytics in once place, there are less costly but just as effective ways to pull data.

For instance, ShipBob’s technology offers built-in inventory management tools, insights into the fulfilment and shipping process, and dozens of direct integrations with the leading ecommerce solutions.

With ShipBob, you can connect your entire supply chain tech stack with your retail fulfilment solution and access all the data you need in one place.

“ShipBob’s dashboard is super intuitive and easy to navigate. love that you can view orders based on when they are processing, completed, on hold, and in other stages. It is super helpful for us to have that and track the order every step of the way.

We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order.”

Ines Guien, Vice President of Operations at Dossier

Reduce shipping time by using predictive route planning

Route planning software can help you optimise your supply chain by accounting for expected delays and allowing you to avoid them. This can help you speed up your shipping process and ensure faster fulfilment while simultaneously reducing shipping costs.

ShipBob makes this easy in a number of ways: Our domestic and global shipping capabilities, carrier partnerships, discounted shipping rates (with regional and international couriers), and automated shipping solutions makes it easier to manage delivery without lifting a finger.

For a more robust solution, ShipBob partners with leading delivery management systems including Route and AfterShip to provide more data, visibility, and transparency into the delivery process.

Supply chain analytics for ecommerce

For many growing direct-to-consumer (DTC) brands, the challenge of managing and analising their ecommerce supply chain can often be solved through outsourcing.

An outsourced supply chain can involve working with a third-party logistics (3PL) company to handle logistics systems while also providing full visibility into operations.

ShipBob is a best-in-class 3PL that offers robust supply chain management services, encompassing everything from warehousing to inventory management, to fulfilment and automated shipping.

For a glimpse into how ShipBob works, watch the video below to get a 3D tour:

Along with our fulfilment capabilities, ShipBob offers an easy-to-use, digestible dashboard that aggregates all the supply chain analytics and information you need to improve supply chain efficiency, as well as keep us accountable on our performance.

ShipBob’s international fulfilment network is powered by a premium technology that provides valuable insights into your supply chain, such as:

- Demand forecasting: to help you plan your procurement and distribution. You can find out seasonal changes in demand, understand when you should reorder inventory, and see which fulfilment centres need more inventory at the SKU level.

- Shipping insights: to determine average shipping costs, most preferred shipping methods, and typical transit times.

- Inventory allocation and distribution map: to determine the best way to split inventory between multiple warehouses.

To learn more about how ShipBob can help you better manage supply chain analytics, click the button below to start the conversation with our team.

Supply chain analytics FAQs

Here are the top questions about supply chain analytics.

Where do I get supply chain analytics?

There are plenty of ways to get supply chain analytics depending on your tech stack. For instance, you can pull historical inventory trends from inventory management software, or you can implement a more robust solution like an ERP. However, partnering with a 3PL like ShipBob makes it easy to streamline fulfilment operations and get access to valuable data and insights.

What tools can help me with supply chain analytics?

There are plenty of tools and resources that can help you with supply chain analytics. For ecommerce, many start with implementing an inventory tracking software, so you can view analytics on inventory, including historical data.

If you manage a warehouse, you might want to consider implementing a warehouse management system, so you can track warehouse activity and storage costs. Another avenue is to partner with a 3PL that combines all the data you need into one dashboard.

What is supply chain analysis?

Supply chain analysis refers to the process of implementing technology, tools, and other resources to collect real-time data, from inventory flow to shipping performance, in order to make better decisions on how to manage their supply chain to save on costs and speed up operations.