Dead Stock: Why It’s a Problem & How to Eradicate It

Offloading dead stock is essential to maintaining healthy profit margins, but ecommerce brands are often challenged with inventory optimisation as they grow their business. It’s often due to a lack of inventory management systems and processes that cause dead stock to accumulate over time.

Request Fulfilment Pricing

Let’s talk. Our experts can help you boost your order volume by 30% year over year.

A fulfilment expert will get back to you shortly. Privacy Policy

What is dead stock?

Dead stock is inventory that is no longer sellable and will likely never sell in the future, oftentimes because it’s expired, obsolete, low quality, or out of season. Dead stock, usually stored in the warehouse, only refers to inventory that has never been sold, which excludes returns.

What causes dead stock?

To avoid dead stock, it’s important to understand what causes it to accumulate in the first place. By figuring out what’s contributing to dead stock pile-ups, you’ll be better equipped to move it out and prevent it from piling up in the future. Here are some of the most common causes of dead stock.

Over-ordering

Ordering excess inventory without understanding how much you’ll sell in a given period is the quickest way to accumulate dead stock and increase carrying costs.

It can be a challenge to understand just how much stock you need to fulfil future orders. There is a fine line in having excess stock, but by taking the time to implement an inventory control system and tracking important distribution metrics, such as inventory turnover ratio, you can make better decisions on inventory restocking, on what is a good order quantity number before making a purchase, and when to purchase it.

Another way retail businesses can avoid over-ordering is by buying less stock more often. For instance, you can reduce the risk of accumulating dead stock by purchasing inventory to meet a month’s demand, rather than the whole year’s.

Inaccurate demand forecasting

Miscalculating future demand happens when the right data isn’t being tracked. This causes ecommerce businesses to be misinformed on what products are in demand and how quickly they will sell. By pulling accurate historical order data, you can better forecast demand instead of buying slow-moving products that consume valuable warehouse space and your bottom line. With accurate demand forecasting, you can make informed decisions on how much inventory to purchase to fulfil future orders.

Poor sales or marketing efforts

If you’re selling a high-demand product, yet inventory isn’t moving out as quickly as you’d hope, there’s a high chance that it could be a lack of marketing and sales efforts; this is a big opportunity cost. Poor communication between you and your marketing and sales team on how to sell products, product messaging that misses the mark, poor web experience, and low customer awareness can all lead to high-quality, high-demand products to be left unsold.

Lack of quality control = defective products

Even if inventory is new, it doesn’t mean it’s of high quality. Defective products are usually returned to the seller, and cannot be resold to another consumer, meaning they’ll sit on shelves forever unless you find a different way to move them out of your warehouse.

Backorders

A business can run out of a particular SKU in its inventory before all orders for that item have been fulfilled. That item is then put on backorder, meaning it will be delivered to the customers that ordered it once it is back in stock.

Once you realize you have backorders to fill, it can be tempting to panic and order more of the item than you actually need to resolve the issue. After the backorders are filled, you’ll be left with excess inventory that could be difficult to sell (or a customer gets fed up after having to wait for so long).

Order cancellations

Canceled orders aren’t just lost revenue — they also prevent you from moving products through your supply chain and out the door. Regardless of why a customer cancels their order, your business will be left holding any inventory that you fail to sell. This can easily lead to dead stock, especially if the canceled order contained perishable or out-of-season items.

Long lead times

Trends change quickly, so it can be difficult to ensure you have what customers want, when they want it. If lead times are long, in the time it takes inventory from your supplier to arrive at your warehouse, demand for that inventory could already have subsided. As a result, lengthy transit times can easily leave you stuck with freight shipments of inventory that no consumer wants to buy anymore.

Why is dead stock bad for your business?

Just by sitting on a warehouse rack, dead stock sucks your business’s profit and hurts your bottom line. Here are a few subtle ways that dead stock costs companies money.

Unsold inventory

Dead stock was initially inventory purchased with the intent to sell it. So if a business is not selling products it’s already invested in, it’s failing to make a profit on that investment — or, at the very least, failing to recoup the cost.

Higher inventory storage fees

While inventory storage costs come in many forms, the outcome is always the same: the more inventory you have, the more it will cost to store it. Dead stock takes up valuable space that could house more popular, newer products. It’s always important to do an inventory audit and act quickly to remove inventory that is unsellable or unlikely to sell.

Lower profit margins

Dead stock chips away at profit and can make a sizeable impact if it sticks around long enough. The increased time and effort it takes to market dead stock, the sunk cost of purchasing stock from the manufacturer, and higher inventory costs all shrink a business’s profit margin.

Increased employee costs

The more inventory you have, the more billable employee hours it will take to sort, move, and organise it. A business has to pay its employees for the time it takes workers to identify dead stock and physically get rid of it — so if you accumulate dead stock consistently, your employee costs could increase significantly.

There is also an opportunity cost to dead stock, as the time your employees devote to managing dead stock could be allocated to activities that drive revenue.

Reduced inventory space

With dead stock taking up space on your shelves, your business has less room to stock items that customers do want. For example, if your business can only store and sell 75 units of a particular product due to crowded shelves, but customer demand could have produced 100 orders, then dead stock has caused you to miss out on 25 orders’ worth of revenue.

How to calculate the cost of dead stock

Calculating precisely how much dead stock has cost you is not as easy as you might think, but it comes down to figuring out the money lost from the inventory that you cannot sell. Here are a few different approaches to getting a dead stock calculation.

Dead stock value

First, you can calculate the value of dead stock as you would calculate the value of sellable inventory using this formula:

Dead stock value = Total units in stock x Unit price

For example, if you had 50 units of dead stock, and each piece of dead stock would have been sold at $10, then you would calculate the value like so:

Dead stock value = 50 units x $10 per unit

Dead stock value = $500

Dead stock sunk cost

You can also calculate how much it cost you to acquire the dead stock in the first place. This amount is considered a sunk cost, as you will not earn or recoup any of your initial investment in the dead stock from sales.

There is no one formula to calculate the sunk cost of dead stock, as different companies incur different kinds of costs when acquiring inventory.

To calculate sunk cost for your inventory, add together all direct costs incurred to create the dead stock, such as:

- Raw materials

- Labor costs

- Any overhead allocated to the dead stock

- Transportation costs to move the product

Dead stock profit & opportunity cost

Dead stock not only costs money to obtain, but also costs you the profit from its sale that you were counting on.

To calculate the opportunity cost of profit from your dead stock, use this formula:

Missed Profit = (Total dead stock units x Price per unit) — Sunk cost

For example, if your business invested in 50 units of what is now dead stock, each of which cost you $6 to make, and you planned to sell each unit for $10, you would calculate missed profit like so:

Missed Profit = (50 units x $10 per unit) — (50 units x $6 each to make)

Missed Profit = $500 — $300

Missed Profit = $200

7 ways to profitably get rid of dead stock

Offloading dead stock can seem challenging, but there are plenty of ways to get rid of dead stock that are both practical and lucrative. Resurrect the value of your dead stock and make room for new inventory using the following best practices.

1. Put dead items on sale

Dead stock presents a unique opportunity to appeal to bargain shoppers. Hold clearance sales or create a discount section of your store where you offer dead stock for a lower price.

2. Offer them as a free gift

Delight customers and enhance the unboxing experience by offering dead stock as a freebie. It’s a great way to boost customer satisfaction and incentivize them to purchase from your business in the future. The gesture means everything, and if you can move out dead stock while doing it, it’s a win-win.

3. Donate them

If all else fails, your business can always donate unsellable inventory and use it as an inventory write-off. While it doesn’t offer the immediate payout that other strategies do, charitable donations are an excellent way to give back to communities, and customers often appreciate a business’s humanitarian efforts.

4. Offer product bundles

Bundling your dead stock with a fast-selling item might help you recoup some of your initial investment — especially if you offer free shipping on the bundle.

5. Try to return them to supplier

Whether the product batch is defective to the point of being unsellable or in pristine condition, it never hurts to check if you can send it back to the manufacturer or supplier you got it from. While this can be a long shot, it could save you the hassle of offloading the dead stock yourself.

6. Build brand partnerships

Even if a SKU is dead for your business, it could be useful to another. Donating or selling sead stock to another company that wants it is a great tool for forging brand partnerships, and could even lead to free or discounted inventory for you down the road.

7. Open new sales channels

Try offering your dead stock on a different channel, or market it to a different audience. What isn’t appealing in your online store could catch shoppers’ eyes at a retail location, or vice versa. Consider adding new channels to your business (such as social media stores, B2B, or online marketplaces like Etsy or Amazon) to give you more sales avenues for dead stock, and to help you avoid it in the first place.

How to prevent and get ahead of dead stock

The best way to deal with dead stock is to prevent it from piling up in the first place. Here are a few of the best practices for preventing dead stock accumulation.

Accurately forecast demand

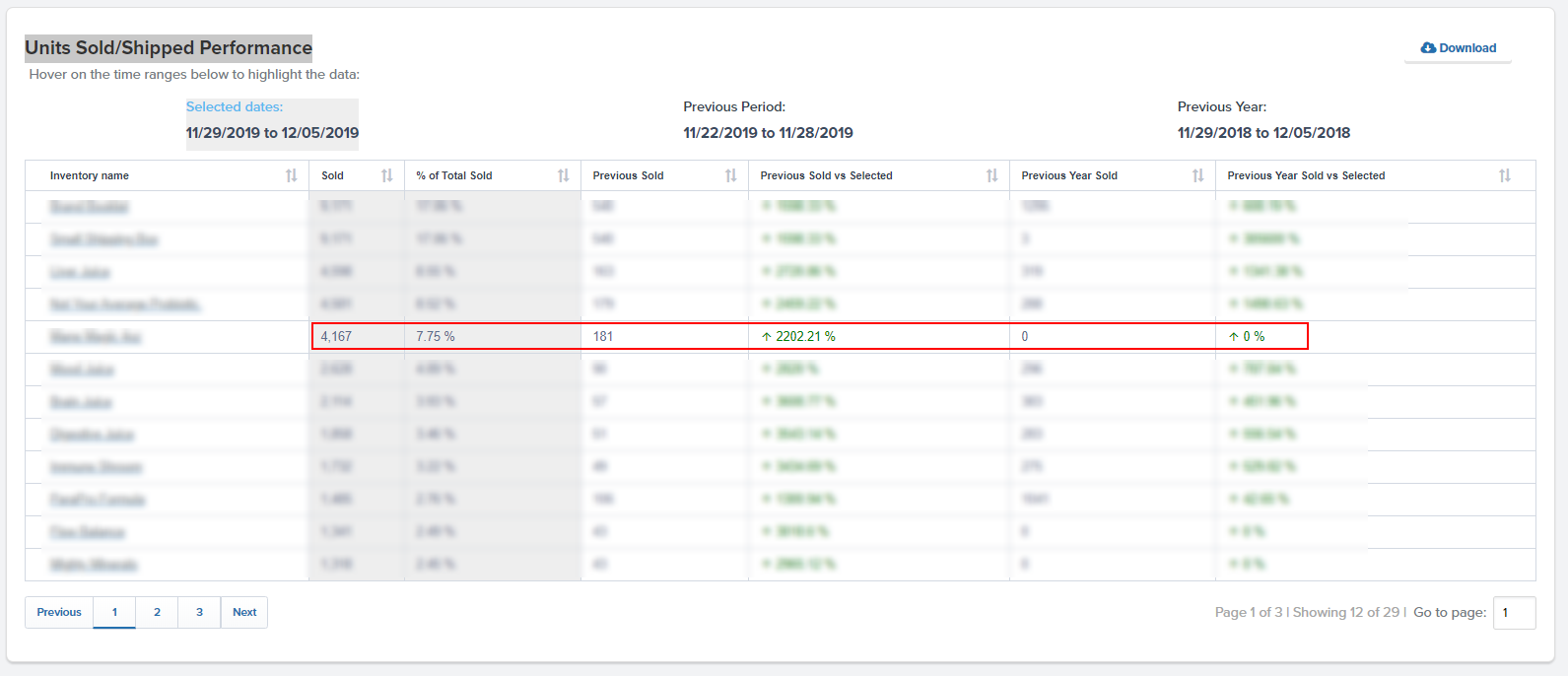

Demand forecasting helps to predict future sales so you can make better decisions on how much inventory to purchase, as well as future warehousing needs, when to run a flash sale, and creating an effective pricing strategy. If you store your inventory with a third-party logistics (3PL) company like ShipBob, you can get insights into future demand with ShipBob’s analytics and reporting tool that provides answers to questions such as:

- How quickly products are selling

- Which items are slow-moving

- How many days of inventory you have until you are expected to run out (based on SKU velocity)

- Daily order status and performance

- How your current demand compares to previous time periods

- How your sales are affected by different seasons and months

- And much more

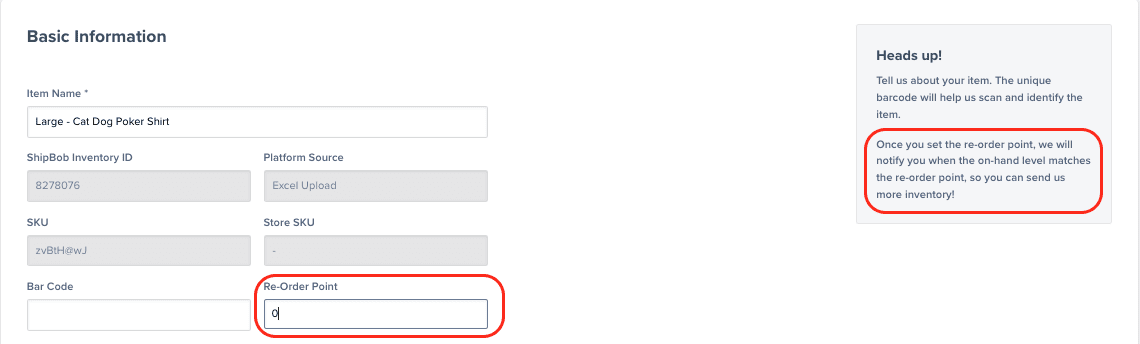

Set reorder points and safety stock

Reorder quantity refers to the total number of product units you request from a manufacturer or supplier on an inventory replenishment purchase order. The exact amount should not be so high that you have too much capital tied up in inventory and risk accumulating dead stock. But you also want to make sure that you have enough safety stock and you’re not at risk of selling out before you can get the next batch of inventory.

With ShipBob, you can easily check inventory counts at each fulfilment centre and set reorder points at the SKU level, so you are notified when stock is running low.

“ShipBob’s analytics tool is also really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

Upgrade your inventory management software

Choosing an inventory management software that’s intuitive and easy to use is absolutely crucial. ShipBob’s order fulfilment solution offers built-in inventory management tools, data, and reporting that offers insights into demand forecasting, order management, and more to help you make better decisions on how to manage your inventory.

Partner with ShipBob to reduce dead stock

Offloading dead stock quickly and finding ways to avoid it is critical to the long-term profitability of your business. To prevent dead stock, proactivity is key — taking time now to put an inventory management process in place will help your business save money, meet customer demand, and optimise your supply chain.

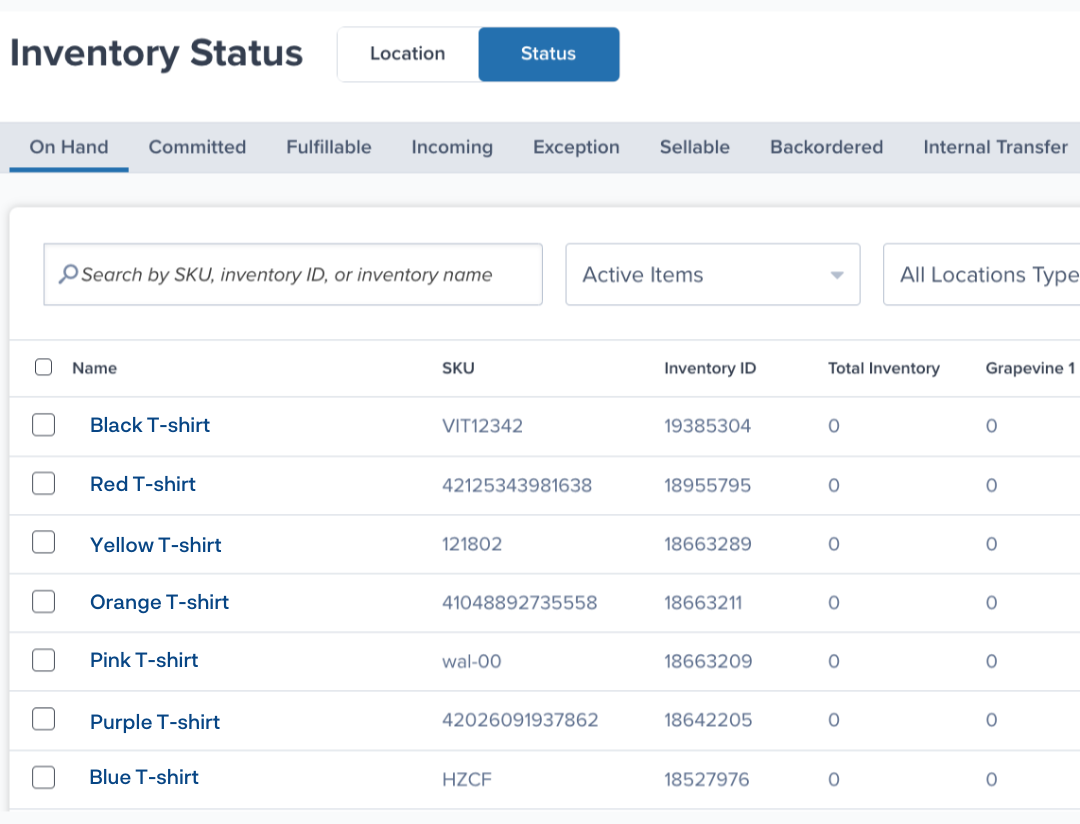

ShipBob’s dashboard comes with inventory management capabilities that help you keep track of your inventory at all times, and keep fulfilment running smoothly. Using ShipBob’s technology, you can:

- Monitor inventory levels at any of our dozens of fulfilment centres.

- Set up automatic reorder notifications to time replenishment perfectly.

- Track valuable sales data over time and forecast demand more accurately, so that you can avoid dead stock whenever possible.

To learn more about ShipBob, click the button below to request pricing and learn more about what we offer.

Dead stock FAQs

Dead stock is a surefire way to cut into profit margins. Here are answers to some of the most frequently asked questions about dead stock so you know how to manage it and prevent it from piling up.

Why is it called dead stock?

Dead stock refers to ecommerce inventory that isn’t selling now and likely won’t sell in the future. Because demand for these products has dwindled (e.g., low quality, a dip in demand, seasonality), they have no more vitality in the market and therefore cuts into profit margins.

What happens to dead stock?

Dead stock usually sits unsold in a warehouse or a 3PL’s fulfilment centre until it is moved out. While there, it quickly increases carrying costs and can occupy warehousing space needed for new, sellable inventory. When dead stock fails to sell, it can cut into profit margins and impact a company’s bottom line. Dead stock is often due to a change in market demand and it can be considered as an inventory write off.

How do I get rid of dead stock?

In offloading dead stock, some options are more profitable than others. There are a few ways to get rid of dead stock, such as bundling a dead stock item with a high-demand product for free, returning it to the manufacturer or supplier, or donating it to a non-profit organisation. It’s important to have a plan in place to remove dead stock from storage as it can quickly increase warehousing costs.