Warehouse Management Guide

Proper warehouse management is what will determine how successful a business will be.

It won’t matter if you have the most modern state-of-the-art warehouse if it’s not operating efficiently. You will be stuck with poor-performing staff, a low-profit margin, high operating and logistics costs, ineffective leadership, and damaged relationships with customers.

Learn how warehouse operations affect supply chain management and how to set your business up for success.

So, what do you want to learn?

Request WMS Pricing

Let’s talk. See if ShipBob’s warehouse management system is right for your warehouse.

A fulfillment expert will get back to you shortly. Privacy Policy

What is warehouse management?

Warehouse management refers to the process of executing, monitoring, and optimizing warehouse operations.

In other words, warehouse management involves overseeing any activities that go on in a business’s warehouse, including inventory reception and storage, order fulfillment, and shipping.

8 key warehouse management processes

So, what exactly happens in an ecommerce business’s warehouse? In order to master your warehouse management, you need to be familiar with the functions, activities, and processes you’re managing.

Here are 8 of the most common operations that take place inside an ecommerce warehouse, which merchants should monitor and manage.

1. Receiving

Before any other activities can take place, a business needs to get inventory into its warehouse.

In receiving, warehouse staff receive inventory or freight from trucks at loading docks, and count the units to ensure they’ve been sent the correct amount. They will also inspect the condition of the goods, and document that the inventory has been received.

2. Put-away

Once inventory has been received, it needs to go somewhere. Warehouse putaway is the process of transporting inventory from the receiving area to the correct storage area.

There are several different approaches to warehouse putaway, so you may need to experiment before finding the best putaway method for your business.

Ultimately, you’ll want to choose a putaway strategy that makes sense based on the type, volume, and variety of inventory you have, as well as your available space and inventory storage options.

3. Inventory storage

You will almost always need to store inventory within your warehouse for at least a little while before orders come in. Inventory storage is one of the most strategic decisions you can make in your warehousing, and should work for your business, not against it.

Typically, ecommerce businesses will store inventory on warehouse racks in pallets or bins, so that each SKU has a dedicated location.

4. Picking

As soon as an order is confirmed and processed, it’s time to pick inventory from shelves.

Depending on the technology and automation you employ in your warehouse, you can either create or generate pick lists for each picker to retrieve items in the most efficient way. This may include zone picking, wave picking, or batch picking.

For each new order, the picker will receive a packing slip of the items ordered and storage locations at the warehouse. The picker will collect the ordered products from their respective locations.

5. Packing

Once an order is picked, it is handed off to a packer, who is responsible for packing it. This means securely placing the items in a box or poly mailer, adding in any needed packing materials, and putting a shipping label on it.

6. Shipping

Based on the delivery options and shipping services you offer to customers, shipping carriers like DHL, USPS, FedEx, and UPS will pick up orders from the warehouse to ship packages to their next destination.

Once the order ships, your warehouse management system should be able to automatically send ecommerce order tracking information back to your store so your customers can track their shipments.

7. Slotting

Some warehouse functions are not part of the supply chain, but still impact its efficiency and performance.

Slotting — the process of organizing a warehouse to maximize space and efficiency — is one of these functions. By carefully planning your warehouse layout and inventory storage strategy, you can reduce picking errors, unlock more storage space, and even reduce operating costs.

8. Reporting

A warehouse management system should provide out-of-the-box operational and inventory reports across the warehouse. This may include accuracy in fulfilling orders (total mispicks, mis-packs, etc.), total orders fulfilled by the hour to measure the efficiency of staff, orders shipped on time, and much more.

There are also reports relating to people’s operations, including inventory forecasting to understand labor management and staffing needs. With a warehouse management tracking system, you can quickly find out which employees have completed safety training, those who have licenses and certifications to operate certain equipment, and other regulatory requirements you must meet to operate a safe warehouse.

5 benefits of 3PL warehouse management

Because warehouse processes are so complicated and expensive, many brands choose to outsource the entire fulfillment process to a third-party logistics (3PL) company. Unlike an on-demand warehousing company that finds warehouses with excess space, 3PLs run their own fulfillment centers and should have standardized warehouse management across all of them.

Here are some of the advantages of working with a professional logistics company to store inventory and ship orders.

1. Logistical optimizations

3PLs work with thousands of companies — including seasonal brands, high-growth brands, and everyone in between — so they have a lot of data and can do everything from analyzing shipping zones to forecast demand and inventory. Continuously aggregating and learning from data helps optimize each warehouse for greater efficiency as well as provide reduced shipping costs and transit times for your customers, all of which help you grow.

2. Multiple warehouses and larger geographic footprint

When you run your own warehouse, you are only shipping from that one location. Partnering with a 3PL means you can store inventory in several of their fulfillment centers to keep inventory closer to more customers. If you ship nationwide, it’s a must that you have warehouses coast-to-coast.

For example, ShipBob has a presence in the largest US cities and regions all over the United States, so you can ship orders via ground to large populations very quickly. This helps meet customer expectations around 2-day shipping by reducing the distance traveled and delivery timelines.

“Touchland sells flammable goods that need to be shipped via ground, so ShipBob has been a great ally as they have fulfillment centers all over the US, facilitating a 2-3 day delivery time for any customer in the US.”

Andrea Lisbona, Founder & CEO of Touchland

3. Huge time savings

Ecommerce order fulfillment services from a 3PL eliminate the most time-consuming logistics tasks (inventory storage, picking, packing, shipping, order tracking, replenishing supplies, returns, kitting, etc.) and the stress of managing a warehouse. While they take care of these tasks for you, you can monitor their performance and use the data they provide to grow and make better business decisions.

4. Better uses of warehouse space

If you’re on the verge of outgrowing your warehouse space, working with a 3PL can make your life a lot easier. Even once you’ve outsourced fulfillment to a 3PL, you can either repurpose your old warehouse space to focus on a different aspect of your business (e.g., growing your B2B ecommerce or wholesale fulfillment channels in-house), or let the lease end.

A 3PL can help you pay for only the space you need — even if that’s by the bin, shelf, pallet, or any combination of those for your products. That way, you’ll never have to worry about outgrowing (or never growing into) the space you’re paying for.

5. Real-time insights

Just because you’re not working inside the 3PL’s warehouse doesn’t mean you won’t know what’s happening. Through their technology, you should be able to see your inventory flow, including when inventory is being received, stowed or put away, picked, packed, shipped, and any other movement.

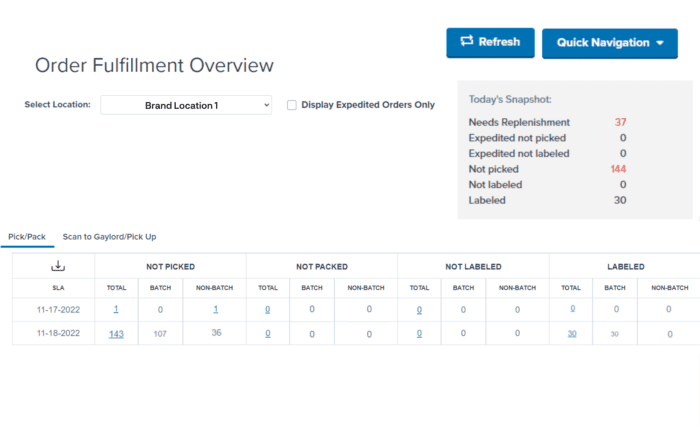

With ShipBob’s proprietary warehouse management software, you can search orders by tracking number, destination country, the number of items it contains, filter by sales channel, and fulfillment center location, as well as get full transparency into performance such as fulfillment speed, orders fulfilled on time, accurately, claim-free, and much more.

Tips for improving your warehouse management

Here are some strategies your business can use to make warehouse management easier, quicker, and more cost-effective.

Automate as much as possible

Warehouse automations are designed to relieve workers of simple, repetitive tasks. By automating operations like order processing, retrieval, or even some aspects of picking, you can speed up fulfillment and enable your workers to focus on tasks that really need human attention.

You may even see your operational accuracy improve, as automation technology helps reduce human errors.

Make sure safety is a priority

The most efficient and successful warehouses are safe ones. Warehouse safety standards not only protect your workers (which should be top priority), but also help your business avoid costly accidents that slow down supply chain velocity.

As part of your warehouse safety checklist, be sure to set specific standards for every warehouse, train employees thoroughly, and regularly audit each warehouse’s spaces, equipment, and layout for potential hazards.

Perform various inspections

You can’t optimize your warehouse without knowing what’s going on inside it. Regular warehouse inspections for cleanliness, safety, inventory protection, equipment condition, and technology performance are necessary to identify opportunities for improvement.

Even though these kinds of warehouse audits can be time-consuming, they are key to maintaining good workflows and quality output.

Adopt a warehouse management system (WMS)

Warehouse management system (WMS) software is designed to optimize operational processes in your warehouse.

By implementing a WMS, you unlock full visibility into real-time inventory levels and storage, staff productivity, demand forecasting, and order fulfillment workflows within a warehouse.

This information helps warehouse managers identify areas of improvement and track progress to drive optimizations throughout the supply chain, from when inventory hits the loading docks to when it’s shipped out to its next destination.

Each warehouse management system may have different functionality deployed depending on the business it serves (e.g., what a direct-to-consumer ecommerce seller needs isn’t the same as a large brick and mortar store chain).

Implement a warehouse control system (WCS)

To keep the physical flow of inventory via material handling equipment, consider integrating a warehouse control system (or WCS) with your warehouse management system (WMS).

While the two are similar, a warehouse control system specifically monitors the movement of inventory through a warehouse. A WCS makes sure that material handling equipment and automations (such as conveyors, sorters, carousels, and scales) are working correctly, and are getting inventory to the right locations within a warehouse.

This extra layer of management can go a long way towards streamlining inventory movement, and provides real-time visibility into your operations.

Evaluate meaningful KPIs

By tracking the right key performance indicators (or KPIs), you can gain new insight into how your operations are performing as well as how to optimize them for efficiency and cost.

Certain metrics may be more valuable to a business than others, depending on your products, channels, and other factors. However, monitoring a wide range of KPIs on inventory, receiving, put-away, picking, and safety (among others) is a great way to get a comprehensive look into what in your warehouse is working and what isn’t.

Outsource to a 3PL

Whether you’re familiar with the ins and outs of warehousing or just getting started, getting help from an expert almost always helps your business.

When you outsource to a third-party logistics partner (or 3PL), you can leverage their technology and infrastructure to run your warehousing operations more smoothly and cost-effectively than you could on your own.

However, the right 3PL partner will be able to handle much more than just warehousing. 3PLs like ShipBob provide fulfillment services (including storage and shipping) across channels and countries, as well as the real-time visibility and analytics that your brand needs to scale.

Add ShipBob’s warehouse management system to your in-house fulfillment

Have your own warehouse? ShipBob has a best-in-class warehouse management system (WMS) for brands that have their own warehouse and need help managing inventory in real-time, reducing picking, packing, and shipping errors, and scale with ease.

With ShipBob’s WMS, brands with their own warehouse can even leverage ShipBob’s fulfillment services in any of ShipBob’s fulfillment centers across the US, Canada, Europe, and Australia to improve cross-border shipping, reduce costs, and speed up deliveries.

Outsource your warehouse management with ShipBob today!

If you aren’t looking to manage your own fulfillment warehouse and license a warehouse management system, but you are interested in outsourcing inventory storage and ecommerce fulfillment to a 3PL, check out ShipBob.

“As our business grew, fulfilling orders quickly became very time-consuming, and warehouse operations became a challenge. We found ShipBob, who checked all our boxes for a 3PL. They have ended up being the perfect solution for us and we have never looked back!”

With a global network of fulfillment centers and proprietary warehouse management software, ShipBob offers businesses a way to manage their warehousing across channels at scale.

Ecommerce businesses can leverage ShipBob’s warehousing services to scale their brands, without having to invest in the technology, infrastructure, or equipment involved in warehouse management themselves.

In addition, merchants that partner with ShipBob can:

- Distribute inventory across our global fulfillment centers

- Achieve affordable 2-day shipping

- Improve order accuracy while speeding up fulfillment

- Access real-time data on inventory levels, operational performance, and more through their ShipBob dashboard

- Integrate their platform with dozens of major ecommerce platforms and partners

- And more!

Warehouse management FAQs

We’ve addressed more of your common warehouse management queries below!

What is the function of warehouse management?

Warehouse management controls the working operations of a warehouse. Including things like order management and inventory control. The purpose is to monitor a company’s goods and products in an efficient and effective manner.

What is the difference between warehouse management and inventory management?

In short, warehouse management deals with the processes within the confines of a warehouse, whereas inventory management deals with stock throughout the supply chain.

How does ERP help in managing supply chain operations along with warehouse management?

An ERP system helps manage supply chain operations and warehouse management by integrating various functions into one centralized platform.

It provides real-time visibility into inventory, orders, and shipping processes, allowing businesses to streamline operations, reduce manual errors, and improve decision-making.

With ERP, companies can better forecast demand, manage inventory levels, and optimize warehouse workflows, ensuring efficient use of resources and timely deliveries.

How can ShipBob help with warehouse management?

ShipBob provides a warehouse management solution for businesses looking to grow and expand their operations. ShipBob has a network of fulfillment warehouses as well as free proprietary warehouse management software.