Think of your ecommerce supply chain like a water pipe. Water should be able to flow smoothly through a pipe from one place to another, and when it gets clogged, it causes major problems. In the same way, all your business’s goods, processes, data, and communications should be able to flow through your supply chain smoothly. When they do, your brand can operate efficiently; but if there’s an issue or a bottleneck, it can spell disaster for your business.

In this article we’ll dive deep into what supply chain flow, what kinds of flows to monitor, common hurdles to overcome when managing supply chain flow, and how experts like ShipBob can help you streamline and optimise your supply chain.

What is supply chain flow?

Supply chain flow refers to the systematic movement of goods, information, and materials throughout your ecommerce supply chain.

In good supply chain flow, all of these things move between different supply chain stages seamlessly and efficiently. For example, it may involve the movement of:

- Raw materials to production.

- Finished goods in transit to suppliers and retailers.

- Data on inventory availability to picking teams.

- Received goods into storage.

Having a clear understanding of the business processes involved in supply chain flow is crucial to optimising how they coordinate and keeping velocity steady. This enables you to maximise efficiency in your supply chain management (SCM) so everything flows smoothly, allowing you to effectively meet customer expectations.

Types of supply chain flows and their importance

There are three main types of supply chain flows that influence your ecommerce operations. Each plays a crucial role in how your overall supply chain functions.

1. Upstream flow

The upstream supply chain flow refers to the movement of materials and information in the pre-production stage, and includes processes like sourcing and transporting raw materials for production.

This type of supply chain flow plays a crucial role in ensuring timely replenishment of inventory, as it directly influences production timelines. Delays or inefficiencies in the upstream flow could lead to shortages affecting your inventory flow and procurement schedule.

2. Downstream flow

The downstream supply chain flow refers to the flow of finished products and information in the post-production stage, and involves processes like inventory procurement, transportation of the final product from the supplier to the seller, and shipment of orders to the end customer.

Like upstream flow, the downstream flow is also vital for ensuring timely replenishments, as it can also impact restocking timelines and stock availability. It also plays a crucial role in order fulfilment timelines and order deliveries, determining whether you can meet customer expectations.

3. Reverse flow

A reverse supply chain flow is the movement of goods in the opposite direction of the usual flow (from production to delivery). It occurs whenever there’s a return, especially in circumstances such as undeliverable addresses, damaged products, inaccurate orders, and so on.

Efficiently managing this flow enables businesses to recoup as much of their inventory investment as possible after the initial sale of that inventory, and to accurately update their inventory counts and data. It also plays a role in customer satisfaction, as it determines the ease and speed of replacements or refunds.

The three core supply chain flows

Multiple different things flow through a supply chain—some of which are more important to monitor than others. Here are the three main flows that businesses need to manage in their supply chain operations.

Product flow

Also known as the material flow, product flow refers to the flow of physical goods through the supply chain. It typically occurs in one direction, from the manufacturer to the supplier to the seller and finally to the end customer. In some cases, however, the flow of materials may occur in the opposite direction if the product is being returned (which requiring reverse logistics).

Regardless of the direction, the goal is to ensure that products move smoothly between different touchpoints to improve supply chain efficiency.

Financial flow

Financial flow is the flow of money from the end customer all the way up to the supplier. However, financial flow isn’t always linear, as merchants must first pay for the inventory they procured from the supplier before receiving money from the customer for those goods. The supplier will raise an invoice, which is then paid by the seller after verifying the inventory order for accuracy.

In some cases, financial flow may also occur in the opposite direction (i.e., from supplier to seller) through debit notes. A smooth financial flow improves cash flow within the supply chain, enabling businesses to seamlessly procure more inventory for their operations.

Information flow

The flow of information and data across the supply chain is known as information flow. This occurs in multiple directions simultaneously, with suppliers providing pricing quotes and order updates to sellers, sellers issuing purchase orders to suppliers and distributors, and customers and sellers communicating with each other about individual orders (including ecommerce order tracking updates, customer complaints, and more).

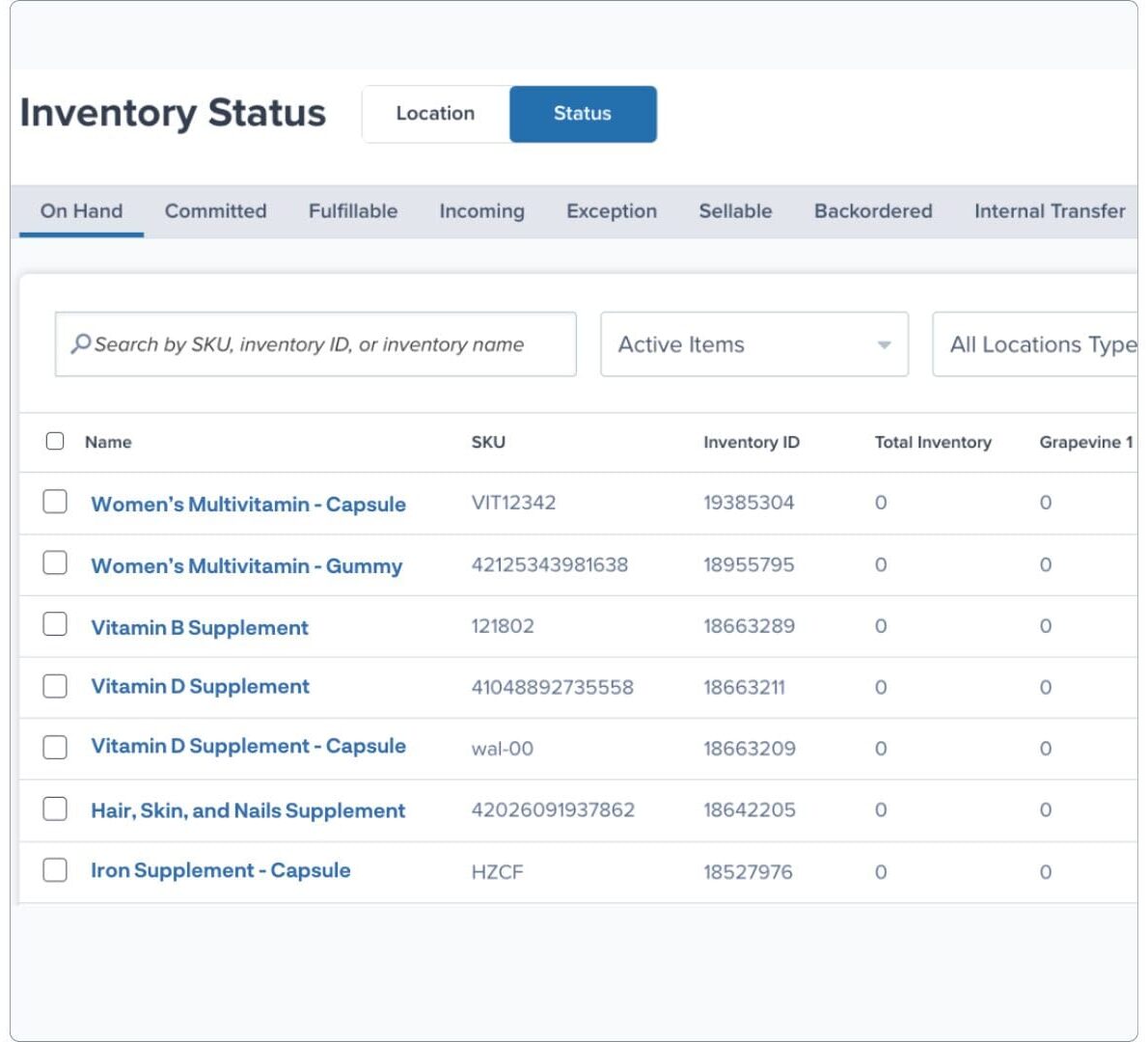

Additionally, businesses should also keep tabs on the internal flow of information about inventory movement and performance, as this informs various aspects of their inventory management. For instance, their inventory levels may be updated in real time as orders are placed through various sales channels. Warehousing staff will then get information about which items need to be picked, while customers see stock levels updated in real time on the seller’s website.

Why efficient supply chain information flow is crucial in ecommerce

Of the three core supply chain flows, information flow is especially important for ecommerce businesses. You can’t ensure an efficient material flow if you’re not exchanging information fast enough; similarly, you may encounter significant delays in payments and invoicing if the relevant parties aren’t receiving the necessary information on time, which could impact your ability to keep your business afloat.

Your information flow also plays a vital role in reducing errors in the supply chain. Real-time access to relevant information empowers teams to get an accurate picture of what’s needed. It lowers the risk of actions and decisions based on outdated data, thus helping with supply chain risk management.

Real-time data tracking and analytics

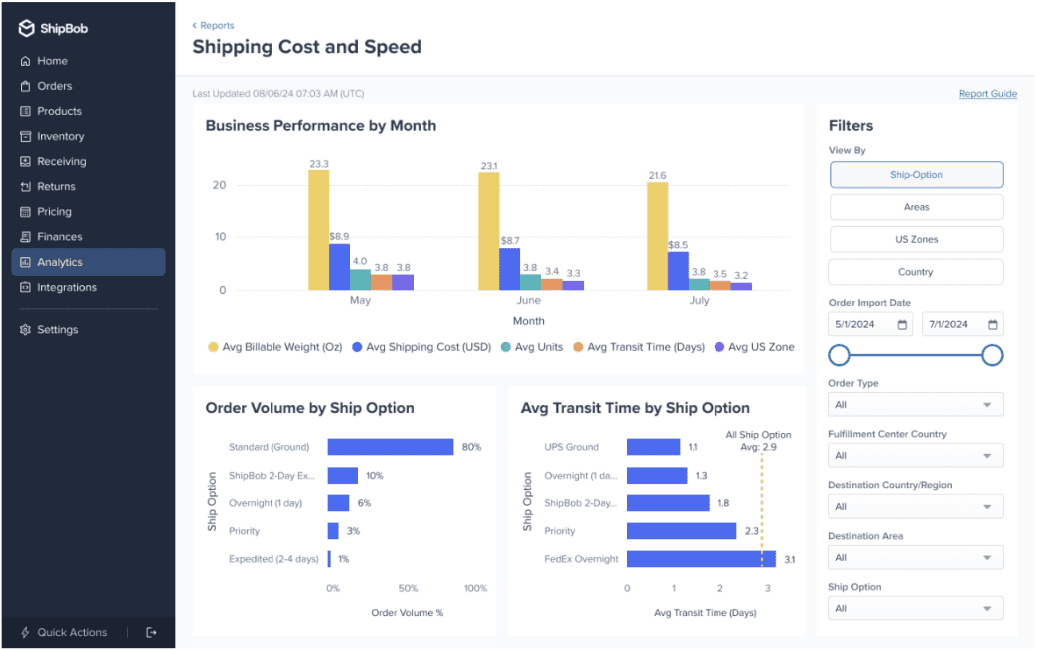

Real-time data and analytics can improve visibility across the supply chain, enabling you to make informed decisions and timely actions.

For instance, real-time inventory tracking is essential to see how much inventory you have at all times. When you get real-time access to your inventory levels and SKU-specific performance, you can better understand your inventory needs and improve your demand forecasting. This then helps with inventory planning, allowing you to send timely purchase orders and replenish your stock before you experience stockouts.

Additionally, real-time supply chain analytics lets you track key metrics to understand supply chain performance and inform various aspects of your operations. You’ll be able to track lead times with specific providers, which can then inform your production planning and procurement timeline. Similarly, you can identify delays and quickly remediate them before they turn into major supply chain disruptions affecting the flow of goods.

“At a senior level, there are certain metrics that we need to look at to manage the business. At Arrae, we take the approach to ‘manage by metrics.’ ShipBob gives us a really clear view on the data that we need.

We’re looking at these fulfilment metrics on a weekly basis. We can quickly go into the ShipBob dashboard and see ‘What are we shipping? How long does it take to ship? What is our time from order to door? Is there a breakdown there? Where do things get stuck and why?’”

Nish Samantray, Co-Founder of Arrae

Communication between supply chain partners

Transparent communication between key players in the supply chain fuels the information flow. Sellers need to clearly communicate their needs to suppliers and manufacturers, whereas the latter need to provide clarity on production timelines and possible delays. This ensures that all parties are aligned on their responsibilities and priorities, reducing delays and errors. In other words, it keeps everyone in the loop and empowers them to deliver on expectations. As such, effective communication also plays a vital role in your supplier relationship management.

The role of technology in enabling information flow

With advancements in supply chain technology, it’s become much easier for businesses to facilitate better information flow throughout the supply chain. Integrated platforms and APIs enable you to connect various supply chain systems and support seamless data sharing.

Information is automatically shared between these systems, allowing for a certain level of automation. For instance, inventory management systems can sync with your online sales channels to automatically update inventory levels, so you can get alerted when stock dips below a certain level.

Common hurdles when managing supply chain flows

Supply chain flow is important, but not always easy to coordinate. Some of the most common challenges businesses encounter when trying to master their supply chain flow include:

Shipping delays and costs

Shipping delays are some of the biggest disruptors of the ecommerce supply chain flow. They create bottlenecks and cause further delays in the supply chain.

Additionally, high shipping costs are another major challenge affecting various supply chain flows. Paying for expensive shipping fees could divert funds from other areas, which could then disrupt financial flow.

This makes it crucial to work with the right ecommerce fulfilment partner or 3PL who can offer fast shipping at affordable rates, minimising the risk of delays while achieving the financial flexibility needed to keep the flow moving.

“Our Trustpilot reviews are a testament to ShipBob’s speed. They’ve proven to us that ShipBob can easily scale to match large fluctuations in demand and still maintain high-quality service. They’ve really helped us unlock our UK growth.”

Kevin Lammers, International Business Manager at TopBuxus

Lack of visibility

A lack of end-to-end supply chain visibility presents a serious issue for businesses when managing their supply chain flow. If they can’t see what’s going on at a key touchpoint, they could face a risk of bottlenecks and disruptions. There’s also the risk of errors and inaccuracies creating issues further down the line.

For instance, if you can’t see your inventory levels in real-time, you could accidentally sell more products than you actually have in stock. This creates backorders and results in customer disappointment.

It’s crucial to invest in platforms that not only provide real-time inventory tracking but also come equipped with advanced reporting and real-time analytics. This helps you stay informed about what’s going on in your supply chain, and allow you to make data-driven decisions.

“Better visibility also makes it so much easier to anticipate and prevent issues. Thanks to ShipBob, we now know how much time it usually takes an order to be fulfilled — so if we go into the dashboard and see that there’s an order that’s not following the pattern, that tells us there must be something wrong. With ShipBob, it’s really simple to spot something that might go wrong when we do the rounds (like a customer entering the wrong address) and fix it before it becomes a problem.”

Maria Osorio, Logistics and Operations Director at Oxford Healthspan

How ShipBob optimises supply chain flows for ecommerce brands

With powerful supply chain technology and fulfilment solutions, ShipBob empowers brands to both streamline their supply chain operations for a seamless flow while optimising your operations for efficiency and accuracy. Here are just some of the solutions that ShipBob offers ecommerce brands to help them master their supply chian flow.

Inventory Placement Program for product flow efficiency

ShipBob’s Inventory Placement Program simplifies inventory allocation and distribution, so you can meet customer demand with less effort. The program uses a proprietary algorithm to analyse your brand’s actual order data and sales history, which it then leverages to recommend the ideal inventory split across ShipBob’s network. This allows you to strategically distribute your inventory between different fulfilment centres so you can ship out each order from the most optimal location.

Additionally, you only need to send your inventory to one hub location and ShipBob will take care of the distribution. As a result, you reduce shipping times and costs, which improves the efficiency of your product flow.

“When we first got started, we checked how ShipBob’s IPP was distributing our inventory based on the models we created when we did distribution in-house – they were on point. ShipBob’s machine learning data works. They took a container with 1,000 SKUs and knew exactly which inventory needed to go to which facilities.

On top of time savings, we were able to realize cost savings because we didn’t have to make any inventory transfers. We send our inventory to ShipBob once, they receive it, and they distribute it across their US network. We’re saving thousands of dollars each month by using IPP. “

Cesar Contreras, Head of Supply Chain of Wholesome Goods

Industry-leading WMS for transparent information flow

ShipBob offers a powerful warehouse management system that serves as an all-in-one platform to manage various aspects of your in-house fulfilment. With the ability to manage your warehouse operations, inventory, order, and transportation in one place, the WMS facilitates a transparent flow of information between different supply chain processes.

The information is automatically synced and transferred between these different processes, allowing for a greater level of accuracy. The platform allows you to maintain a single source of truth across the end-to-end supply chain, reducing the risk of errors and discrepancies.

“Eventually, ShipBob approached us about implementing ShipBob’s WMS in our warehouse to reduce our shipping costs and improve our warehouse efficiency. We were skeptical at first, but we knew that their system was working well internationally and across their entire fulfilment network, so we decided to give it a try.

The week that we launched ShipBob WMS, we had a massive sale, where we did our biggest numbers of the year. It was a good way to stress test the system. We saw what was working, what wasn’t, and how rearranging our warehouse and processes to fit the ShipBob system could optimise our fulfilment. There were the expected growing pains, but overall it was a success.”

Tom Wall, Vice President of Global Warehousing & Logistics at Beachwaver Co.

Sharper finance management with a distributed fulfilment network

With an expansive global network of dozens of facilities, ShipBob lets you store your inventory across multiple fulfilment centres. A distributed inventory strategy allows you to ship out orders from the most convenient locations, reducing transit times and shipping costs so you can enjoy fast and efficient fulfilment at a much lower cost and increase your profit margins.

Brands like PetLab Co. have been able to effectively scale their operations with the help of ShipBob’s distributed fulfilment network. By leveraging five ShipBob fulfilment centres in the U.S., the brand ships out over 45,000 orders per week on average, with a 20% year-over-year increase in orders. More importantly, 85% of those orders are delivered in 0-4 days.

“The biggest obstacles you face as an ecommerce business are the unexpected ones. When something unexpected happens, your first thought is: 1: What was the root cause of this issue? And 2: Do we have a partner that has the same sense of urgency as we that can help us identify a solution? ShipBob is that partner for us. I know that if something goes wrong, we can lean on ShipBob to get it handled quickly. That’s what it means to have a true partner. Having that peace of mind makes everyone’s jobs easier, mine included.”

Stephanie Lee, Co-CEO at PetLab

For more information about how ShipBob can help optimise your supply chain flow, click the button below to get in touch.

Supply chain flow FAQs

Below are answers to some of the most common questions about supply chain flow.

What is the role of technology in managing supply chain flows?

Technology gives you real-time visibility into your end-to-end supply chain, which improves information flow and allows you to efficiently manage your other supply chain flows.

How does ShipBob help with supply chain flow?

ShipBob gives you real-time supply chain visibility to support information flow and provides fast and affordable fulfilment to streamline product flow.

How do you map and analyse a supply chain flow?

You can map and analyse your supply chain flow by identifying the key stakeholders and touchpoints involved and collecting data on their performance to evaluate it.

How do disruptions in supply chain flow impact business operations?

Disruptions in the supply chain flow create bottlenecks and delays that interrupt your business operations, cause inefficiencies, and cost you time and money.