Digital Inventory Guide

Inventory, inventory, inventory.

As an online brand, inventory will always be on your mind. You’ll constantly be asking yourself:

- How much inventory do I have on hand?

- When should I reorder and how much?

- What are my best-selling items?

In this article, you will learn how digital inventory management works and best practices you can easily implement.

So, what do you want to learn?

Request Fulfilment Pricing

Let’s talk. Our experts can help you boost your order volume by 30% year over year.

A fulfilment expert will get back to you shortly. Privacy Policy

What is digital inventory?

Digital inventory refers to the ability to oversee real-time inventory activity.

It involves the use of inventory tracking systems and other types of technology to enhance visibility by tracking data and collecting information as finished goods move through the supply chain.

By integrating an inventory management software or a more robust solution like an ERP inventory system, a business can track how much ecommerce inventory is available, where items are located, and how each SKU is performing over time.

With the right digital inventory systems in place, data is automatically recorded, which allows brands to oversee inventory control and make decisions and predictions on inventory allocation, restocking, and more.

Traditional vs. digital inventory: What’s the difference?

Traditionally, inventory management involved making updates or changes to spreadsheets or paper every time more inventory was ordered, a sale was made, and items were shipped.

It should go without saying that the traditional process of manually tracking inventory is time-consuming and prone to human error.

On the other hand, digital inventory best practices reduce human error, improve accuracy and productivity, and streamline data and information.

By integrating a digital inventory system along with a warehouse automation system or 3PL’s software, it enables more accurate order accuracy, faster fulfilment, and the ability to track inventory across distribution centres.

Challenges traditional inventory management faces

With the rise of on-demand logistics, traditional inventory methods are no longer enough to maintain supply chain efficiency, especially now that online brands are moving away from centralised inventory and into multiple fulfilment centres and expanding into different sales channels (most often through an outsourced logistics model, so they don’t have to invest in facilities and labour themselves).

Here is an overview of why digital inventory methods are replacing traditional inventory management.

Siloed supply chain communication

Traditional inventory management lacks the capabilities of tracking inventory between inbound and outbound logistics operations (and sometimes even within a warehouse), which hinders communication between teams and third-party logistics.

With traditional inventory, it’s almost impossible to expand your logistics operations and still be able to track and manage inventory throughout your network.

This can lead to inaccuracies, stockouts and backorders, higher logistics costs, and lower customer satisfaction, whereas digital inventory management can improve these.

Lack of demand forecasting

Forecasting demand is one of the most important parts of inventory management. Proper inventory forecasting can provide a distinct competitive advantage to even a small business.

But traditional inventory management cannot provide suppliers, retailers, and logistics experts the information they need to plan ahead and make the best decisions.

Digital inventory solves for a lack of demand forecasting by connecting upstream manufacturing activities with downstream sales. That way, you can predict optimal inventory quantities that need to be ordered over a given period of time (even at the SKU level).

Poor inventory visibility

Proper inventory management relies on visibility.

As you expand your supply chain, it’s important to have a system in place that allows you to view and track inventory in real time, so you can gain insights into exactly how many units of each SKU are in stock at each location. This form of digital inventory management is a fundamental and basic requirement to thrive in today’s landscape.

Traditional inventory management lacks this level of inventory visibility and makes it difficult to have an accurate picture of stock availability across multiple locations and channels.

Digital inventory management benefits for ecommerce

Especially in the age of multichannel distribution, digital inventory has much to offer to ecommerce retailers.

Here are some of the top benefits of using technology to improve inventory:

Omnichannel inventory tracking

Establishing an omnichannel strategy has become a necessity for brands that want to grow their business fast, reach more customers, and stay competitive.

If you want to eventually sell across a variety of platforms and provide a consistent experience for your customers, then you need to be able to track inventory across all sales channels.

Digital multichannel inventory management solutions offer automated inventory tracking covering multiple channels via one streamlined dashboard.

“I used to have to pull inventory numbers from three places everyday and move all the disparate data into a spreadsheet. ShipBob has an analytics tab in their dashboard with all of this information, which is great for end-of-month reconciliations.

It’s really nice to not have to operate three 3PLs.

For inventory planning, I love the SKU velocity report, daily average products sold, and knowing how much inventory we have left and how long it will last. The enhanced visibility is great.”

Wes Brown, Head of Operations at Black Claw LLC

Reduce inventory carrying costs

Optimising inventory to meet demand while also optimising storage is much like weighing two items on a balance scale.

Without the right data and insights to find balance in both inventory levels and costs, you risk overspending on inventory carrying costs and accumulating dead stock.

Having access to inventory storage data can help you gain a better understanding of which slow-selling items are incurring and increasing costs.

By optimising inventory, you can decide how much inventory you need to store to meet demand without overspending in warehousing, labour, insurance, rent, and depreciation costs of unsold goods.

For example, ShipBob’s 3PL software provides insights into storage costs, so you know exactly how much you’re spending per unit in each fulfilment centre location.

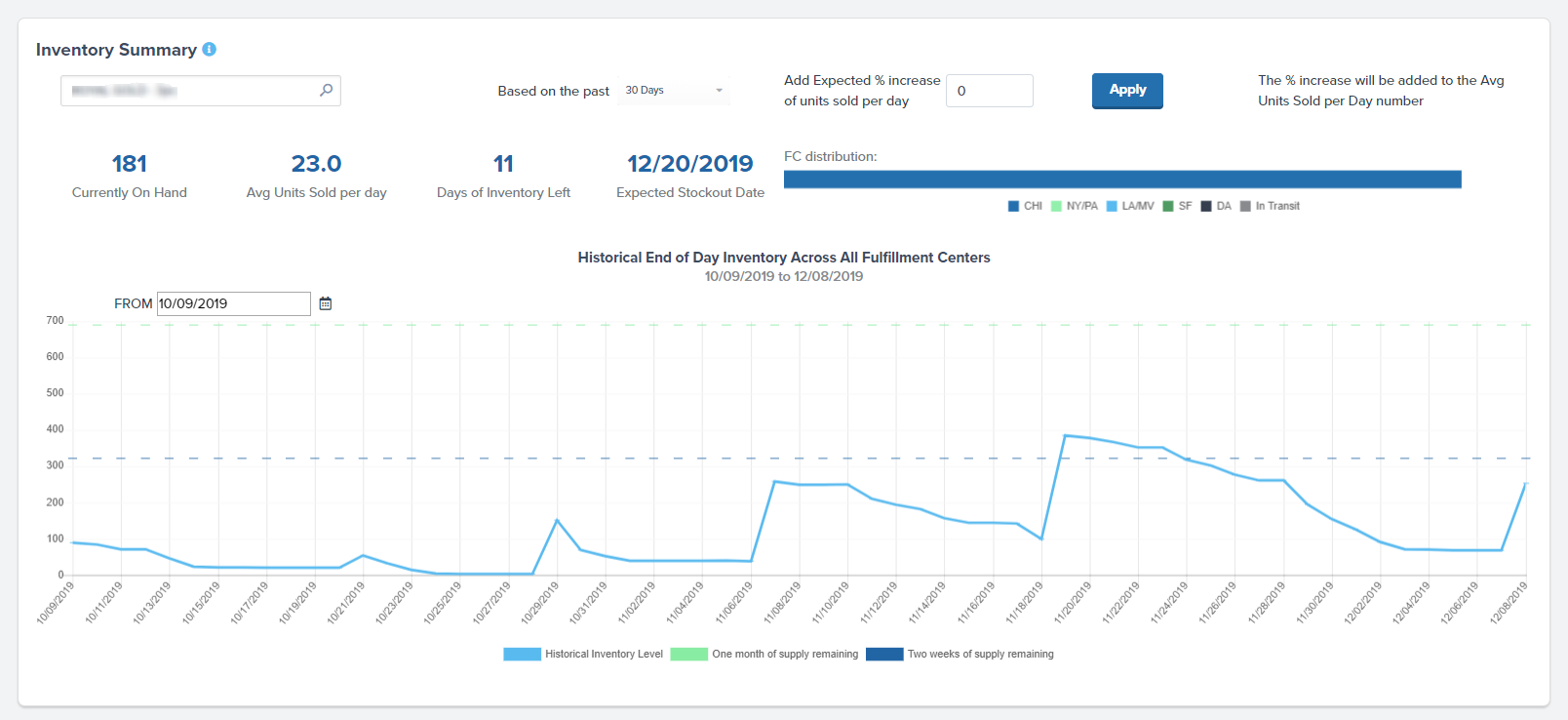

Access real-time inventory

Being able to view how much inventory you have on hand across fulfilment centres has become a bare minimum for running a successful retail business.

With digital inventory management, you gain access to real-time inventory.

For instance, ShipBob’s merchant-facing dashboard provides an overview of how much inventory is in transit and what inventory you have available at each fulfilment centre location in real time.

That way, merchants can easily view inventory levels and make decisions on whether or not it’s time to reorder more inventory, run a promotion or a flash sale, or discontinue an item.

“We roll out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each week.

It’s really easy to create new SKUs and restock existing ones using ShipBob’s technology, which is especially important with high inventory turnover.”

Carl Protsch, Co-Founder of FLEO

Automated inventory reorder points

If order volumes shoot through the roof, restocking inventory to meet the demand while keeping costs low can be a struggle.

Thankfully, technology can help automate inventory processes and inform you right away when inventory levels are running low. This, in turn, will improve the efficiency and speed up the reordering process.

“ShipBob’s analytics tool is also really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

Minimizes inventory errors

Most retailers would agree that even the smallest of inventory errors can lead to big consequences on customer satisfaction.

Digital inventory management ensures that there is no discrepancy between the actual physical inventory stored in a warehouse or elsewhere, and what is recorded.

Automatically recording real-time data improves higher inventory accuracy across the supply chain and lowers the chances of inaccurate inventory accounting.

Digital inventory also enables the use of shipping barcodes that will accurately mark shipments with the correct product details (upon receipt of goods), leading to fewer inventory data entry errors caused by miscounting, mistyping, and miscalculations.

“With ShipBob, you see exactly what is picked. With the new [previous 3PL] fulfilment network, we had to rely on our rep for everything. It doesn’t give you the ability to be self-sufficient.

Because of a lack of ownership of the entire fulfilment stack, it’s been difficult to rectify, unlike ShipBob who owns the entire stack: inventory and order management system, warehouse management system, and their fulfilment centres.”

Gerard Ecker, Founder & CEO of Ocean & Co.

Boosts supply chain productivity

By transitioning to digital inventory systems, your supply chain will run smoother and faster.

Digital inventory management solutions also aid in improving supply chain planning, which means that you can establish processes for various operational stages to deliver the best possible customer experience.

For instance, ShipBob’s fulfilment and digital inventory technology provides access to a wide range of distribution metrics to easily monitor fulfilment performance and productivity.

4 best practices to take your inventory digital

Digital transformation is taking over the retail supply chain. A big part of this shift involves adding digital inventory solutions to improve internal efficiency and build supply chain resilience.

Here are some of the ways you can “digitize” your inventory management strategy.

1. Implement a digital inventory management system

A great place to start is implementing an inventory management system. There are several solutions on the market with different types of capabilities based on your needs, including multichannel inventory management.

Keep in mind that tech-enabled 3PLs like ShipBob use best-in-class technology with digital inventory management systems built in.

That way, brands can outsource fulfilment and be able to track digital inventory and manage SKUs from a single dashboard at no extra cost.

“We utilise ShipBob’s Inventory API, which allows us to programmatically retrieve real-time data on how many units of each product are currently stored at ShipBob’s warehouses.

We currently use this API to generate custom reports to tie this inventory data into our accounting platforms.”

Waveform Lighting Team

2. Choose apps that automate inventory management

You also have the option to choose from different types of inventory apps to help you further automate the inventory management process from start to finish, across multiple channels and warehouses.

For instance, ShipBob’s technology includes digital inventory automation features solutions, including the ability to set reorder notification point notifications when inventory levels fall below a certain threshold.

3. Install a warehouse management system

Warehouse digitization involves implementing a warehouse management system (WMS) and connecting it with your digital inventory management solution.

This makes it easy to improve productivity within your warehouse while also providing visibility into operations.

For instance, ShipBob uses a proprietary WMS to automatically assign similar orders with inventory in the same area so they’re assigned to the same picker to reduce the number of steps required to pick orders and create a more batchable, efficient workflow.

By digitizing warehouse inventory management processes, you can also monitor what inventory is being received and what’s being picked and prepared to ship.

“We are very impressed by ShipBob’s transparency, simplicity, and intuitive dashboard. So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on.

I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

4. Find the right digital inventory partner

Instead of choosing to work with a variety of partners to support different supply chain issues, you should look for a logistics company that offers warehousing, reliable fulfilment services, and digital inventory management technology under one roof.

ShipBob is a 3PL that offers a global fulfilment network operated by the same proprietary technology. This enables visibility, transparency, and consistency into operations, without you having to take on the work yourself.

You also get access to advanced data and analytics reporting, which makes it easy to delegate digital logistics to the experts and still maintain control with insights in inventory levels, orders, shipping, and more.

Top 5 digital inventory management systems

There are several digital management systems to choose from based on your needs.

Some of the top tech-forward inventory management solutions on the market include:

- ShipBob

- Skubana

- Cin7

- Linnworks

- Inventory Planner

Note: ShipBob offers a direct integrations with all the digital inventory solutions listed here to create a more robust inventory management system.

| Digital inventory system | Features |

| ShipBob | A best-in-class 3PL with easy-to-use built-in digital inventory management software that offers:

|

| Skubana | An inventory and order management tool that:

|

| Cin7 | A multichannel inventory and order management platform that:

|

| Linnworks | An ecommerce platform that:

|

| Inventory Planner | A multichannel inventory management app for online stores that:

|

Time to transform your ecommerce store with digital inventory

You don’t have to invest a lot of time and money to go digital. ShipBob can help you make the switch from traditional inventory tracking to digital inventory and order fulfilment.

ShipBob is a technology-driven 3PL that operates an international fulfilment network with a premium retail fulfilment technology.

With full visibility into operations, merchants can outsource fulfilment to a 3PL to save time and money in the long as they expand their business.

From one dashboard, you can manage SKUs, view inventory velocity, forecast demand, optimise product allocation, and replenish inventory efficiently by setting reorder point notifications.

At any time, you can view inventory levels at a glance across your entire distribution network.

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order. The analytics are super helpful.

We download Excel files from the ShipBob dashboard all the time and use them to analyse everything from cancelations, to examining order weights, to checking on whether ShipBob is shipping orders on time.

Even the way their warehouse receiving orders (WROs) work for sending inventory is very straightforward.”

Ines Guien, Vice President of Operations at Dossier

At the end of the day, managing the digital inventory and digital logistics side of your business is a time-consuming process and a costly investment.

ShipBob takes the complexity out of inventory management by providing you with the infrastructure and technology you need to grow your business by spending less time on supply chain management.

Digital inventory FAQs

Here are the most commonly asked questions and answers related to digital inventory.

How does digital inventory work?

Digital inventory systems track the flow of inventory, from production to warehouse(s), point of sale, and returns. It also automates many of the time-consuming inventory management processes. Digital technologies can be harnessed to improve inventory management and speed up fulfilment.

Does digital inventory cut down on your overall costs?

Digital inventory systems offer automation functionality, which means your warehouse staff can spend less time on inventory tracking and auditing, data entry, and managing reorders to save on the second biggest warehousing expense (labour costs). Efficient digital inventory management also helps you optimise stock, which also reduces storage costs.

Does digital inventory improve order fulfilment accuracy?

Digital inventory management refers to real-time inventory tracking that’s often connected with a warehouse management system (including a 3PL’s technology if you outsource fulfilment). Being able to track real-time inventory levels across a distribution network provides full visibility without the need to be involved in the day-to-day operations, while digital inventory data enables you to make better business decisions and forecast demand.

What’s the best way to implement digital inventory management?

It is recommended that you choose a 3PL, such as ShipBob, that not only digitizes your multichannel inventory management and other aspects of the global supply chain but also offers access to a distributed network of fulfilment centres.